Manufacturing method of soft-packed cylindrical battery

A technology for cylindrical batteries and manufacturing methods, applied in primary batteries, secondary battery manufacturing, secondary batteries, etc., can solve the problems of consuming manpower and material resources, cumbersome processes, etc., and achieve the goals of improving production efficiency, simplifying procedures, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention provides a method for manufacturing a soft-packed cylindrical battery, comprising the following steps:

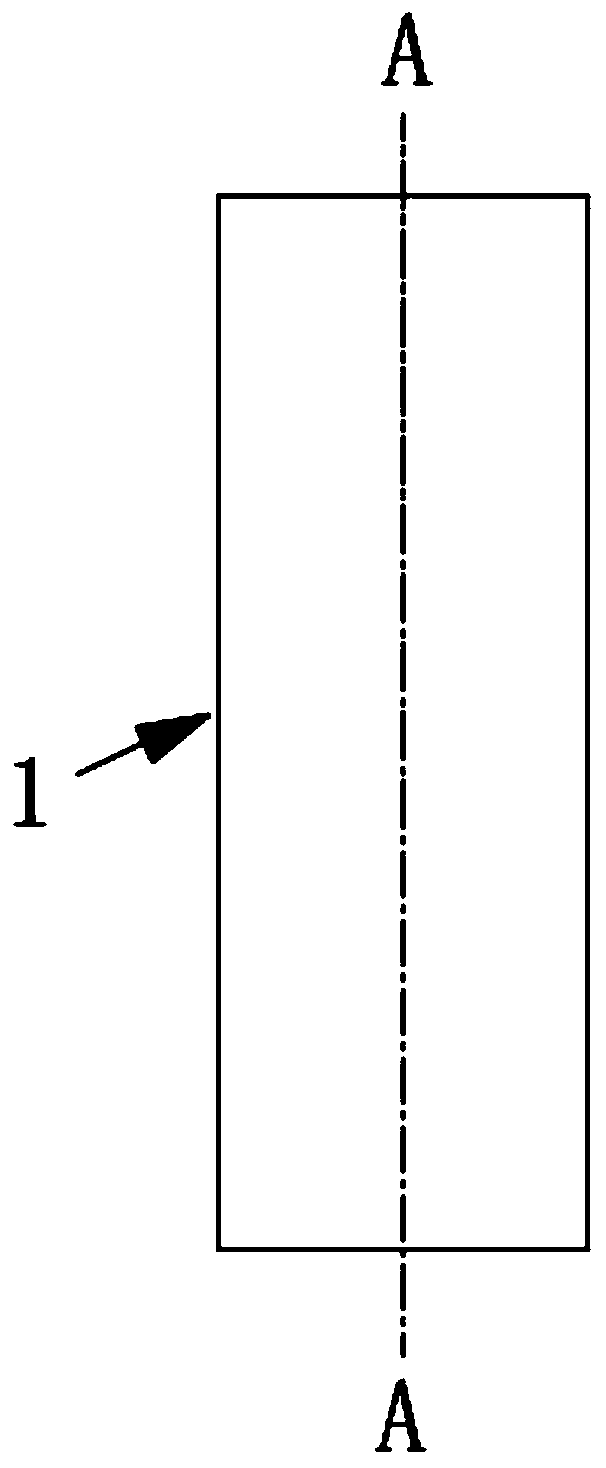

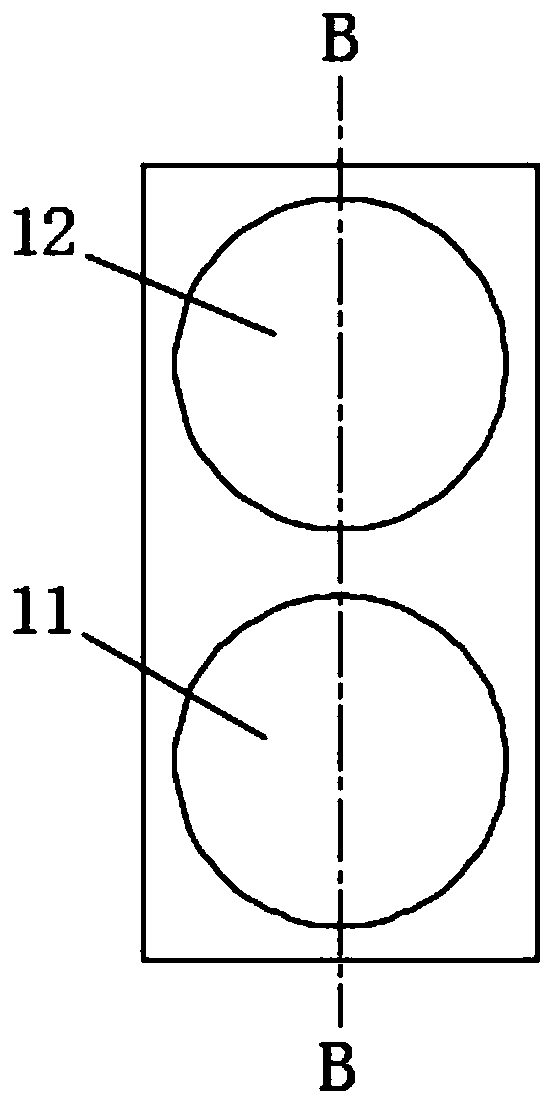

[0032] (1) Please refer to Figure 1 ~ Figure 4 , stamping the aluminum-plastic film 1, so that the upper part of the aluminum-plastic film 1 forms a first accommodation pit 12, and the lower part forms a second accommodation pit 11;

[0033] (2) Please refer to Figure 7 and Figure 10 , the aluminum-plastic film 1 is cut along the middle of the upper part and the lower part, the aluminum-plastic film 1 is cut into a first aluminum-plastic film 13 and a second aluminum-plastic film 14, and the first accommodating pit 12 is located in the first aluminum-plastic film 13 On, the second accommodating pit 11 is located on the second aluminum-plastic film 14;

[0034] (3) Please refer to Figure 5 , placing the upper part of the battery core body 31 of the wound battery 3 into the first accommodation pit 12, and placing the lower part of the battery core...

Embodiment 2

[0041] The difference between the second embodiment and the first embodiment is that the angle between the two tabs 32 of the electric core 3 is 90°. Of course, the angle between the two tabs 32 in other embodiments is also It can be any value between 0°-180°. It is only necessary to adjust the angle between the two tabs 32 according to actual needs before encapsulation.

[0042] Other steps in the second embodiment are the same as those in the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com