A Creep Fatigue Test System

A technology of creep fatigue test and sodium storage, which is applied in the field of creep fatigue test system, can solve the problems such as the inability to simulate the stretching, damage and corrosion of parts, and achieve a simple structure, saving raw materials, and controllable cycle speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

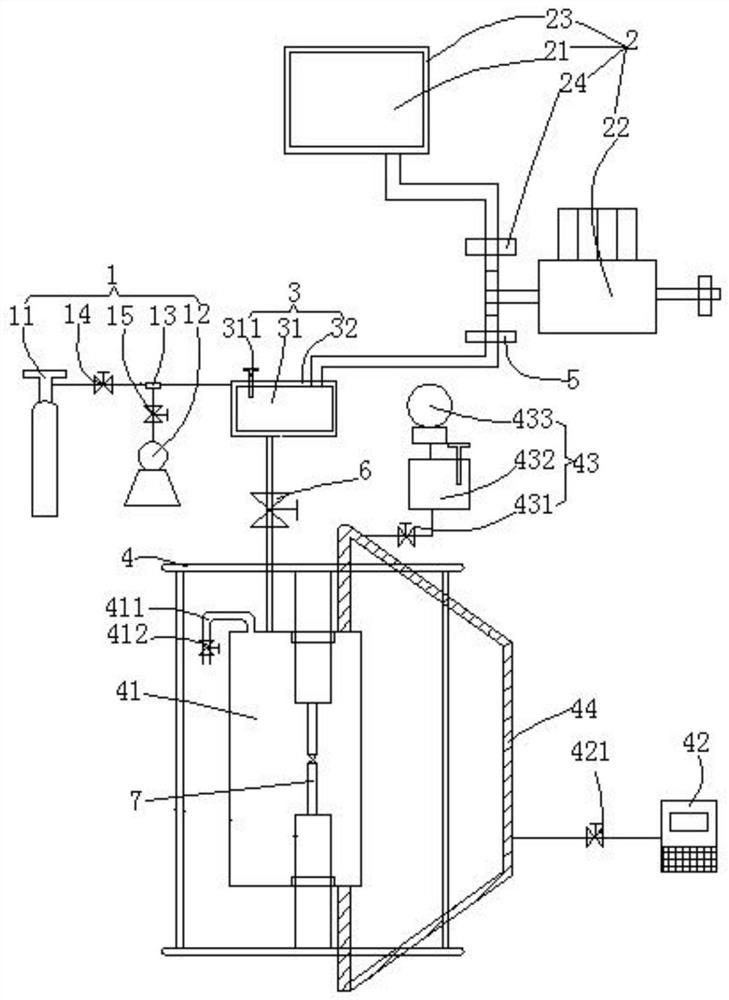

[0033] Such as figure 1As shown, the present embodiment provides a creep fatigue test system, including an air supply mechanism 1, a sodium supply mechanism 2, a sodium storage mechanism 3 and a creep fatigue testing machine 4, and the sodium storage mechanism 3 has a air inlet, sodium inlet and sodium outlet, the gas supply mechanism 1 has an air outlet, the sodium supply mechanism 2 has a sodium outlet, the gas outlet of the gas supply mechanism 1 is connected to the sodium storage mechanism 3 The air inlet of the sodium supply mechanism 2 is connected and communicated with the sodium inlet of the sodium storage mechanism 3, and a first valve 5 is provided at the communication point. The creep fatigue test The machine 4 has a sodium inlet, and the sodium outlet of the sodium storage mechanism 3 is connected with the sodium inlet of the creep fatigue testing machine 4, and a second valve 6 is arranged at the connection between the two, and the creep fatigue testing machine 4 ...

Embodiment 2

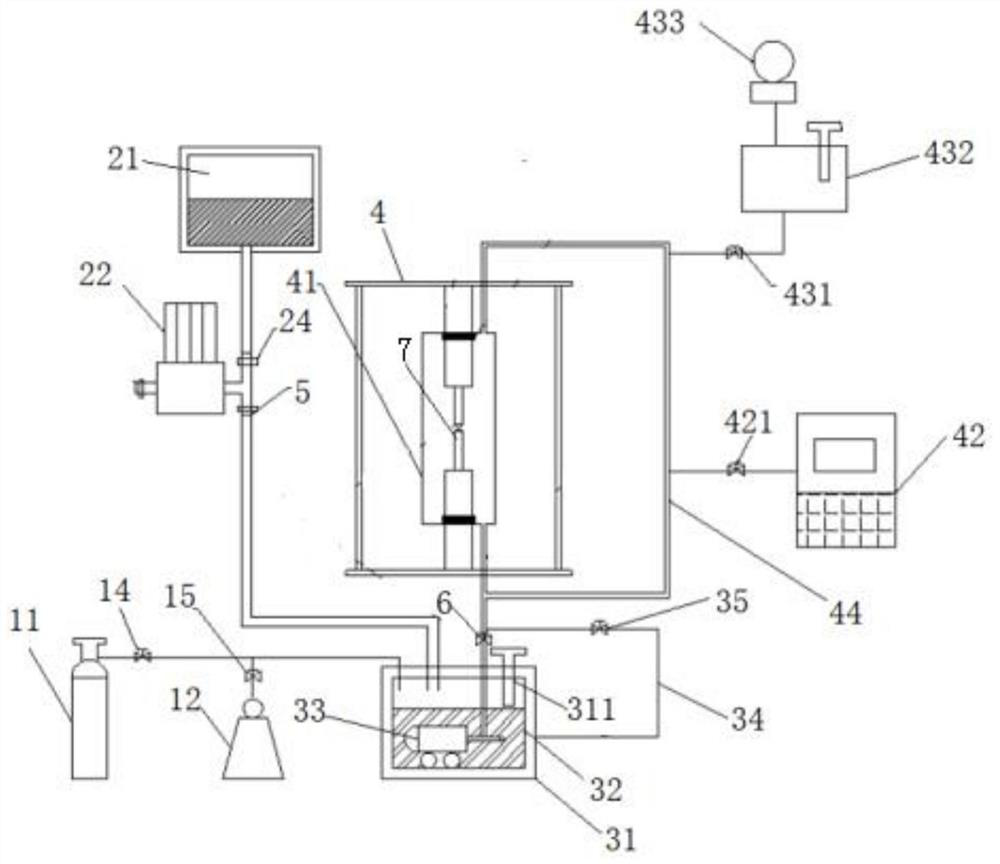

[0049] With embodiment 1, its difference is, as figure 2 As shown, the sodium storage mechanism 3 in the above technical solution also includes a delivery pump 33 and a return pipe 34, the delivery pump 33 is placed at the inner bottom of the second sodium storage tank 31, and its inlet is connected to the second storage tank 31. The sodium tank 31 is internally communicated, and its outlet communicates with the end of the sodium outlet of the second sodium storage tank 31 located in the second sodium storage tank 31, and the sodium inlet of the creep fatigue testing machine 4 is connected with the second valve. 6 is provided with a second tee, the remaining interface of the second tee is connected and communicated with one end of the return pipe 34, and the other end of the return pipe 34 extends to the second sodium storage tank. 31 is internally communicated, and the level of the second tee is higher than the level of the connection between the return pipe and the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com