Patents

Literature

67 results about "Aerospace manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

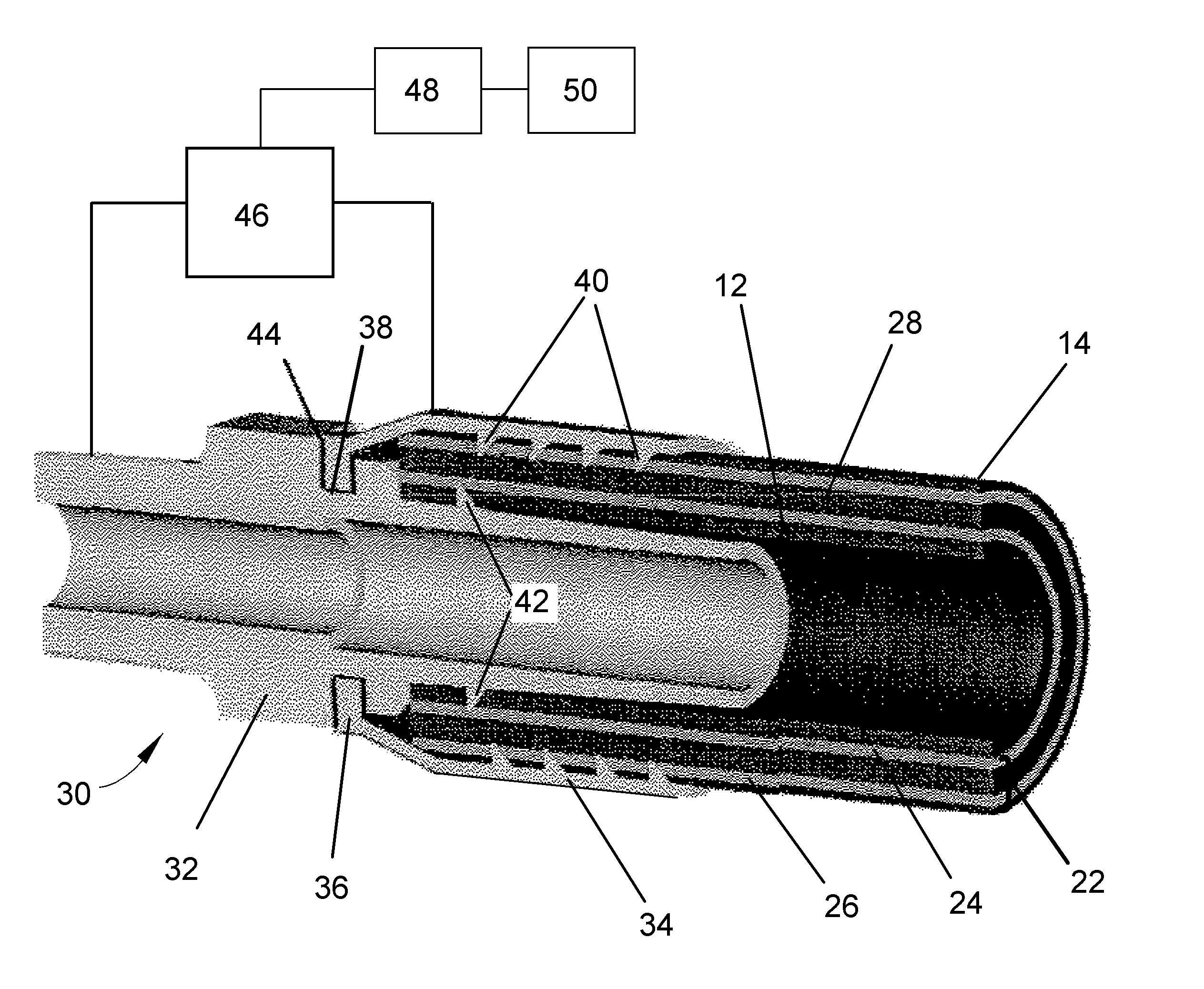

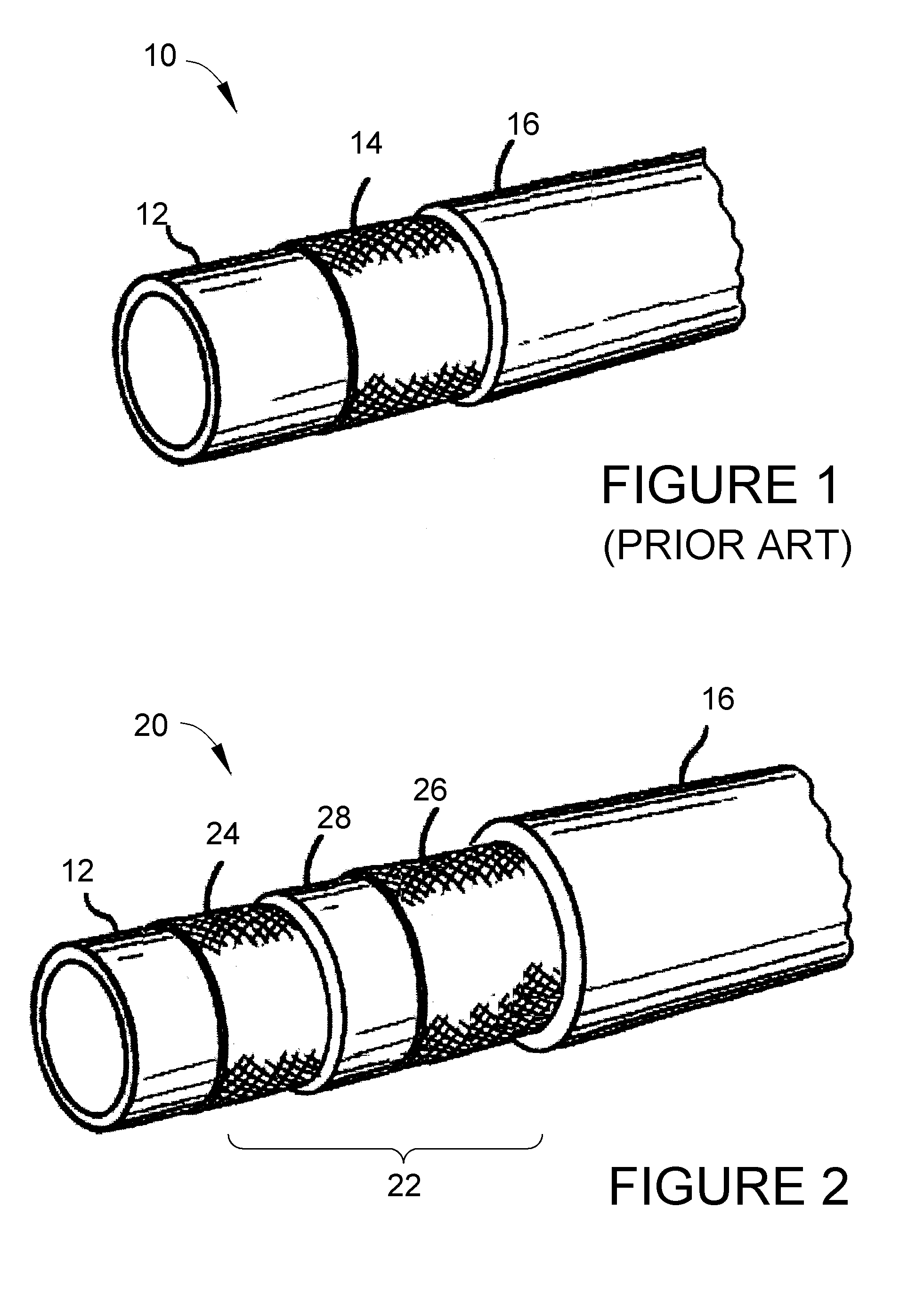

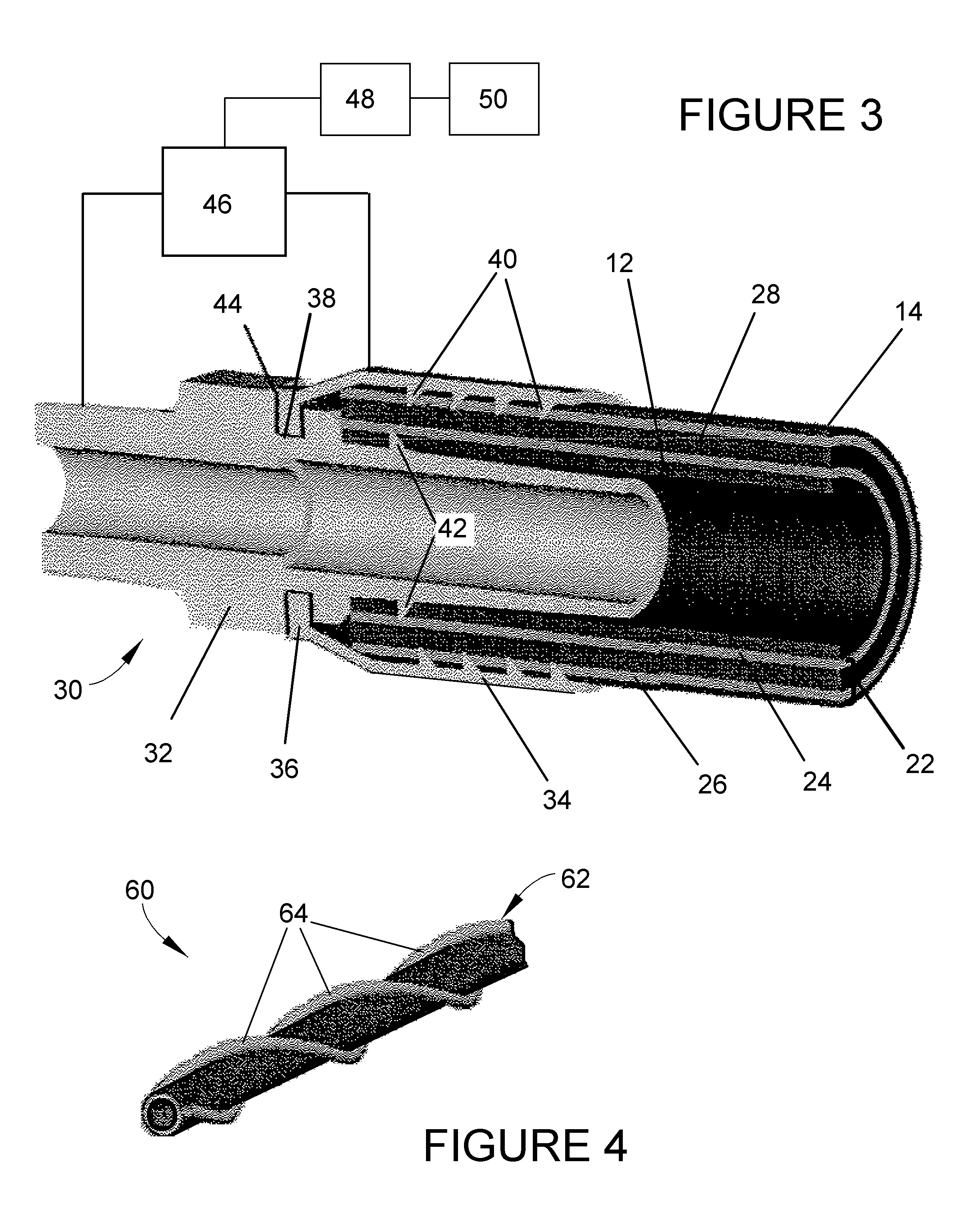

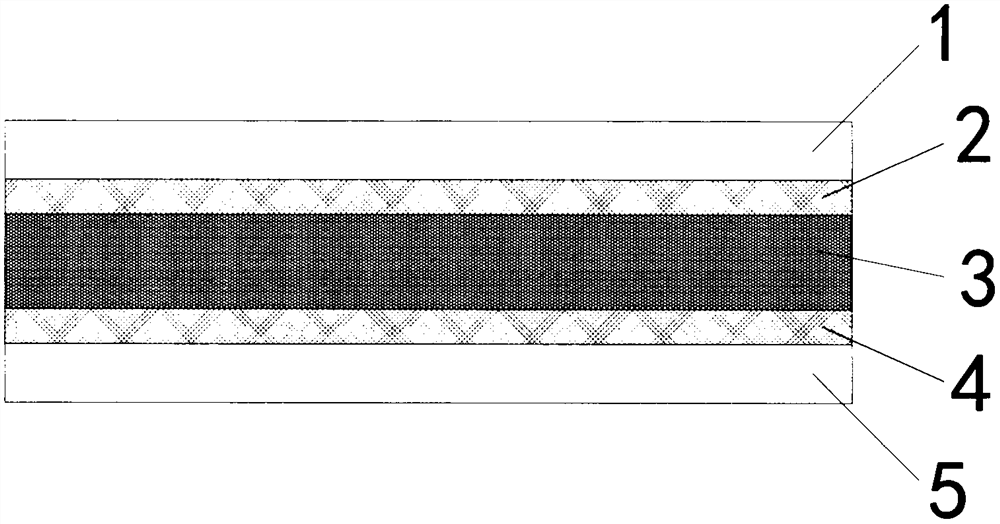

Hydraulic hose with integral life-sensing capability and method therefor

ActiveUS20060196252A1Detection of fluid at leakage pointTesting/calibration apparatusElectrical conductorProcess equipment

A system and method for predicting structural failure of a wall of a fluid containment vessel, such as a hydraulic hose or other type of pressurized conduit of types used in mobile machinery, automotive, aerospace, manufacturing, and process equipment. The wall of the vessel has an innermost layer for contact with the fluid contained by the vessel, and an outermost layer parallel with the innermost layer. The system includes strain-sensing means between the innermost and outermost layers and comprising at least one conductor parallel to the innermost layer of the wall. The system and method entail sensing changes in an electrical property associated with the at least one conductor resulting from distortion of the wall of the vessel causing distortion of the at least one conductor.

Owner:PURDUE RES FOUND INC

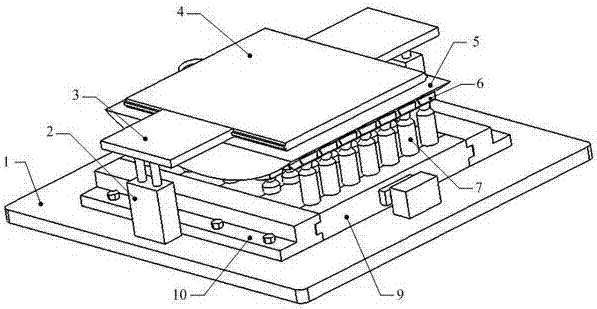

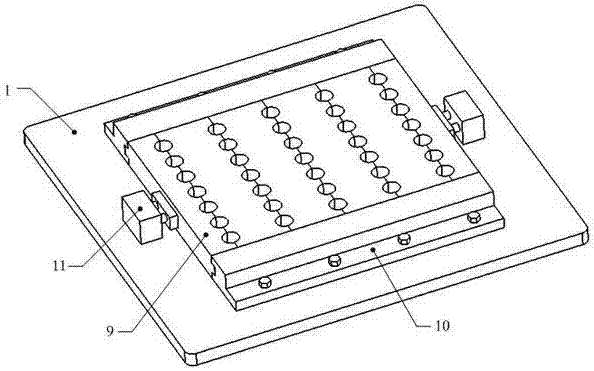

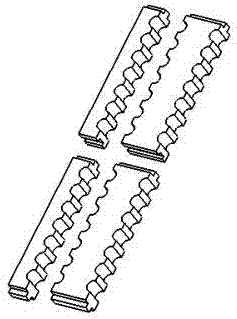

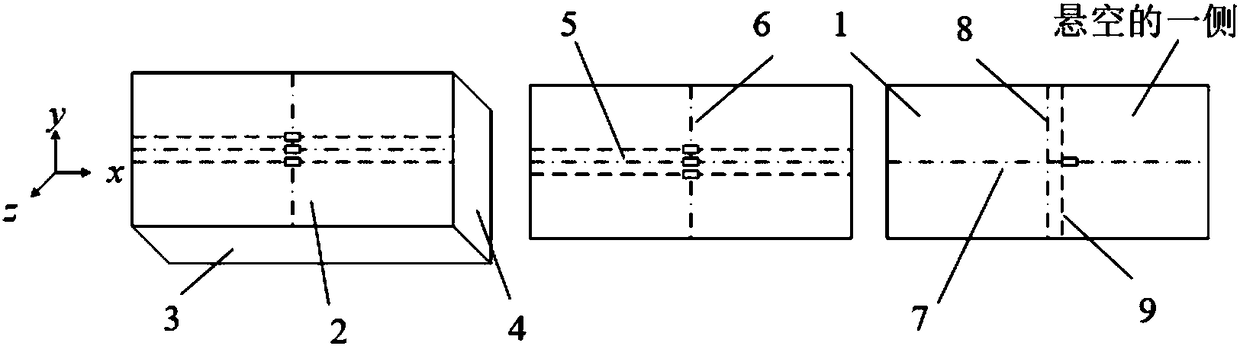

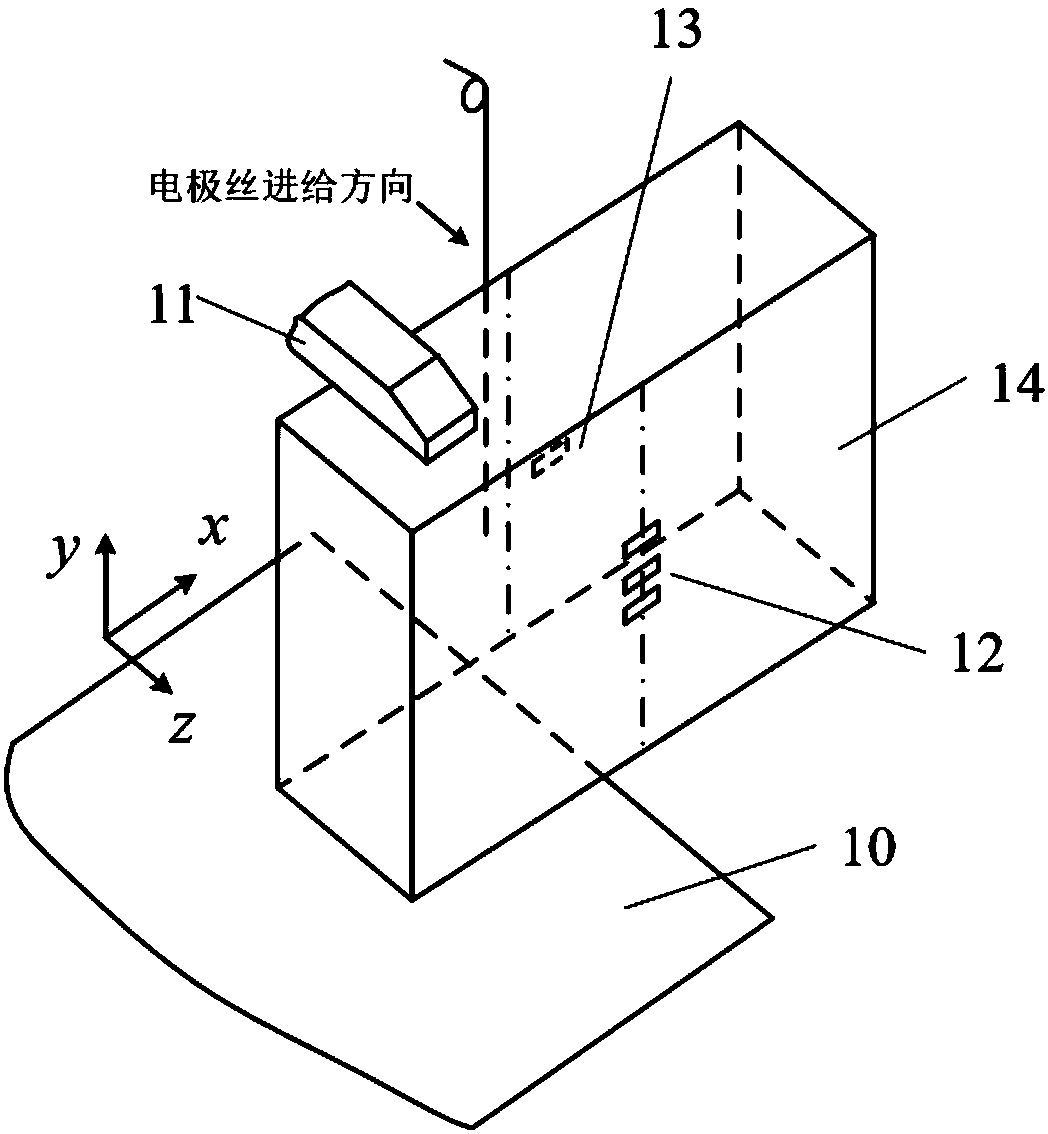

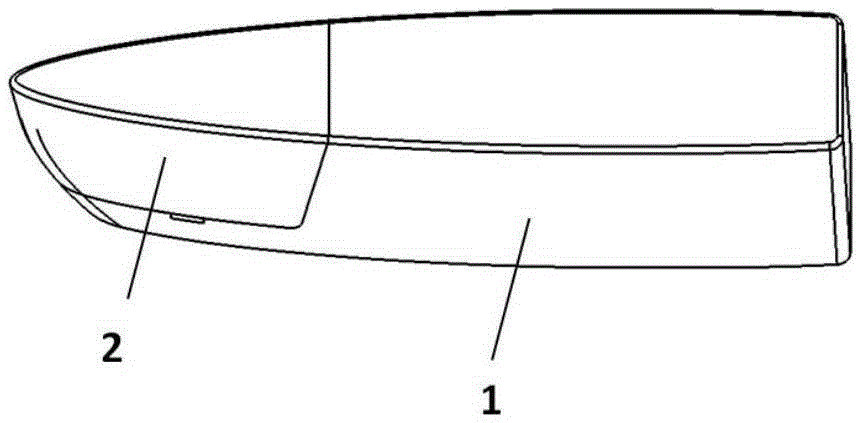

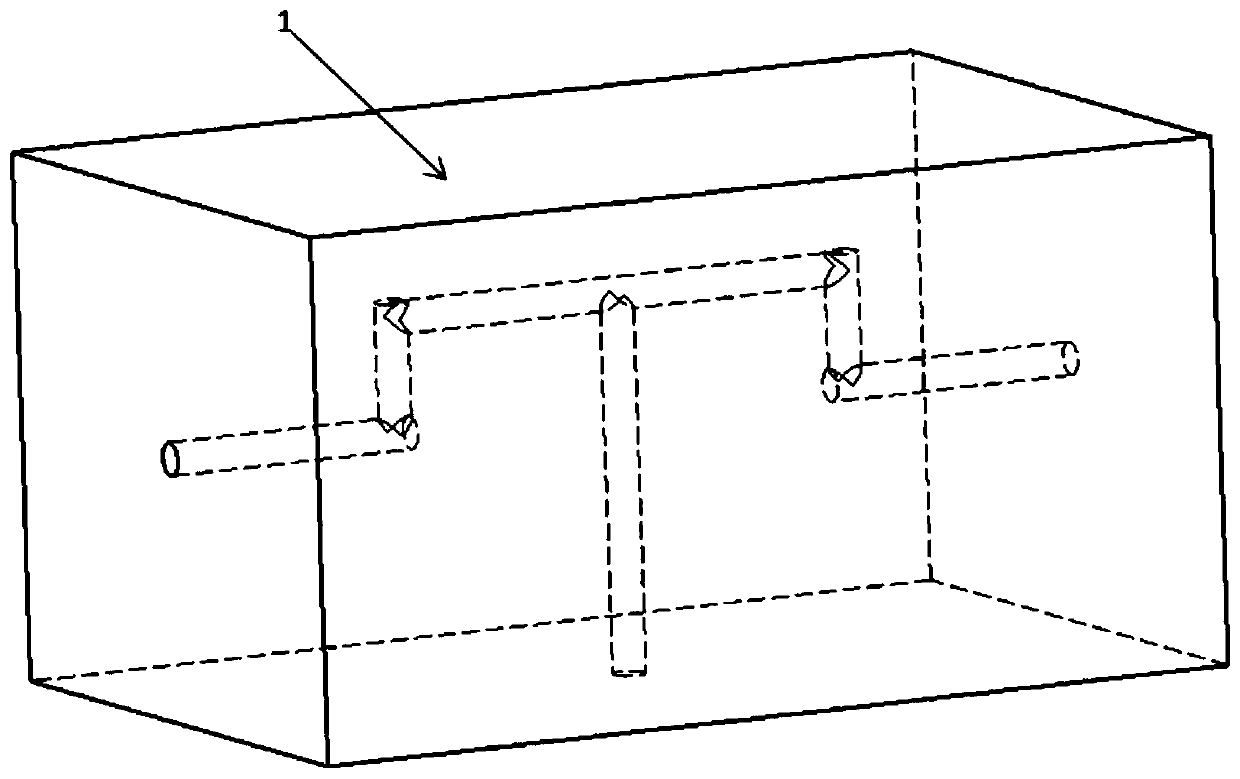

Flexible combined clamping device and clamping method of weak-rigidity composite material parts

ActiveCN107160216AQuick clampingHigh degree of flexibilityWork holdersPositioning apparatusEngineeringAerospace manufacturing

The invention belongs to the field of mechanical devices, and in particular, relates to a flexible combined clamping device and a clamping method of weak-rigidity composite material parts applied to the field of aerospace manufacturing. The clamping device comprises a combined base, a flexible support system and a positioned pressing device; the flexible support system is mounted on the combined base; the positioned pressing device is positioned above the flexible support system; the flexible support system comprises multiple support units; each support unit comprises a support rod, a vacuum sucker and a spring; two ends of the support rod are respectively connected with the vacuum sucker and the spring; and the vacuum sucker is connected with the support rod through a spherical joint. The clamping device can realize quick clamping of the weak-rigidity composite material parts with different molded surface characteristics, adapts to different shapes and sizes of the parts, greatly improves the flexibility degree of the clamping mode, and is suitable for multi-variety and small-batch production demands.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

