Aircraft wing and fiber metal laminate forming part of such an aircraft wing

A technology of fiber metal and laminates, applied in the direction of metal layered products, wings, layered products, etc., can solve the problems of reducing the fatigue performance of laminates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

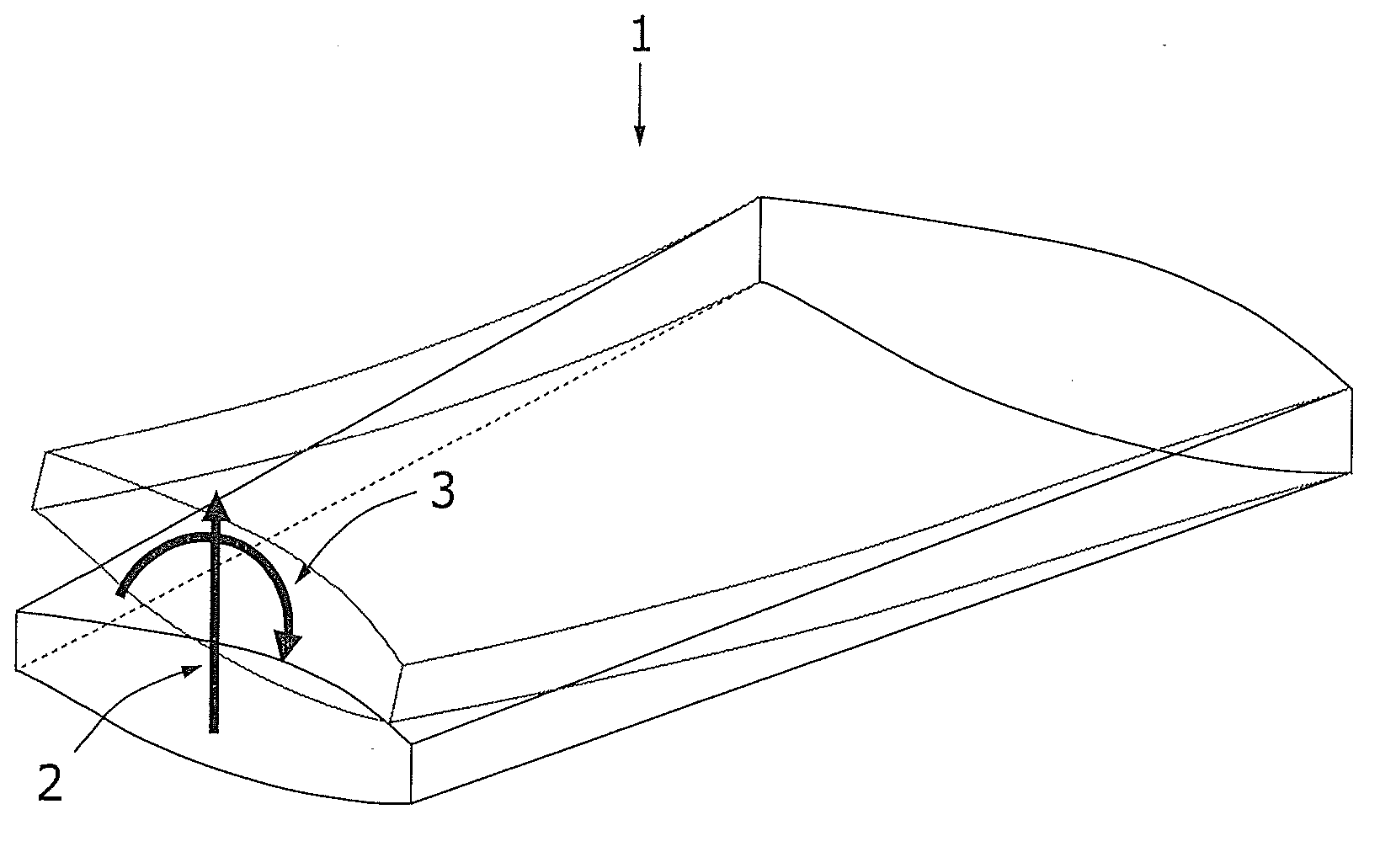

[0029] first reference figure 2 , shows a portion of the wing 1 which, in use, is subjected to an upward bending force indicated by arrow 2 generated by the lift. Wing 1 is also subjected to torsional forces indicated by arrow 3 .

