Parameterization numerical control machining method and system for aviation large thin-wall non-rigid part

A processing method, non-rigid body technology, applied in the general control system, control/adjustment system, program control, etc., can solve the problems of processing accuracy, large positioning error, low clamping accuracy, etc., to improve processing accuracy and quality The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

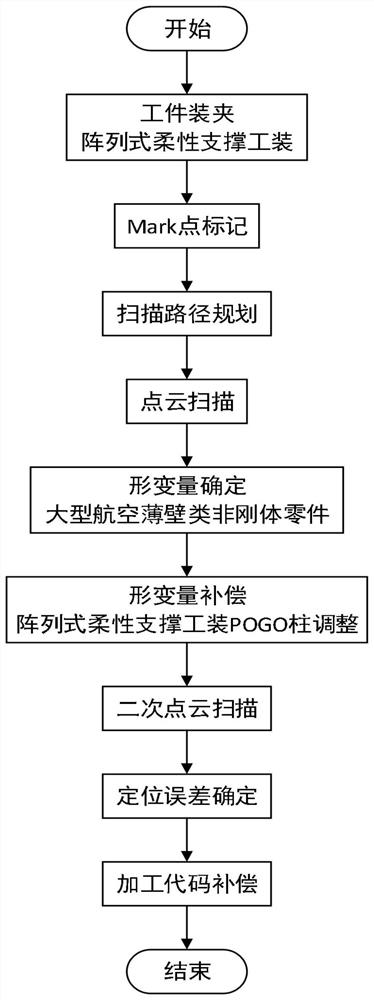

[0093] Such as figure 1 Shown, be the overall technical flow scheme of the present invention, comprise the steps:

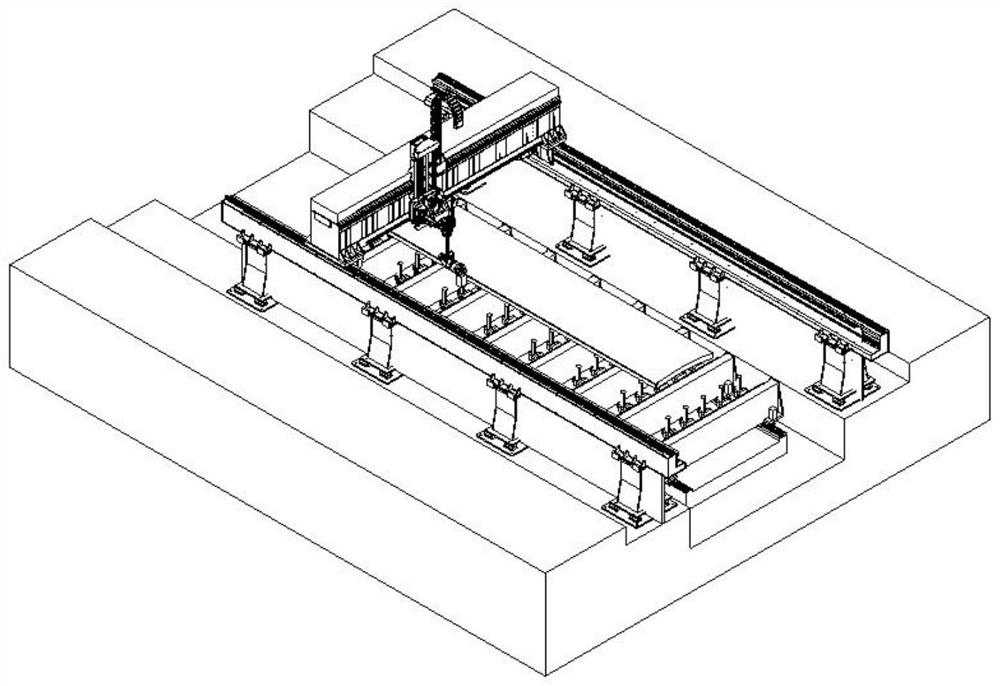

[0094] 1) Combined with the requirements of the processing technology, the large-scale aviation thin-walled non-rigid parts are clamped on the array flexible support tooling.

[0095] In 1), according to the three-dimensional design model of thin-walled parts, the spatial position and support height of each POGO column in the array flexible support tooling are adjusted to realize the clamping and positioning of thin-walled parts under low deformation.

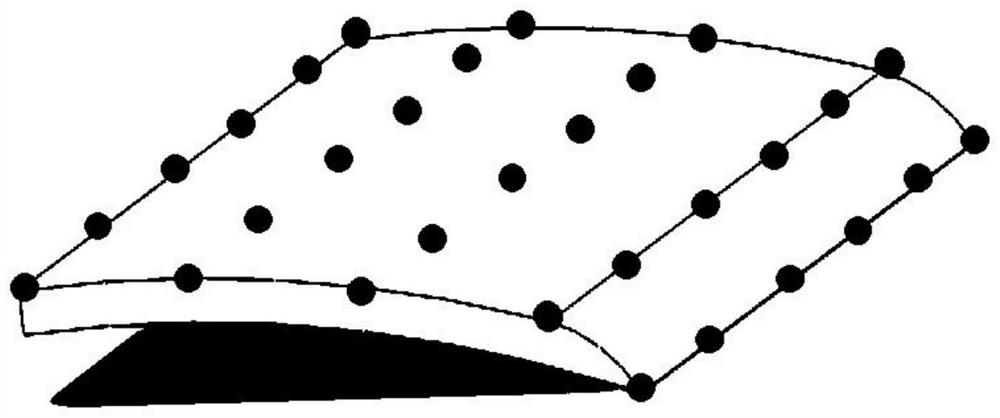

[0096] 2) Combined with the geometric modeling of thin-walled parts, Mark points are marked on the edges and transition vertices of the parts, so as to determine the deformation error and positioning error later. Specific as figure 2 with image 3 shown.

[0097] 3) According to the accuracy, efficiency and safety, combined with the specific parameters of the RGB-D camera, plan the scanning path of large thin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com