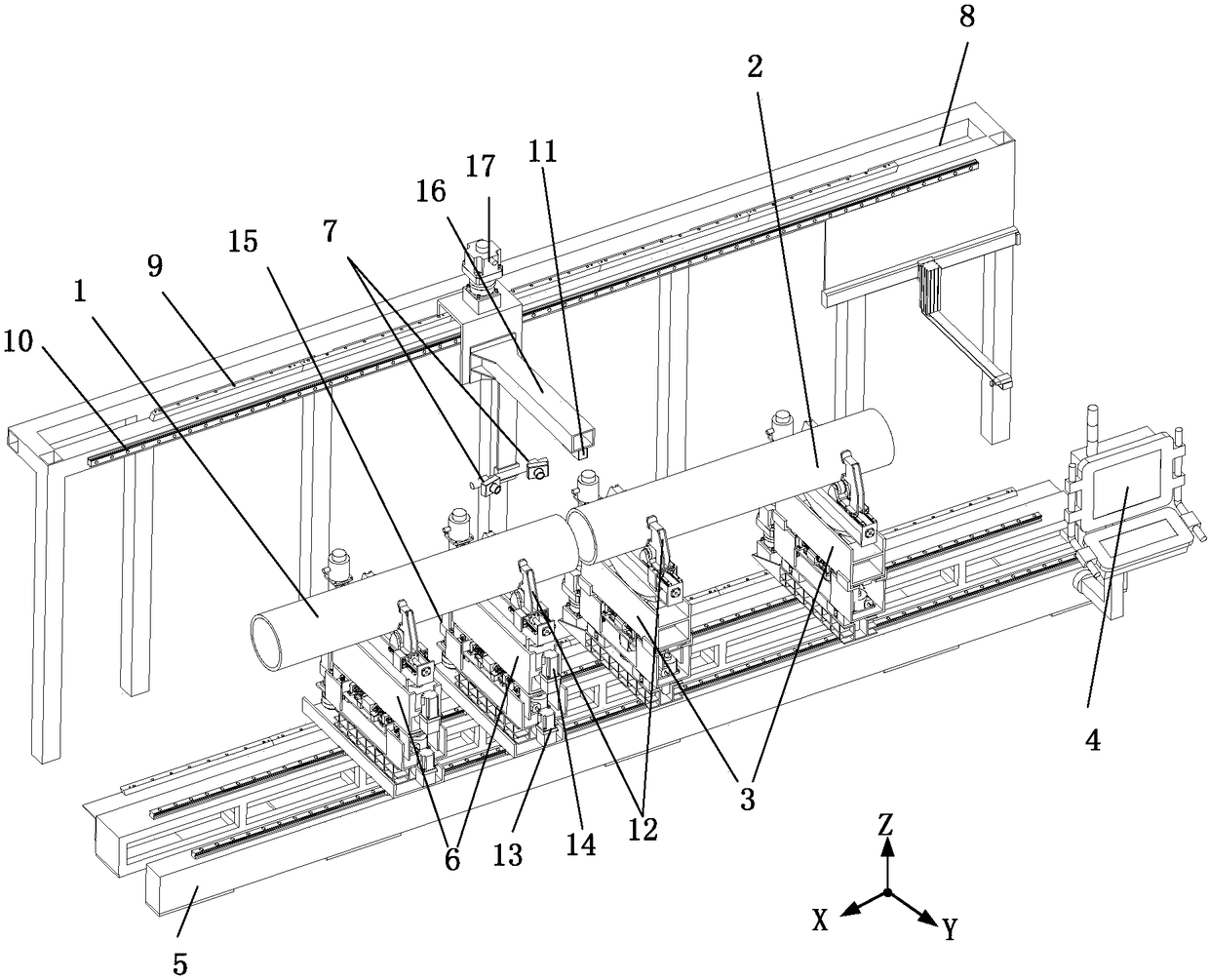

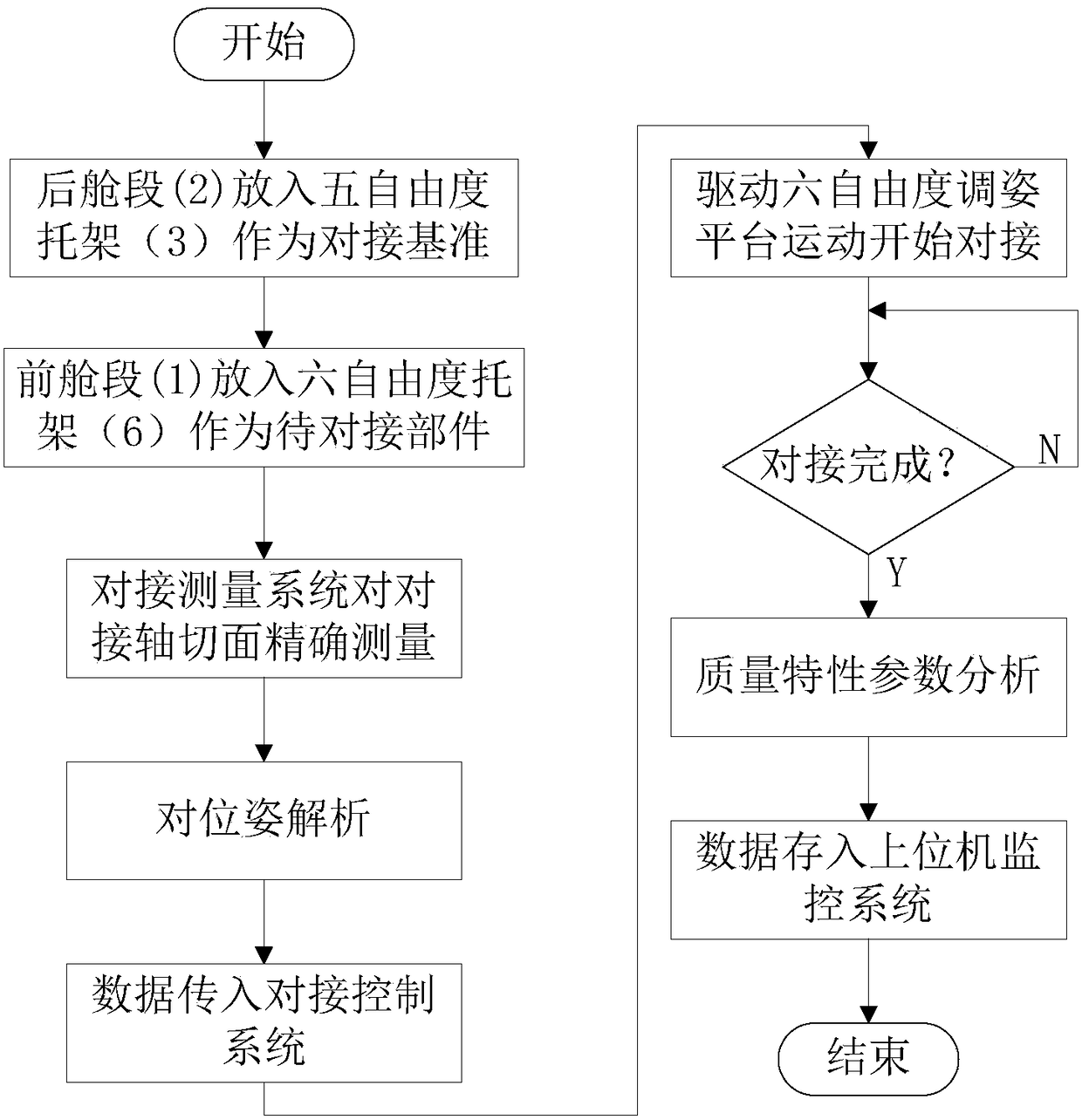

Automatic docking device and control method for hold section parts

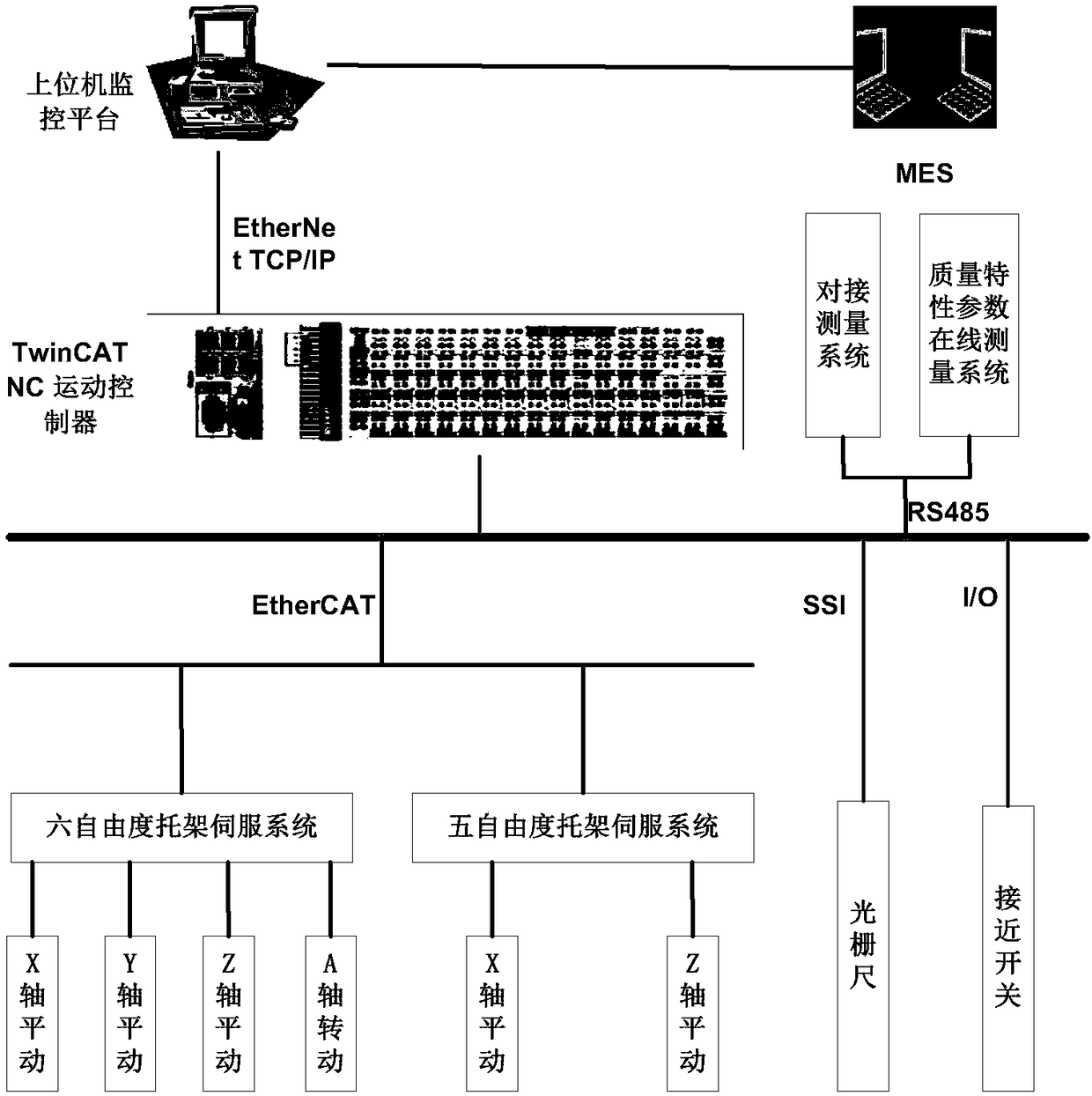

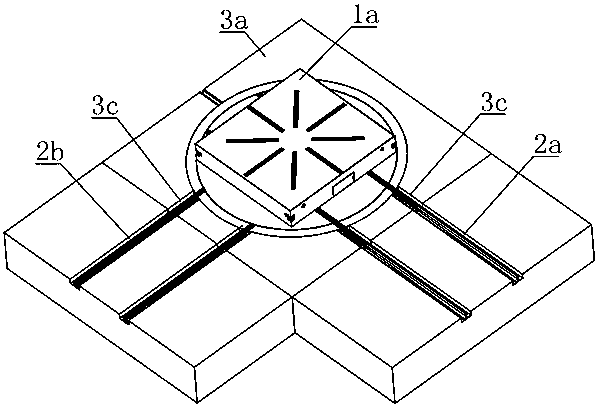

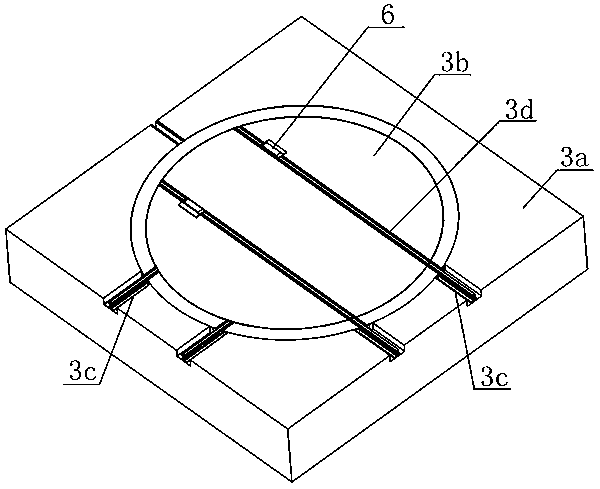

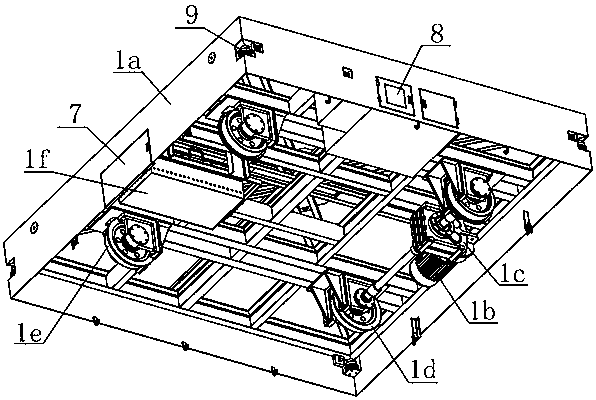

ActiveCN108274231ARealize automatic docking assemblyReduce engagementMetal working apparatusReal-time dataComputer monitoring

The invention provides an automatic docking device for hold section parts. The automatic docking device comprises a six-degree-of-freedom adjustment platform, a docking measurement platform, a dockingcontrol platform, a docking host computer monitoring platform and the like. The six-degree-of-freedom adjustment platform includes six-degree-of-freedom brackets, five-degree-of-freedom brackets, anda chassis, and the docking measurement platform includes a bracket, a rack, a linear guide, industrial cameras, a laser displacement sensor and a cantilever beam. The docking host computer monitoringplatform has the function of storing and recording docking data parameters and quality characteristic analytical data. The automatic docking device for the hold section parts is mainly used for on-line measurement of automatic docking and mass and centroid of different hold section parts and forming a new mode of hold section assembly with features of precise docking, real-time data visualizationand process online control, the assembly efficiency is improved, the assembly labor is reduced, and finally the aerospace manufacturing industry is further promoted to enhance the core competitiveness.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Vertical airspace engine track switching system

PendingCN108438788AEasy steeringLow structural requirementsMechanical conveyorsVehicle frameDrive wheel

The invention relates to the field of aerospace manufacturing and provides a vertical airspace engine track switching system. The vertical airspace engine track switching system comprises an electricflat carriage, a track mechanism, a transfer platform mechanism and a control unit. The electric flat carriage comprises a flat carriage frame, a motor, a speed reducer, a driving wheel set, a drivenwheel set and a electric storage device providing electric energy for the motor, and the motor, the speed reducer, the driving wheel set, the driven wheel set and the electric storage device are arranged at the bottom of the flat carriage; the motor is in transmission connection with the driving wheel set through the speed reducer; the track mechanism comprises a pair of parallel first tracks anda pair of parallel second tracks, and the first tracks and the second tracks are arranged on the ground; the first tracks are perpendicular to the second tracks; the transfer platform mechanism comprises a platform frame and a rotary disk body arranged in a table top of the platform frame. Two sets of transition tracks are in docking connection with the first tracks and the second tracks are arranged on the platform frame. The rotary disk body is provided with a set of rotary disk tracks. The bottom of the rotary disk body is provided with a rotating assembly. The vertical airspace engine track switching system is powered through electric energy and is eco-friendly and safe. Moreover, the flat carriage can conduct steering more easily.

Owner:HENGYANG LIMEI BATTERY VEHICLES MFG CO LTD

Testing method for residual stress in aluminum alloy pre-stretched plate

ActiveCN108536970ATest accurateImprove test accuracyDesign optimisation/simulationApparatus for force/torque/work measurementAviationCrazing

The invention provides a testing method for residual stress in an aluminum alloy pre-stretched plate. Residual stress distribution in aluminum alloy sheets applied in the field of aerospace manufacturing can be precisely tested; compared with an existing crack compliance method, strain of finite element simulation can be identical to measured strain. Compared with the prior art, the method has themultiple advantages that the testing precision is significantly improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Coefficient of thermal expansion control structure

ActiveUS7968021B2Low thermal expansionConstrain diametric growthLayered productsConfectioneryThermal expansionEngineering

Owner:THE BOEING CO

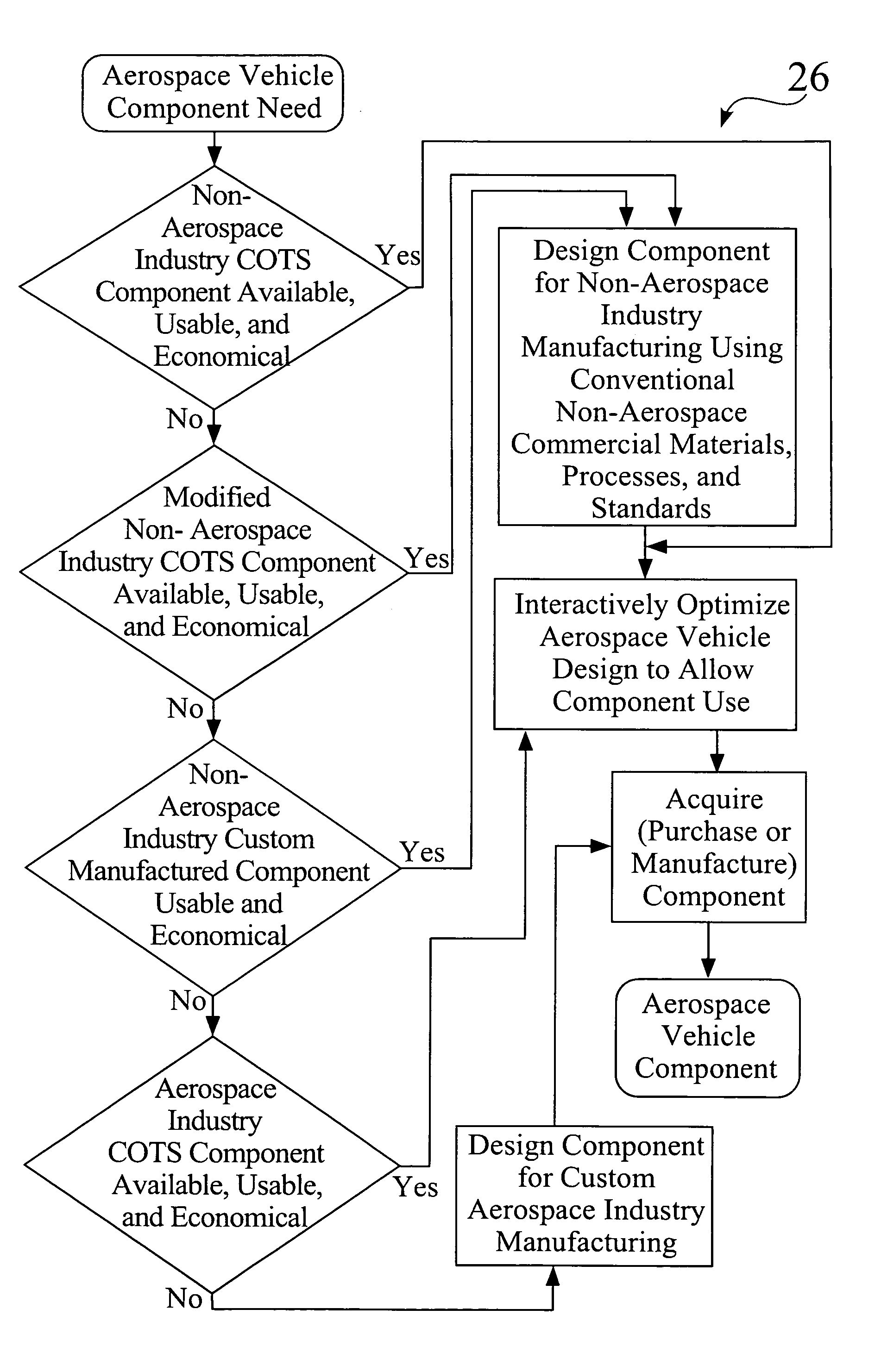

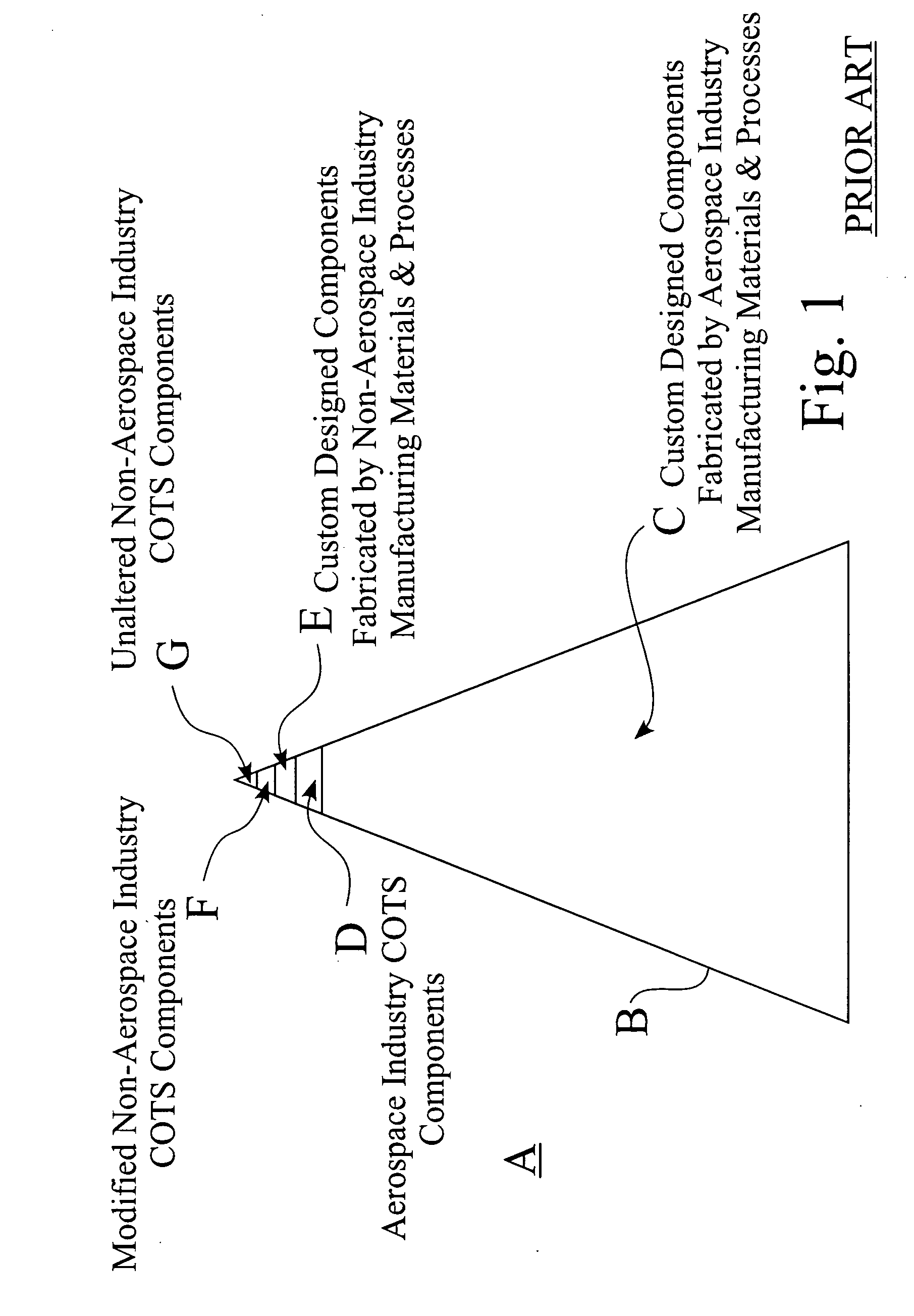

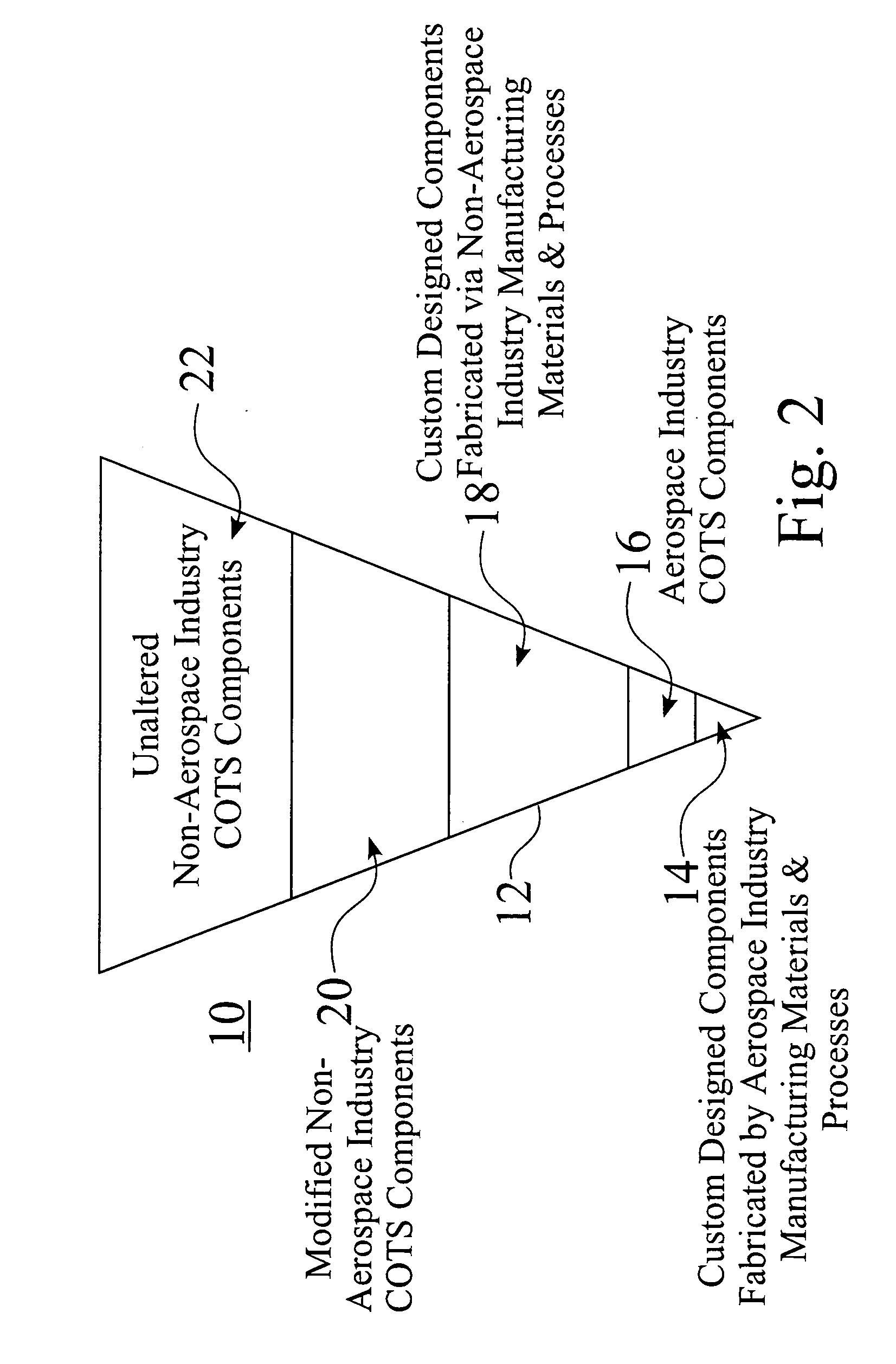

Aerospace manufacturing system

InactiveUS20100019084A1Reduce manufacturing costMaximize useLaunch systemsInstrumentsAviationAerospace manufacturing

An Aerospace Manufacturing System is disclosed, which comprises methods and apparatus for reducing the manufacturing costs in an aerospace product. In one embodiment, this method is accomplished by designing the aerospace product to use non-aerospace industry components and by maximizing the use of said plurality of readily commercially available, non-aerospace industry components. These commercially available, non-aerospace components are sometimes referred to by the term “commercial off the shelf” or “COTS” products.

