Skin part longitudinal stretching woolen size determination method

A technology for skin parts and wool, which is applied in the field of longitudinal drawing wool size determination of skin parts, can solve problems such as large blindness and material waste, and achieve the effect of reducing material waste and increasing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Example: see Figure 1 to Figure 5 .

[0021] A method for determining the size of longitudinally stretched wool for skin parts, the steps of which are as follows:

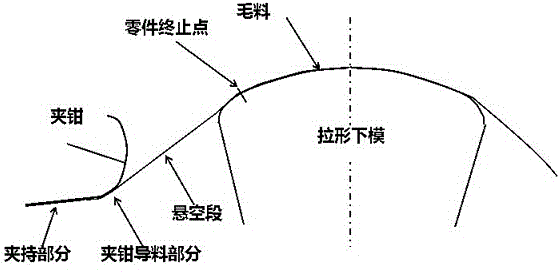

[0022] Step 1 analyzes the composition of the drawn wool,

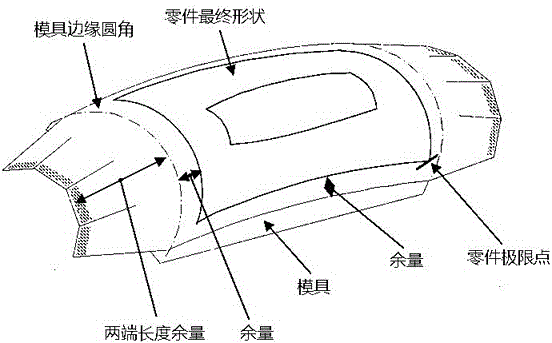

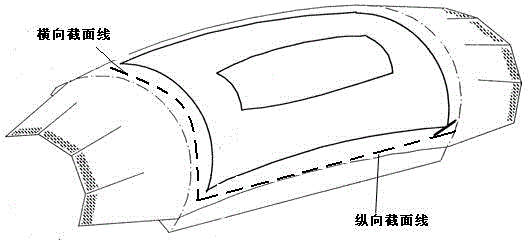

[0023] Such as figure 1 shown. The wool is first held in the clamps of the device. The wool is manually clamped on the drawing equipment at a certain wrap angle. This is followed by pre-stretching and over-stretching. Sometimes it is necessary to continue to increase the cladding angle, and at the same time further increase the plastic deformation of the wool so that the wool can be fully attached to the mold. Finally, under the condition that the wrapping angle is basically unchanged, the wool is stretched again, which is called supplementary stretching. The final covering stretch and supplementary stretching are also collectively referred to as supplemental stretching. In the process of skin pulling shape, the limit point of the part is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com