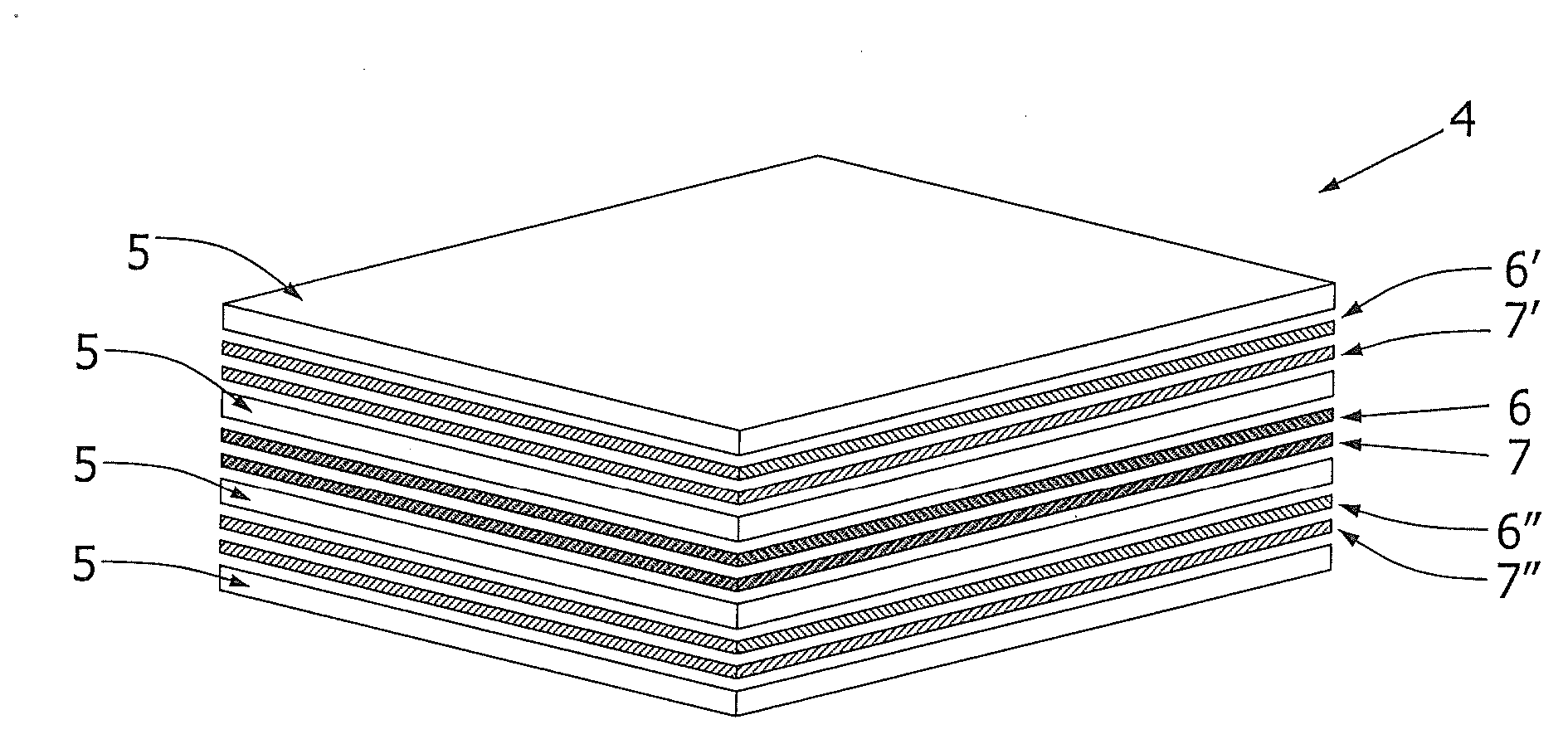

[0030] figure 1 A laminate 4 of the invention is shown comprising a plurality of metal layers 5 and a plurality of layers 6 , 7 of fiber reinforced plastic between said metal layers 5 in or near the plane of symmetry of the laminate 4 . Furthermore, on opposite sides of said fiber reinforced plastic layers 6, 7 in the plane of symmetry of the laminate between the metal layers 5, there are fiber reinforced plastic layers 6', 7' and 6", 7' '. The metal layer 5 and the fiber reinforced plastic layers 6, 7; 6', 7'; 6'', 7'' are all bonded together.