Owner:KT ENG

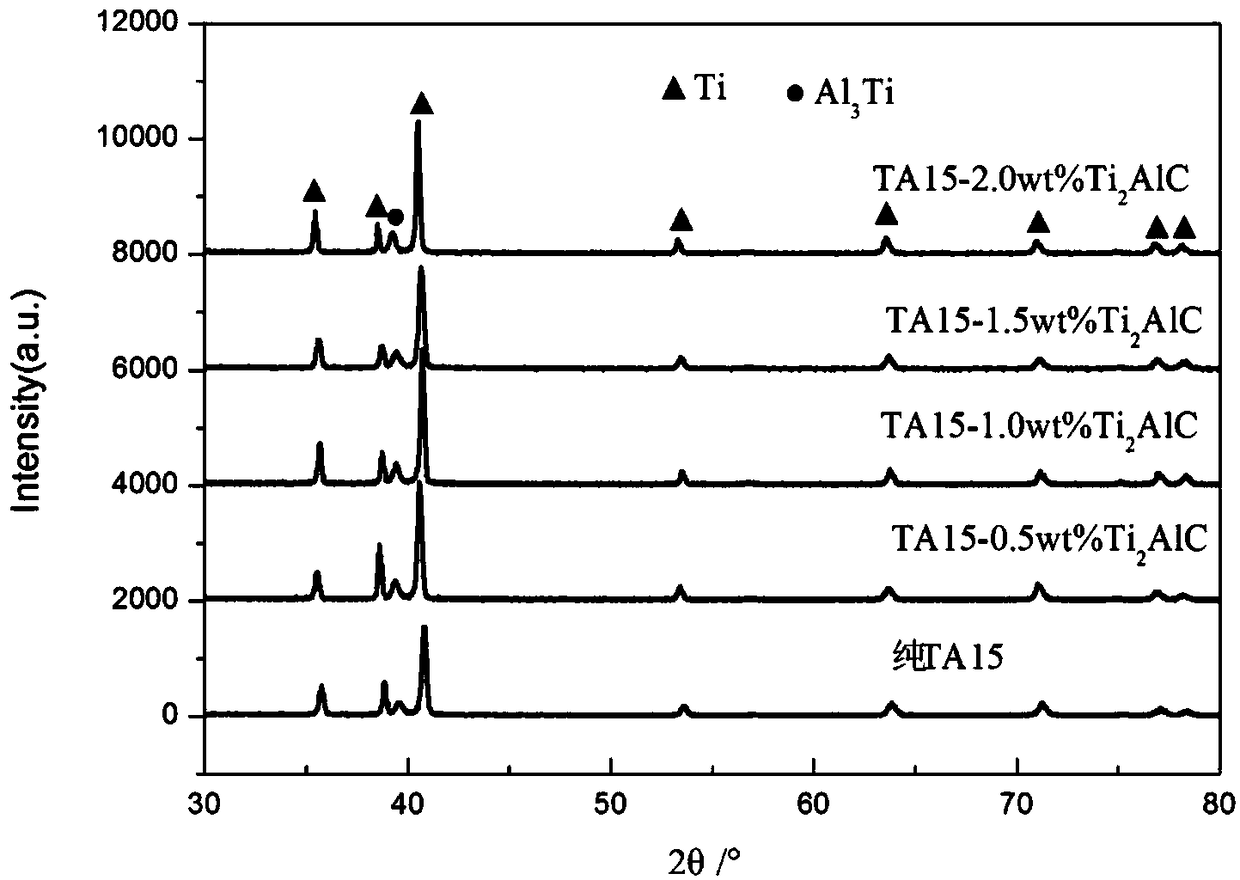

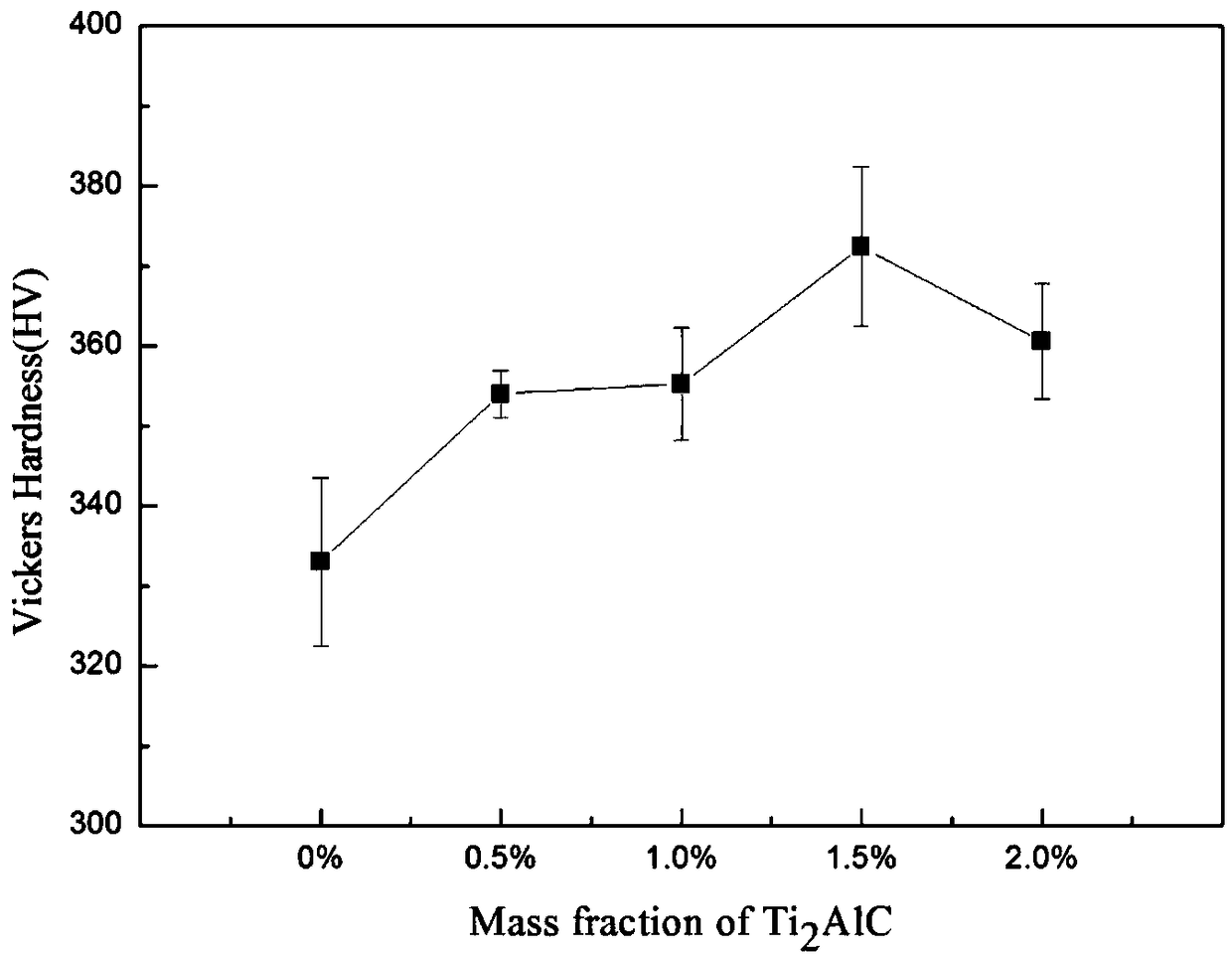

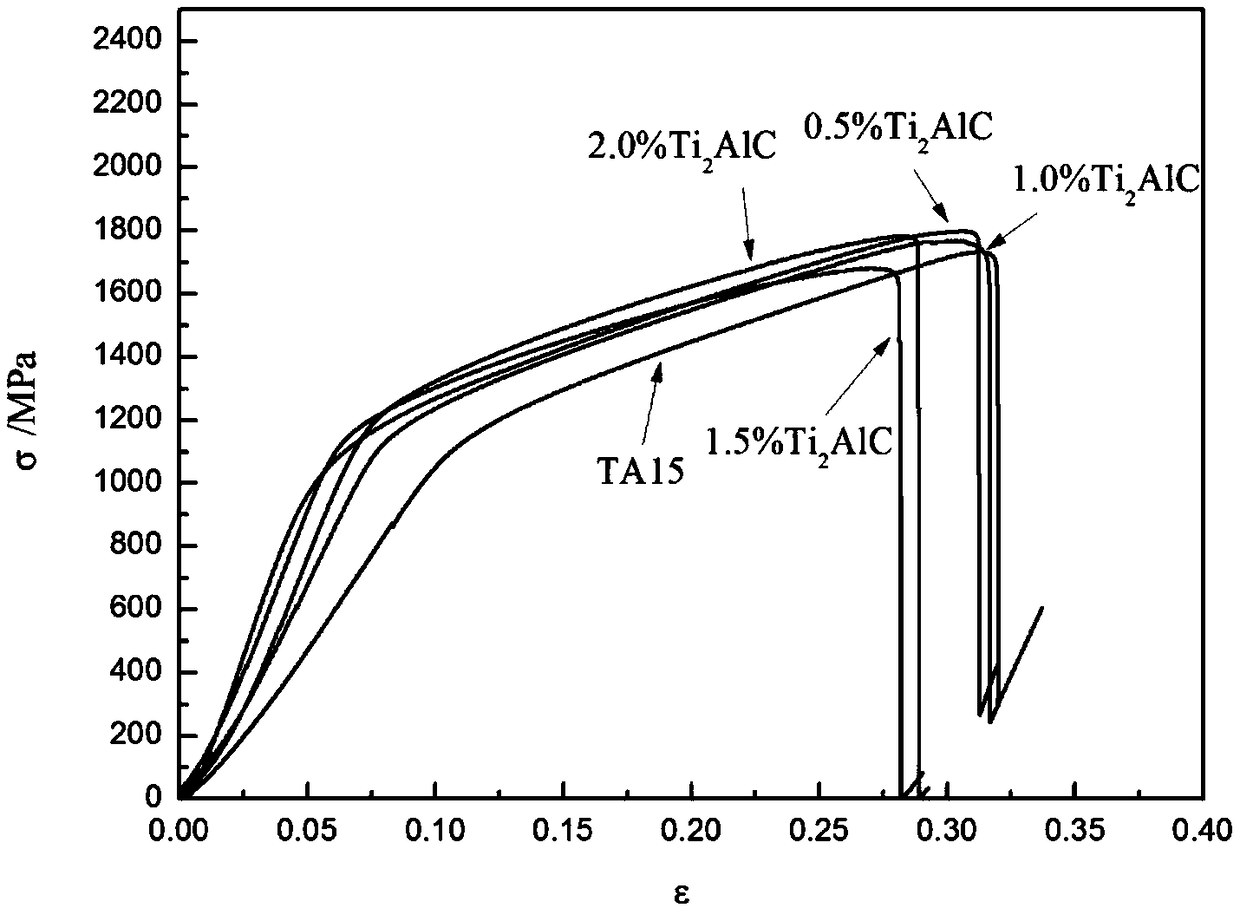

Ti2AlC reinforced titanium matrix composite material and preparation method and application thereof

The invention discloses a Ti2AlC reinforced titanium matrix composite material and a preparation method thereof. The composite material mainly takes a titanium alloy as a matrix and Ti2AlC as a reinforcing phase, and a block composite material is obtained through a powder metallurgy process. Ti2AlC, as one of the representatives of MAX phase ceramic materials, has a ternary layered structure and integrates the advantages of the ceramic materials and metal materials, the density is low, the modulus and toughness are high, the electrical and thermal conductivity is good, thermal shock resistanceis achieved, the friction coefficient is low, and self-lubrication is realized; and the interface bonding with the titanium matrix is good, the hardness, strength, elastic modulus and wear resistanceof the titanium alloy can be significantly improved, and higher shaping is maintained. The Ti2AlC reinforced titanium matrix composite material can be applied to automobile manufacturing and aerospace manufacturing industries.

Owner:SOUTHEAST UNIV

Composite material forming mould

InactiveCN105252790AGuaranteed positioning accuracyGuaranteed Surface AccuracyAerospace manufacturingSoluble polymer

The invention belongs to the technical field of aerospace manufacturing and particularly relates to a composite material forming mould used for forming of composite material parts of a unilateral closed angle and closed edge strip structure. Existing composite material forming moulds comprise metal moulds, composite material moulds, rubber moulds, foam moulds, gypsum moulds, soluble polymer moulds and the like. Traditional composite material parts of a special-shaped structure can be manufactured in the mode that parts are formed through rubber contraction moulds, foam moulds, gypsum moulds and other moulds and then moulds are destroyed, but the moulds are only suitable for one-time or several-time forming, batch production is not facilitated, and the surface precision, quality and the like of the composite material parts manufactured through the moulds are inferior to those of the metal mould on the whole. The composite material forming mould used for forming of the composite material parts of the unilateral closed angle and closed edge strip structure is reasonable in design and easy to manufacture, and forming and mould releasing of the composite material parts of the unilateral closed angle structure are achieved.

Owner:AVIC BASIC TECH RES INST

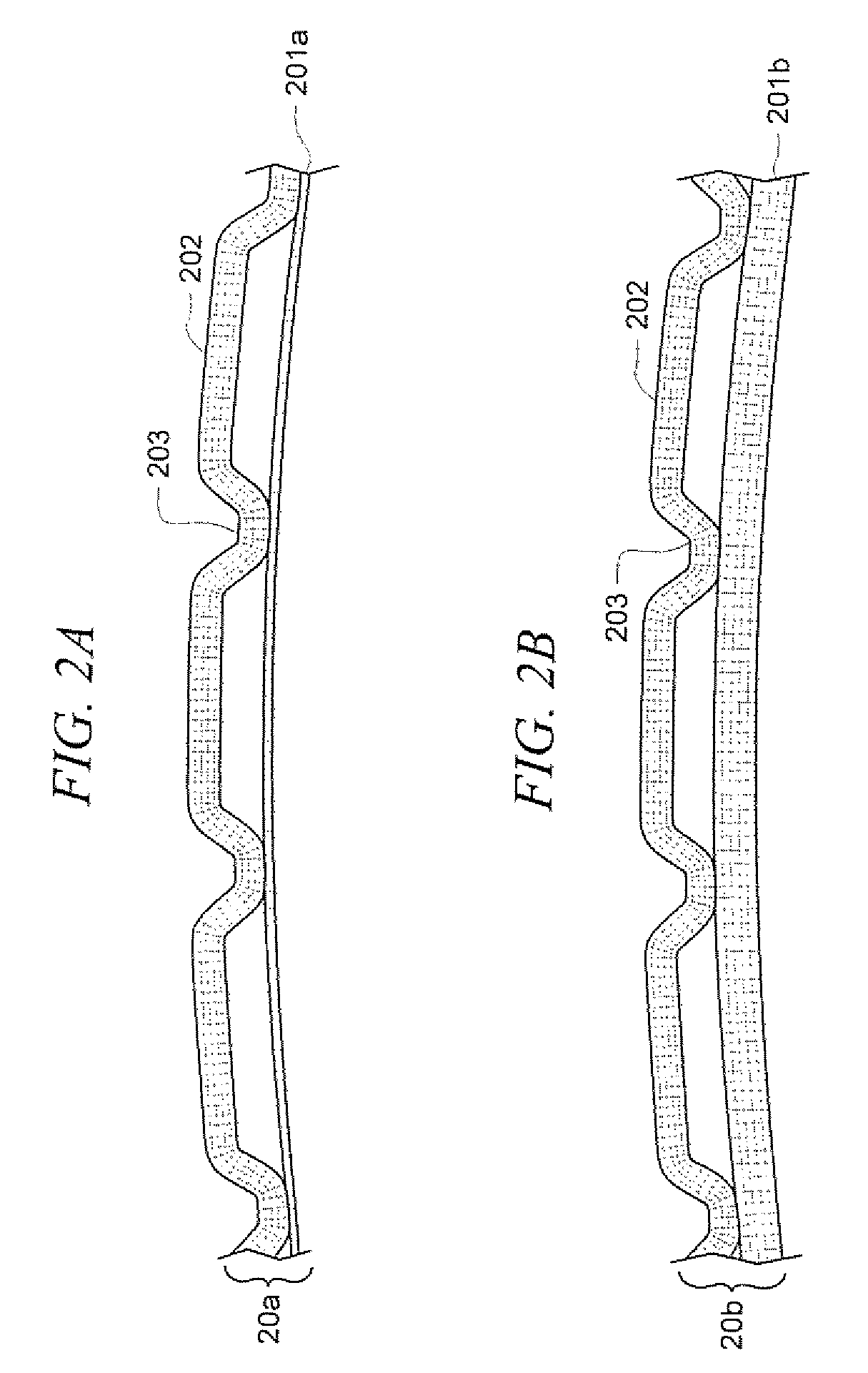

Coefficient of thermal expansion control structure

ActiveUS20090035406A1Low thermal expansionConstrain diametric growthTailstocks/centresInduction heatingAviationEngineering

The present invention is directed to the incorporation of a substructure into tooling for constructing composite structures in order to control thermal expansion of the tooling during aerospace manufacturing processes. Substructure, such as headers and / or gussets is added to the tooling to constrain the growth of the laminate expansion and / or control the diametric growth of the tool during the curing cycle. The thickness of the face-sheet of the tooling also may be reduced in order to further reduce the effective coefficient of thermal expansion (CTE) of the tooling.

Owner:THE BOEING CO

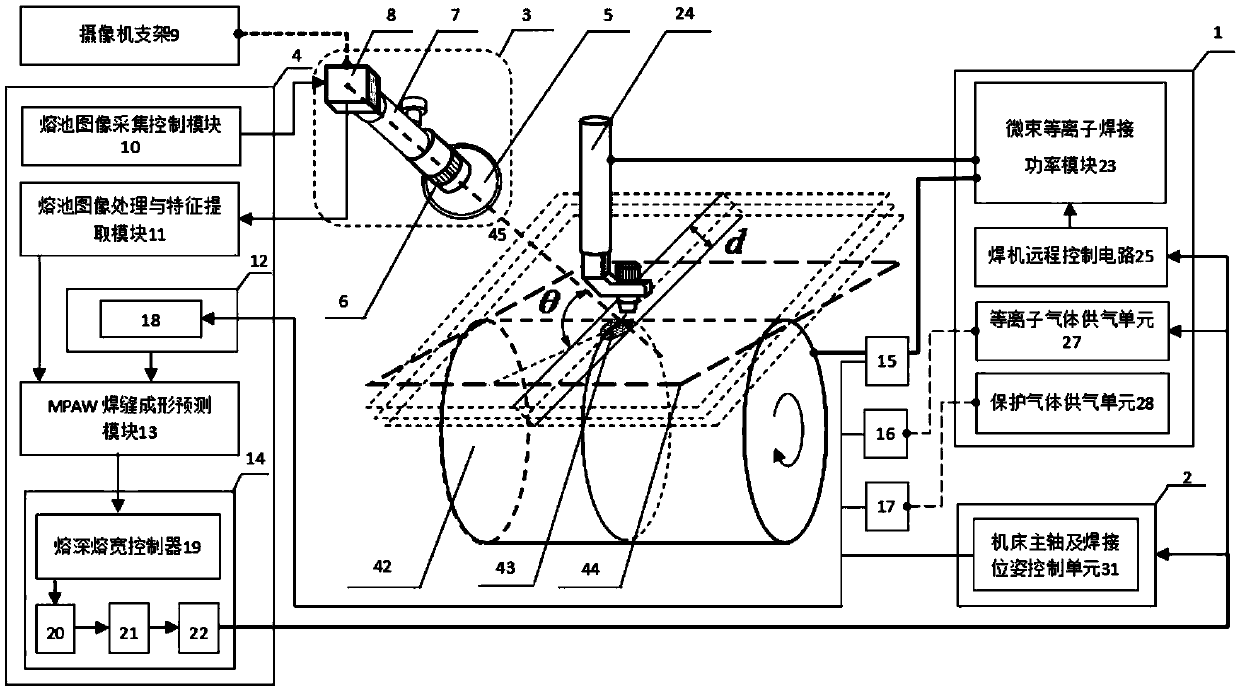

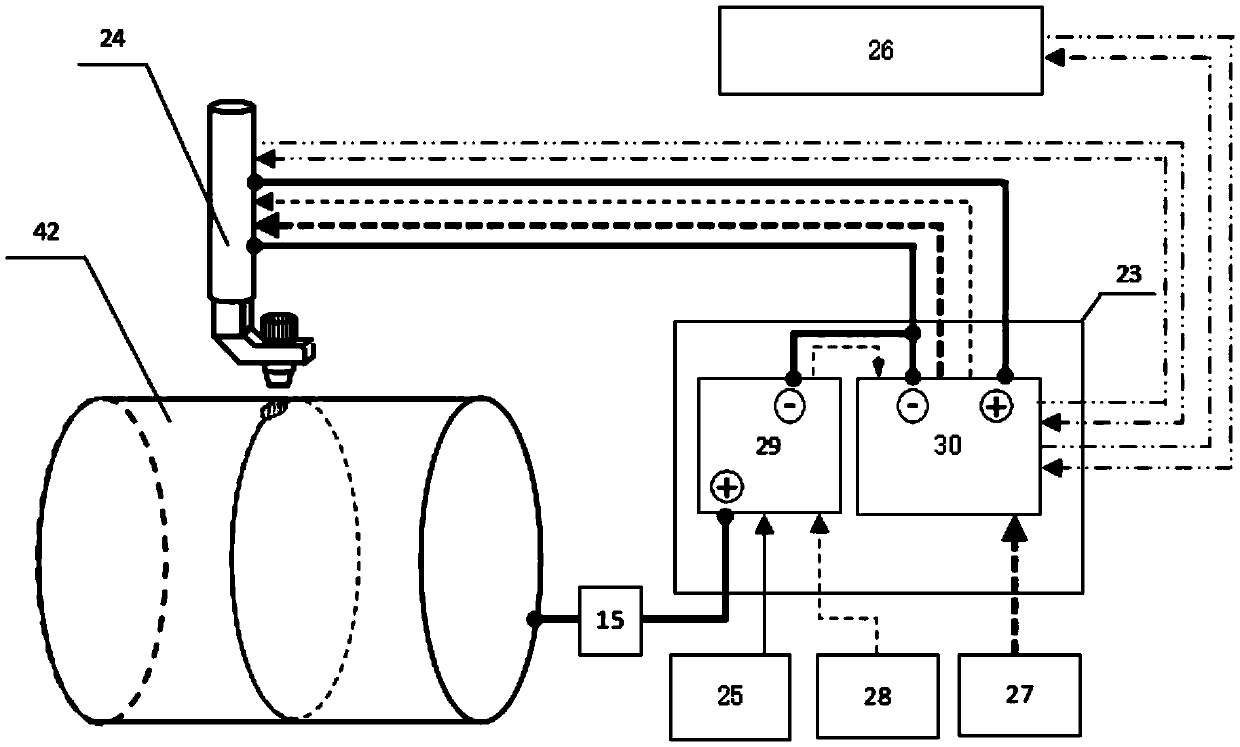

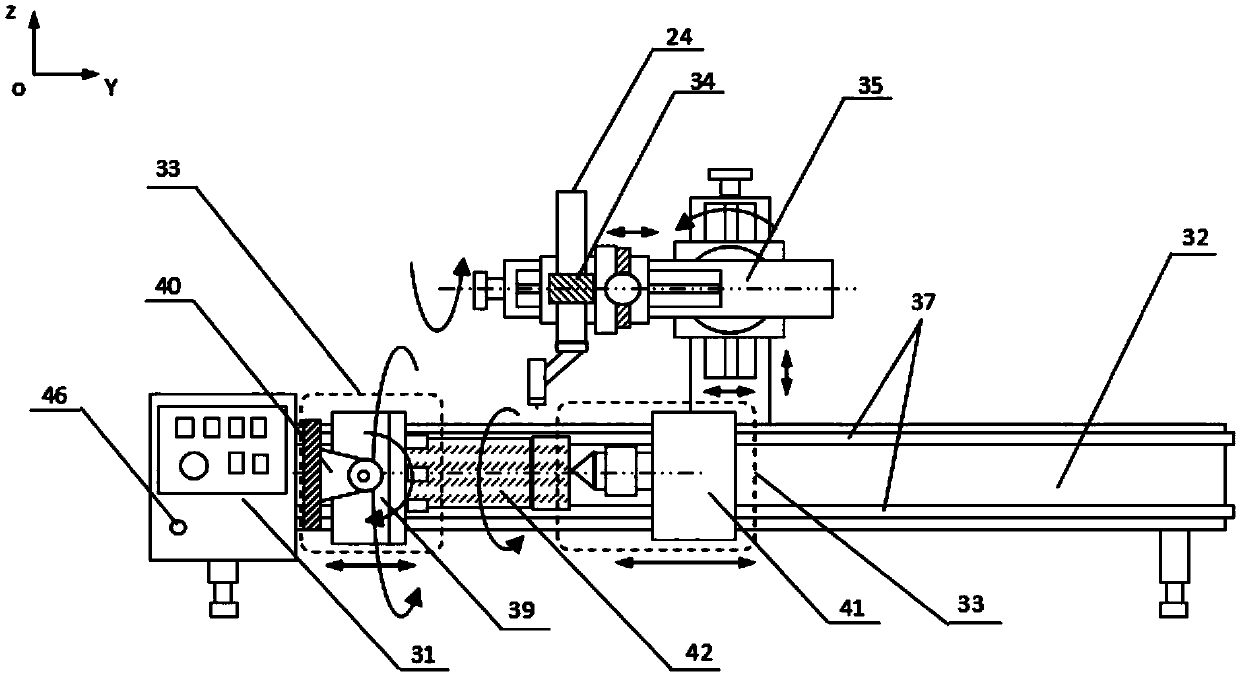

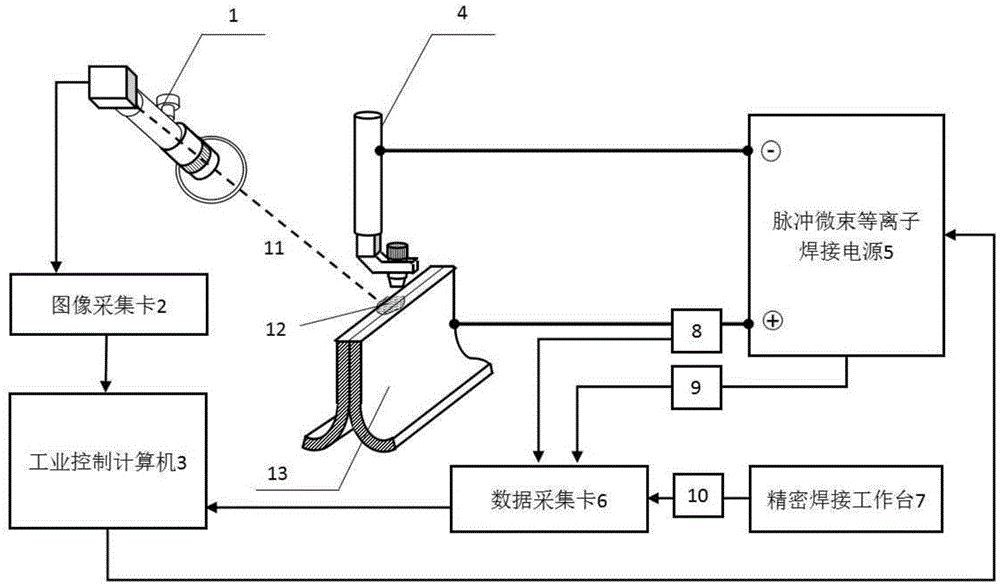

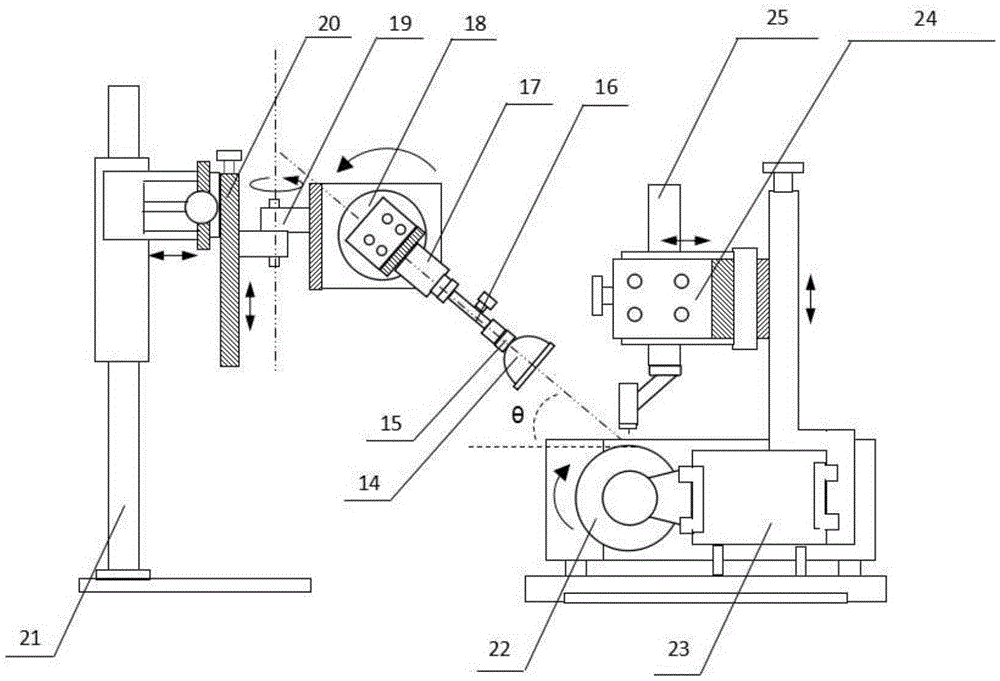

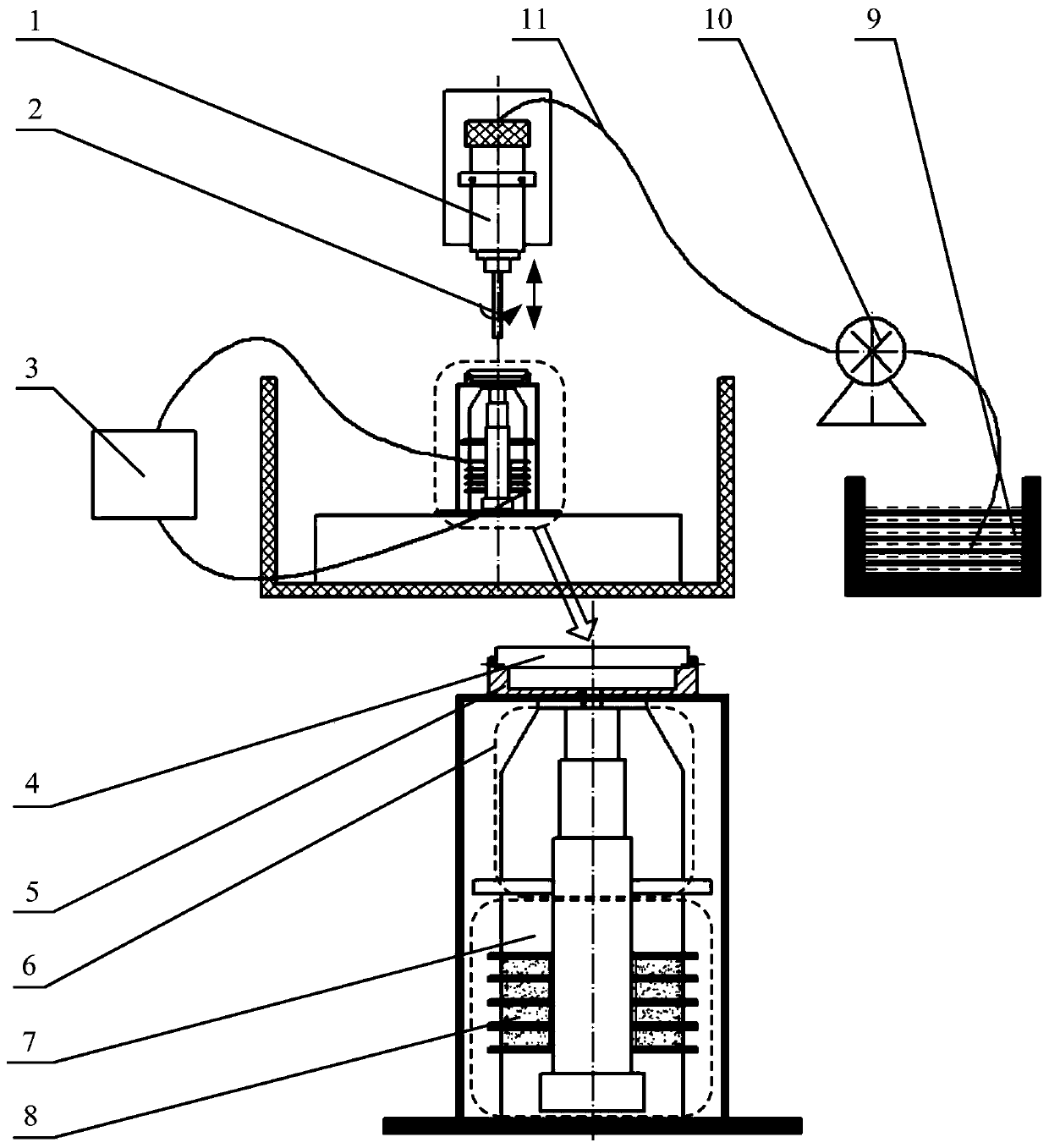

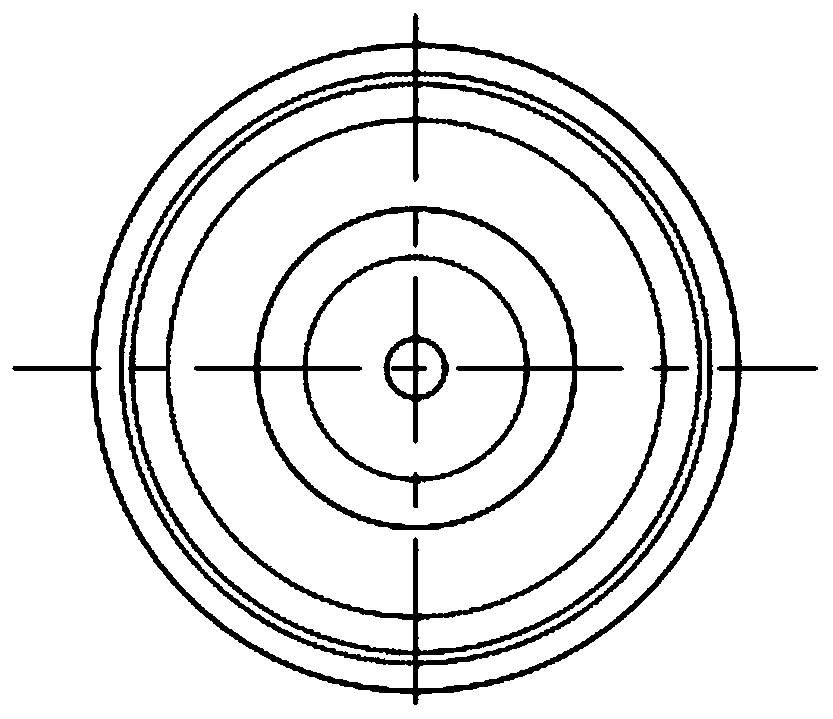

Control system for micro-beam plasma welding formation of thin-wall slit circular longitudinal seam

