Manufacturing method of soft button lithium battery and soft button lithium battery

A manufacturing method, the technology of the soft clasp button, is applied in the field of small batteries to achieve the effects of simple manufacturing process, cost reduction and strong consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] This embodiment provides a single manufacturing method of a soft-packed button-type lithium battery. The soft-packed button-type lithium battery includes a casing and a roll-wrapped battery cell arranged in the casing, wherein the casing is made of aluminum-plastic film after die-cutting. The formed soft shell has a positive pole piece and a negative pole piece drawn out from the roll-packed battery core, and protrudes from both sides of the shell respectively.

[0079] The manufacturing method of the soft pack button lithium battery is as follows:

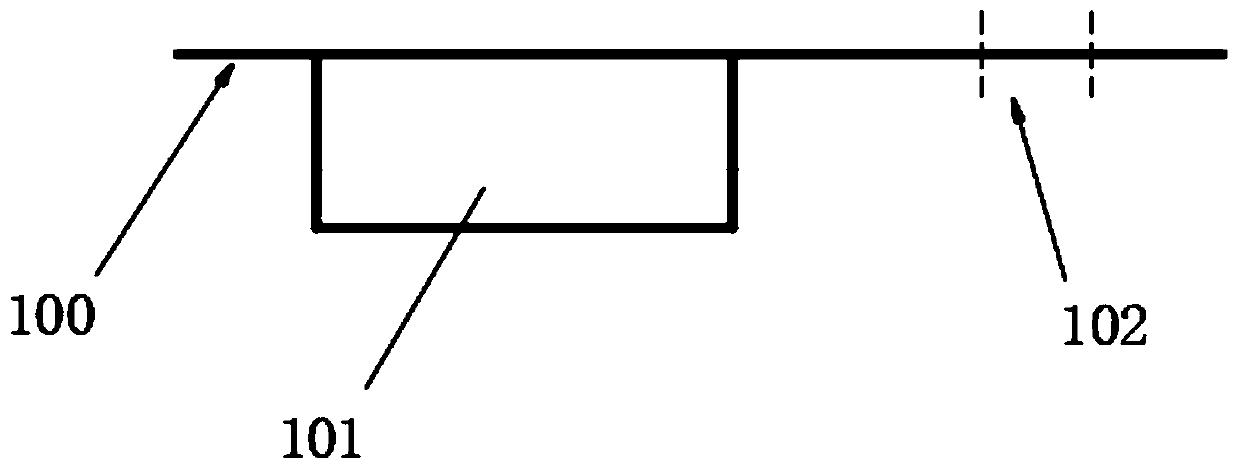

[0080] Such as figure 1 As shown, an aluminum-plastic composite film with a thickness of 0.10 mm is selected as the lower layer of aluminum-plastic film 100, and the lower layer of aluminum-plastic film 100 is stamped to form a deep groove 101 that matches the shape of the packaged battery 300, and the lower layer of aluminum-plastic film The positioning part 102 is formed on the surface of 100 and at a certain distance fr...

Embodiment 2

[0093] The present invention provides a button lithium battery structure, which is manufactured using the manufacturing method provided in Example 1, such as Figure 7 As shown in -9, the button-type lithium battery includes a lower layer of aluminum-plastic film 100 , an upper layer of aluminum-plastic film 200 and a roll-wrapped battery cell 300 .

