Structural element for reinforcing a fuselage of an aircraft

A technology of structural elements and fuselage, applied in the field of structural elements, can solve the problems of increased weight of reinforced profiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

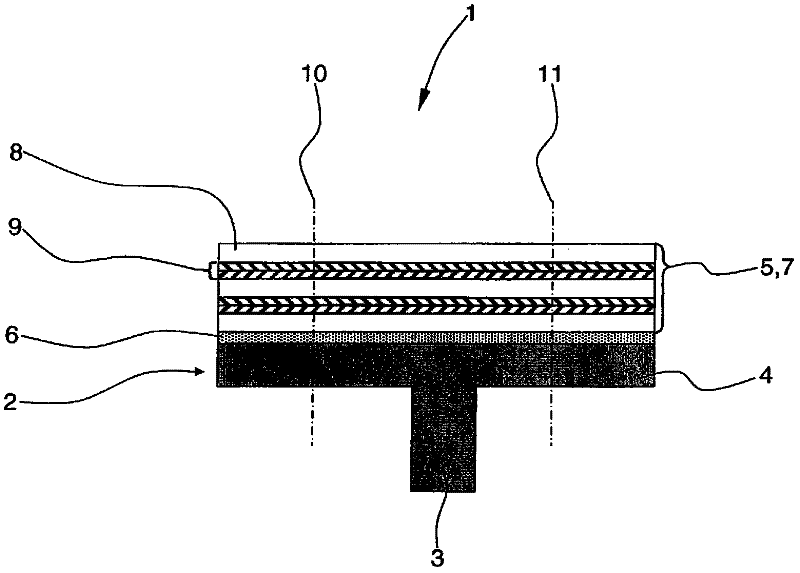

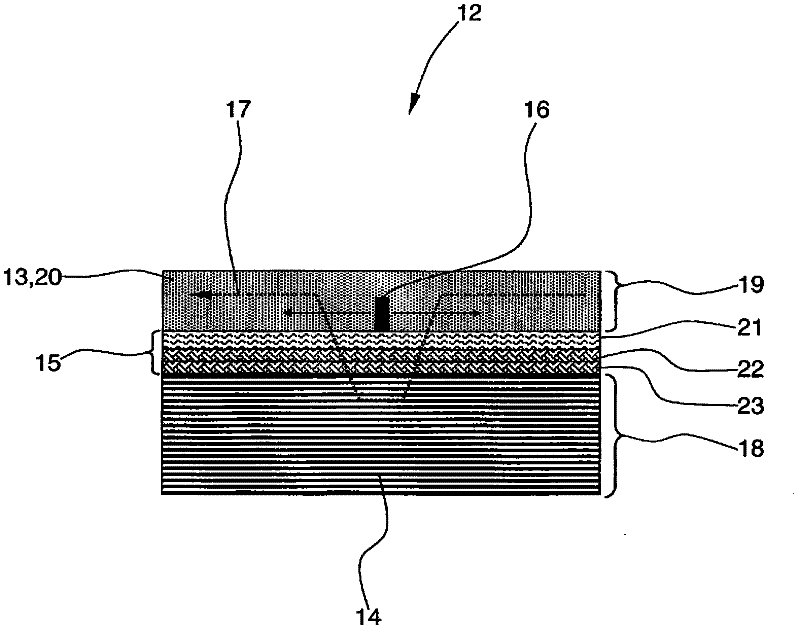

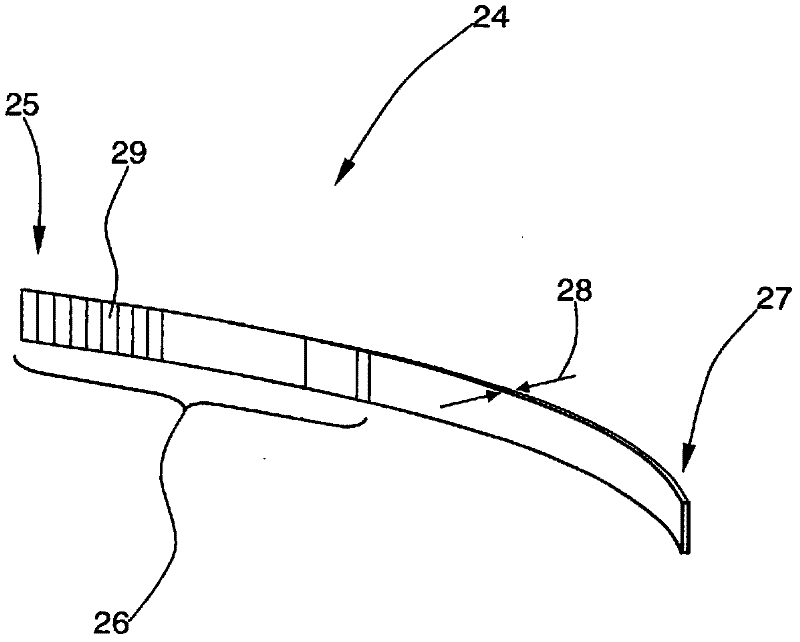

[0033] In the drawings, like reference numerals represent like constructional elements in each aspect.

[0034] figure 1 is a schematic cross-section of a structural element according to the invention. The structural element 1 includes in particular a reinforcement profile 2, which is in figure 1 The rib segments 3 are configured by way of example to reinforce a fuselage unit (not shown) of an aircraft. The rib segments 3 are manufactured from a suitable high strength aluminum alloy material and have a double T-shaped cross-sectional geometry. Alternatively, the rib segments 3 may have a U-shaped or L-shaped cross-sectional geometry. The rib segments 3 may be made from a one-piece solid aluminum alloy material, eg by milling, forging or stamping. According to the invention, the inner flange 4 of the rib segment 3 is bonded to the strip 5 over the entire surface. According to the invention, the strap 5 ideally almost prevents the propagation of cracks in the inner flange. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com