Rack machining process

A processing technology and rack technology, which is applied in the field of rack processing technology, can solve the problems of unitary production and manufacturing of components, cannot guarantee product quality and require product functions, etc., and achieve the effect of standard shape and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation

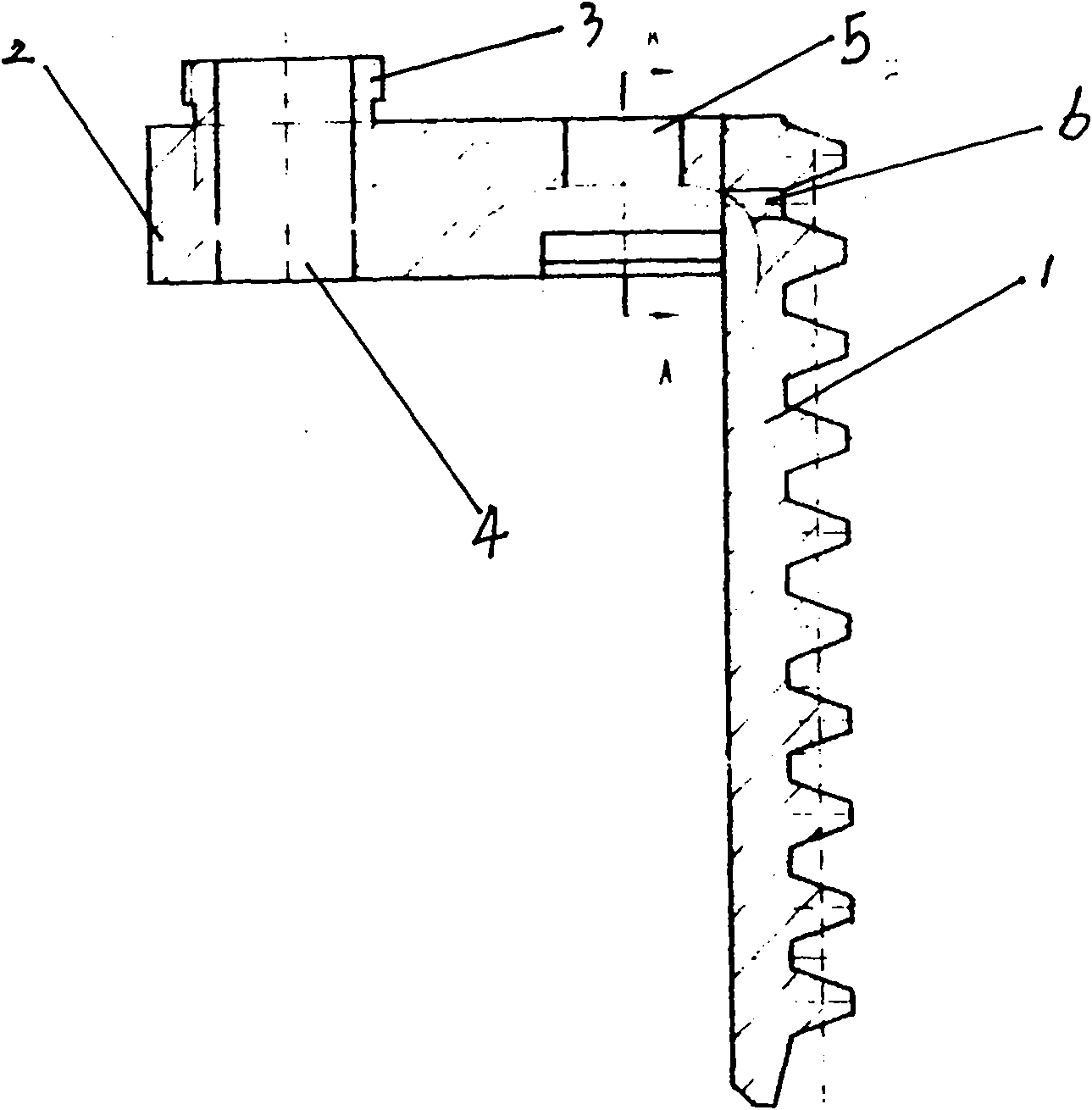

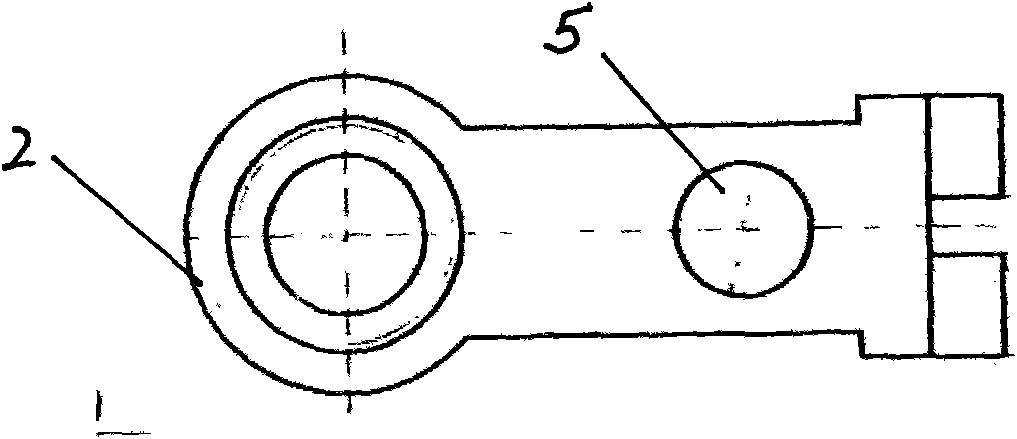

[0011] The invention will be further described below in conjunction with the accompanying drawings.

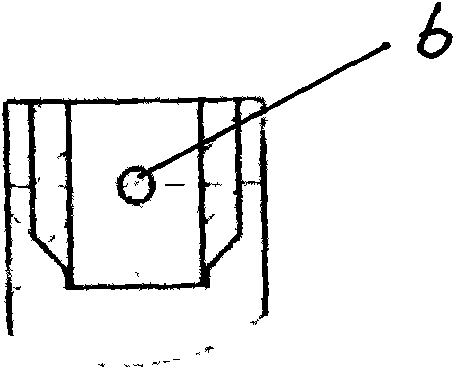

[0012] In the view, take rack 1 as an example: choose zinc alloy hot-casting rack 1 blank-remove casting burr-boring and milling cap seat 2 upper taper hole 4, column hole 5-turning thread 3-drilling pin hole 6-overall Removal of sharp corners, burrs, polishing - immersion degreasing, passivation, cleaning - chrome plating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com