Mechanical device for prestressing of carbon fiber reinforced polymer (CFRP) sheets

a technology of carbon fiber reinforced polymer and mechanical device, which is applied in stretching, textiles and papermaking, manufacturing tools, etc., can solve the problems of low prestressing level, difficult to achieve, and high cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Main Components

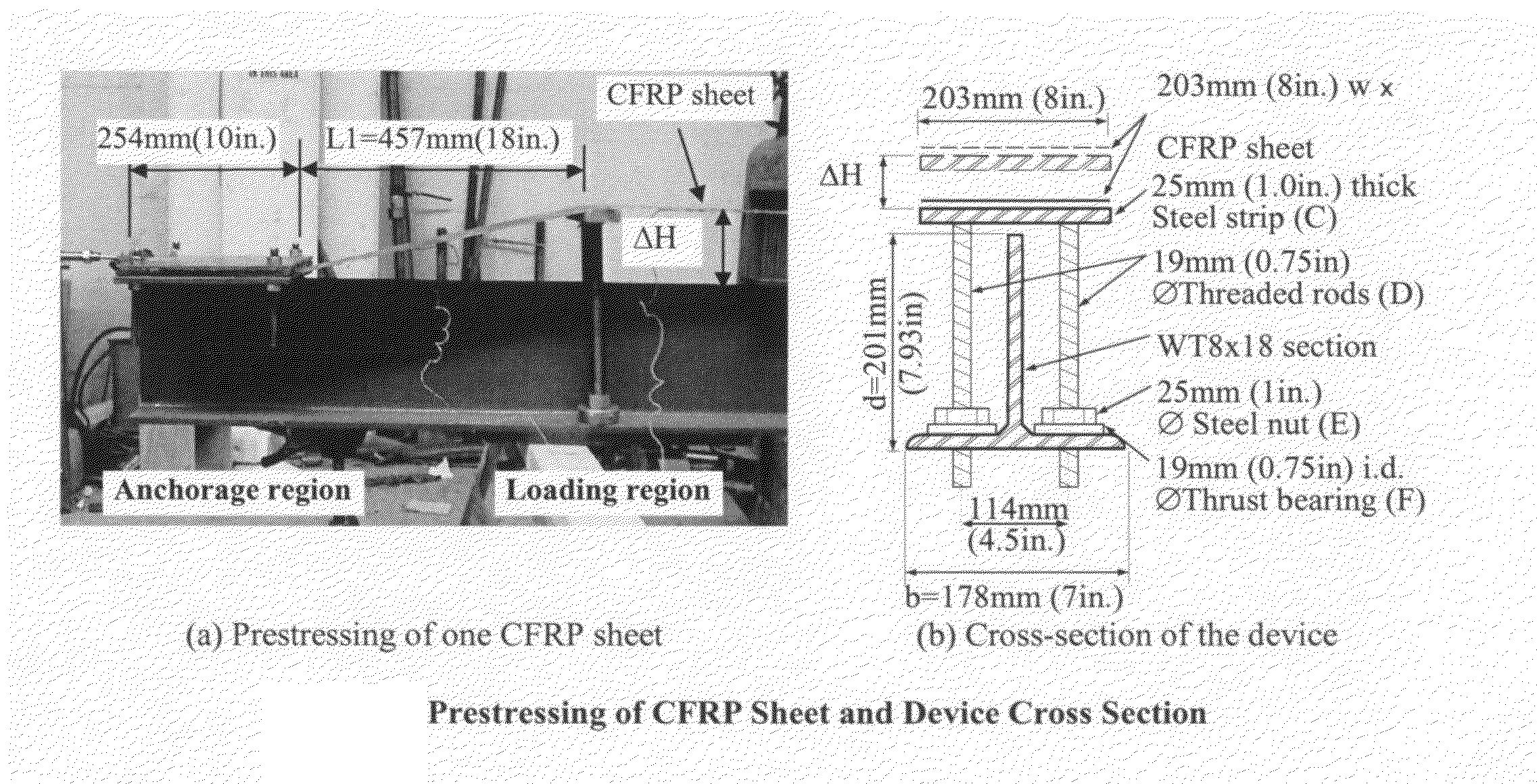

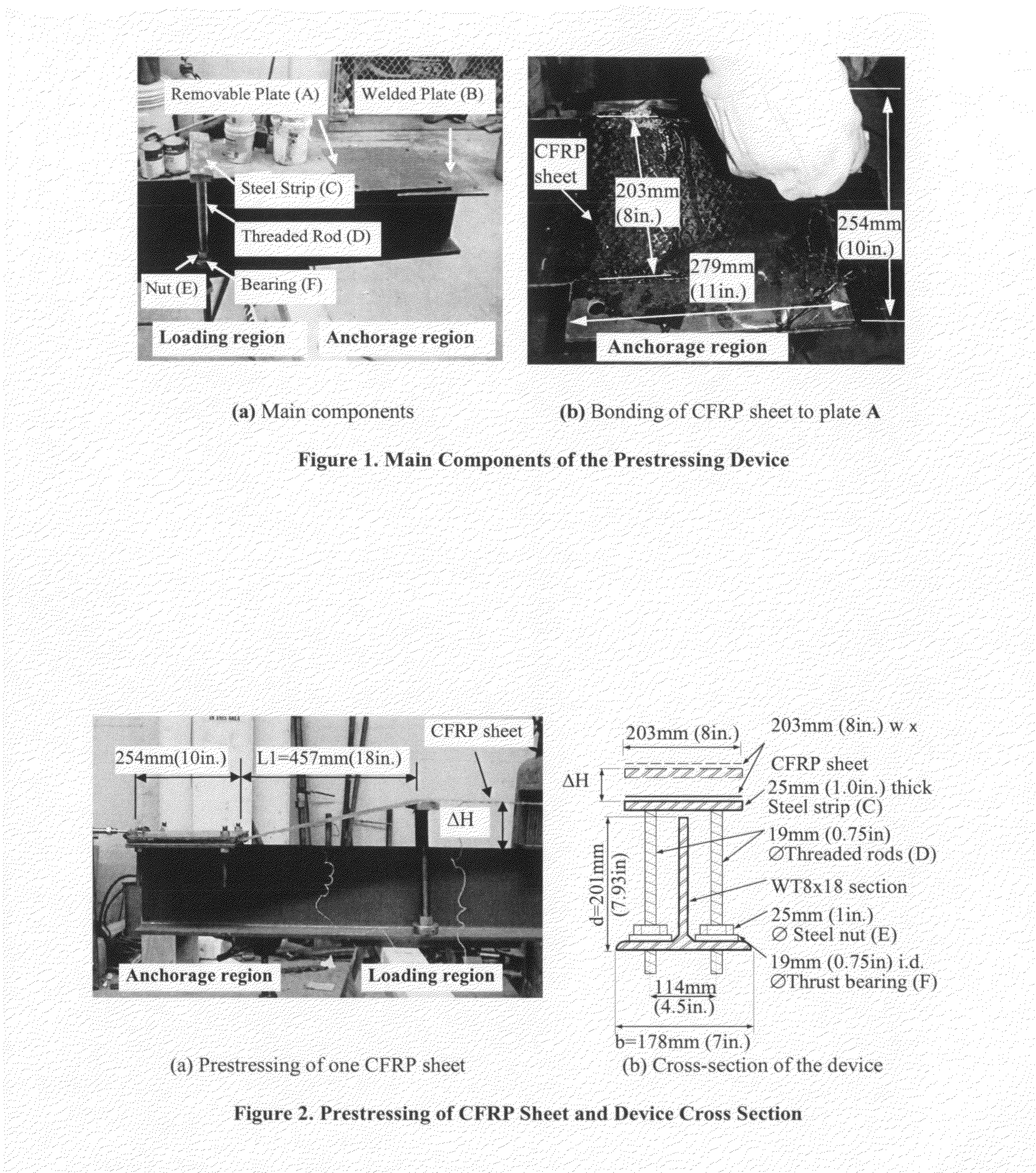

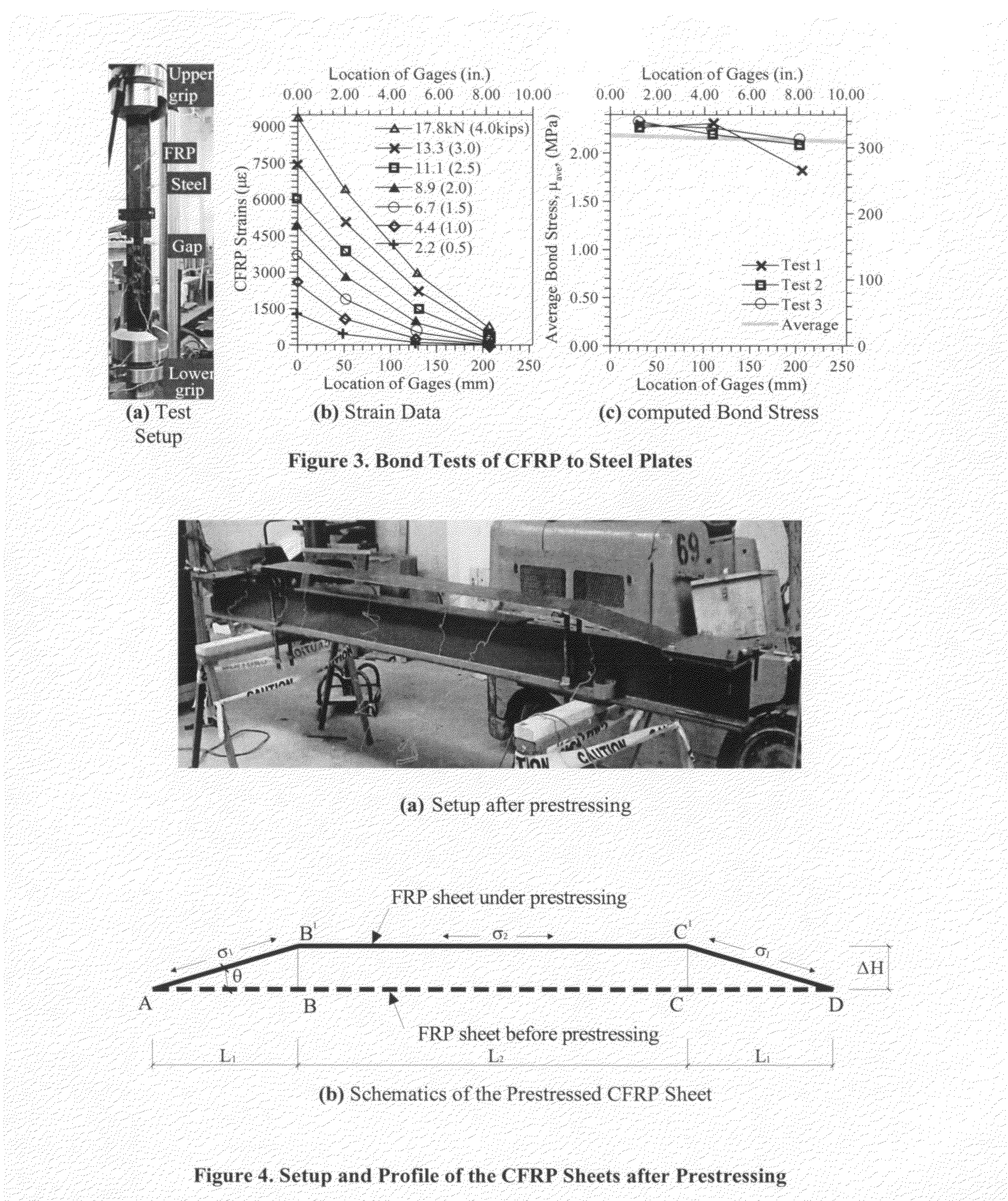

[0010]Referring to FIGS. 1 and 2, the mechanical device consists of one WT steel section and four regions, including two anchorage and two loading regions. A summary of main components and dimensions of the mechanical device is also presented in Table 1. Located at each end of the WT section, each anchorage region consists of: (1) a removable steel plate, designated as part A, (2) a steel plate welded to the WT-section, designated as part B, and (3) the corresponding bolts and nuts. Located away from the anchorage regions, each loading region consists of: (1) one steel strip welded to two steel threaded rods, designated as parts C and D, respectively, and (2) two steel nuts and two thrust bearings, designated as parts E and F, respectively. The thrust bearings are a vital component because they must be used to decrease the friction between the steel nuts and the WT section.

Assemblage

[0011]The first step in the assembly operation consisted of impregnating the CFRP shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com