ActiveCN105499772AAchieve clear imagingImprove quality reliabilityPlasma welding apparatusEngineeringFeature parameter

The invention provides a control system for micro-beam plasma welding formation of a thin-wall slit circular longitudinal seam. The control system comprises a micro-beam plasma welding system, a precision welding workbench, a monocular coaxial telecentric visual sensing system and an MPAW (micro plasma arc welding) formation real-time control unit; the monocular coaxial telecentric visual sensing system is used to acquire a weld pool front transient image for thin-wall slit circular longitudinal seam micro-beam plasma welding, the MPAW formation real-time control unit is used to perform multi-electricity parameter synchronous acquisition of a welding process and online real-time prediction of seam formation feature parameters, and the micro-beam plasma welding system and the precision welding workbench perform real-time adjustment of welding process parameters according to a control command transmitted by the MPAW formation real-time control unit. The system enables an improvement in the quality reliability of welded products and success rate of single welding, is applicable to the micro-beam plasma welding process of thin-wall metal precision members in the fields such as aerospace manufacturing and is particularly applicable to precision welding of elastic elements such as ultrathin-wall membrane boxes and bellows.

Owner:TSINGHUA UNIV

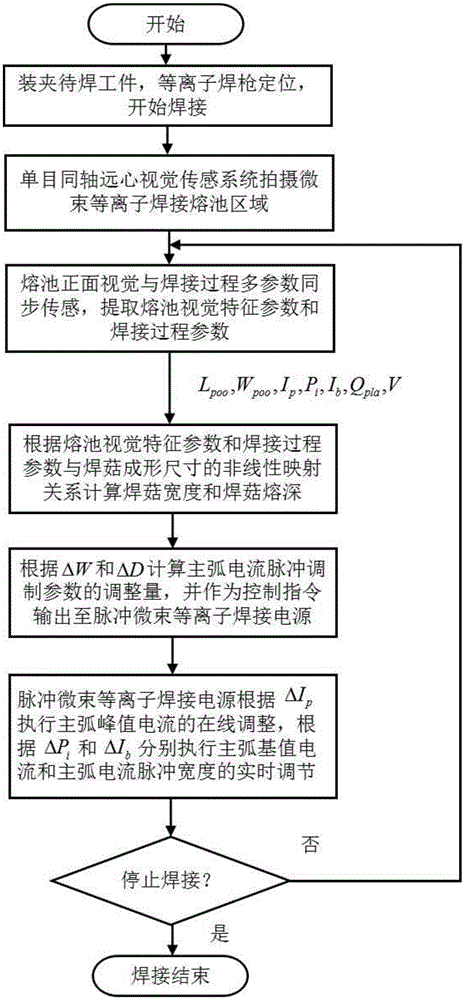

Edge micro-plasma arc welding forming control method based on telecentric vision sensing

ActiveCN105478975AAchieve clear imagingImprove quality reliabilityPlasma welding apparatusEngineeringVisual perception

The invention provides an edge micro-plasma arc welding forming control method based on telecentric vision sensing and belongs to the technical field of welding quality control. Aiming to solve the problems of unstable welding process and non-uniform weld forming caused by energy parameter fluctuation, heat dissipation condition change and the like in a thin-walled edge joint pulsed micro-plasma arc welding process, the method adopts a monocular coaxial telecentric vision sensing system for acquisition of sharp front transient images of a molten pool, performs real-time adjustment on main arc current pulse modulation parameters on the bases of the front transient images of the molten pool and a mapping relation of multiple electric parameters and mushroom weld forming characteristic parameters in a welding process, and realizes accurate control of the edge micro-plasma arc welding mushroom weld forming. The edge micro-plasma arc welding forming control method can improve the quality reliability of welded products and increase the one-time welding qualification rate, can be applied to an edge micro-plasma arc welding process for thin-walled metal precision components in the fields of aerospace manufacture and the like and is particularly applicable to precision welding occasions for elastic components such as ultra-thin-walled capsules, bellows and the like.

Owner:TSINGHUA UNIV

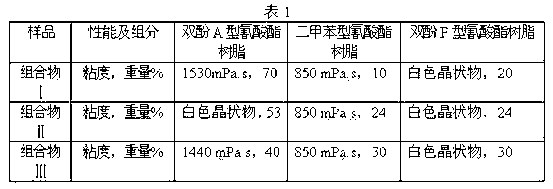

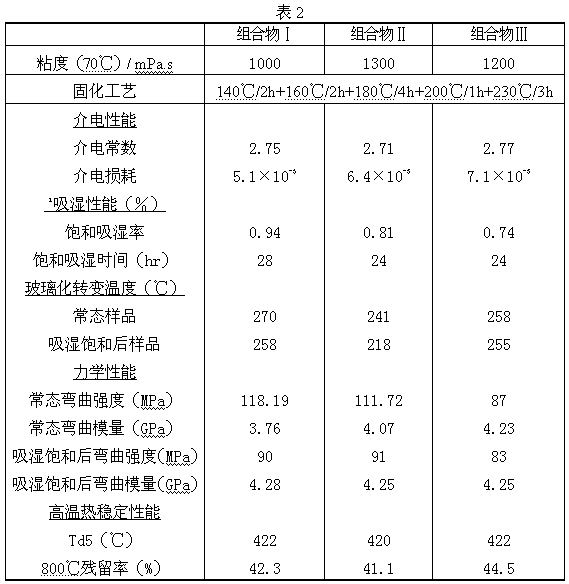

Cyanate ester based thermosetting resin and application thereof

The invention relates to a solidified composition based on bi- or polyfunctional group aromatic cyanate ester and application thereof. After solidification, a thermosetting plastic is provided by the composition of the aromatic cyanate ester provided by the invention, and comprises cyanate ester having a main chain including a biphenol A structure, an alkyl dimethylbenzene structure or a tetramethyl biphenol A structure and a prepolymer thereof. The thermosetting plastic has the advantages of excellent damp and hot resistance, low dielectric constant and dielectric loss, higher glass-transition temperature and mechanical property. The cyanate ester based thermosetting resin is particularly suitable for producing a printed circuit board, an electric insulator, a coating or a low dielectric wave-transparent material in aviation manufacturing industry.

Owner:EAST CHINA UNIV OF SCI & TECH

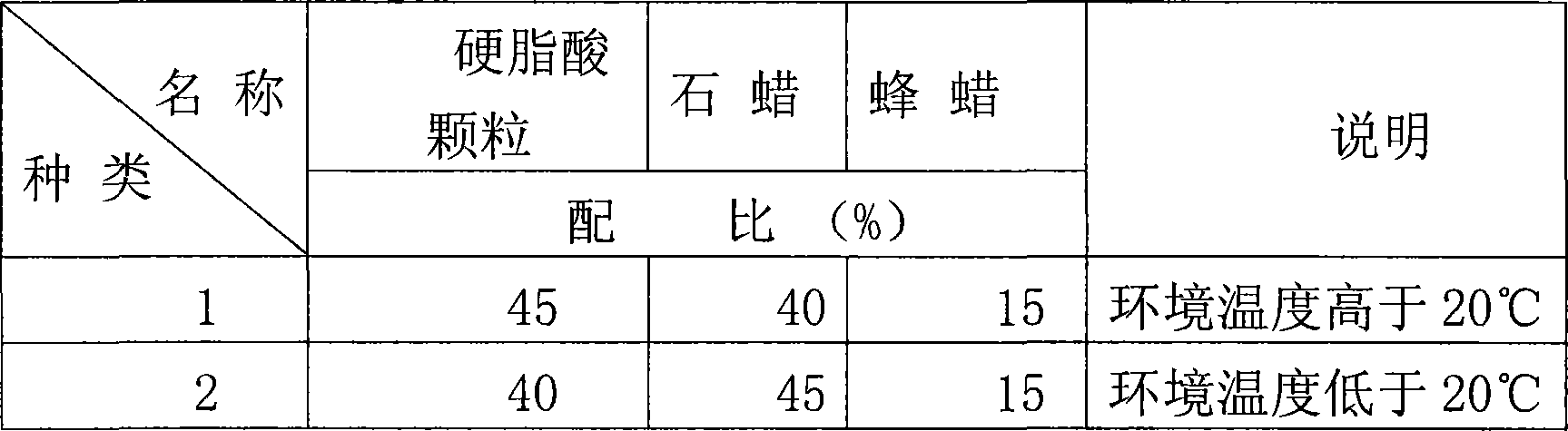

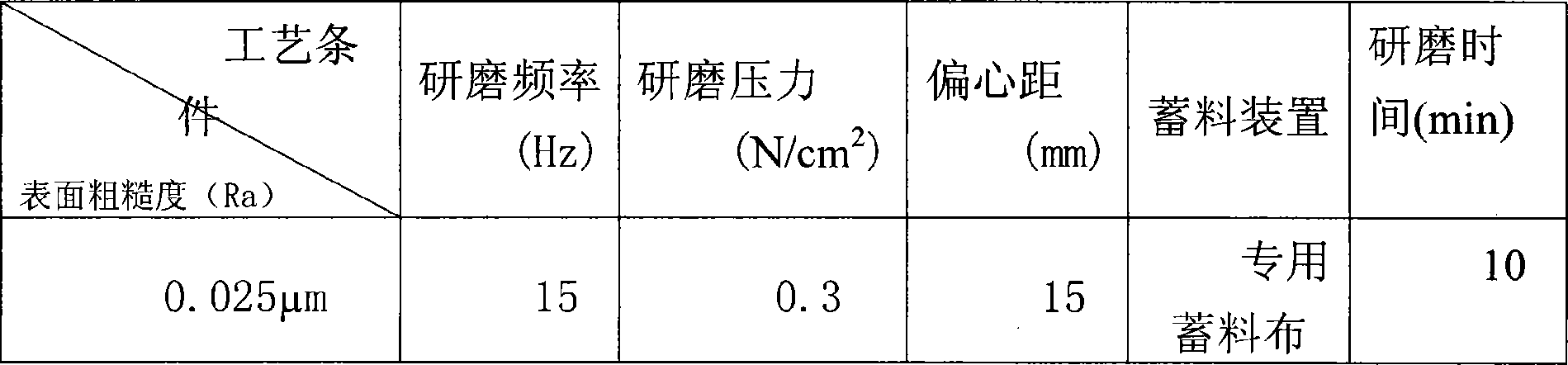

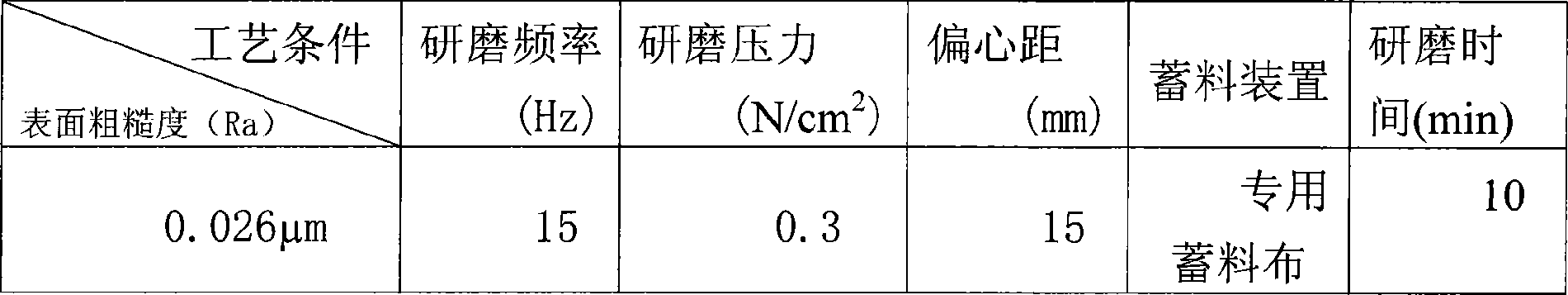

Metallic tantalum, special-purpose grinding fluid for alloy of the same and preparation method thereof

The invention discloses a grinding liquid of tantalum and its alloy and making method in the precise mechanical polishing domain, which comprises the following parts: 25% even composition of grinding material and composite grease, 25% vegetable oil and 50% kerosene, wherein the bulk rate of grinding material and composite grease is 1: 1; the composite grease is composed of 45% stearic particle, 40% paraffin and 15% beeswax when the environmental temperature is over 20 deg. c or 40% stearic particle, 45% paraffin and 15% beeswax when the environmental temperature is below 20 deg. c. The preparing method of grinding liquid comprises the following steps: heating the allocated composite grease to fusion; filtering; adding the grinding material, vegetable oil and kerosene sequently and proportionally.

Owner:BEIJING UNIV OF TECH

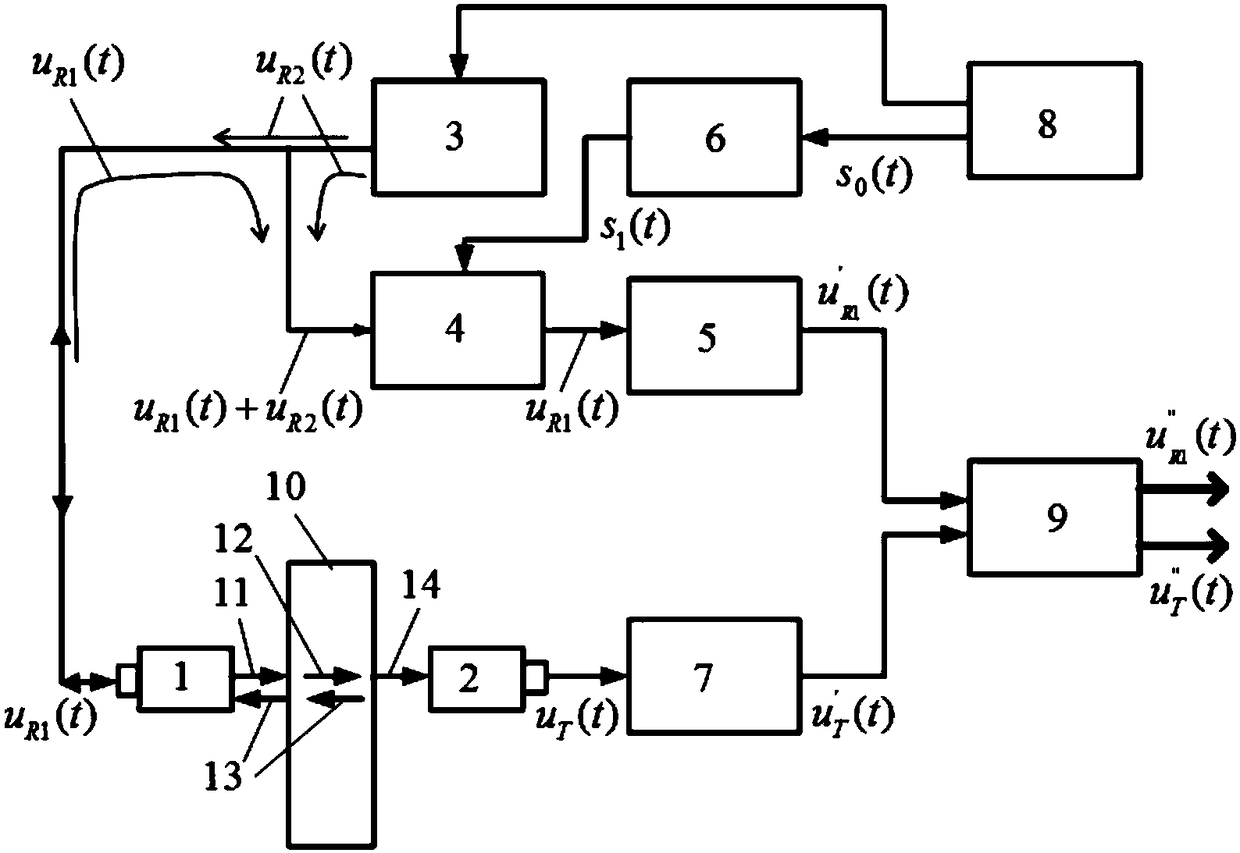

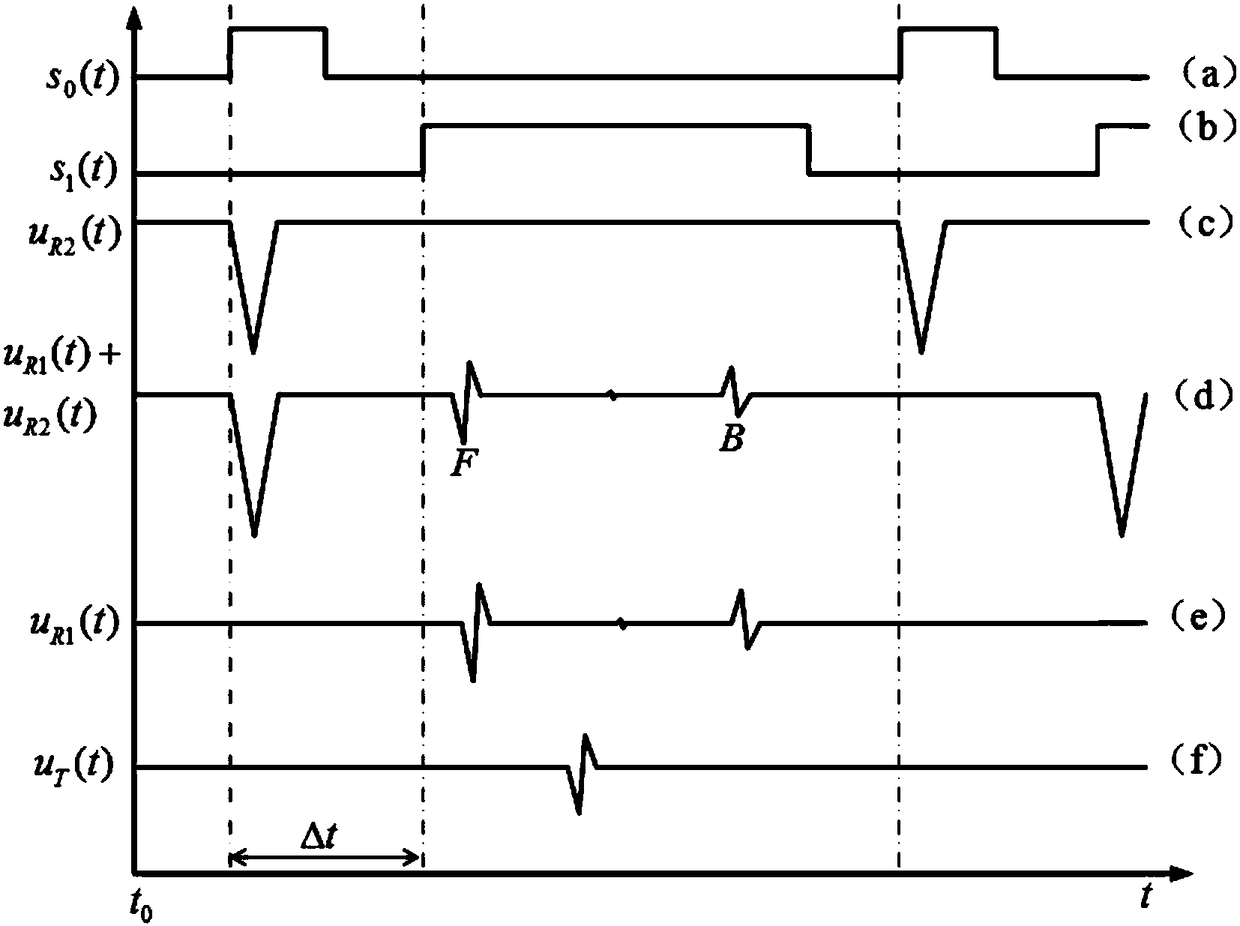

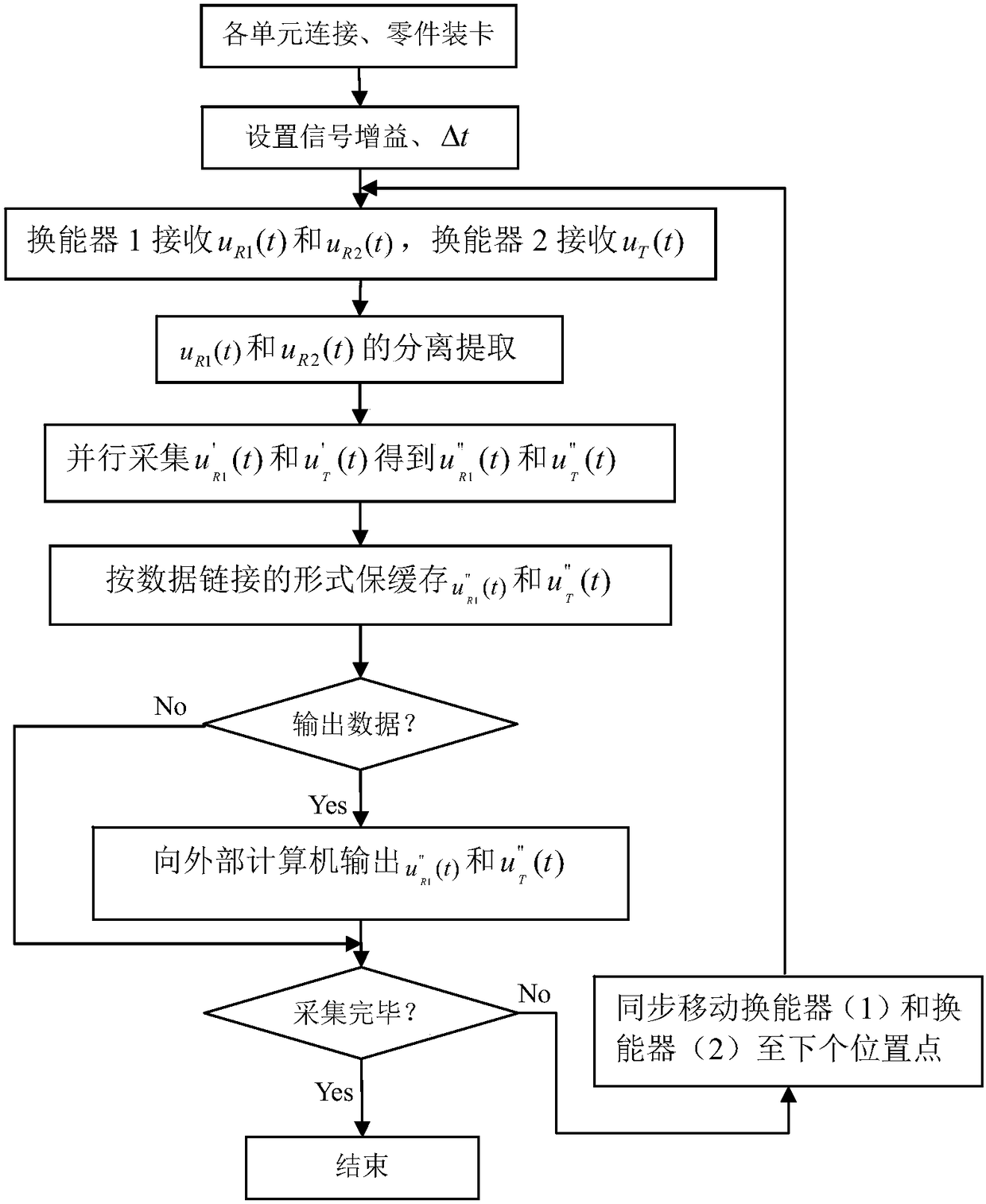

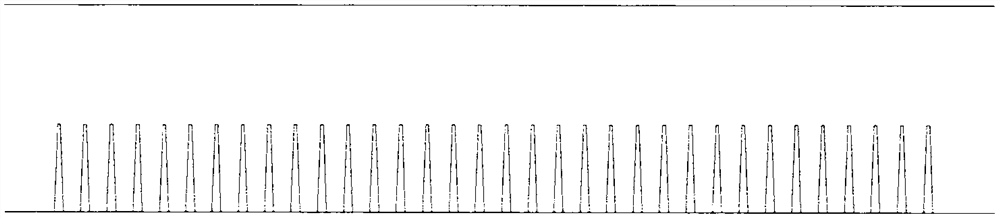

Signal acquiring method for ultrasonic reflecting transmitting parallel detection of sandwich structure

ActiveCN108318582AImprove reliabilityImprove accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationSonificationTime delays

The invention belongs to the technical fields of aerospace manufacturing, traffic, building, electronic engineering and nondestructive detection, and relates to a signal acquiring method for ultrasonic reflecting transmitting parallel detection of a sandwich structure. The device for acquiring a detecting signal comprises a transmitting and receiving energy converter, a receiving energy converter,an ultrasonic emitting unit, a door selection unit, a reflecting signal handling unit, a time delay unit, a transmittance signal handling unit, a synchronizing unit and a data acquiring unit. According to the method, an ultrasonic signal in the single scanning process of the detected composite sandwich structure is preprocessed, collected and recorded, and the ultrasonic signal can be synchronously applicable to ultrasonic reflecting and transmittance scanning imaging; the detection costs a little time; the detection efficiency is high; the detection cost is obviously decreased; a high-pressure ultrasonic pulse exciting original signal is not directly loaded to the input stage in the preprocessing, so that a primary amplifier of a preprocessing device is prevented from blockage and damage, and as a result, the reliability and the accuracy of the detection result can be improved.