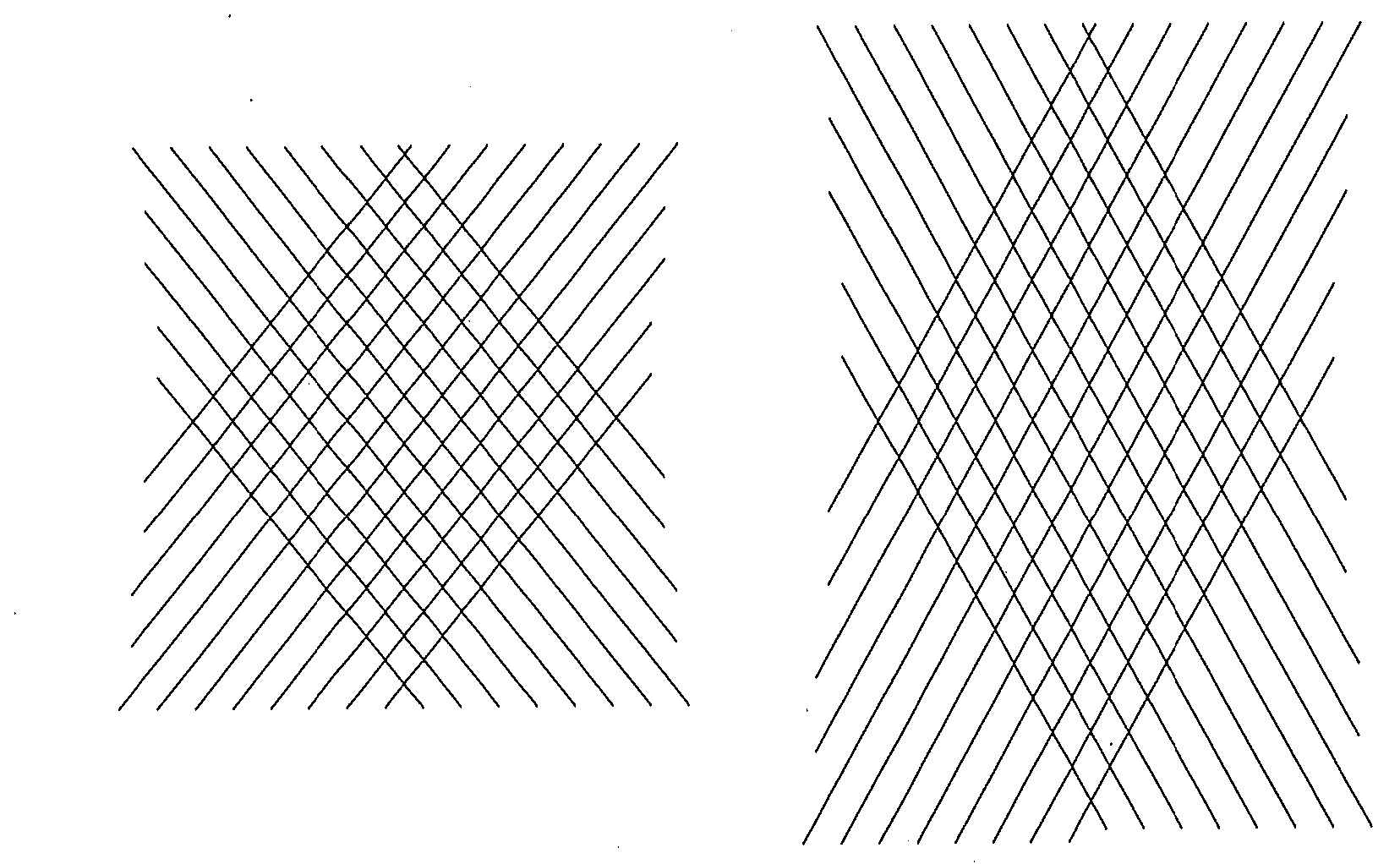

[0031] At least one or some of the fiber reinforced plastic layers 6 ′, 7 ′ and 6 ″, 7 ″ that are not in or near the plane of symmetry of the laminate 4 exhibit a first type of fiber. This longitudi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com