Composite girder partially reinforced with carbon fiber reinforced polymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

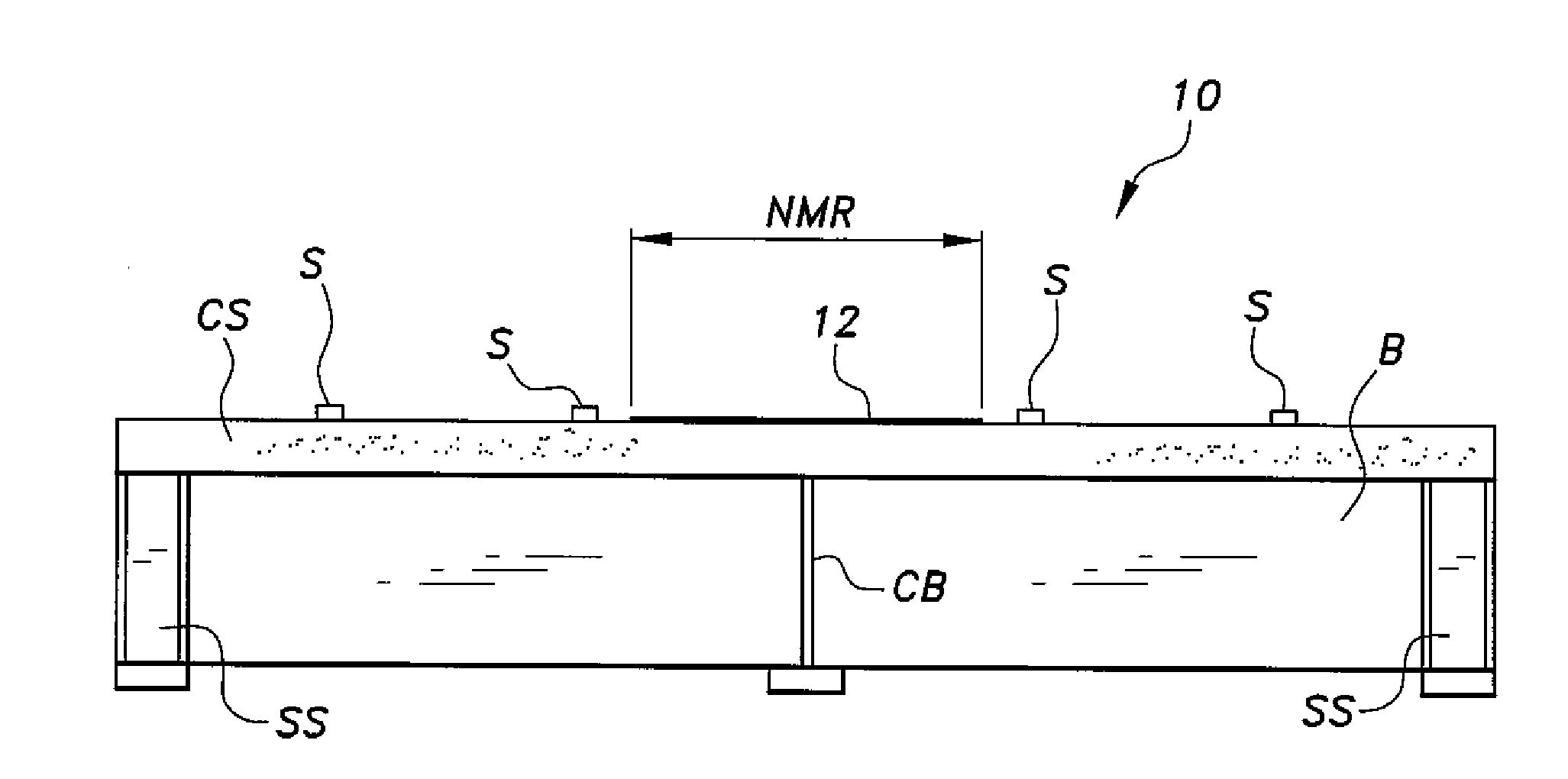

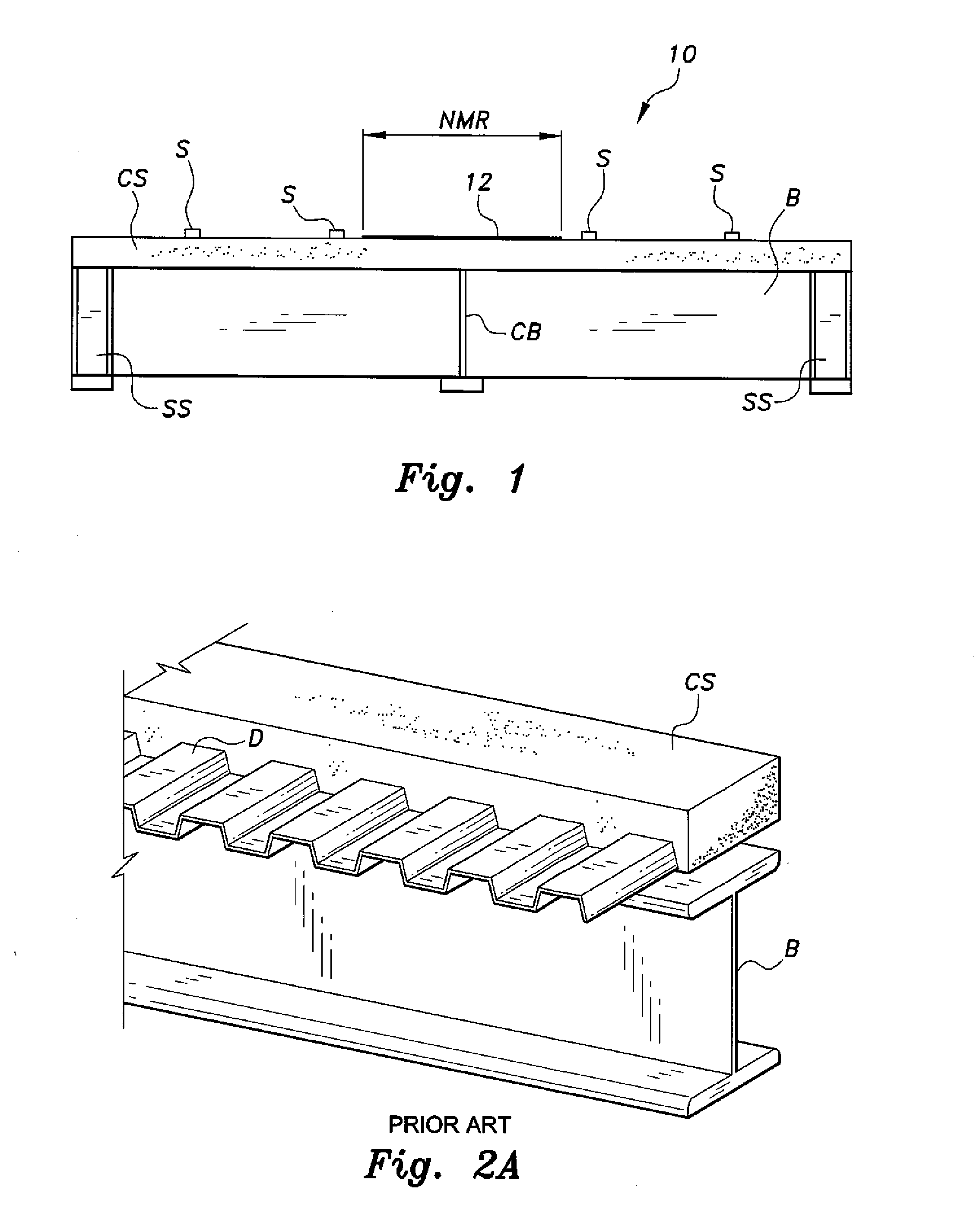

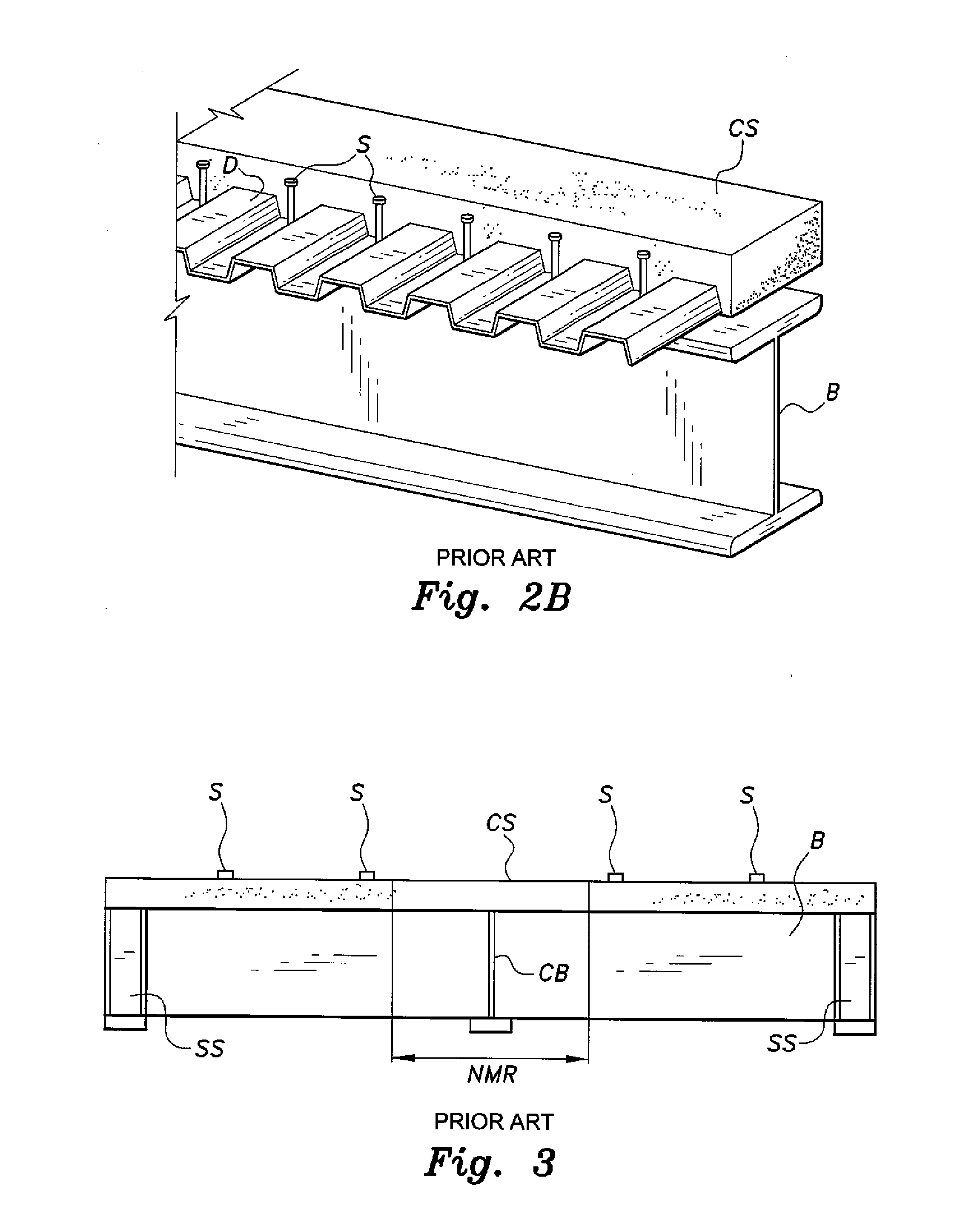

[0022]The composite girder partially reinforced with carbon fiber reinforced polymer (CFRP) 10, as shown in FIG. 1, is similar to the prior art steel-concrete composite beam shown in FIG. 3, but with a layer 12 of carbon fiber reinforced polymer mounted on the upper surface of concrete slab CS and extending across the negative moment region NMR. For a conventional composite construction girder having a length of 9.6 m, the NMR has a length of about 2.36 m; i.e., extending 1.18 m along either side of the fulcrum point of cross beam CB. The polymer is preferably epoxy, although polyester, vinyl ester, or nylon may be used. The sheet of CFRP is bonded to the concrete slab by an adhesive, which is preferably a 2-part epoxy impregnation resin, although any suitable concrete adhesive may be used.

[0023]In order to examine the effectiveness of the carbon fiber reinforced polymer layer 12 a finite element analysis was performed, comparing a conventional continuous composite steel-concrete (C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com