Powder-solid coupling forming method for internal complex multi-flow passage piece

A multi-channel, complex technology, applied in the field of aerospace manufacturing, to achieve the effect of fewer processing passes, improved performance, and high material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

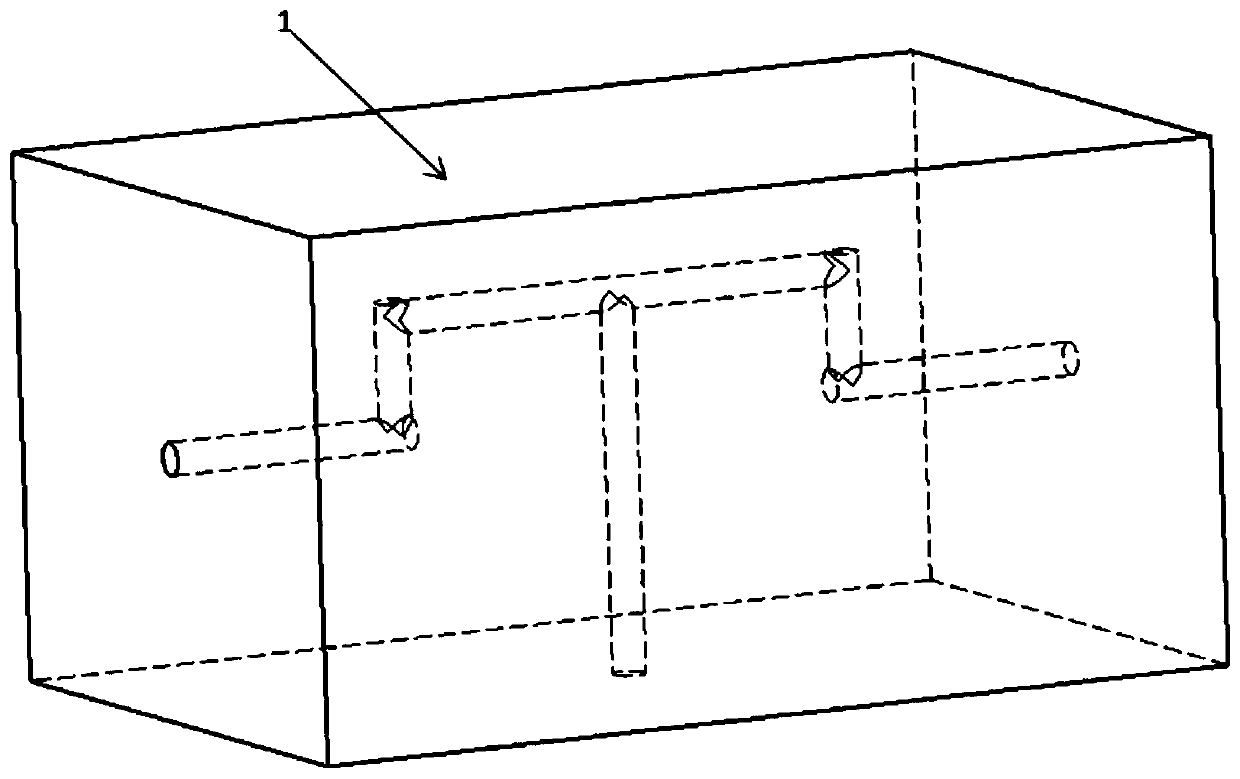

[0031] The typical complex internal multi-channel parts formed by the powder-solid coupling method for alloy complex internal multi-channel parts provided by the present invention will be described in detail below with reference to the drawings and specific embodiments.