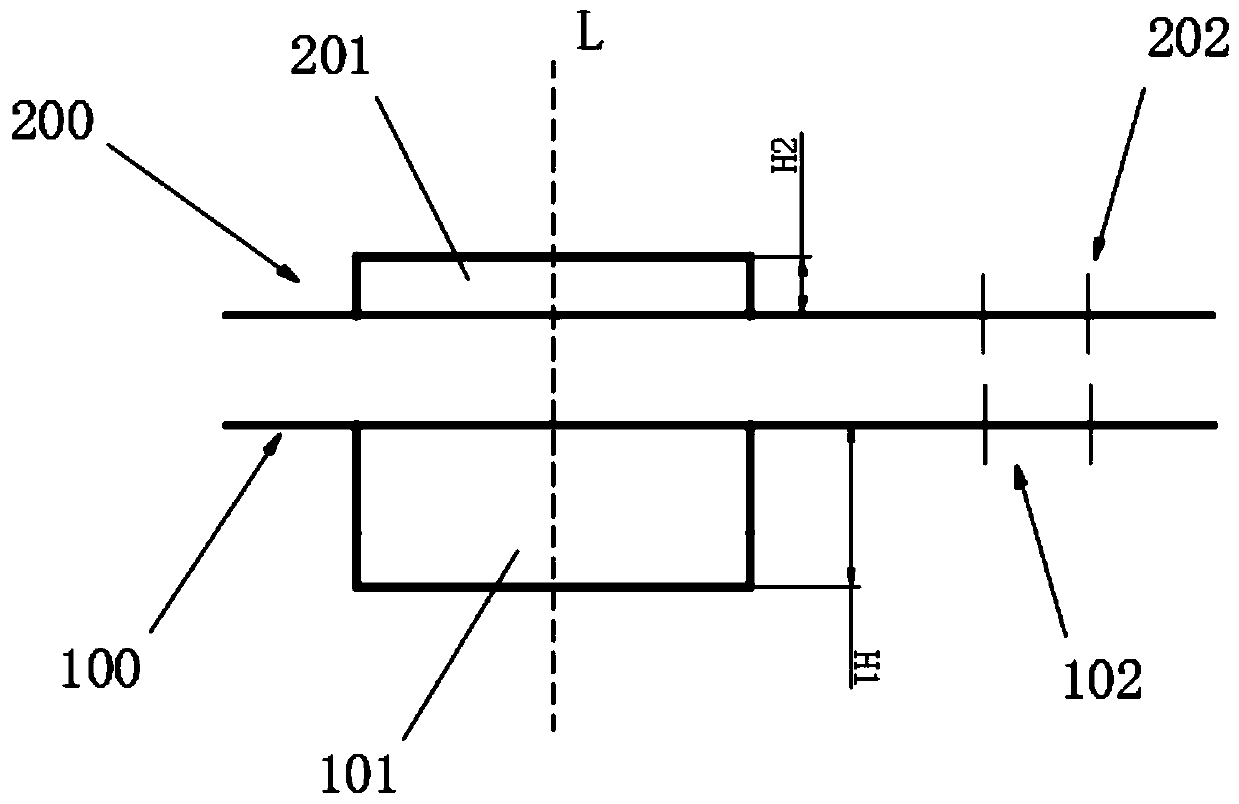

[0094] Among them, a deep groove is formed on the lower aluminum-plastic film 100, and a shallow groove is formed on the upper aluminum-plastic film 200, and the shape of the shallow groove matches the shape of the deep groove; the roll-packed battery 300 is placed in the deep groove and the shallow groove , and is wrapped by the lower layer of aluminum-plastic film 100 and the upper layer of aluminum-plastic film 200.

[0095] The packaged cell 300 includes a positive pole piece 301, a negative pole piece 302, and a separator 303; the separator 303 is located between the positive pole piece 301 and the negative pole piece 302, a...

Embodiment 3

[0100] Such as Figure 10 As shown, on the basis of Embodiment 1, the present invention provides a combined manufacturing method of a soft-pack button lithium battery, comprising the following steps:

[0101] Punching and forming four linearly spaced deep grooves 101 on the lower layer of aluminum-plastic film 100, and forming a positioning part 102 on the surface of the lower layer of aluminum-plastic film 100;

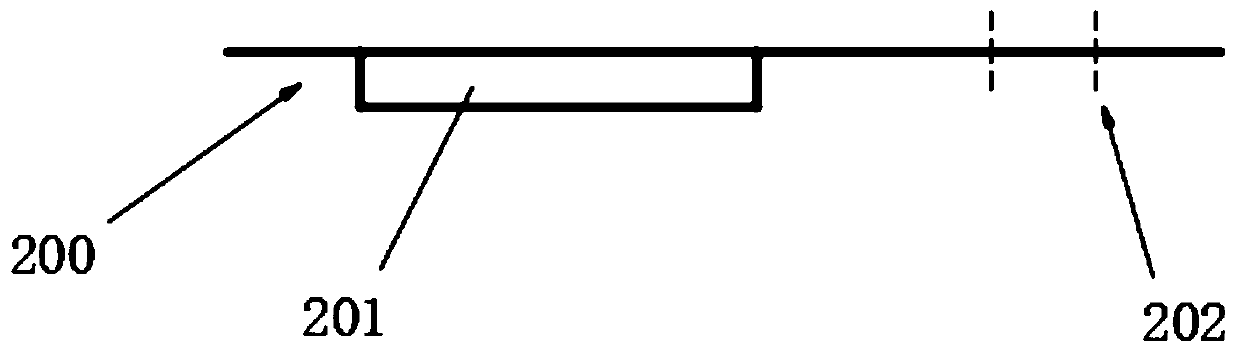

[0102] The upper aluminum-plastic film 200 is punched to form shallow grooves 201 corresponding to the four deep grooves 101, and the positioning matching part 202 is formed on the surface of the upper aluminum-plastic film 200;

[0103] Each deep groove 101 is loaded with rolled batteries for packaging, and the upper layer of aluminum-plastic film 200 is covered on the lower layer of aluminum-plastic film 100 through the positioning part 102 and the positioning matching part 202, and the two ends of the rolled batteries 300 are respectively placed in the correspond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com