Owner:AVIC BASIC TECH RES INST

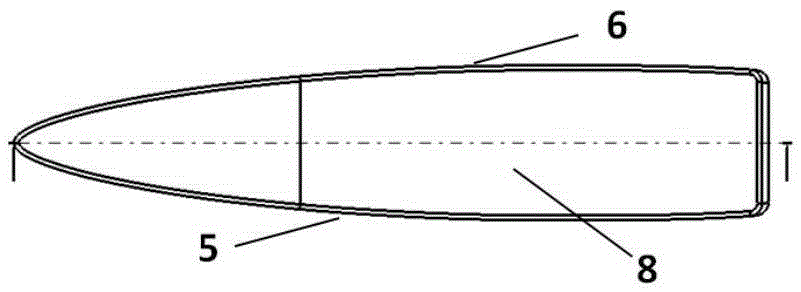

Large cast stainless steel wing cabin fusion cabin section machining method

ActiveCN112276490AImprove efficiencyImprove processing stabilityProduct inspectionMaterials preparation

The invention discloses a large cast stainless steel wing cabin fusion cabin section machining method, and belongs to the field of aerospace manufacturing. The machining method solves the problems that according to an existing wing cabin fusion cabin section machining method, clamping and alignment are difficult, the efficiency during machining is low, machining is prone to deformation, the production efficiency is low, and the machining precision consistency is difficult to guarantee. According to the process scheme of the machining method, the method comprises the steps of material preparation, three-dimensional scanning, scribing, benchmark rough machining, shape inner cavity rough machining, inspection, aging treatment, three-dimensional scanning, shape inner cavity semi-finish machining, inspection, aging treatment, inspection, shape finish machining, inner cavity finish machining, high-precision boring, fluorescence detection, finished product inspection and warehousing. According to the machining method, machining is carried out on a wing cabin fusion cabin section, the shape machining efficiency and machining stability of the wing cabin fusion cabin section are effectivelyimproved, and meanwhile the product quality is guaranteed.

Owner:航天科工哈尔滨风华有限公司

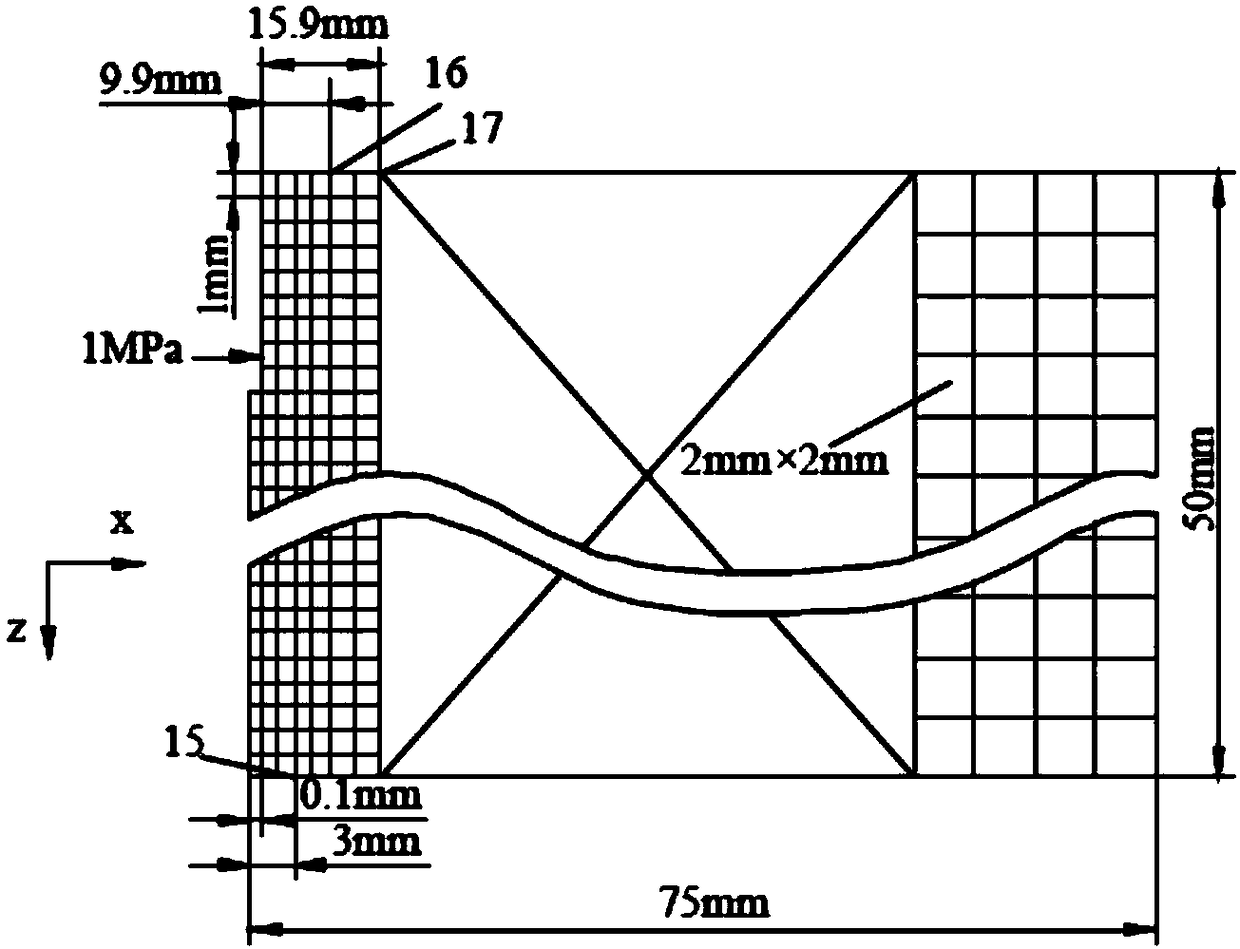

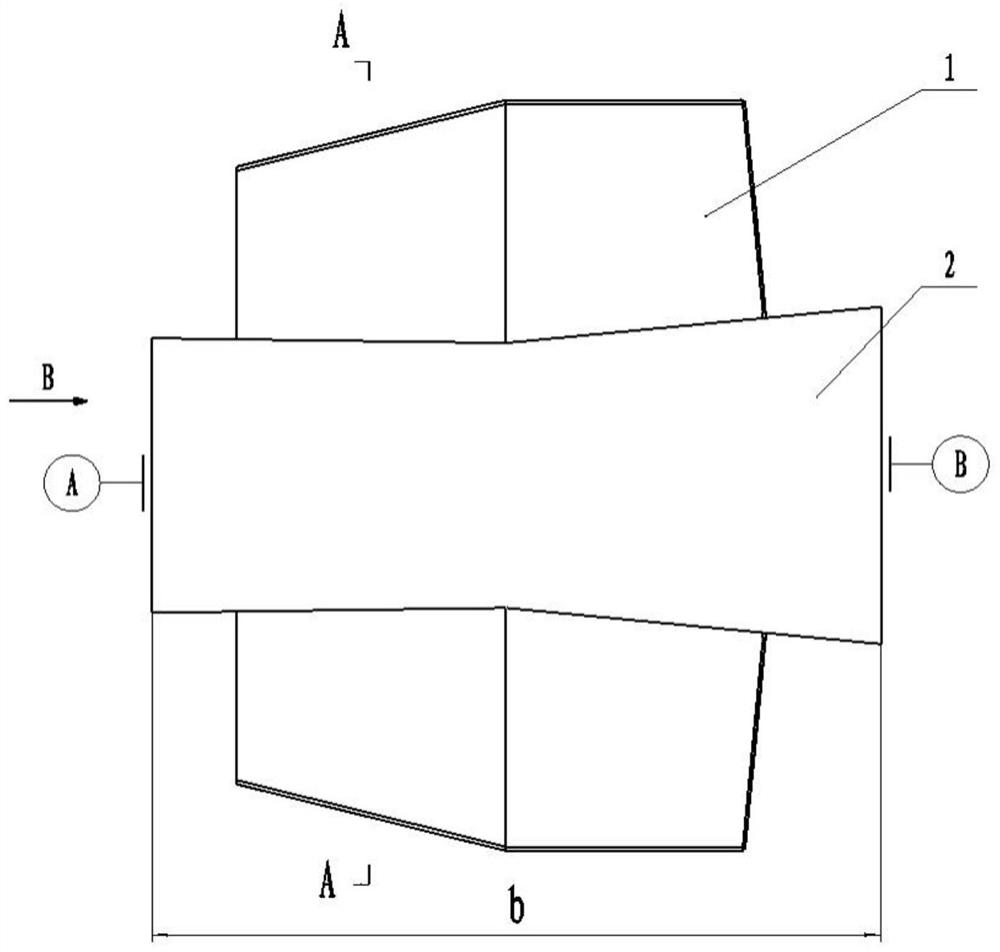

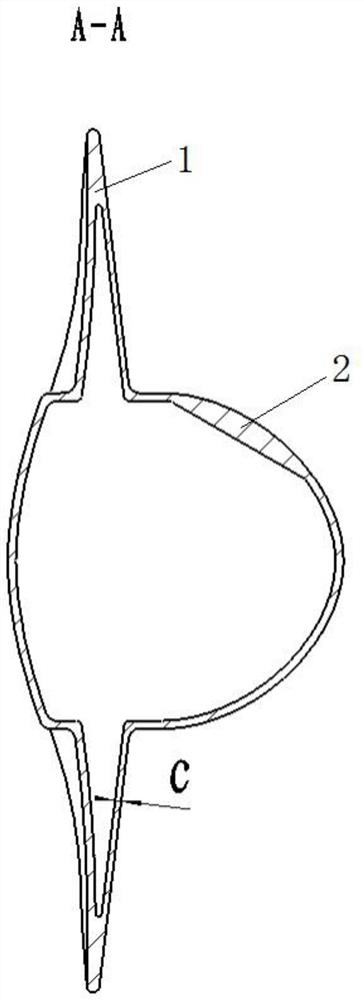

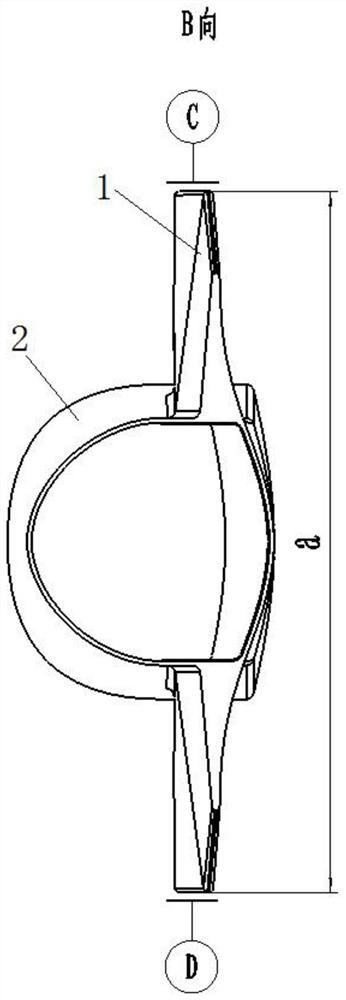

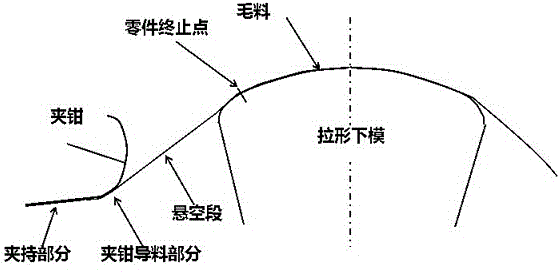

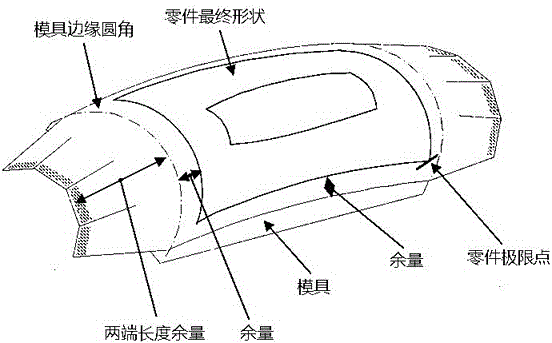

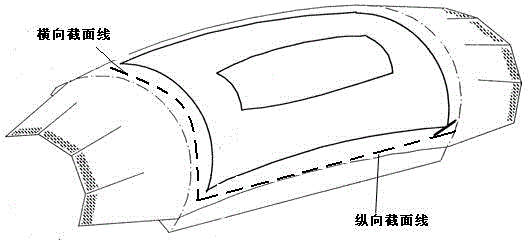

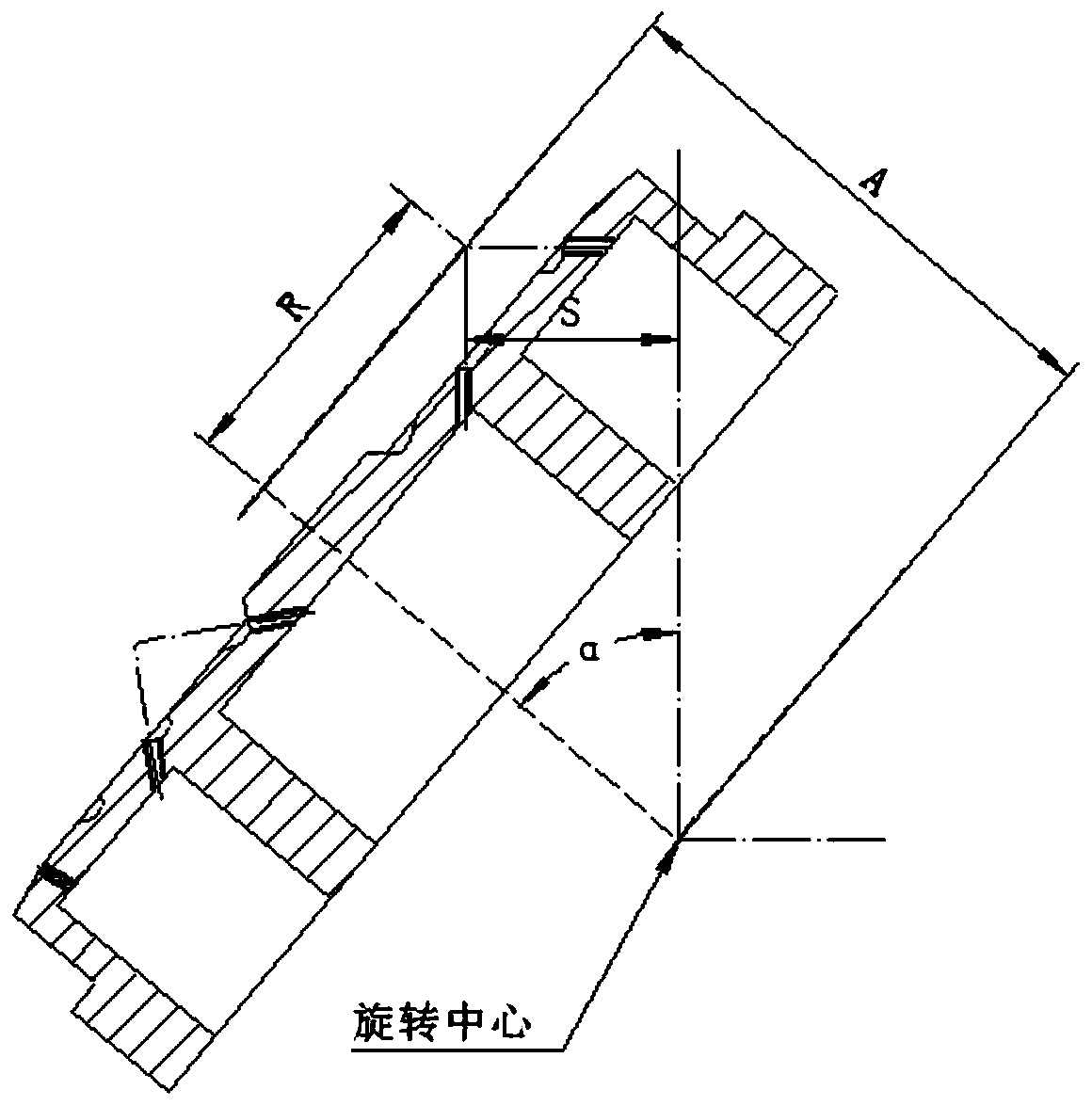

Skin part longitudinal stretching woolen size determination method

InactiveCN104588474AReduce wasteAvoid increasing the difficulty of longitudinal stretch formingSize determinationAerospace manufacturing

The invention relates to the field of aerospace manufacturing, in particular to a skin part longitudinal stretching woolen size determination method. The method comprises the steps that 1, the composition of stretching woolen is analyzed, in the skin longitudinal stretching process, the situation that the woolen wraps a mold is analyzed, the woolen is divided into a part zone, a mold allowance, a suspending section, a clamping section and a clamping guiding section according to the contact between the woolen and the mold and a clamp, and the size of the woolen should be obtained by overlaying the sections; 2, the part size range is obtained through the method for calculating the longitudinal and transverse part length; 3, the woolen size is calculated and is composed of the part unfolding length, the allowance, the suspending section and the length of the clamp. According to the skin part longitudinal stretching woolen size determination method, material waste can be reduced, the woolen size design better adapts to the stretching technological process, and the phenomenon that the longitudinal stretching difficulty is increased due to the poor woolen size is avoided.

Owner:JIANGXI HONGDU AVIATION IND GRP

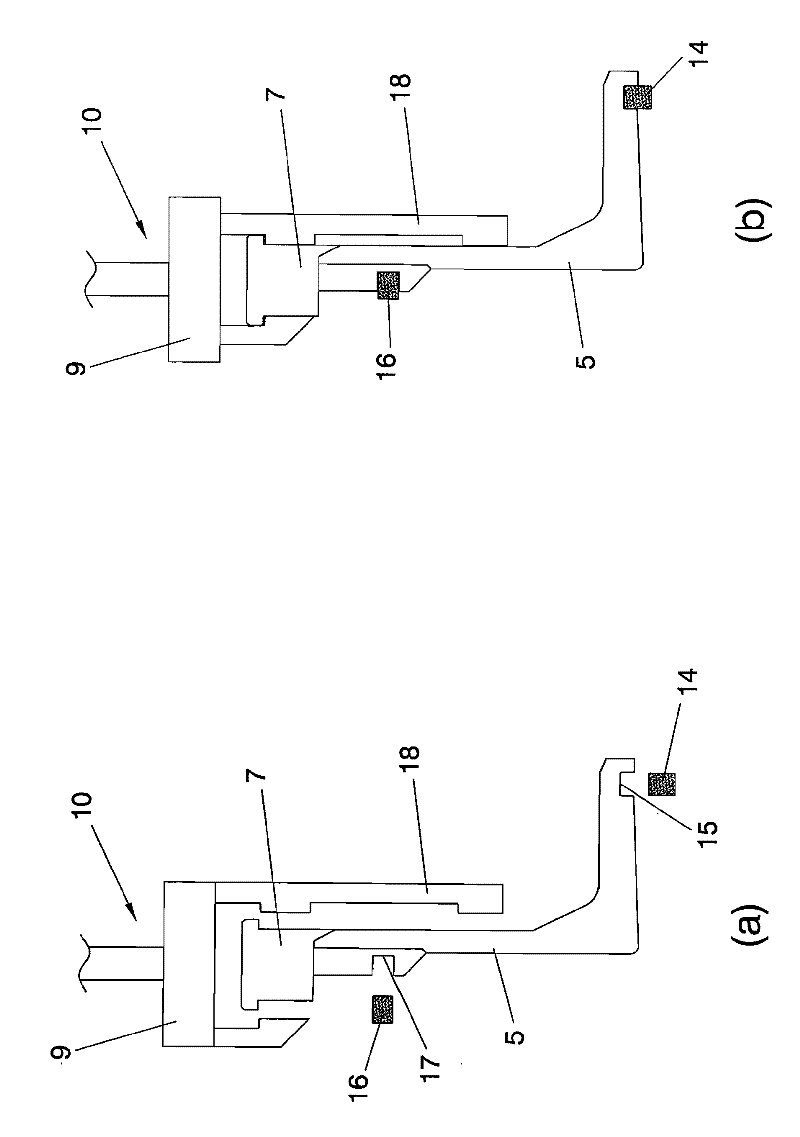

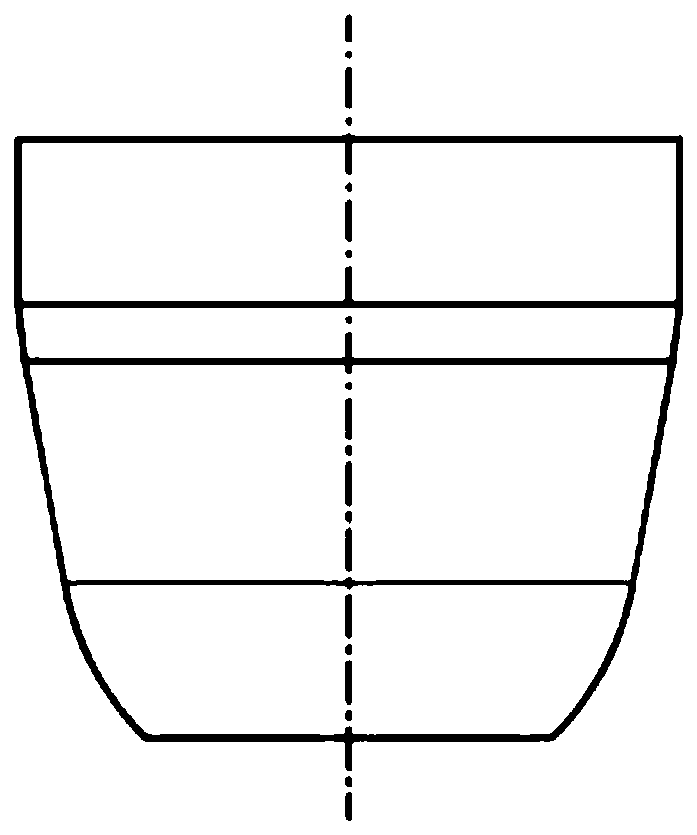

Drill positioning guider

InactiveCN104353872AGuaranteed verticalitySimple structureDrilling/boring measurement devicesMachine partsEngineering

The invention discloses a drill positioning guider, and belongs to the technical field of aerospace manufacturing. The drill positioning guider comprises a positioning block, a mounting seat and a guide block, wherein the positioning block takes the shape of an inverted frustum with a hole in the center; a small head end of the positioning block can be put into a prefabricated nail hole; the bottom surface of the small head end is a positioning surface; the positioning surface is perpendicular to the normal direction of the bottom surface of the prefabricated nail hole of a to-be-machined part; the shape of the positioning block is matched with the contour of the prefabricated nail hole; the hole is drilled in the center of the guide block; the central hole of the guide block is matched with a drill bit used for machining the drill hole; one end of the guide block is connected with a big head end of the positioning block, and the central hole is concentric; the component which is formed by connecting the guide block with the positioning block is named as a positioning guide body; the positioning guide body is fixedly arranged on a mounting seat; the axis of the positioning guide body is in the same direction as the normal direction of the positioning surface of the positioning block. According to the drill positioning guider, the machining precision and the working efficiency of the hole can be greatly improved, and the production cost is reduced; the drill positioning guider has a simple structure, is convenient to operate and can be widely popularized in production.

