Ti2AlC reinforced titanium matrix composite material and preparation method and application thereof

A titanium-based composite material and titanium alloy technology, applied in the field of metal-based composite materials, can solve the problem of no Ti, etc., and achieve the effects of improving elastic modulus and wear resistance, reducing plasticity reduction, and good strengthening and toughening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

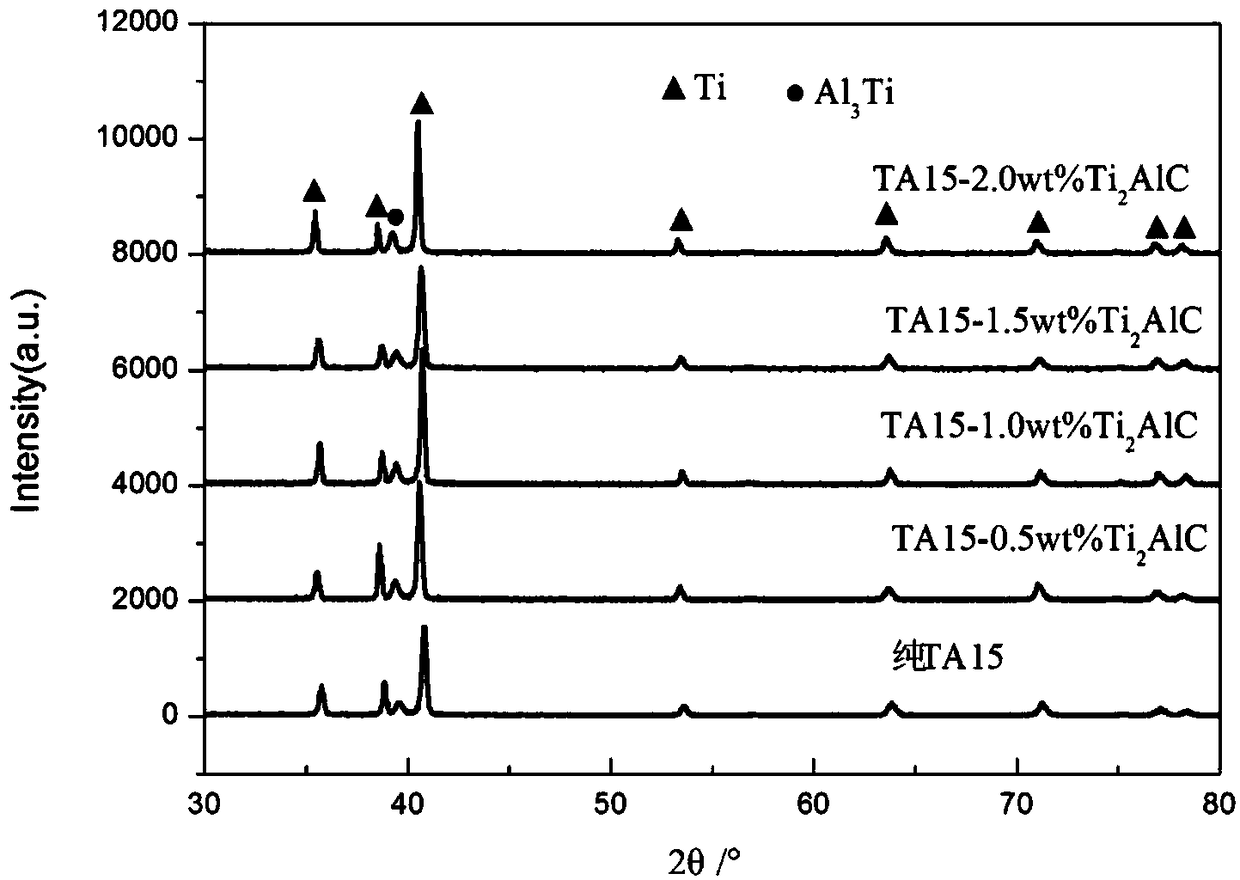

[0035] Production of Ti by Sintering with Spark Plasma Technology 2 AlC reinforced titanium matrix composites, using Ti 2 AlC powder and spherical TA1 pure titanium powder are used as raw materials. A cylindrical composite material sintered body with a diameter of 20 mm and a height of 12 mm was prepared.

[0036] Specific steps are as follows:

[0037] (1) Weigh 10g TA1 powder (purity is 99.5%) and mass fraction is 0.5wt% Ti 2 AlC powder, first weigh a good Ti 2 Put the AlC powder in a beaker, add absolute ethanol, vibrate for 20 minutes by an ultrasonic oscillator, then add the weighed TA1 powder into the above solution, and repeat the above oscillation operation for 20 minutes.

[0038] (2) Take the preliminarily mixed powder solution and place it in a ball milling tank at a ball-to-material ratio of 10:1. The ball milling medium is absolute ethanol. On a planetary ball mill at a speed of 250r / min, it is rotated forward and backward for 2.5 h procedure, ball milling ti...

