Testing method for residual stress in aluminum alloy pre-stretched plate

A technology of internal residual stress and pre-stretched plates, applied in the direction of force/torque/work measuring instruments, measuring devices, special data processing applications, etc., can solve problems such as complex calculations and inability to realize finite element calculation strains, and achieve improved testing The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical scheme of the test method for the internal residual stress of the aluminum alloy pre-stretched plate provided by the present invention will be further explained in detail below in conjunction with the accompanying drawings.

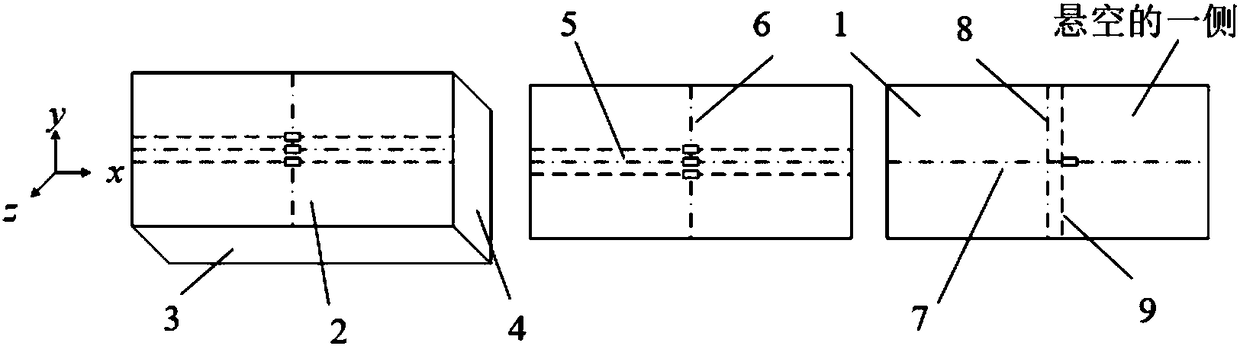

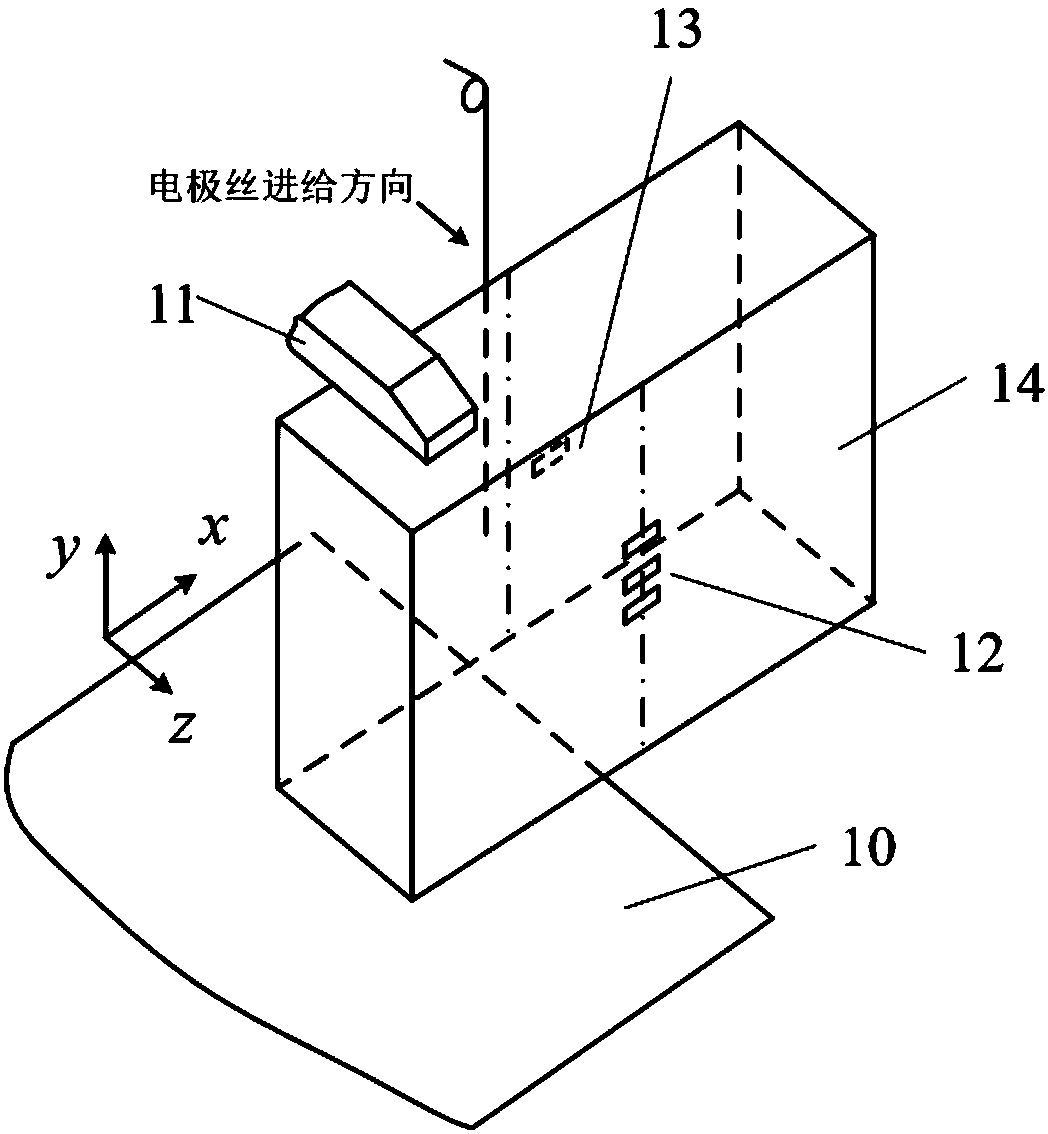

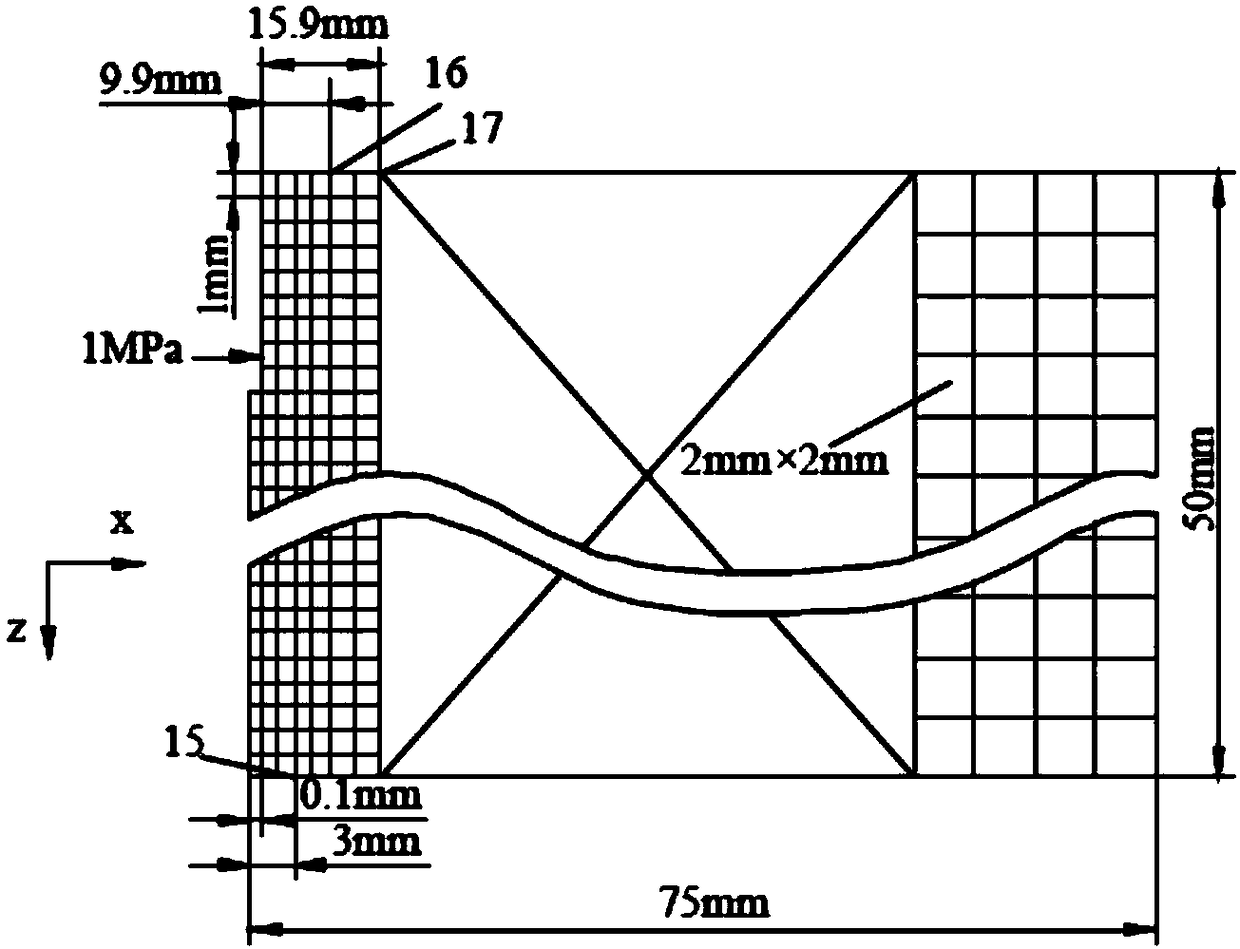

[0048] figure 1 , 2 The preparation of the test piece and the arrangement of the strain gauges in a specific embodiment of the method provided by the present invention are shown. A certain length of pre-stretched plate is taken as a test piece. The length of the test piece is 2 to 2.5 times the thickness of the plate. The length direction of the test piece is parallel to the direction of the stress component to be measured. The surface formed by the length direction and the width direction of the specimen is marked as the front side 1, and the side opposite the front side 1 is marked as the back side 2. A plane formed by the length direction and the thickness direction of the test piece is the first reference plane 3 . A plane form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com