Owner:JIANGSU A STAR AVIATION IND

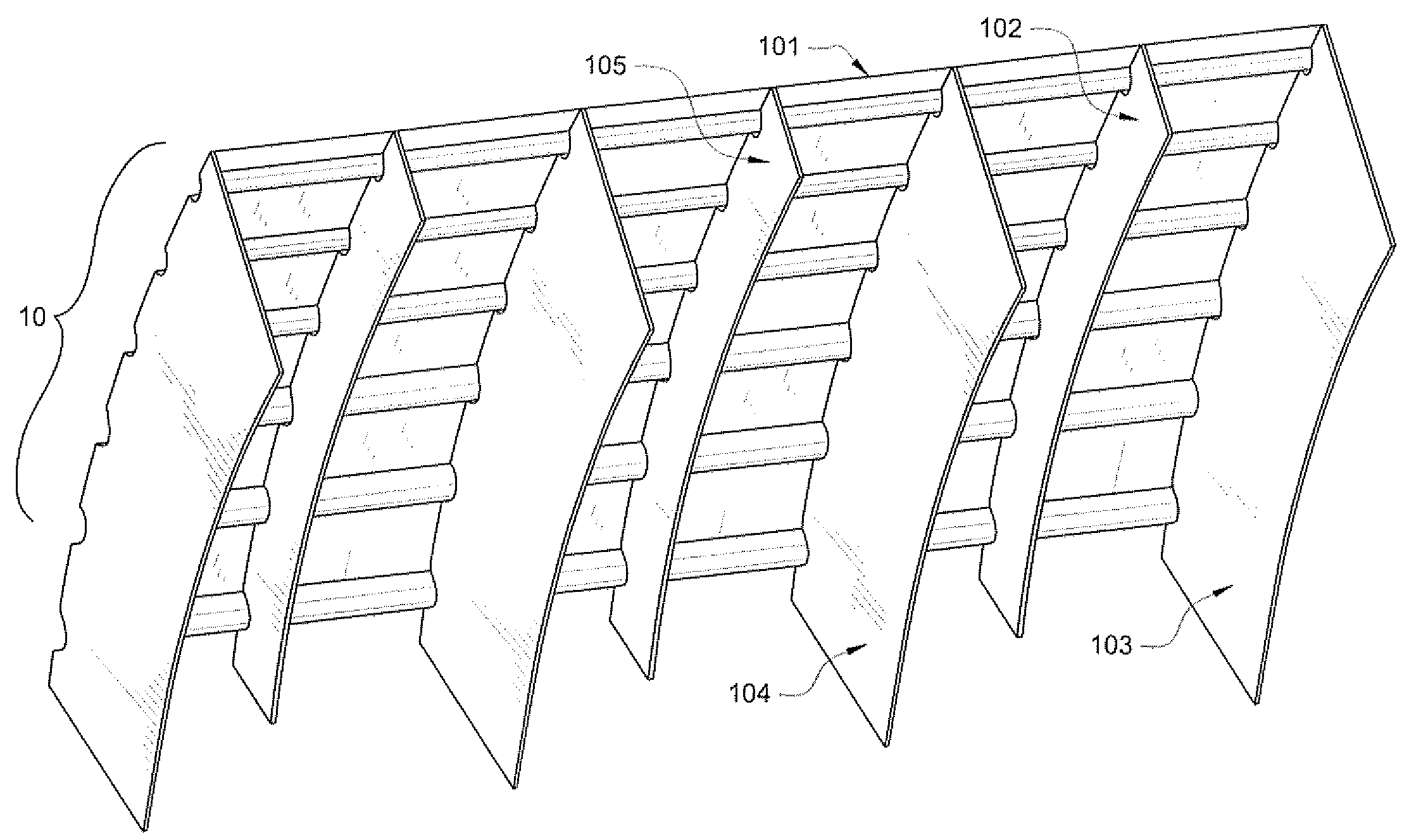

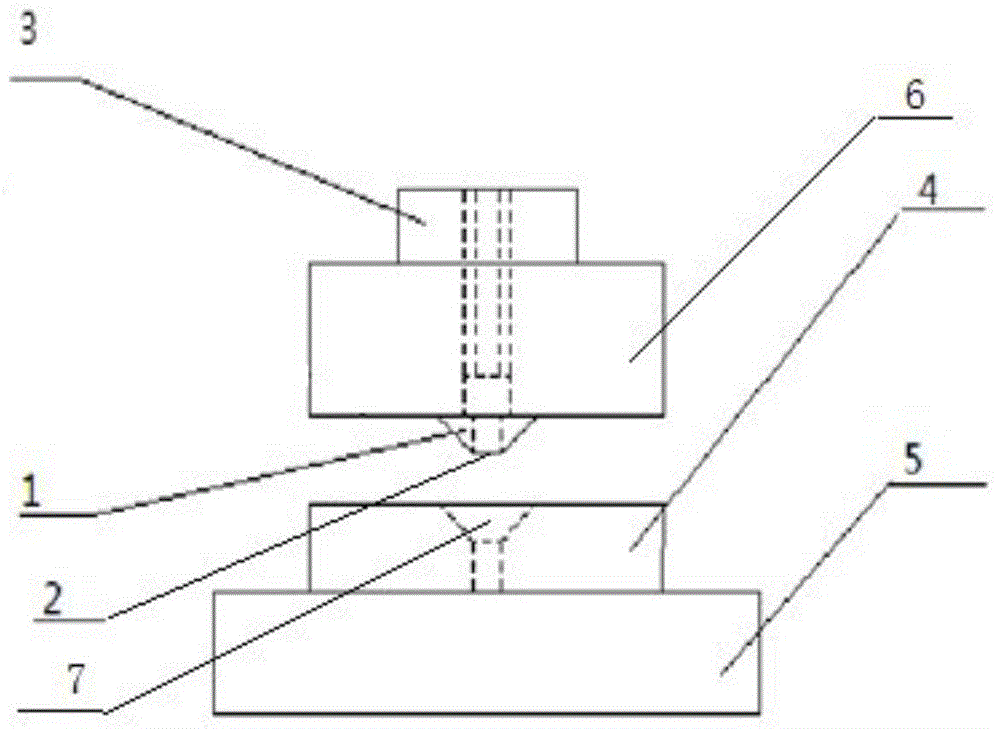

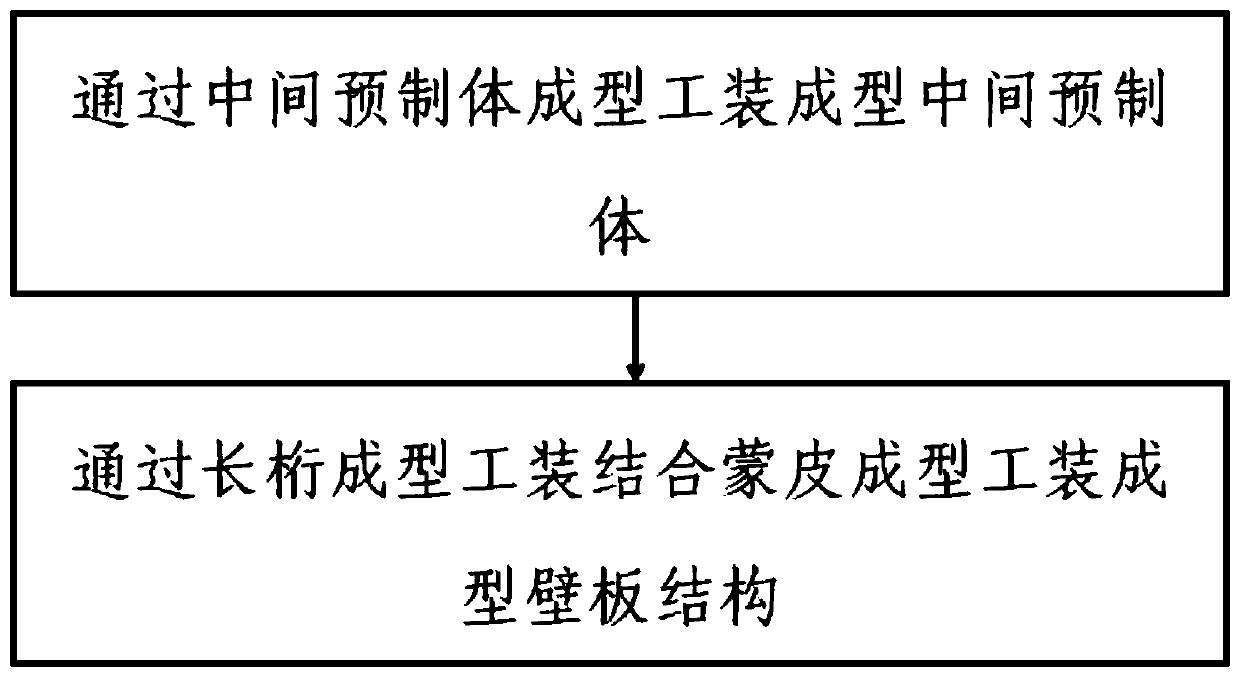

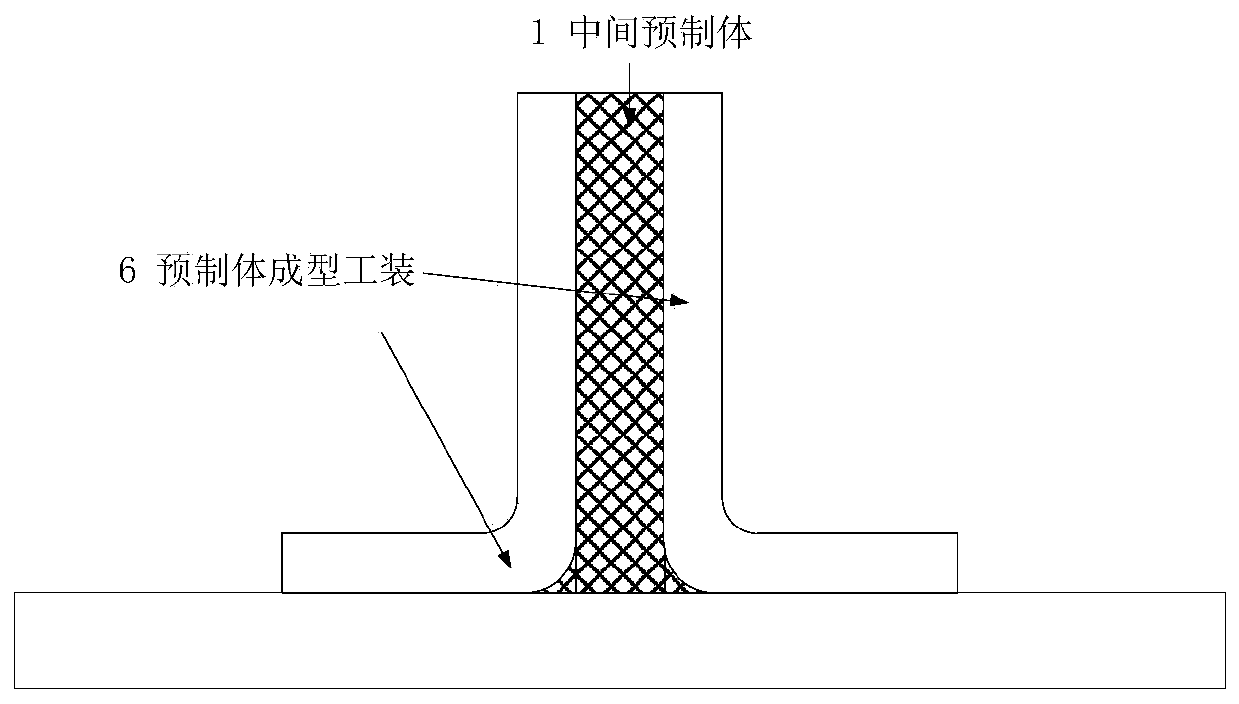

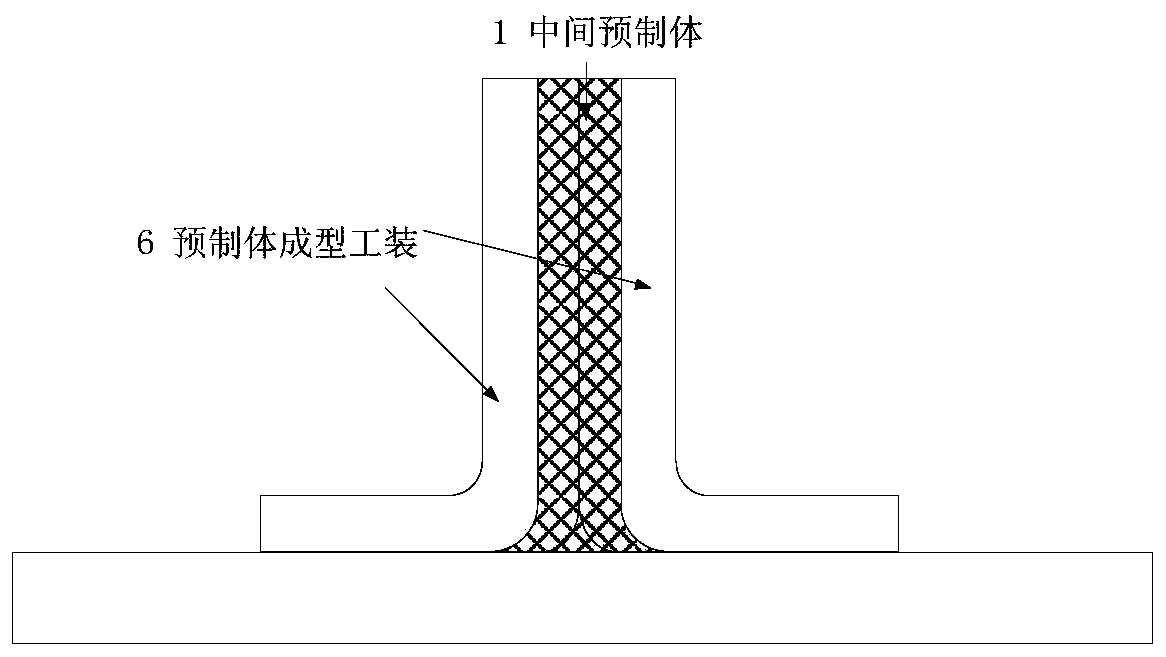

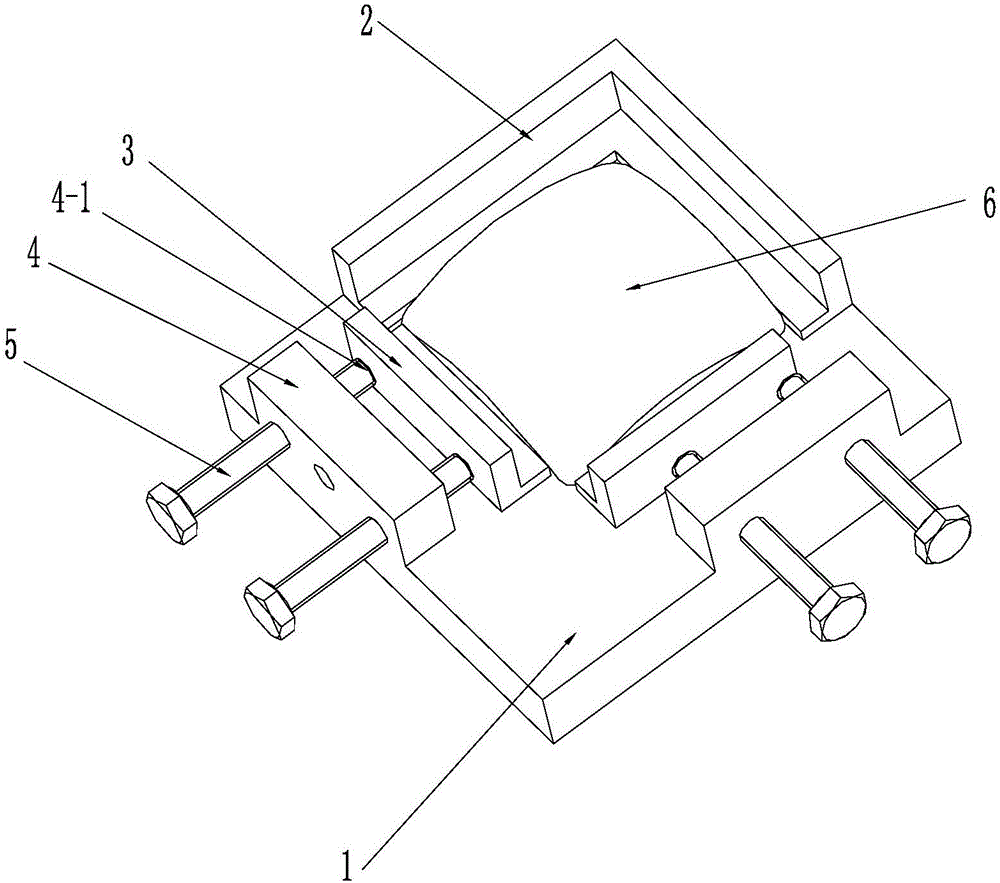

Composite material U-shaped long-girder wall plate integral formation method and tool of method

ActiveCN111070724AGuarantee molding qualityPrecise positioningDomestic articlesAerospace manufacturingBoard structure

The invention discloses a composite material U-shaped long-girder wall plate integral formation method and a tool of the method, and belongs to the technical field of aerospace manufacturing. According to the method, it is adopted that stepwise integral assembly is carried out, and solidification is carried out afterward. The method specifically comprises the steps that a middle preform is formedthrough a middle preform forming tool; and integral formation of a long-girder wall plate is completed through a long-girder forming tool in cooperation with a skin forming tool. According to the technical field of the composite material U-shaped long-girder wall plate integral formation method and the tool of the method, while it is guaranteed that the forming quality of a long-girder middle insertion layer and a spill strip filling area is effectively controlled, the assembly and positioning process of a long-girder web is simplified, accurate control over the position, relative to skin, ofthe middle preform is guaranteed, and then it is guaranteed that the long-girder web is positioned accurately, and the dimensional accuracy of the long-girder web is under control; and the composite material U-shaped long-girder wall plate integral formation method and the tool of the method can be suitable for stiffened wall plate structures of various composite materials, and the structural forming quality of composite material parts is improved.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

Curved surface auxiliary measuring device and curved surface coordinate system determining method for symmetrical double-curvature panels

A curved surface auxiliary measuring device and a curved surface coordinate system determining method for symmetrical double-curvature panels relate to the field of aviation and aerospace manufacturing machinery. The device and the method are provided to solve the problem that the existing curved surface auxiliary measuring device and the coordinate system determining method are complex and need large amount of calculation. According to the technical scheme, the upper and lower end faces of a base are kept parallel to each other, two intersecting side walls on the base are respectively equipped with a first fixed seat, the remaining two side walls on the base are respectively equipped with a boss, each boss is provided with two internal threaded holes, and one end of each bolt is fixedly connected to a second fixed seat after passing through the corresponding internal threaded hole. The method comprises the following steps: step 1, putting and fixing a curved piece in the device; step 2, acquiring point cloud data; and step 3, establishing a coordinate system, and using Imageware software to process the point cloud data. The curved surface auxiliary measuring device and the curved surface coordinate system determining method of the invention are used in auxiliary measurement of the curved surface of a symmetric double-curvature panel.

