Tower crane foundation with four-beam steel structure and counterweight that can be quickly folded and moved

A technology of tower crane foundation and steel structure, which is applied in the direction of basic structure engineering and construction, which can solve the problems of loose confinement devices, different shapes, bump damage, etc., and achieve the effects of saving reinforced concrete, high reuse rate, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

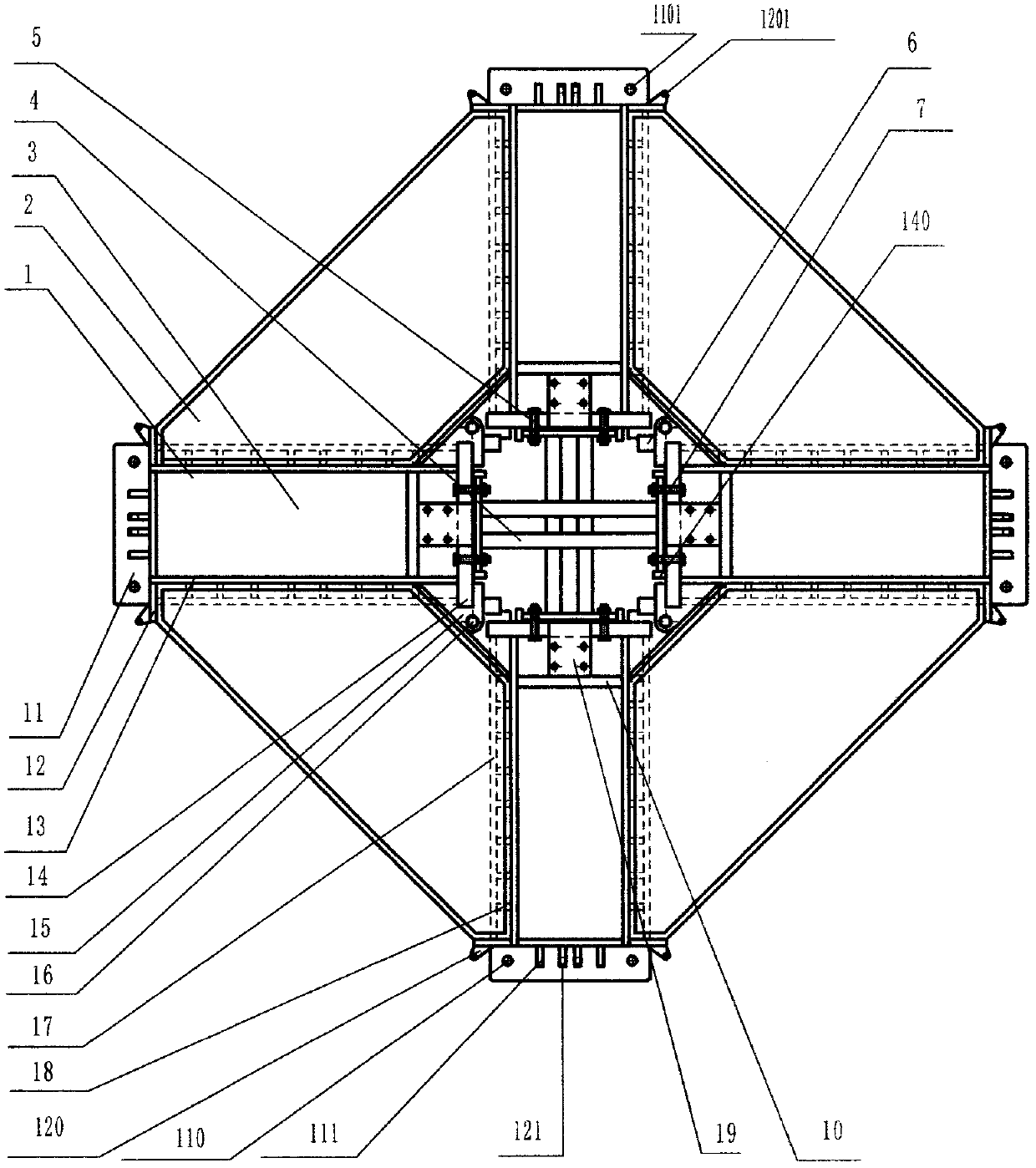

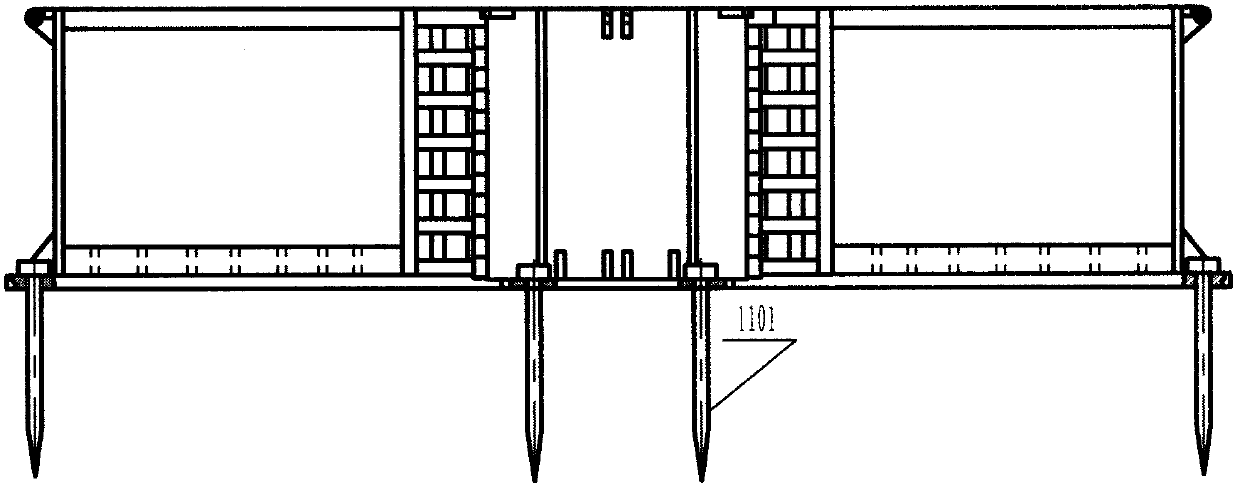

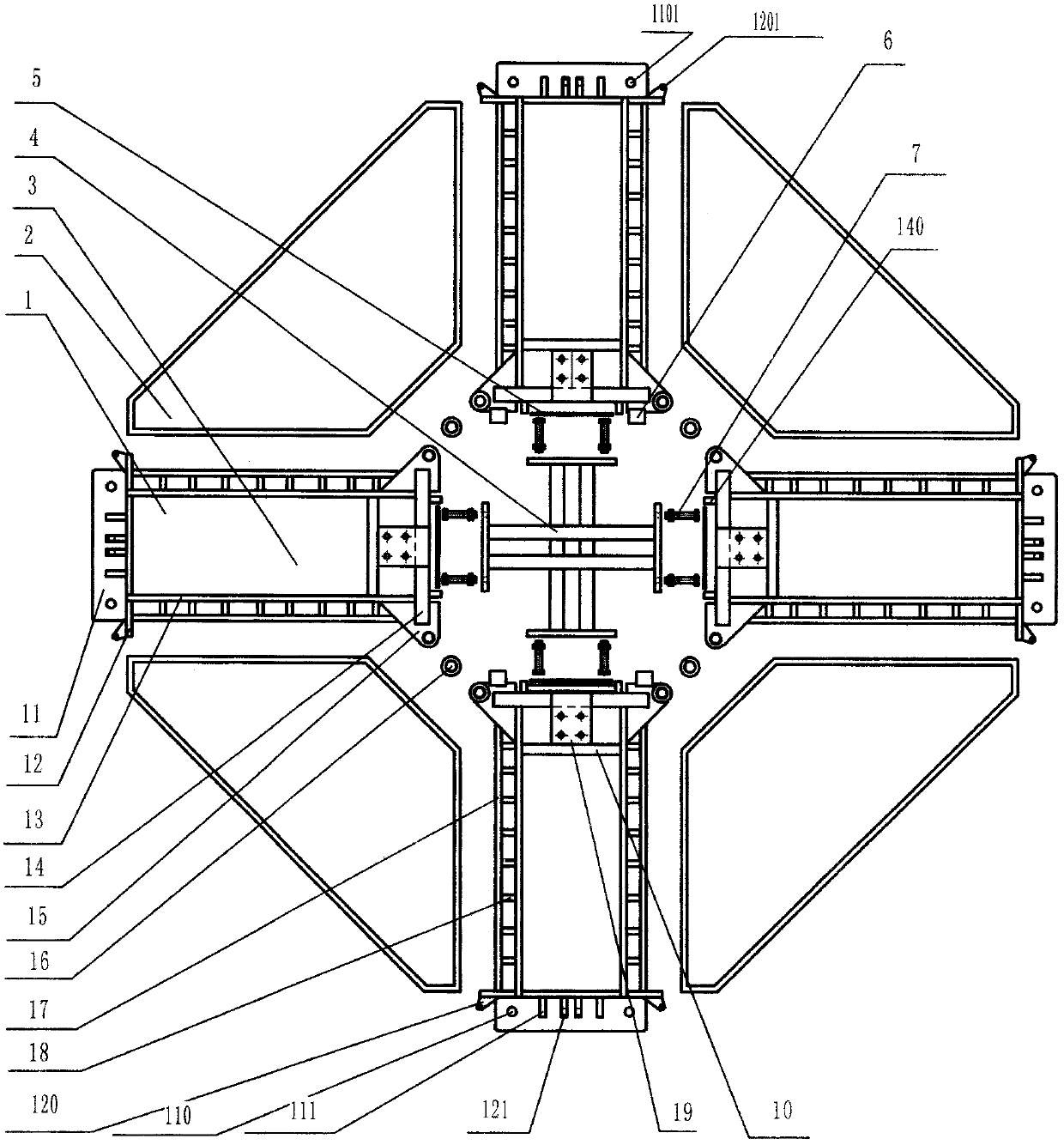

[0050] The foundation of the tower crane of the present invention is mainly composed of two basic parts: a force-bearing part made of a steel structure and a counterweight part served by building materials. refer to Figure 1 to Figure 3 As shown, the stressed part of the steel structure is the skeleton of the tower foundation of the present invention, which mainly includes four main girders 1, two cross support frames 4, four pin shafts 16, four sets of correction pad irons 5, and link bolts 7; The main girder 1 includes a base plate 11, a rear block 12, a side block 13, a front block 14, an ear plate 15, a main reinforcement plate 17, a rib plate 18, a bracket foot plate 19, a bracket vertical plate 10, and a lock ear plate 120 , support bar seat 121, slideway bar 140, positioning bar 6; refer to Figure 6-9 As shown, the main girder 1 is a rectangular box structure without a cover, which is welded by the bottom plate 11, the rear block 12, the side block 13 and the front b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com