Embodiment 2

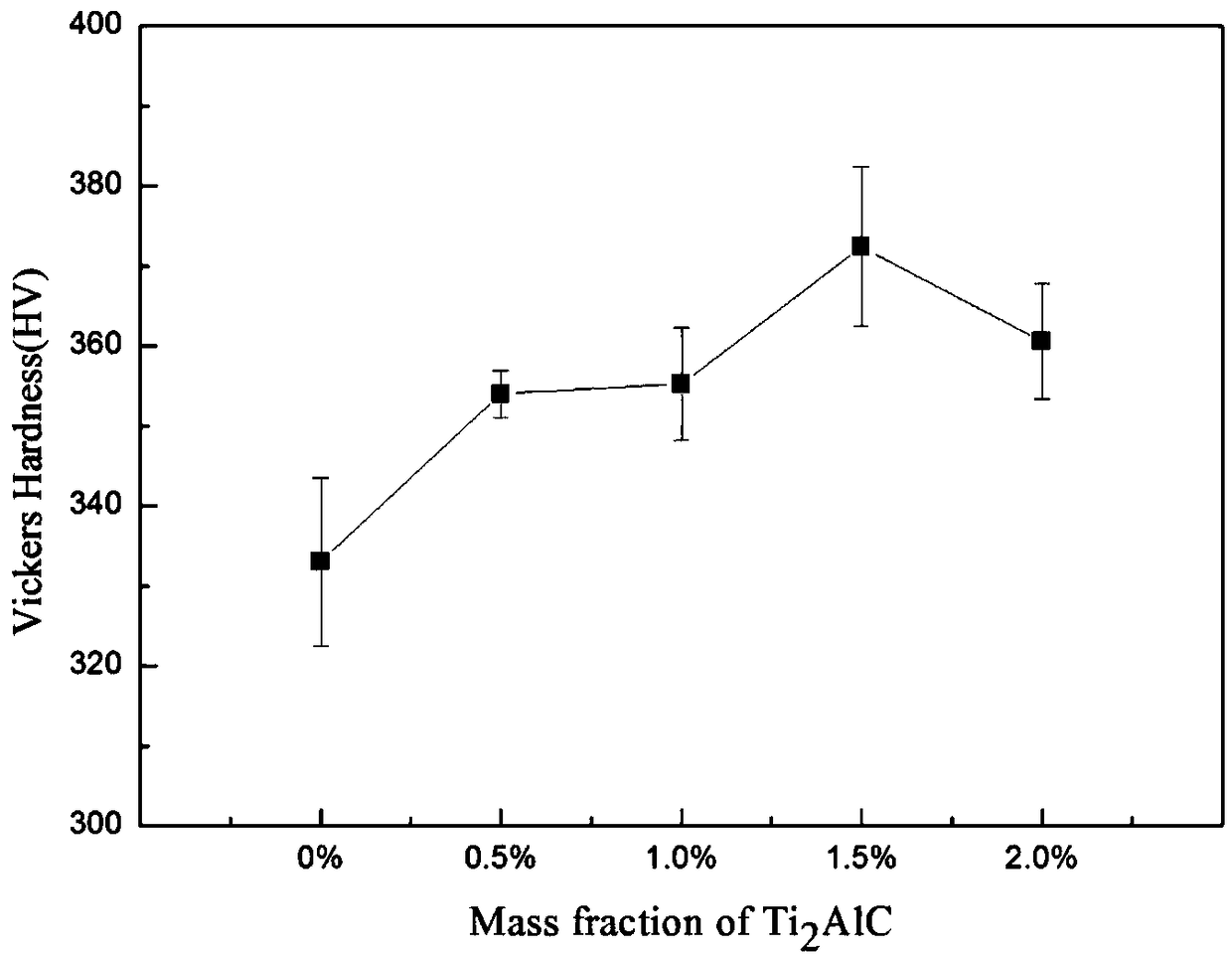

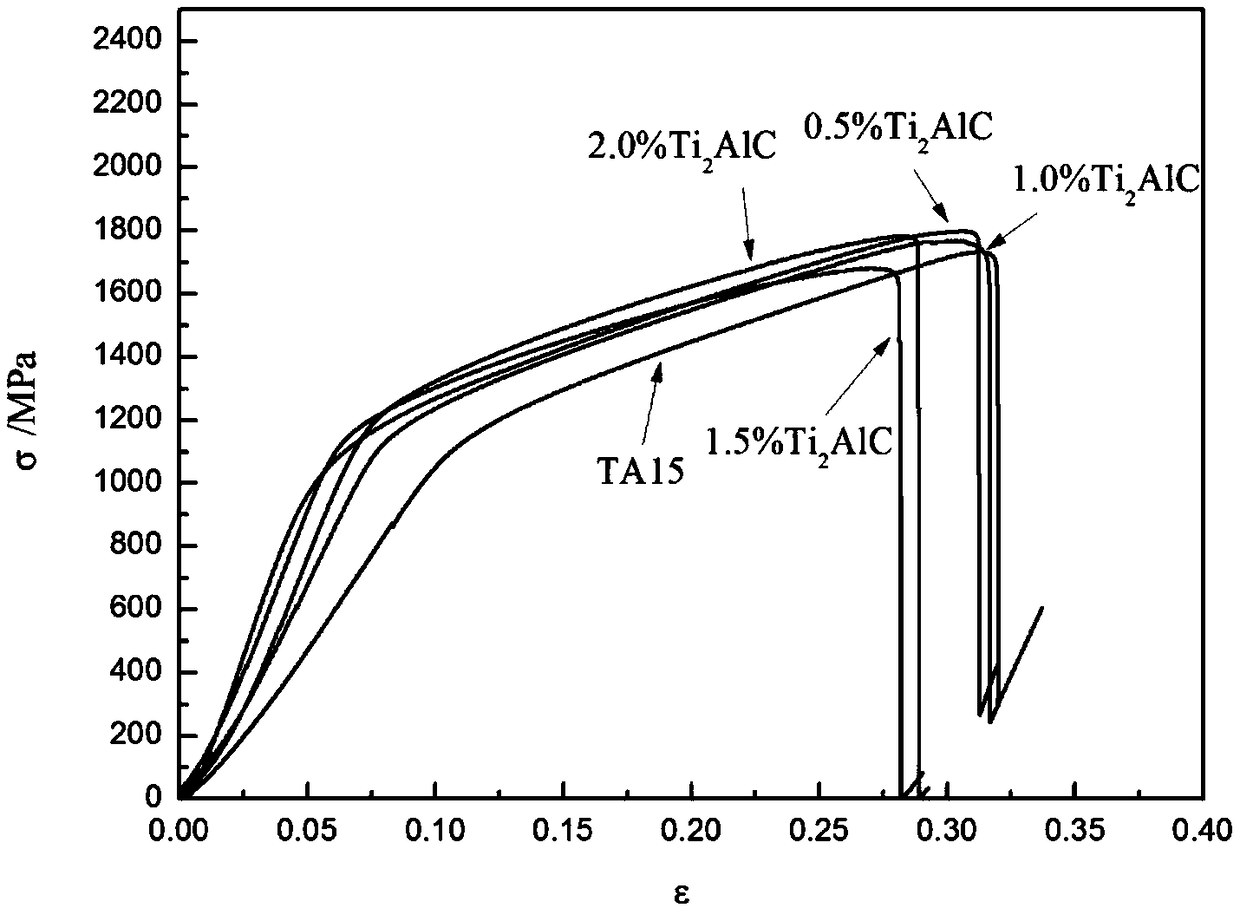

[0043] Production of Ti by hot pressing and sintering 2 AlC reinforced titanium matrix composites, using Ti 2 AlC powder and spherical TA15 powder are used as raw materials. A cylindrical composite material sintered body with a diameter of 20 mm and a height of 12 mm was prepared.

[0044] Specific steps are as follows:

[0045] (1) Weigh 10gTA15 powder (purity is 99%) and mass fraction is the Ti of 1.0wt% 2 AlC powder, first weigh a good Ti 2 Put the AlC powder in a beaker, add absolute ethanol, vibrate for 15 minutes by an ultrasonic oscillator, then add the weighed TA15 powder into the above solution, and repeat the above oscillation operation for 30 minutes.

[0046] (2) Take the preliminarily mixed powder solution and place it in a ball milling tank at a ball-to-material ratio of 10:1. The ball milling medium is absolute ethanol. On a planetary ball mill at a speed of 250r / min, it is rotated forward and backward for 2.5 h procedure, ball milling time is 5h, fully bal...

Embodiment 3

[0051] Production of Ti by Vacuum Pressureless Sintering 2 AlC reinforced titanium matrix composites, using Ti 2 AlC powder and spherical TC4 powder are used as raw materials. A cylindrical composite material sintered body with a diameter of 20 mm and a height of 15 mm was prepared. Specific steps are as follows:

[0052] (1) Weigh 10gTC4 powder (purity is 99%) and mass fraction is the Ti of 1.5wt% 2 AlC powder, first weigh a good Ti 2 Put the AlC powder in a beaker, add absolute ethanol, vibrate for 10 minutes by an ultrasonic oscillator, then add the weighed TC4 powder into the above solution, and repeat the above oscillation operation for 25 minutes.

[0053] (2) Take the preliminarily mixed powder solution and place it in a ball mill tank at a ball-to-material ratio of 10:1. The ball mill medium is absolute ethanol. On a planetary ball mill at a speed of 200r / min, turn forward and reverse for 3 hours. According to the program, the ball milling time is 6h, and the ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com