Owner:HARBIN INST OF TECH

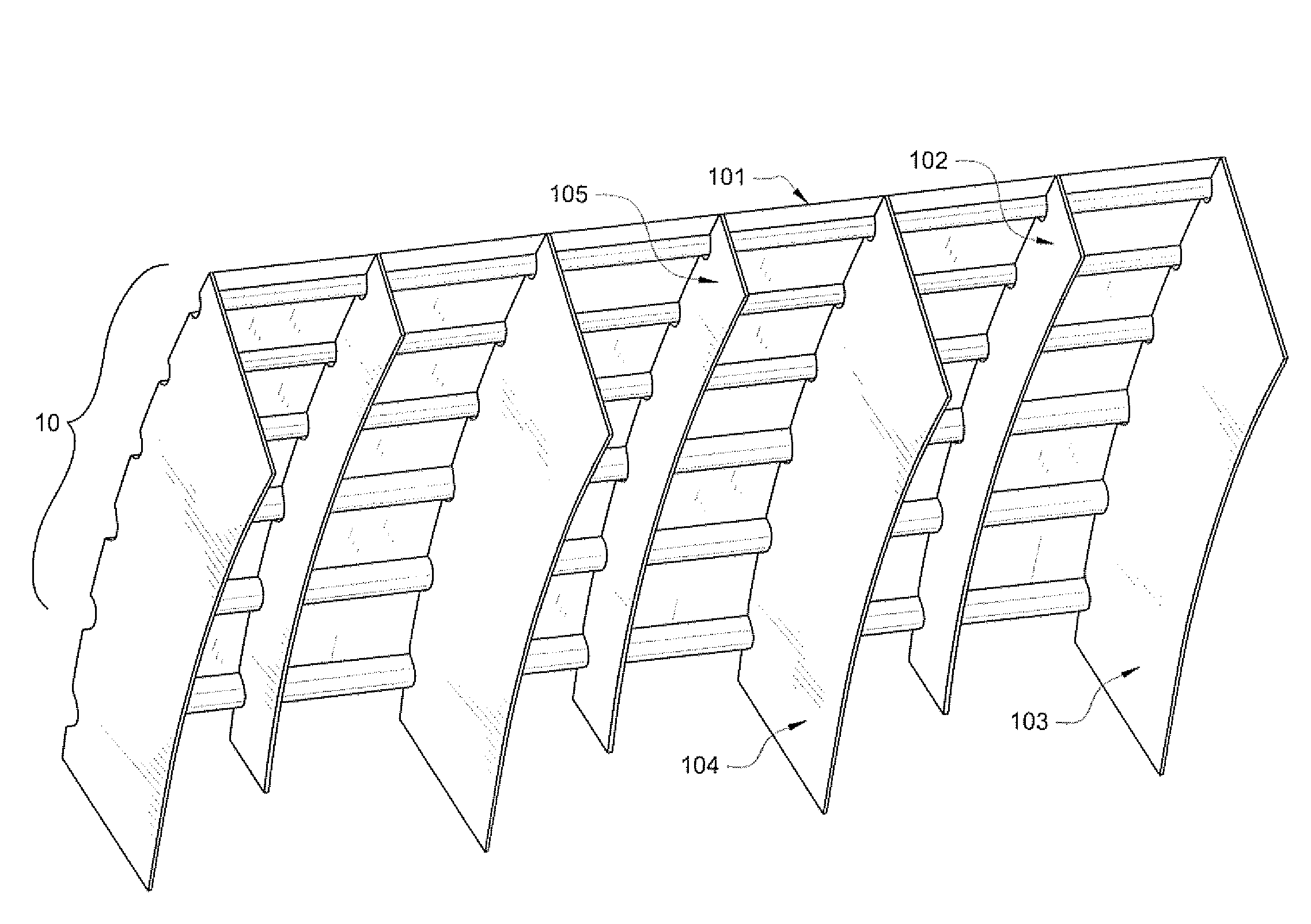

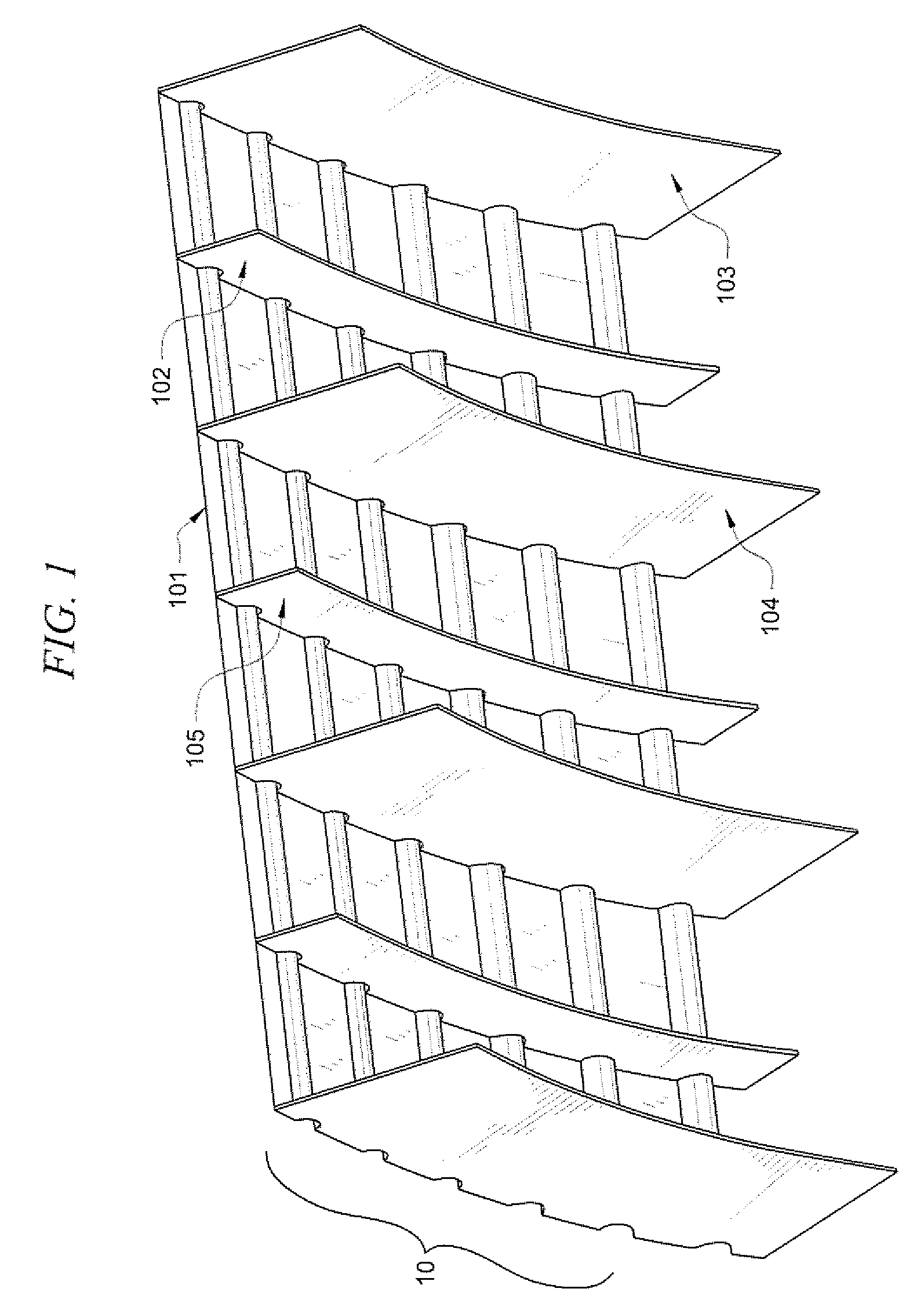

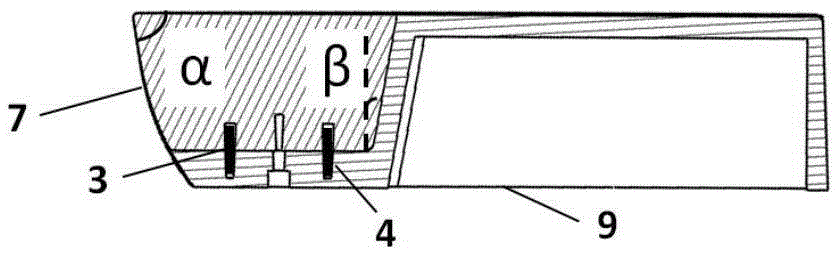

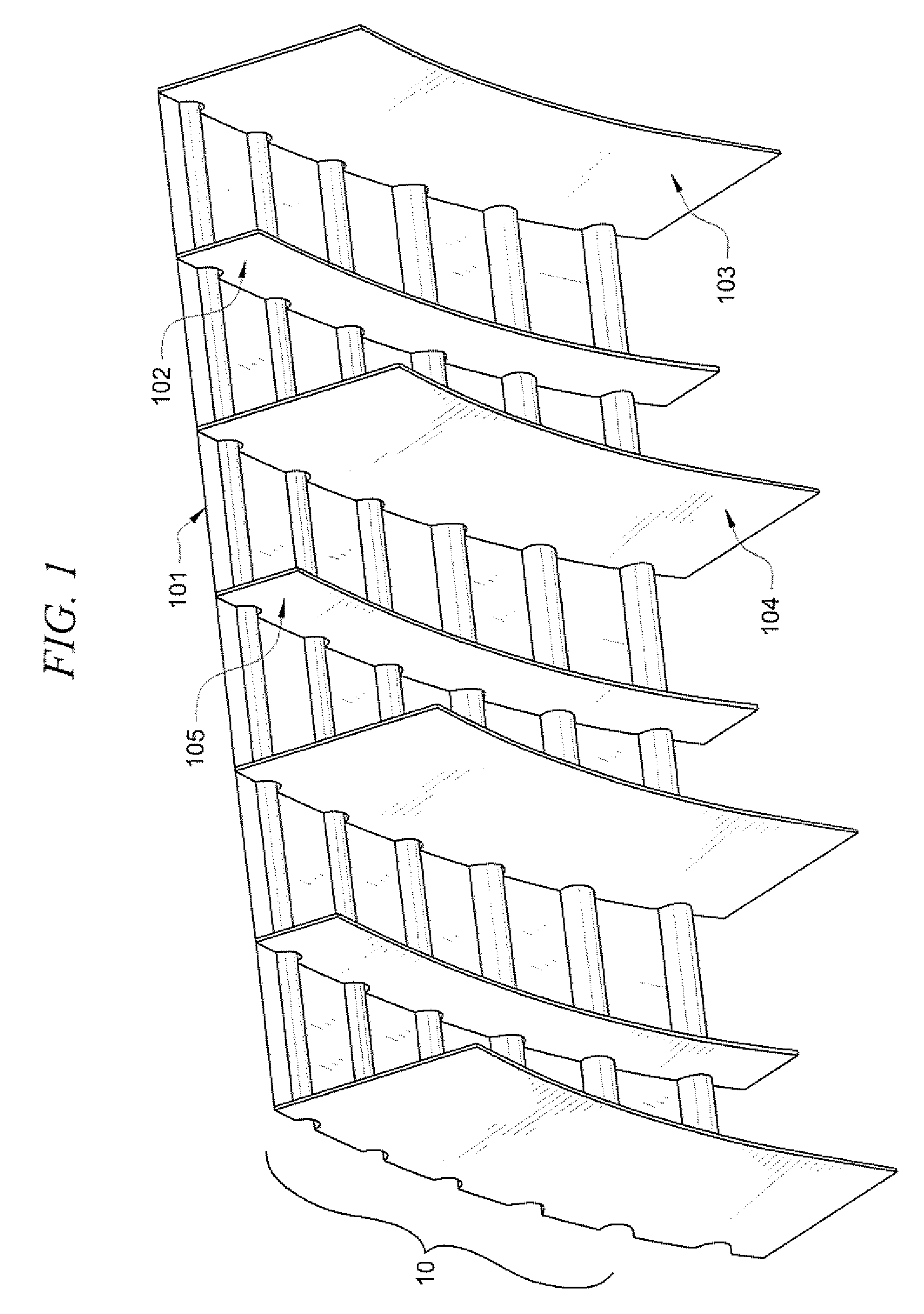

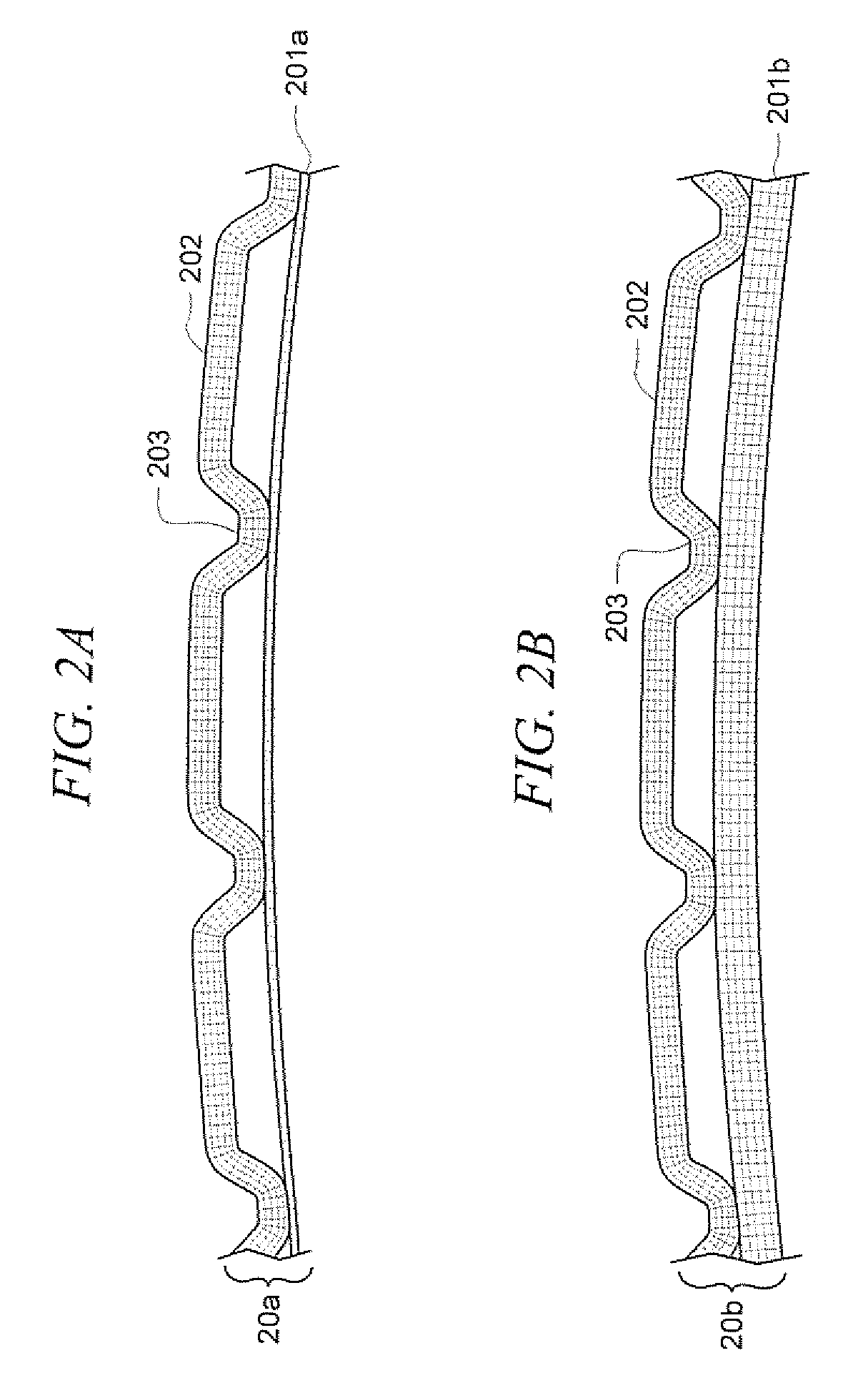

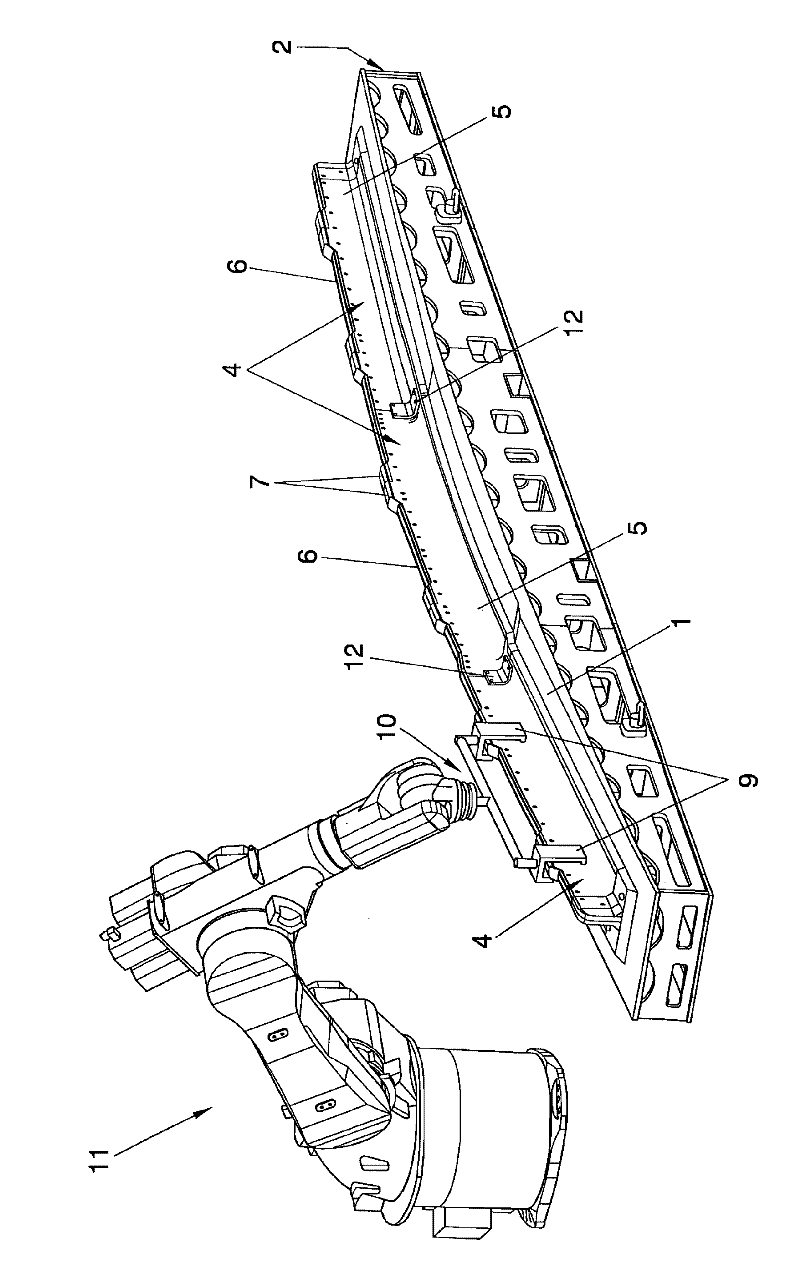

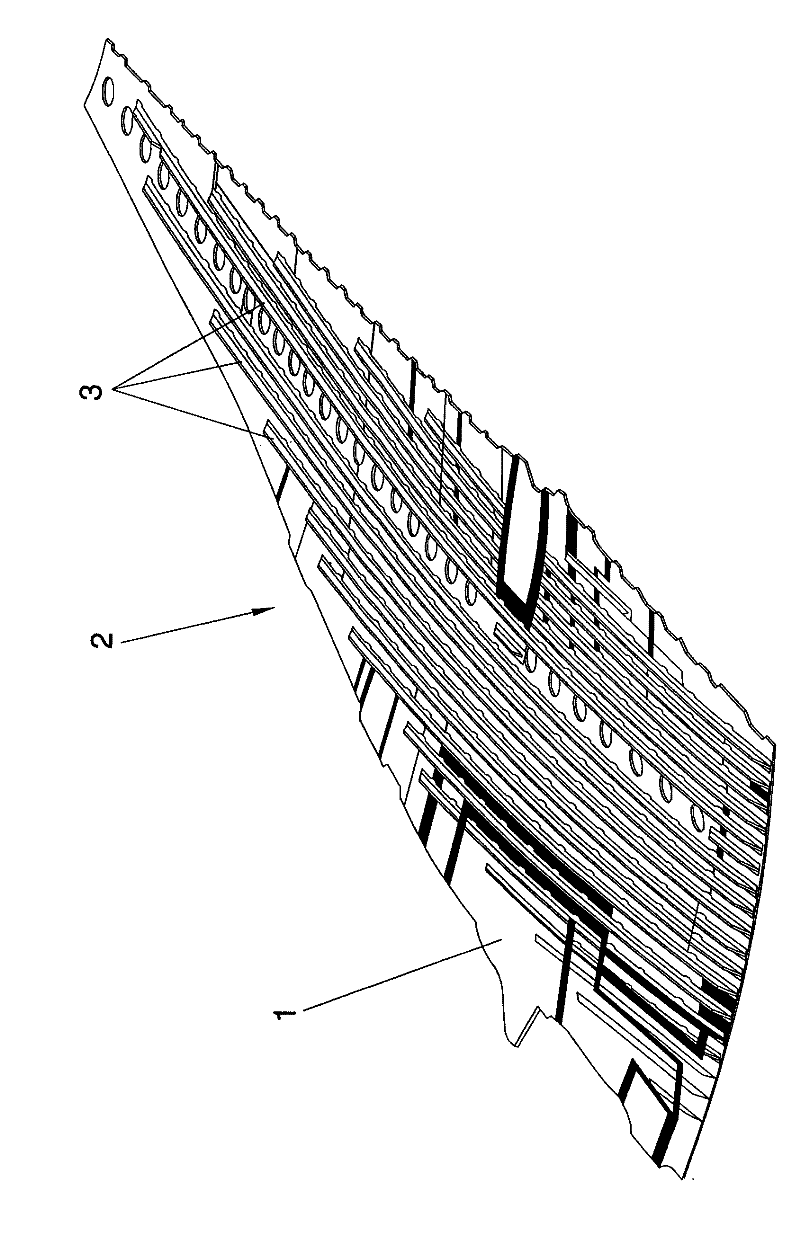

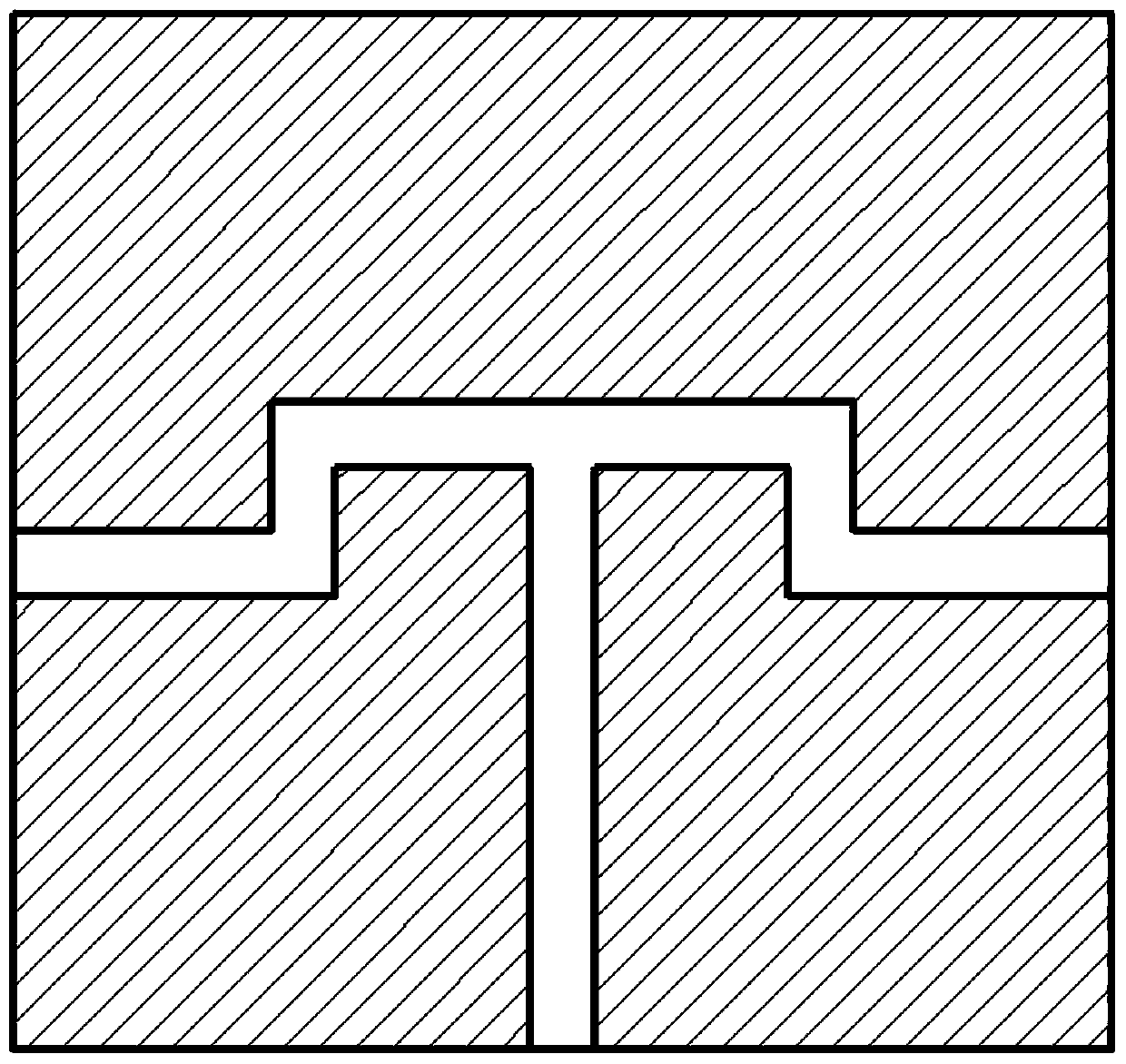

Positioning, handling and assembly systems for manufacturing aerospace parts

The system has special application in the manufacture of aircraft wing covers (10 made of carbon fiber and the stringers (3) cured jointly with the wing cover during the polymerization in autoclave. The tool pieces (4) being used are defined by angular elements (5, 6) copying the geometry of the stringers (3). The shape of these stringers corresponds to the “T” section. The angular elements (5, 6) comprise, in their upper part, a pair of battlements (7) in order to be caught by part of the clamps (9) of a head (10) linked to a robot (11) of the spherical type with articulated arm with six axes. The angular elements (5, 6) are made of INVAR material and they are used to keep in position the stringers during the curing cycle in the autoclave.

Owner:AIRBUS OPERATIONS SL

Deep microporous ultrasound-assisted electrosparking system based on inner impact liquid of main shaft

InactiveCN110052679AImprove processing stabilityEasy dischargeMechanical vibrations separationAviationUltrasonic vibration

The invention belongs to the technical field of special processing of aviation and aerospace manufacturing and in particular relates to a deep microporous ultrasound-assisted electrosparking system based on n inner impact liquid of a main shaft. The system comprises an ultrasonic vibrating device and a main shaft inner impact liquid device. A to-be-processed workpiece is mounted at the output endof the ultrasonic vibrating device and is driven to vibrate supersonically through the ultrasonic vibrating device, and the main shaft inner impact liquid device is used for providing a continuous working liquid to the surface of the to-be-processed workpiece and carrying out deep microporous processing on the workpiece in a rotary processing mode under a fine discharging energy.

Owner:XIAN SPACE ENGINE CO LTD

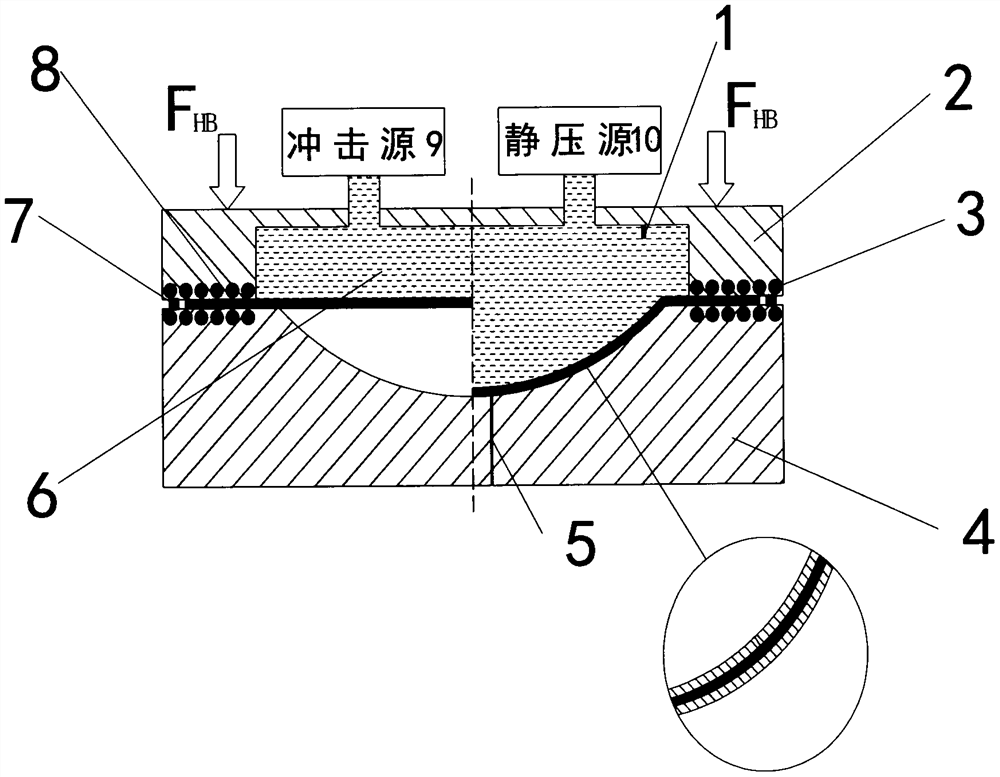

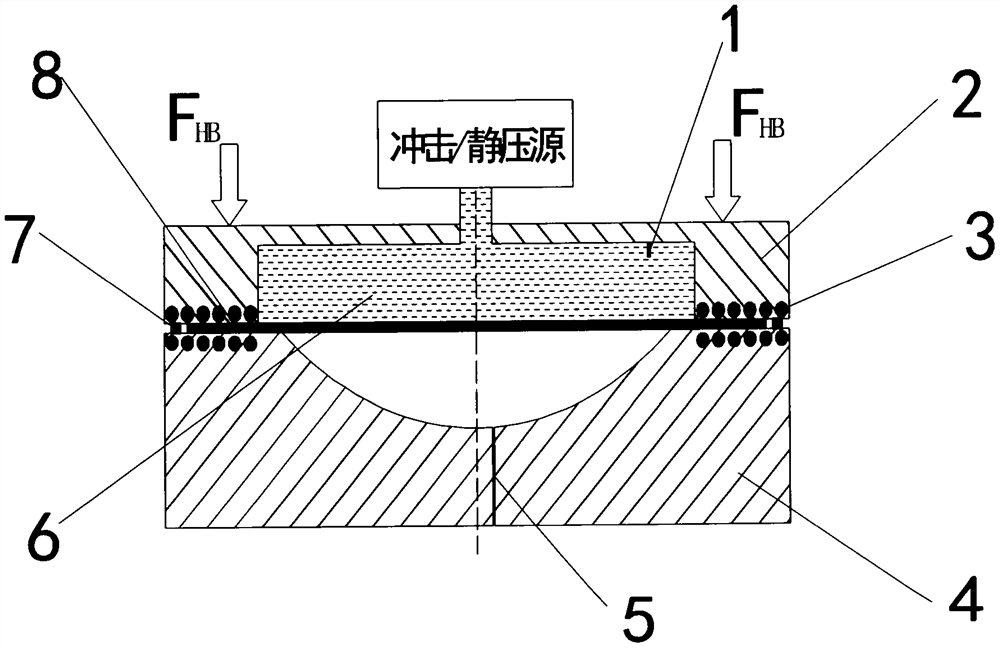

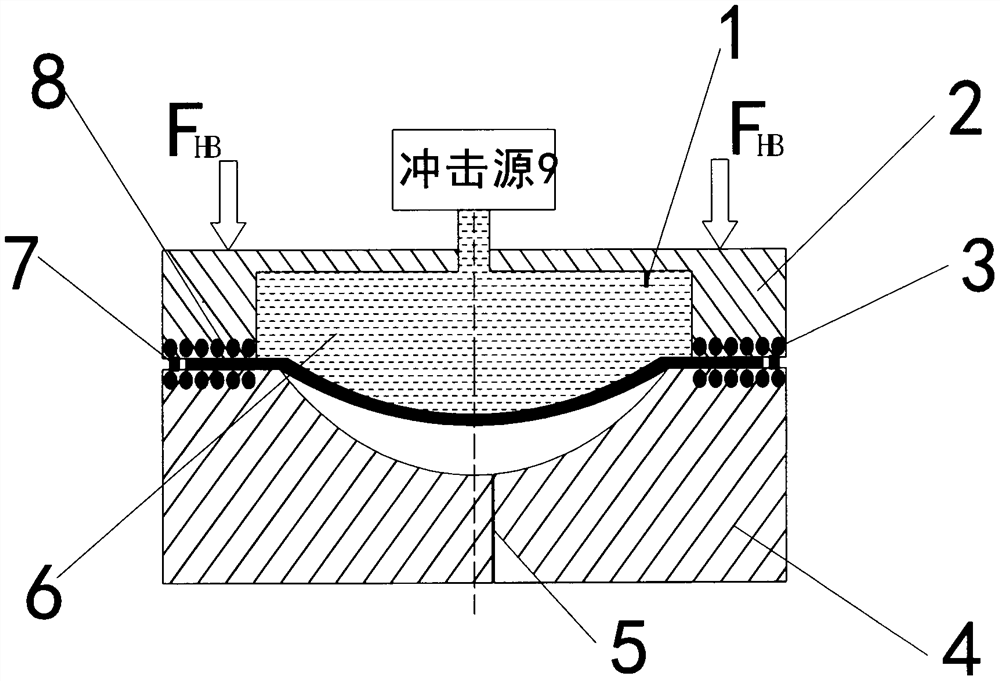

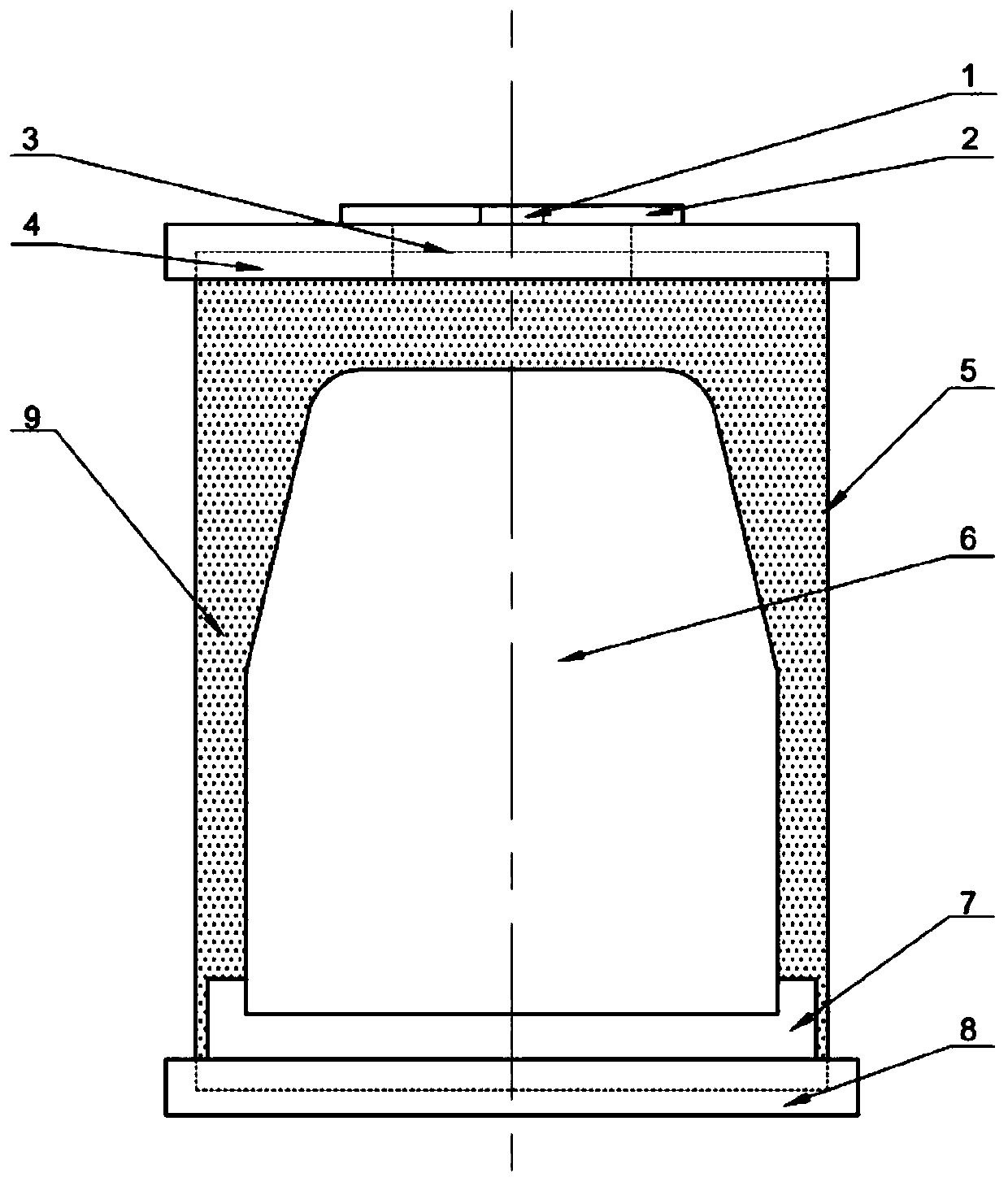

Thermal medium variable energy rate surface force loading forming method for fiber metal laminate

The invention provides a fiber metal laminate thermal medium variable energy rate surface force loading forming method, and belongs to the field of composite material forming. The novel method is a novel technology integrating high-energy-rate impact forming and liquid-filling static pressure forming in a crossed mode, and has the advantages of the two. The problems that in traditional forming, fiber materials are stacked and distributed unevenly, and in the material curing process, interlayer residual stress is large, and resilience is large are solved. The part rigidity can be enhanced, the die number is reduced, the equipment tonnage is reduced, and the forming efficiency is improved. The forming process mainly comprises the steps that a mold is cleaned, the surface of a metal layer is treated, a blank layer is placed on the forming mold, the mold is closed downwards, liquid is loaded, heating is conducted till thermoplastic resin enters a viscous state and high-elastic state mixed state, and at the moment, high-energy-rate fluid impact forming is conducted on the composite blank. And after forming, solidification is carried out under the synergistic effect of fluid high-pressure variable-path loads and gradient cooling, and interlayer tight combination of laminates is achieved. The method is mainly used for accurate forming of large complex thin-wall components in the aerospace manufacturing field.

Owner:HEBEI UNIV OF TECH

Hot isostatic pressing shape control method for titanium alloy thin-wall part

InactiveCN111266588ALow costHigh precisionTransportation and packagingMetal-working apparatusMetallurgyManufactured material

The invention discloses a hot isostatic pressing shape control method for a titanium alloy thin-wall part in the technical field of aerospace manufacturing. A cover plate with a vacuum hole, a top plate with a powder filling opening, a cylindrical wall, a rigid base plate for fixing a die, a bottom plate and titanium alloy powder. The method comprises the steps of die design and preparation, jacket preparation, hot isostatic pressing pretreatment, hot isostatic pressing process control, post treatment and the like, and provides a die shape and size design method aiming at the deformation problem of the titanium alloy thin-wall part in the whole forming process. According to the hot isostatic pressing shape control method constrained by the die and a jacket, the forming efficiency of the part and the utilization rate of raw materials can be improved, the compactness of the formed titanium alloy thin-wall part is high, the structure is uniform, the performance is excellent, an inner cavity of the formed titanium alloy thin-wall part can be near to the final shape, and the outer wall has enough machining allowance to meet the final size requirement.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Metal layer bionic microstructure fiber metal laminate capable of realizing resin self-infiltration

ActiveCN113043682ASolving Infiltration Outgassing ProblemsSolve Exhaust ProblemsSynthetic resin layered productsVehicle componentsAviationFiber metal laminate

The invention discloses a metal layer bionic microstructure fiber metal laminate capable of achieving resin self-infiltration, and belongs to the field of plate composite materials. The structure can effectively solve the problem of difficulty of infiltration of resin into deeper blind hole or blind pit microstructures in the surface of the metal layer of the fiber metal laminate, and the interlayer bonding performance of the metal matrix and the fiber prepreg is enhanced. The structure is composed of a vertical conical hole dense array structure which is of a spatial geometry asymmetric structure and is spaced by a certain distance, a multi-stage structure composed of a conical hole main hole and conical hole auxiliary holes, or a pit structure of an Archimedes spiral or logarithmic spiral track with different spatial curvatures, and a groove microstructure provided with an Archimedes spiral or logarithmic spiral track. The structure is mainly used for infiltrating resin into deeper blind hole or blind pit microstructures inthe surface of a metal layer of the fiber reinforced metal laminate, and the laminate is mainly used for manufacturing aviation covering parts such as fuselages, skins and the like of large aircrafts and high-speed aerospace vehicles in the field of aerospace manufacturing.

Owner:HEBEI UNIV OF TECH

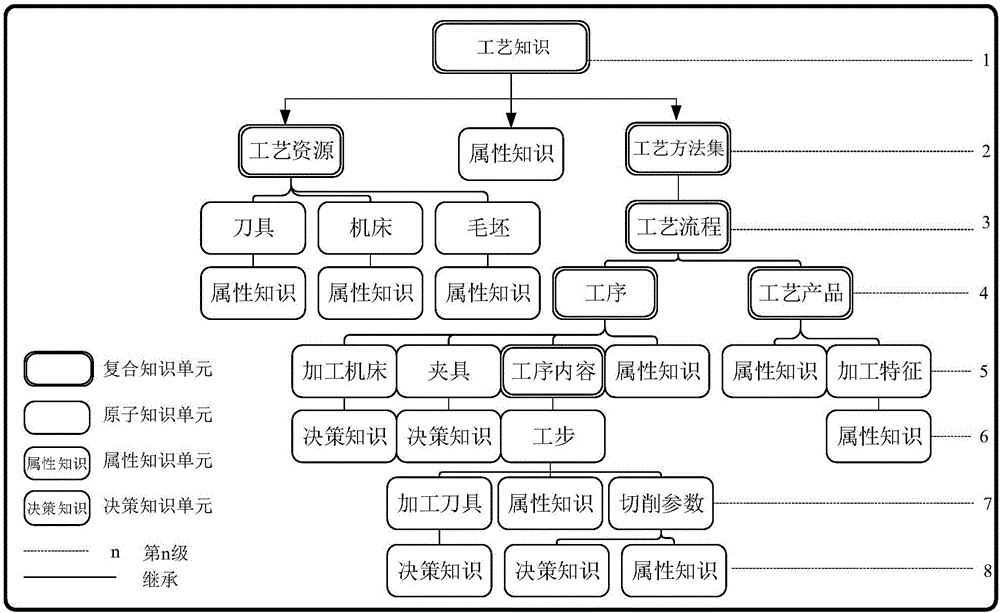

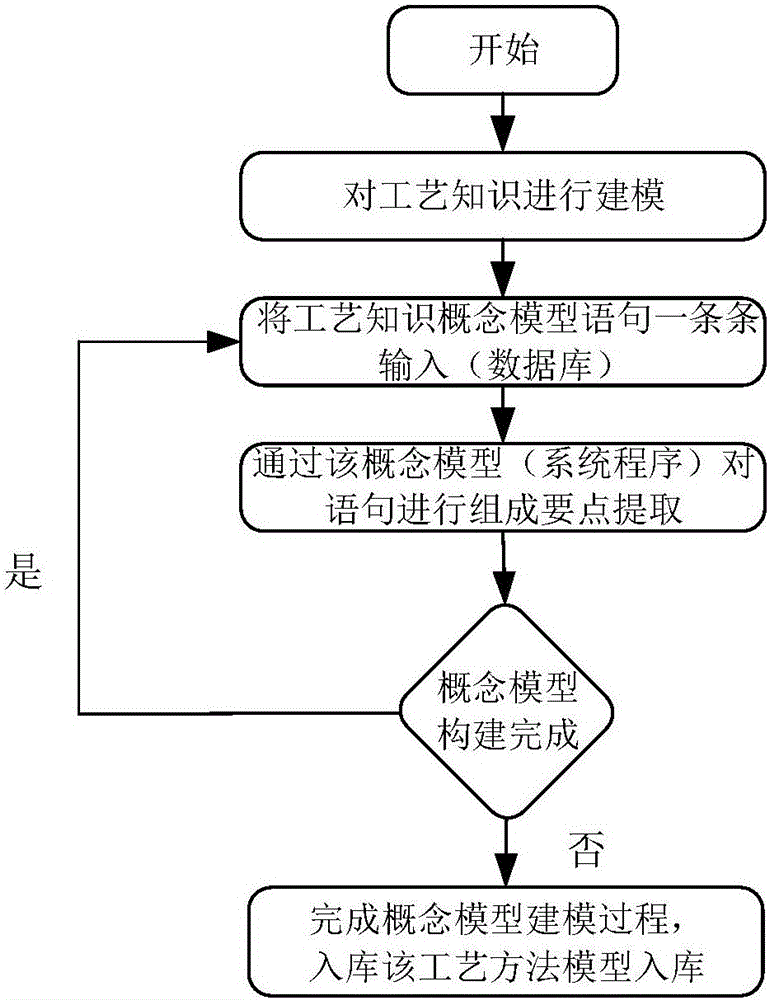

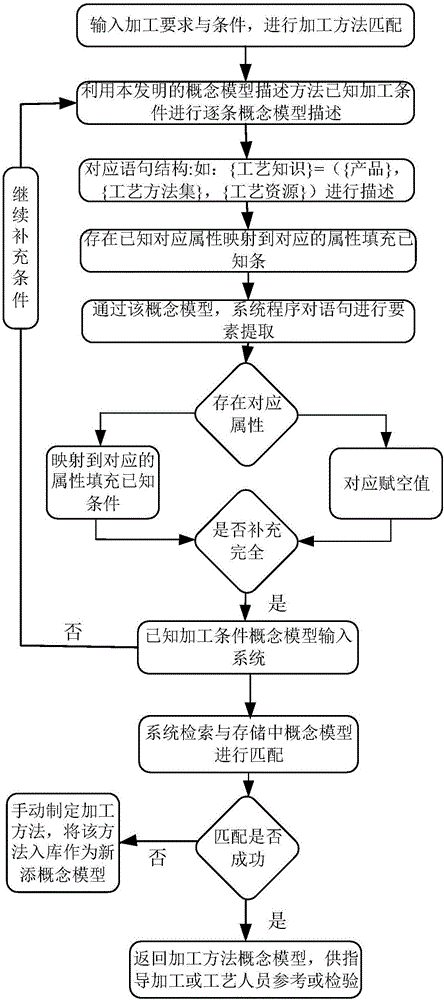

Aircraft structural part process design-oriented process knowledge conception model description method

InactiveCN106528953APracticalIn line with the characteristics of the process fieldGeometric CADDesign optimisation/simulationAviationManufacturing technology

The invention discloses an aircraft structural part process design-oriented process knowledge conception model description method, and belongs to the technical field of aerospace manufacturing. The description method comprises the steps of classifying process knowledge; determining a hierarchical relationship among knowledge units; mapping the determined hierarchical relationship to an aircraft structural part processing process; and building the conception model. According to the description method, based on a view angle of a user, the return to the essence of the conception model again is realized; the process knowledge of existing aircraft structural part processing design corresponds to an actual processing scene process of a factory; a thought of aircraft structural part processing process planning is researched; technologists are imitated to perform a working process of the process planning; and a description form of the conception model is determined, so that the effect of serving as a language for realizing barrier-free communication between the user and database designers can be brought into full play, and the description method has higher practicality.

