Preparation method of bridged type polysilsesquioxane/boron carbide nano anti-corrosion protective film

A polysilsesquioxane, protective film technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems affecting the anti-corrosion effect of the film layer, poor impact resistance, film shrinkage, etc., to achieve good anti-corrosion protection effect, The effect of good stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] For small objects without concave holes (the volume is generally below 50cm*50cm*50cm), the dip coating method is generally used.

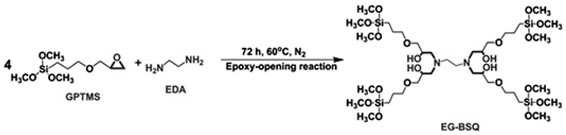

[0026] (1) First, dissolve 3-(2,3-glycidyloxypropoxy)propyltrimethoxysilane and ethylenediamine in ethanol respectively, seal and stir for 10 minutes until they are evenly mixed; secondly, dissolve the ethanol solution of ethylenediamine Add it to the ethanol solution of 3-(2,3-glycidoxy)propyltrimethoxysilane, and flush the air in the reaction vessel with nitrogen gas, then seal the above-mentioned reactant mixed solution and place it in an oil bath at 60°C Vigorous stirring in the pot for 72 hours yielded a clear precursor solution. Among them: the molar ratio of 3-(2,3-epoxypropoxy)propyltrimethoxysilane to ethylenediamine is 4:1, and the molar concentration of silicon atoms (CSi) in the precursor is 0.2-0.05mol / L;

[0027] (2) Dissolve a certain amount of ammonia water in ethanol, stir evenly, drop the ethanol solution of ammonia water...

Embodiment 2

[0031] For medium-sized objects (the volume is generally below 100cm*100cm*100cm), the brushing method is generally used.

[0032] (1) (2) The steps are the same as in Example 1;

[0033] (3) When coating the film, add nano-boron carbide to the bridged polysilsesquioxane sol, ultrasonically disperse for 30 minutes, and the mass percentage of nano-boron carbide in the mixture is 5%;

[0034] (4) Heating and curing after brushing, first curing at 60°C for 24 hours, and then curing at 100°C for 2 hours, after curing, a dense organic / inorganic hybrid nano-anti-corrosion protective film can be formed.

Embodiment 3

[0036] For large objects (the volume is generally above 100cm*100cm*100cm), the spraying method is generally used:

[0037] (1) (2) The steps are the same as those in Examples 1 and 2;

[0038] (3) When coating the film, add nano-boron carbide to the bridged polysilsesquioxane sol, ultrasonically disperse for 30 minutes, and the mass percentage of nano-boron carbide in the mixture is 0.3%;

[0039] (4) Secondary spraying and secondary curing method: after the first spraying, first cure at room temperature and dry for 12 hours; after the second spraying, heat and cure, first cure at 60°C for 24 hours, and then at 100°C Curing under the same conditions for 2 hours, a dense organic / inorganic hybrid nano-anti-corrosion protective film can be formed after curing.

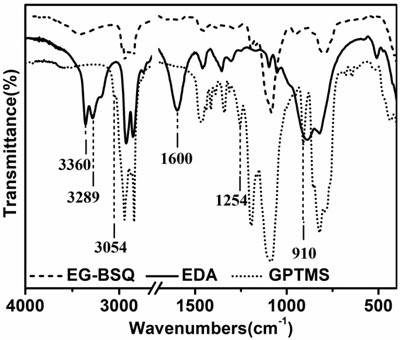

[0040] Depend on figure 2 It can be seen that the -NH in the EDA molecule 2 at 3360 cm -1 and 3289 cm -1 (N-H symmetric and antisymmetric stretching vibrations) There are two characteristic absorption peaks around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com