Thermal medium variable energy rate surface force loading forming method for fiber metal laminate

A fiber metal laminate and heat medium technology, which is applied in the field of preparation and forming of complex cross-section thin-walled components of fiber metal super-hybrid composite materials, can solve the problem of multi-fluid deformation and curing of fiber resin, difficult to form FMLs components, and large differences in FMLs performance. and other problems, to achieve the effect of high forming limit, low forming limit and small residual stress between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

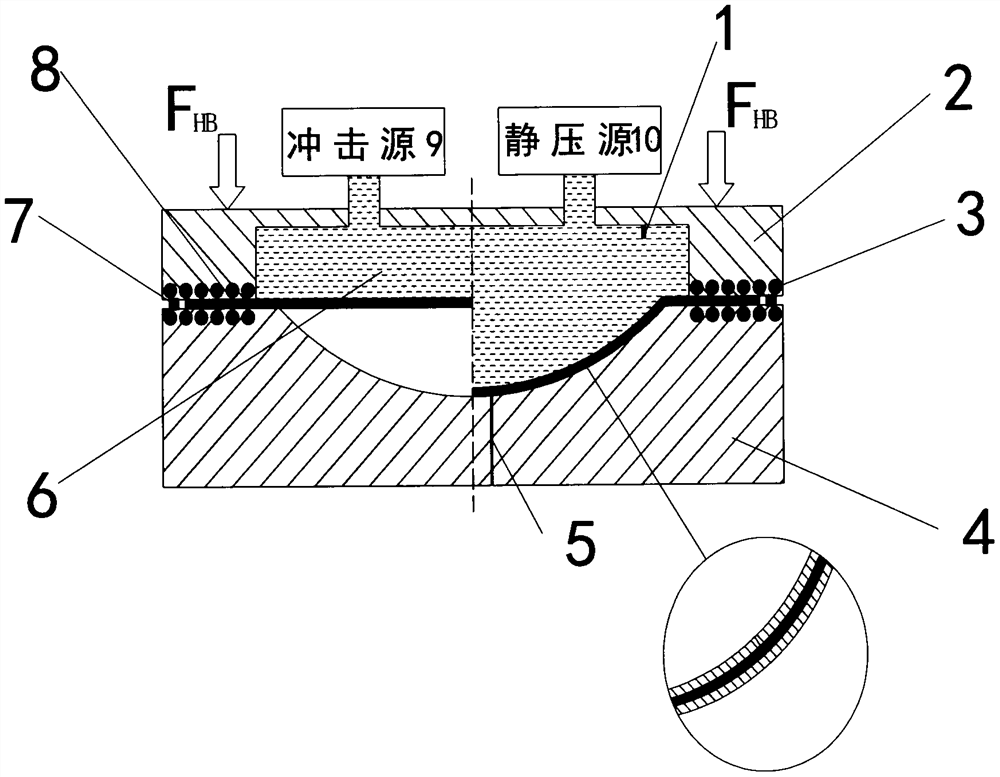

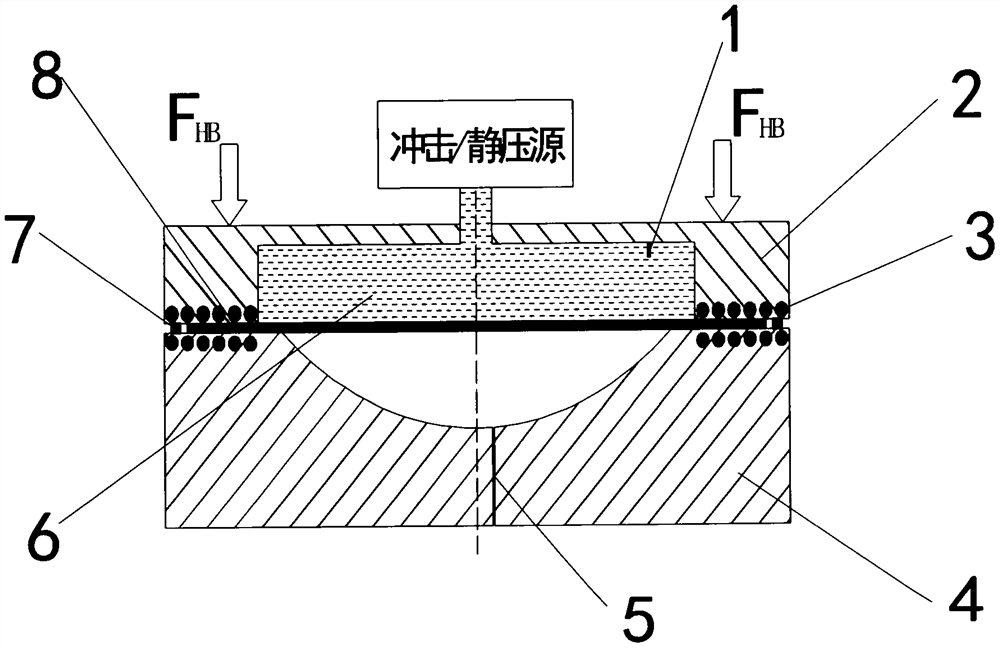

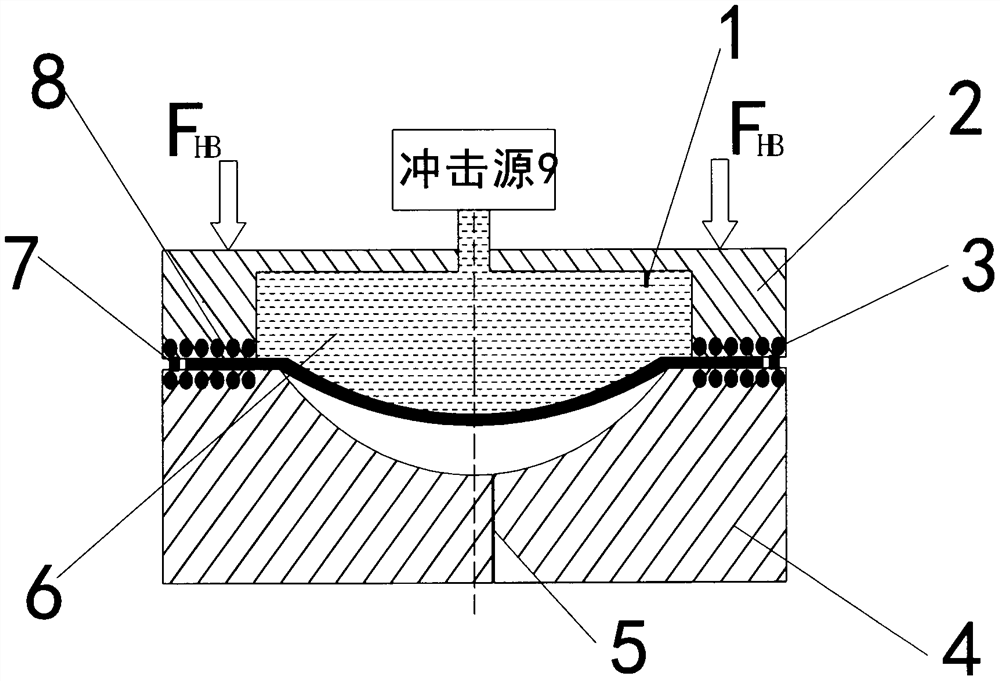

[0024] A method for forming a fiber-reinforced metal laminate under thermal medium variable energy rate surface force loading provided by the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0025] Such as Figure 1-4 As shown, a method for forming a fiber-reinforced metal laminate heat medium with variable energy rate surface force loading provided by the present invention includes the following steps in order:

[0026] 1) After the installation and debugging of the mold is completed, the liquid chamber cavity 6 is cleaned to remove remaining impurities.

[0027] 2) Surface treatment of the metal layer: wipe the surface of the metal plate to remove oil stains, and perform anodic oxidation.

[0028] 3) The blank 8 is placed on the forming mold 4 in sequence, positioned by the positioning device, the blank holder 2 moves downward to close the mold, the sealing ring 7 seals, and the blank holder force presses the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com