Owner:BEIHANG UNIV

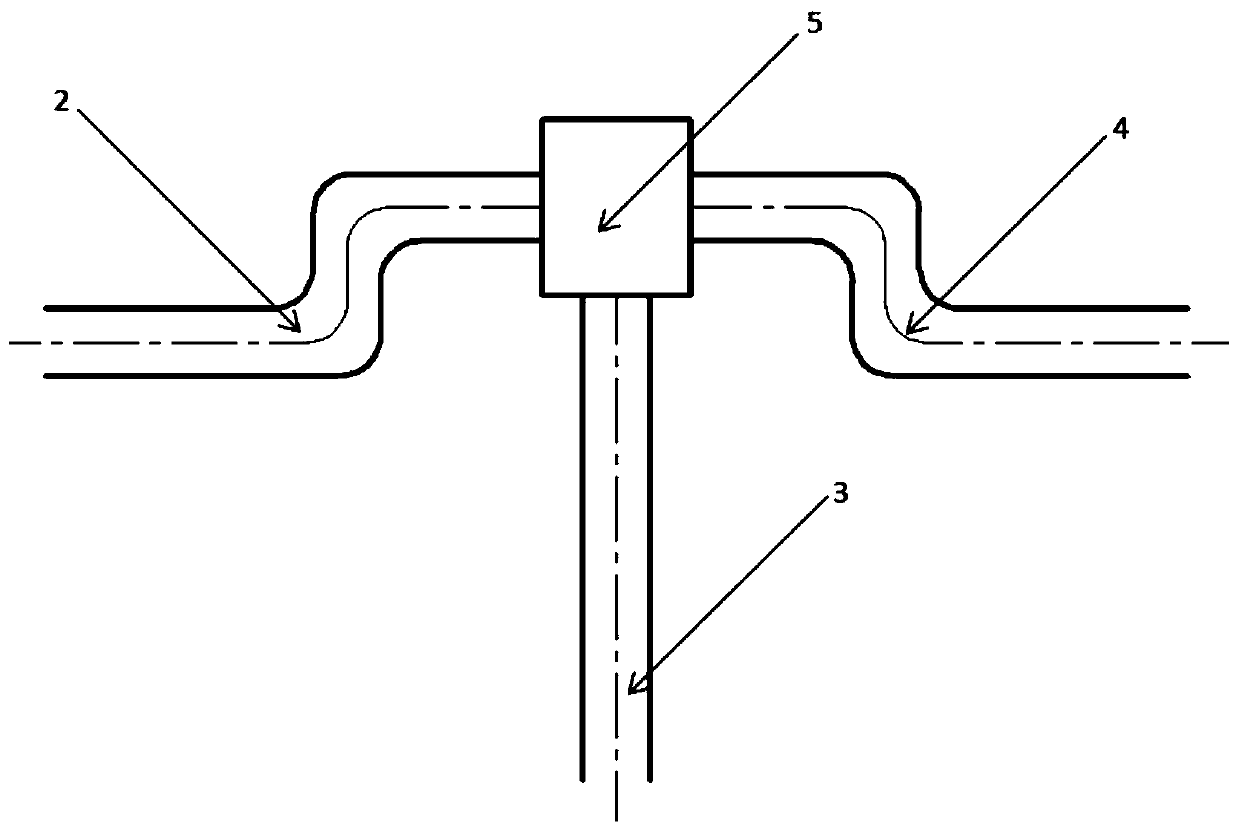

Powder-solid coupling forming method for internal complex multi-flow passage piece

The invention provides a powder-solid coupling forming method for an alloy complex internal multi-flow passage piece, and belongs to the field of aerospace manufacturing. The method comprises the steps of design and preparation of a pipeline, design and preparation of a multi-way connector, design and processing of a solid supporting block, design and processing of a sheath, material selection ofpowder, an integral quality detection process, selection of process parameters and the like. The method is characterized in that powder in a jacket and a solid block of the same kind (dissimilar kind)metal are diffused and connected into a whole in a closed container by means of hot isostatic pressing in a high-temperature high-pressure environment. Before forming, a traditional inner flow channel is replaced by the pipeline which is designed in advance, and then the corresponding multi-way connector is designed according to the pipeline for connection, so that the problem of connection amongmulti-way pipelines is solved, the later-stage cleaning and leakage detection are facilitated, and the use risk caused by residual powder is greatly reduced. The powder-solid coupling forming methodcan change the structure and the material according to the needs, and better solves the related problems of the current inner flow passage piece.

Owner:BEIHANG UNIV

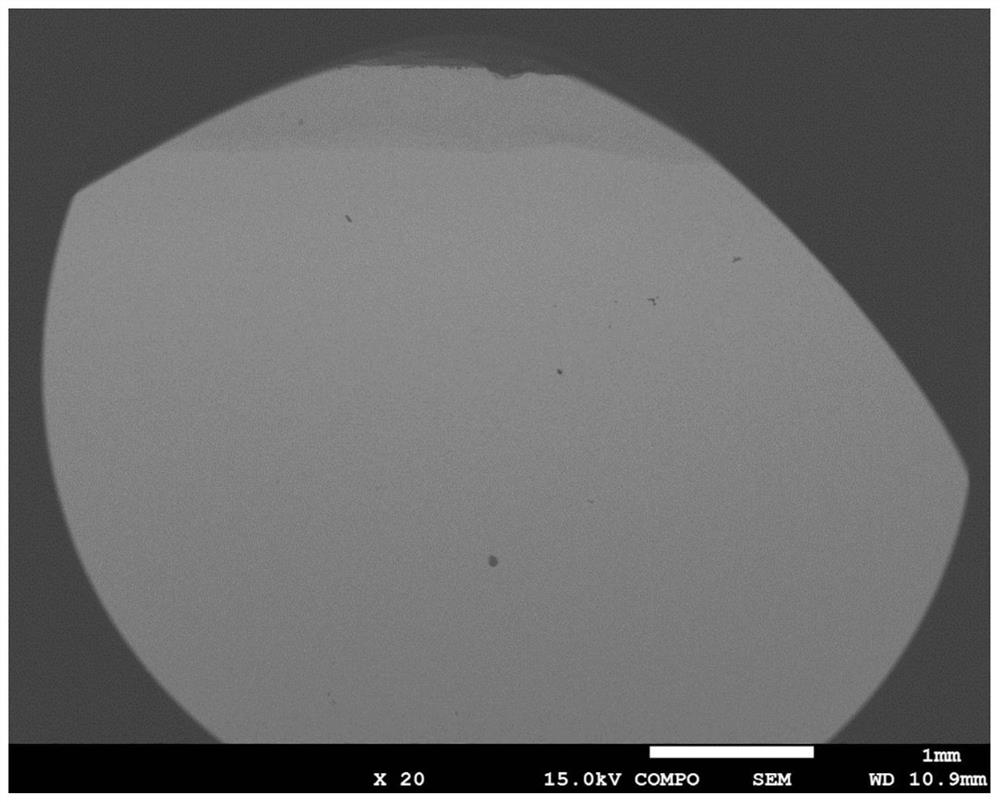

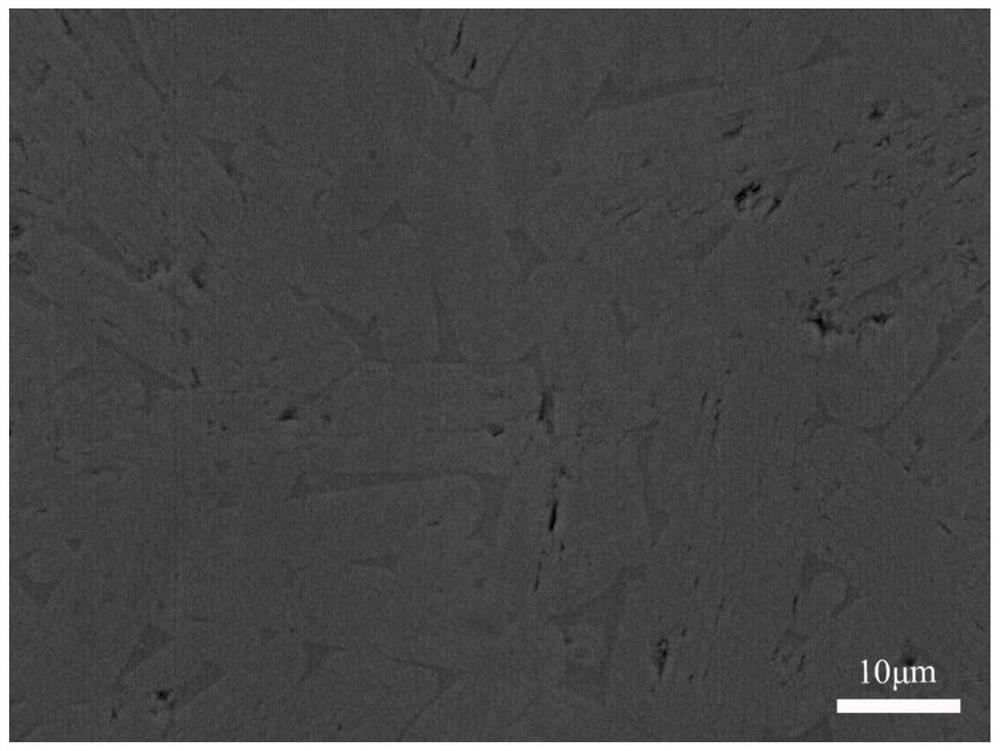

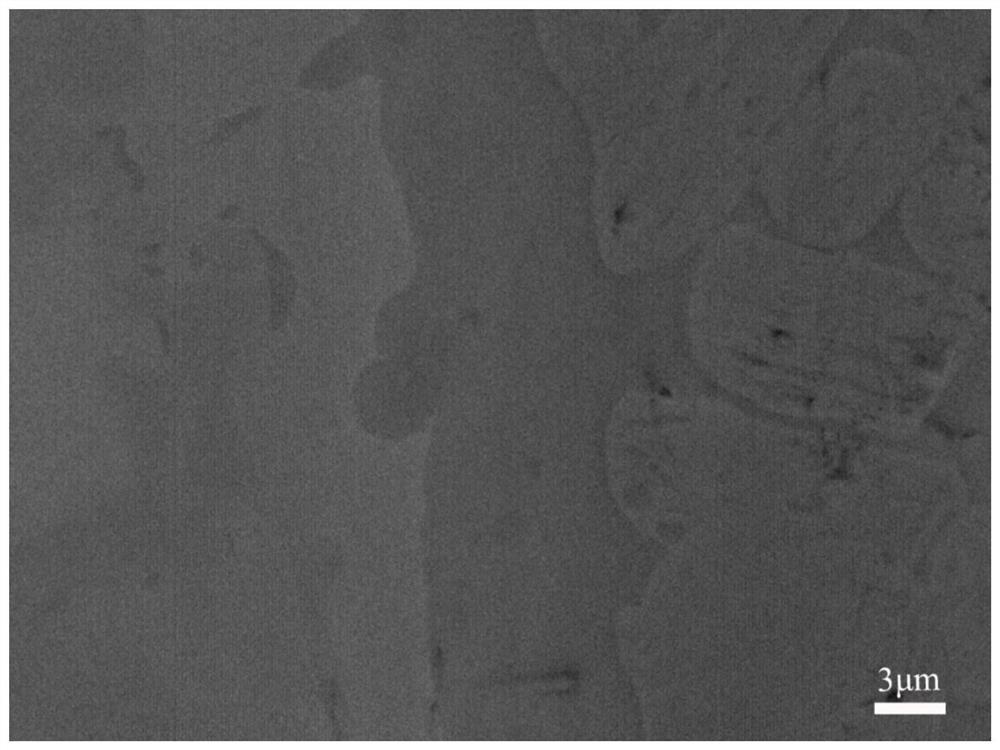

In-situ generated Ti2AlC ceramic layer on surface of titanium substrate and preparation method of in-situ generated Ti2AlC ceramic layer

The invention discloses an in-situ generated Ti2AlC ceramic layer on the surface of a titanium substrate and a preparation method of the in-situ generated Ti2AlC ceramic layer. A Ti2AlC ceramic layer with a controllable and stable thickness range is generated on the surface of a titanium and titanium alloy substrate in situ from a composite material by adopting a powder metallurgy means. Ti2AlC serving as one of representatives of an MAX phase material has good self-lubricating performance and excellent tribological performance, and the Ti2AlC serving as a protective layer is beneficial to improving the tribological performance and the use temperature of a titanium and titanium alloy surface. In addition, a TiXAly transition layer is generated between the ceramic layer and the titanium substrate, and the interface bonding between the transition layer and the ceramic layer and the interface bonding between the transition layer and the substrate are good, so that the transmission of mechanical properties between the ceramic layer and a substrate layer is facilitated. The method disclosed by the invention can be applied to the fields of aerospace manufacturing and high temperature.

Owner:BEIJING JIAOTONG UNIV

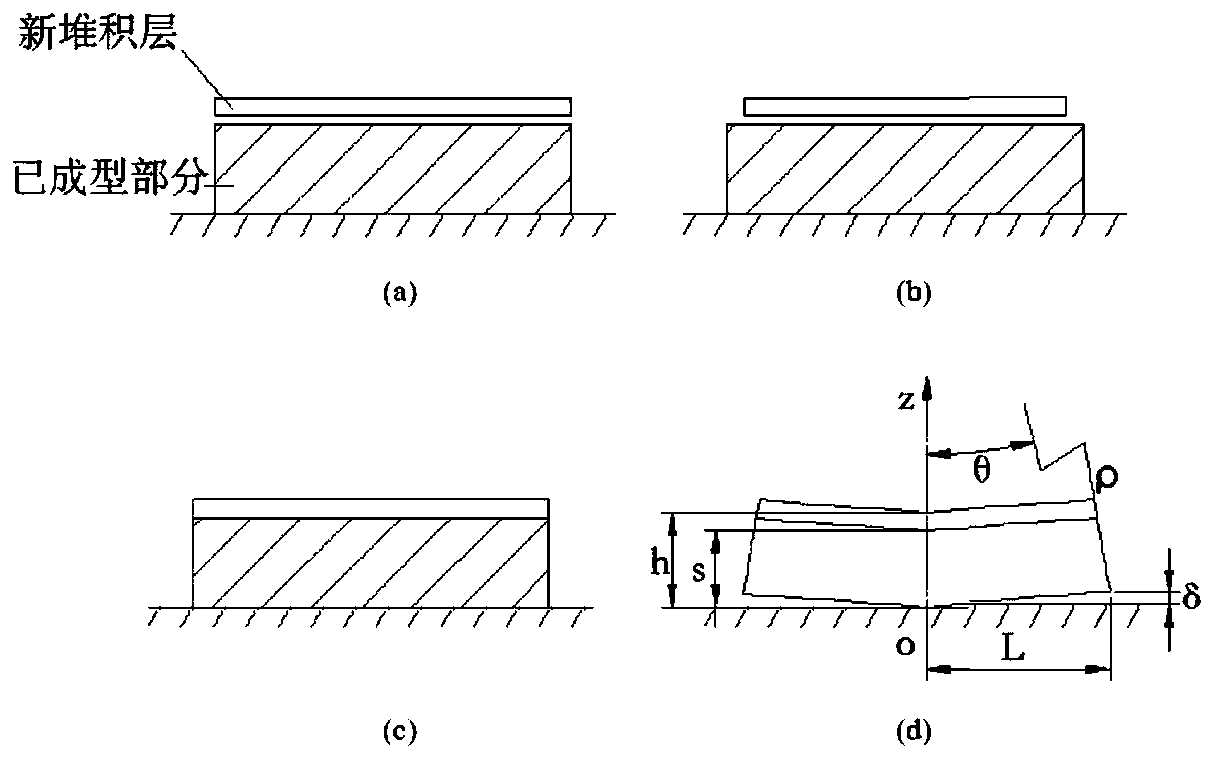

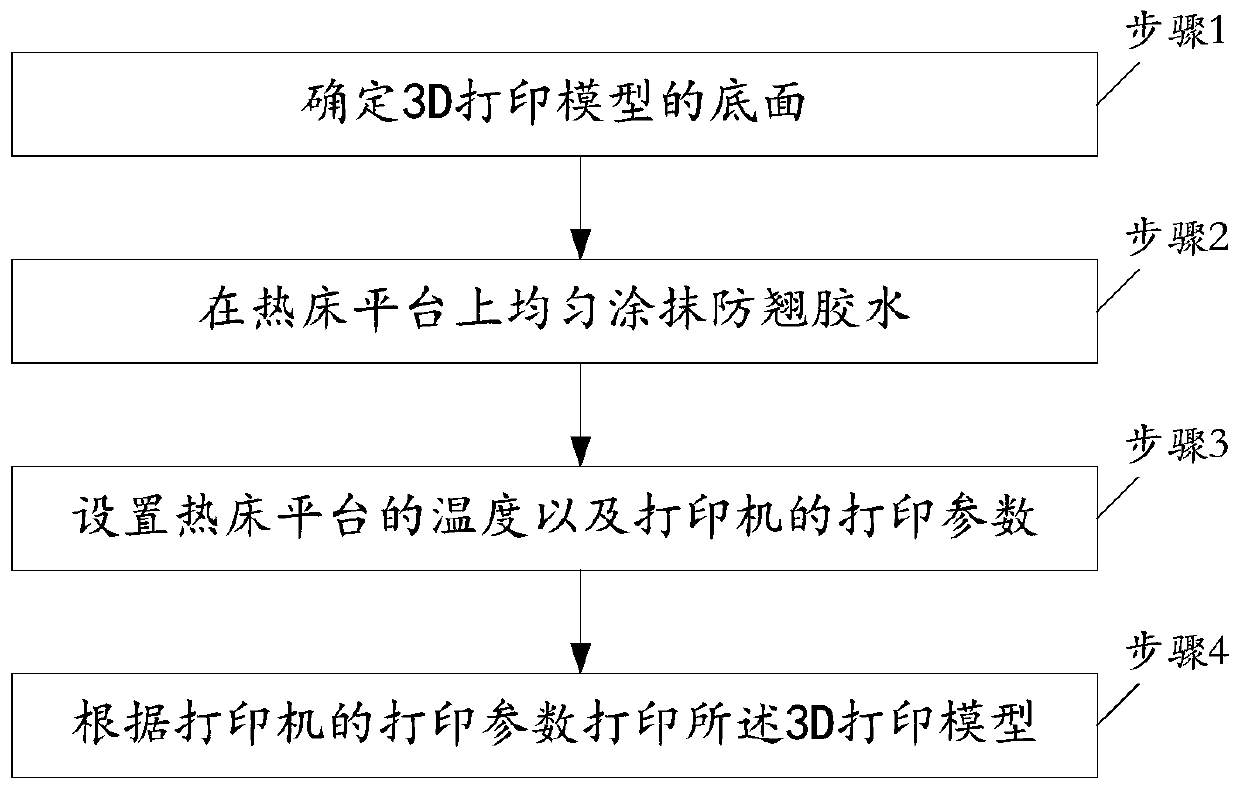

Method for preventing 3D printing model from warping in FDM (Fused Deposition Modeling) printing

InactiveCN110539479ASolve warping deformationGuaranteed to print successfullyAdditive manufacturing apparatus3D object support structuresEngineeringAerospace manufacturing

The invention belongs to the technical field of aerospace manufacturing, and discloses a method for preventing a 3D printing model from warping in FDM (Fused Deposition Modeling) printing. The methodcomprises the steps of (1) determining the bottom surface of the 3D printing model, wherein the bottom surface of the 3D printing model expresses the surface, which is printed first to make contact with a hot bed platform, in all surfaces of the 3D printing model; (2) uniformly applying anti-warping glue to the hot bed platform; (3) setting the temperature of the hot bed platform and printing parameters of a printer; and (4) printing the 3D printing model according to the printing parameters of the printer. The warping deformation of a 3D printed piece can be effectively solved, and the successful printing of a 3D product is guaranteed.

Owner:SHAANXI QIANSHAN AVIONICS

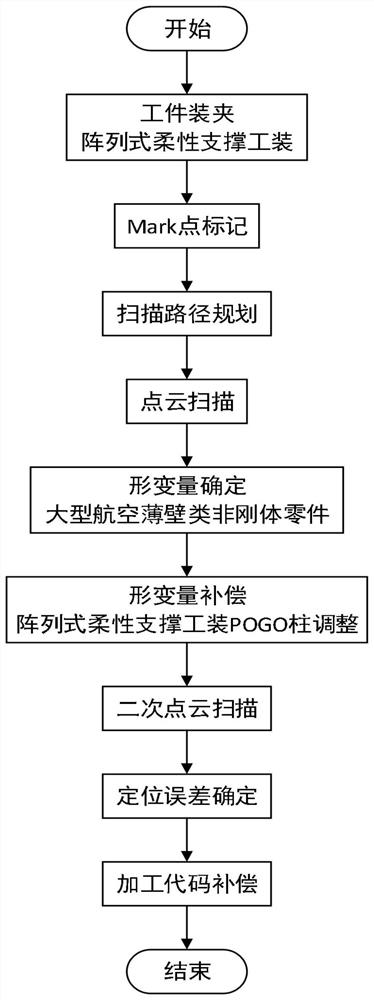

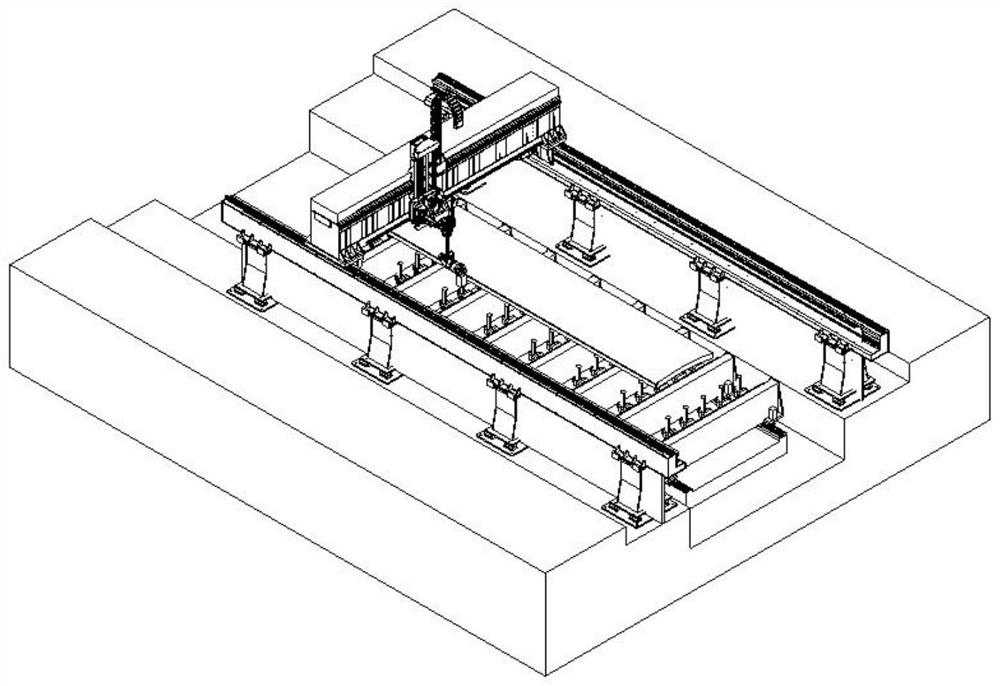

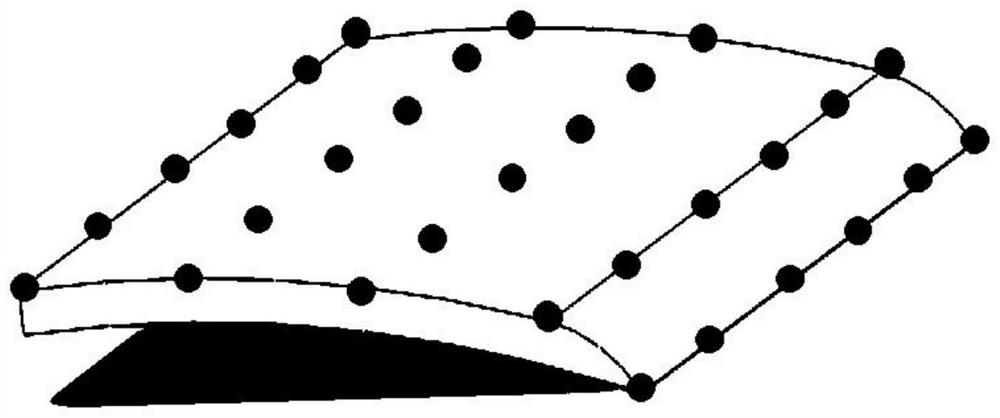

Parameterization numerical control machining method and system for aviation large thin-wall non-rigid part

PendingCN114115123AEffective detection of clamping positioning errorsEffective detection of deformation errorsProgramme controlComputer controlNumerical controlAviation

The invention provides a parameterization numerical control machining method and system for a large thin-wall non-rigid part in aviation. The parameterization numerical control machining method comprises the steps that 1, a workpiece is clamped; step 2, marking Mark points; step 3, planning a scanning path; step 4, point cloud scanning; step 5, deformation analysis; 6, adjusting a POGO column; step 7, carrying out secondary scanning; 8, based on the secondary point cloud and the three-dimensional design model, the positioning error of the large thin-wall part is obtained; and 9, on the basis of the positioning error obtained in the step 8, the machining code of the large thin-wall part is compensated. According to the method, the clamping and positioning error of the array type flexible supporting tool and the deformation error of the large aviation thin-wall non-rigid part can be effectively detected, a numerical control machine tool machining code is compensated and corrected on the basis, machining is conducted on the basis, and therefore the machining precision of the aviation thin-wall part is greatly improved, and the machining efficiency of the large aviation thin-wall non-rigid part is improved. And therefore, the quality stability of thin-wall parts in aerospace manufacturing is improved.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com