Light emitting diode package and method for making same

a technology of led package and light-emitting diodes, which is applied in the direction of printed circuit, sustainable manufacturing/processing, final product manufacturing, etc., can solve the problems of adding significant cost to the fabrication of led package, and the packaging is not well suited for multi-die array, so as to achieve cost-effective construction and versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

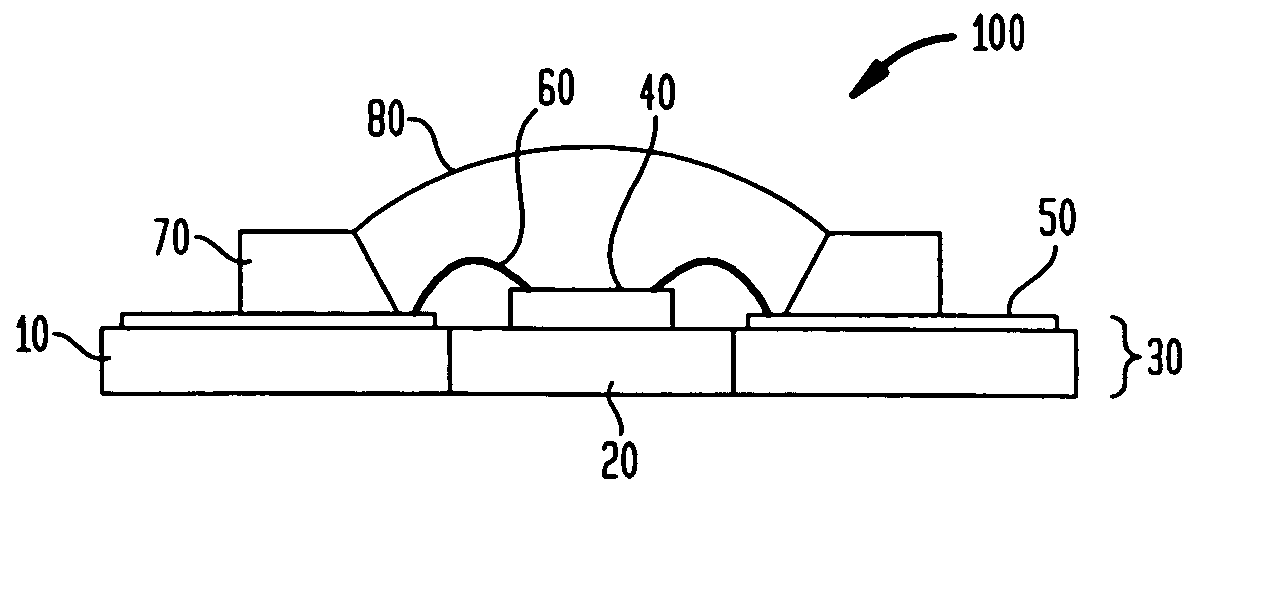

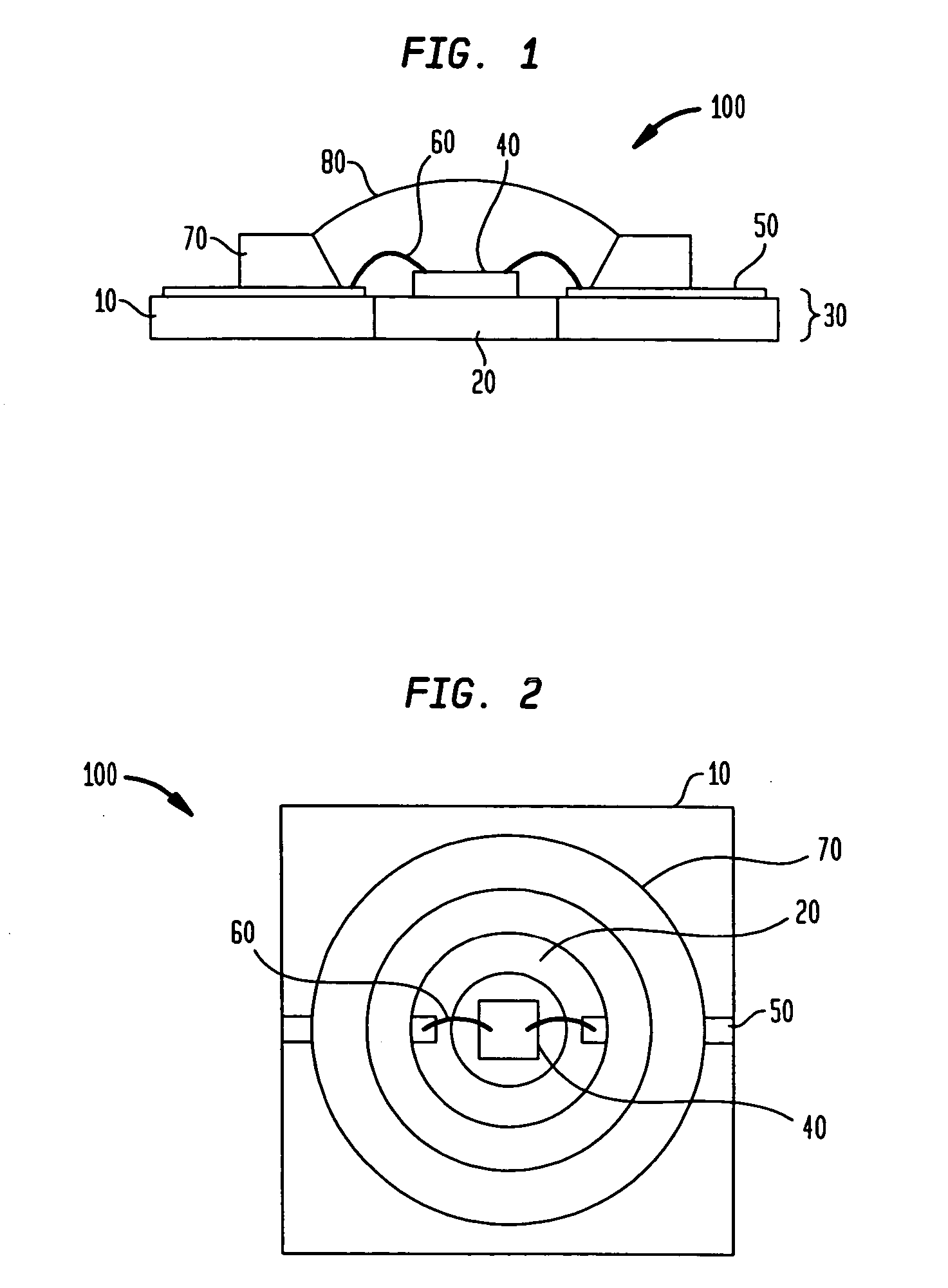

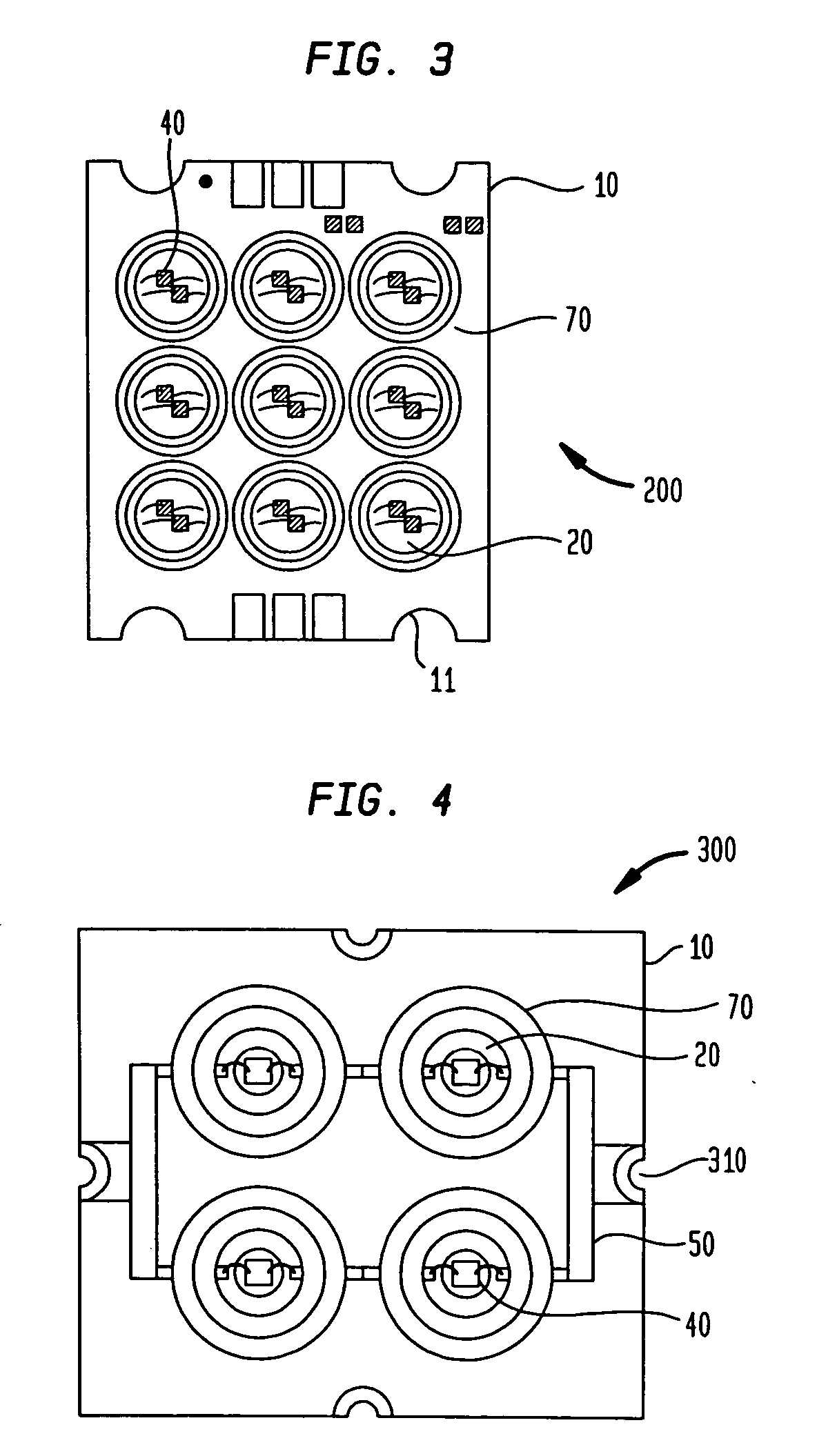

[0034] The present invention relates to light emitting packages, and methods for making same, wherein the light emitting package comprising at least one light emitting assembly including a printed wired board having one or more heat sink studs integrated therein to form a monolithic integrated base for mounting one or more light sources thereon. As used herein, the term “package” or “LED package” is intended to include, but is not limited to, an LED assembly comprising one LED or an array of LEDs, according to the present invention. As used herein, the term “array” is intended to refer to a plurality of elements, and is not intended to be limited to elements arranged in regular columns and / or rows. According to an embodiment of the present invention, the LED package may include an array of LED assemblies, with each LED assembly including an array of LED die.

[0035] According to an embodiment of the present invention, the one or more light sources comprise light emitting diode (LED) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com