Welding fixed disc

A technology for fixing discs and discs, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inability to meet processing requirements, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

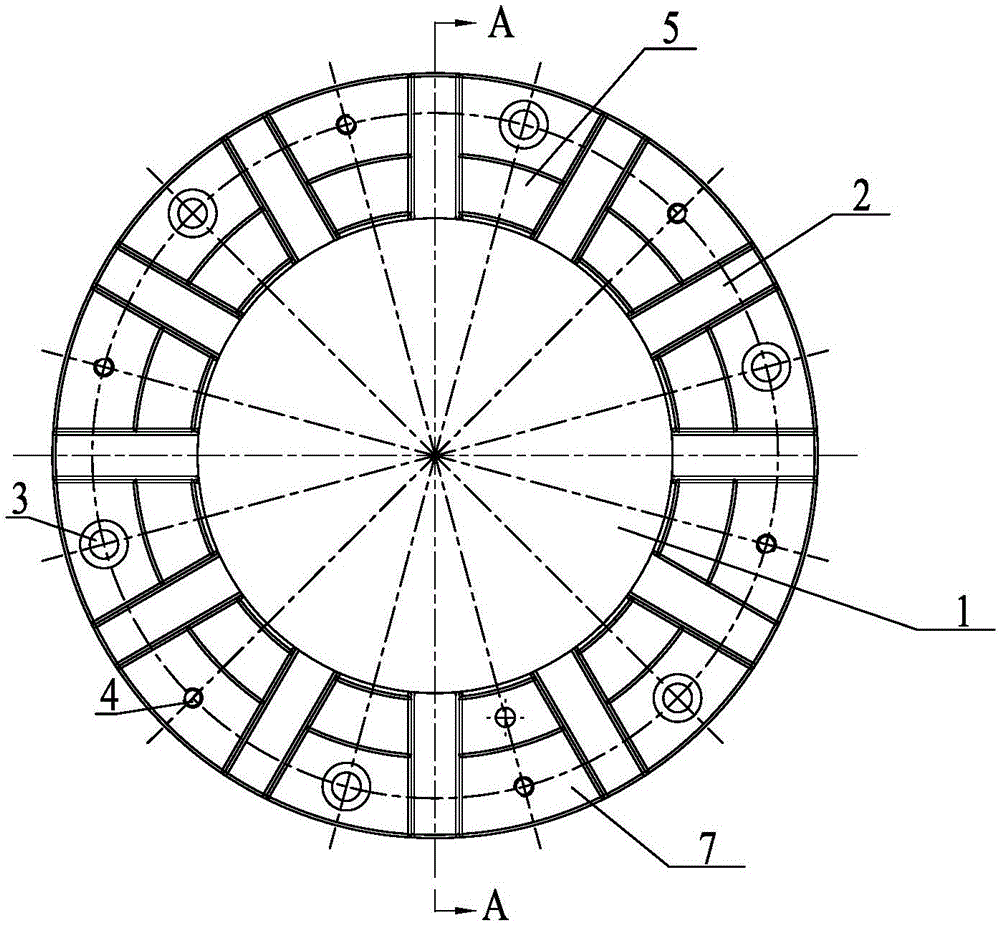

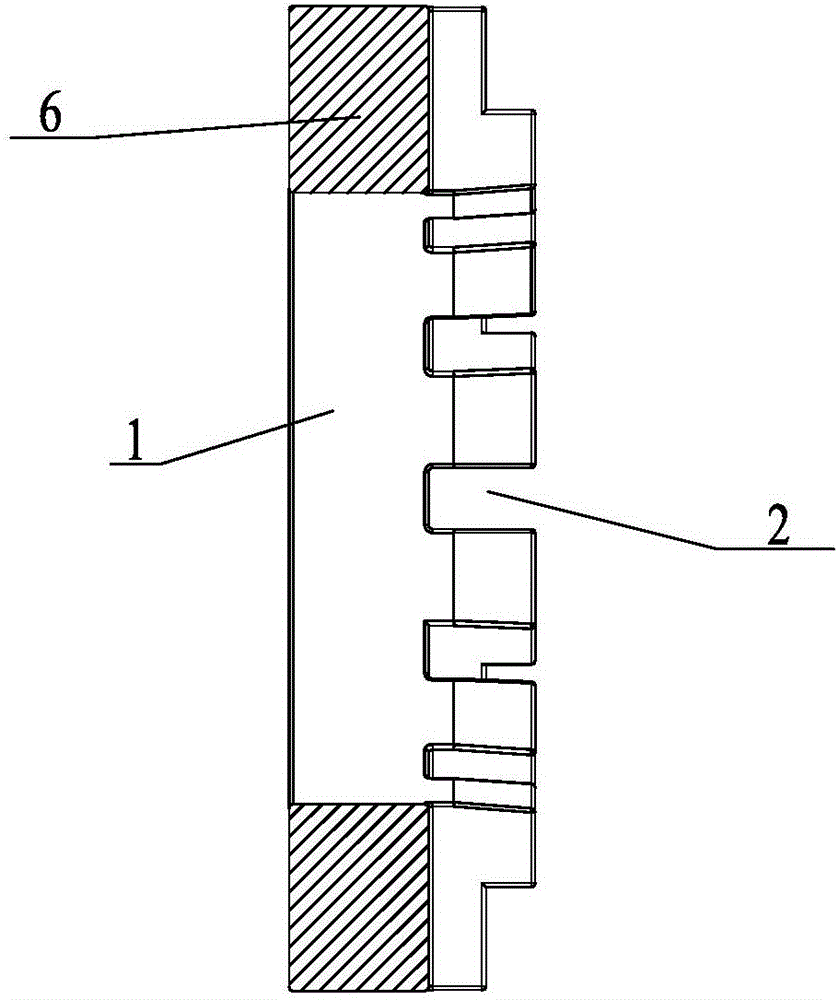

[0011] Such as figure 1 and figure 2 As shown: In order to support the welding of the air conditioner stator and realize effective restriction on the shape of the air conditioner stator, the present invention includes a disc body 6, a disc body through hole 1 is arranged in the central area of the disc body 6, and the upper end of the disc body 6 Several evenly distributed dividing grooves 2 are set, and the upper end of the disc body 6 forms a number of evenly distributed dividing supports through the dividing grooves 2. The outer support platform 7 on the outside, the height of the outer support platform 7 is lower than the height of the inner support block 5 .

[0012] Specifically, the disk body 6 is columnar or ring-shaped, and the disk body through hole 1 is located in the central area of the disk body 6 and runs through the disk body 6 . The disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com