Metal layer bionic microstructure fiber metal laminate capable of realizing resin self-infiltration

A technology of fiber metal laminates and metal layers, applied in the field of plate composite materials, can solve problems such as delamination and infiltration of laminate parts that cannot be effectively solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

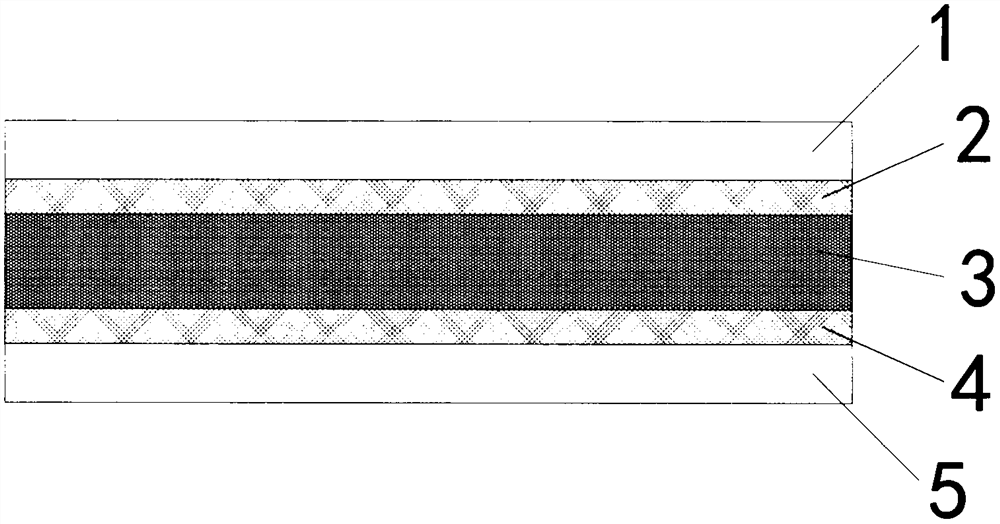

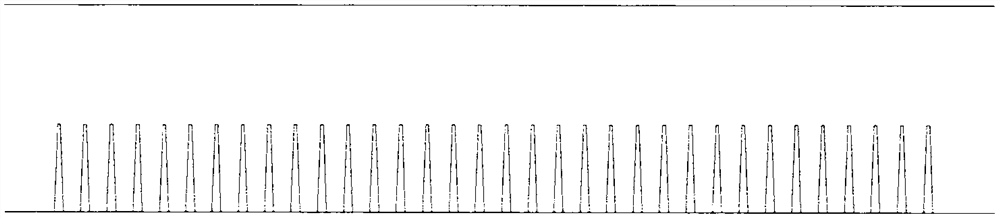

[0021] The surface of the metal layer in contact with the fiber resin prepreg is infiltrated with microstructures such as figure 2 Shown: The microstructure on the surface of the metal layer is composed of a dense array of vertical tapered holes at a certain distance. The side of the tapered hole with a larger opening faces the resin side, and the side with a smaller opening faces the metal layer side. The size of the openings on both sides of the tapered hole and the depth of the tapered hole are determined by the actual infiltration effect of the resin in the tapered hole and the interlayer bonding performance of the laminate parts. After the metal layer is prepared, the metal layer, resin, and fiber reinforced material are laminated in a certain way. According to the way that the thermosetting resin laminate is heated and cured, and the thermoplastic resin laminate is heated to the viscous state of the resin and cooled and solidified, the laminate blank is cured at a certa...

Embodiment 2

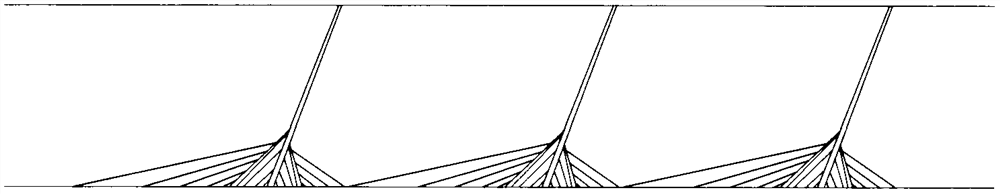

[0023] The surface of the metal layer in contact with the fiber resin prepreg is infiltrated with microstructures such as image 3 Shown: the microstructure on the surface of the metal layer is composed of the main hole of the tapered hole and the secondary holes of the tapered hole distributed around the main hole. The main hole forms a certain angle with the auxiliary hole and the auxiliary hole, the main hole of the tapered hole is a through hole, and the auxiliary hole communicates with the main hole. The parameters and included angles of the main and auxiliary holes of the tapered hole are determined by the effect of resin infiltration and the bonding performance of the laminate part interface. After the metal layer is prepared, the metal layer, resin, and fiber reinforced material are laminated in a certain way. According to the way that the thermosetting resin laminate is heated and cured, and the thermoplastic resin laminate is heated to the viscous state of the resin...

Embodiment 3

[0025] The surface of the metal layer in contact with the fiber resin prepreg is infiltrated with microstructures such as Figure 4Shown: the microstructure on the surface of the metal layer is an Archimedes spiral or a logarithmic spiral pit structure. The pit track is an Archimedes spiral or a logarithmic spiral, and the microstructure pits are a regular dense array structure. The parameters and dimensions of the pit track are determined by the effect of resin infiltration and the bonding performance of the laminate interface. After the metal layer is prepared, the metal layer, resin, and fiber reinforced material are laminated in a certain way. According to the way that the thermosetting resin laminate is heated and cured, and the thermoplastic resin laminate is heated to the viscous state of the resin and cooled and solidified, the laminate blank is cured at a certain temperature, a certain pressure, and a certain degree of vacuum, and finally the required by the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com