[0032] like Figure 1-Figure 6 As shown, the powder-solid coupling method for forming complex internal multi-channel parts of alloys provided by the present invention includes the following steps:

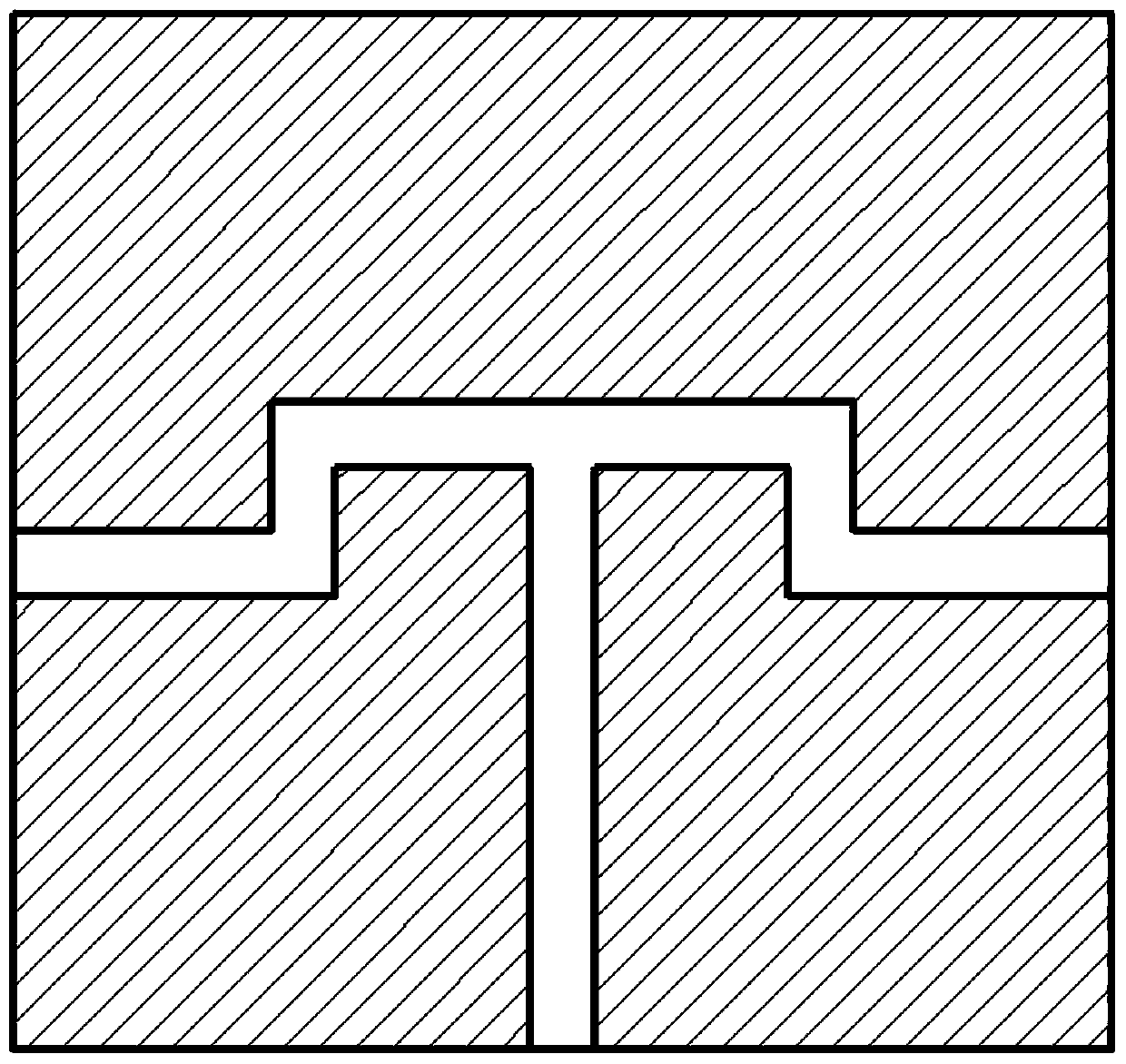

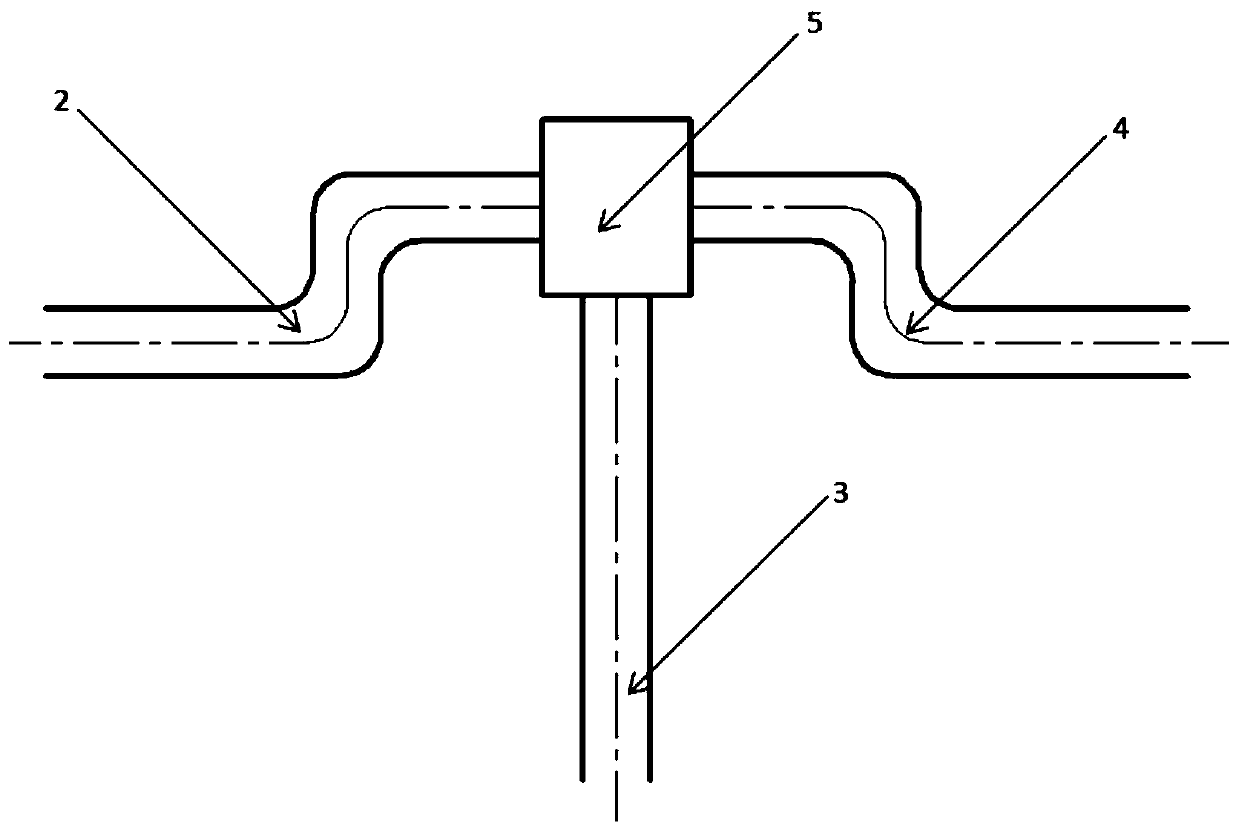

[0033] (1) According to figure 1 The direction of the flow channel of the inner multi-channel member 1 ( figure 2 ) design and prepare the corresponding pipeline 2, pipeline 3, pipeline 4 ( image 3 ) and tee connector 5 ( Figure 4 ), and design the matching solid support block 6 ( Figure 5 ).

[0034] (2) According to the size of the pipeline 2, the pipeline 3 and the pipeline 4, corresponding holes are processed inside the tee connector 5 for subsequent assembly and connection.

[0035] (3) Groove 7 , h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com