Method for preventing 3D printing model from warping in FDM (Fused Deposition Modeling) printing

A 3D printing and model technology, applied in 3D object support structure, additive manufacturing, processing data acquisition/processing, etc., can solve the problem that the printing parameters of printing equipment cannot be set accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

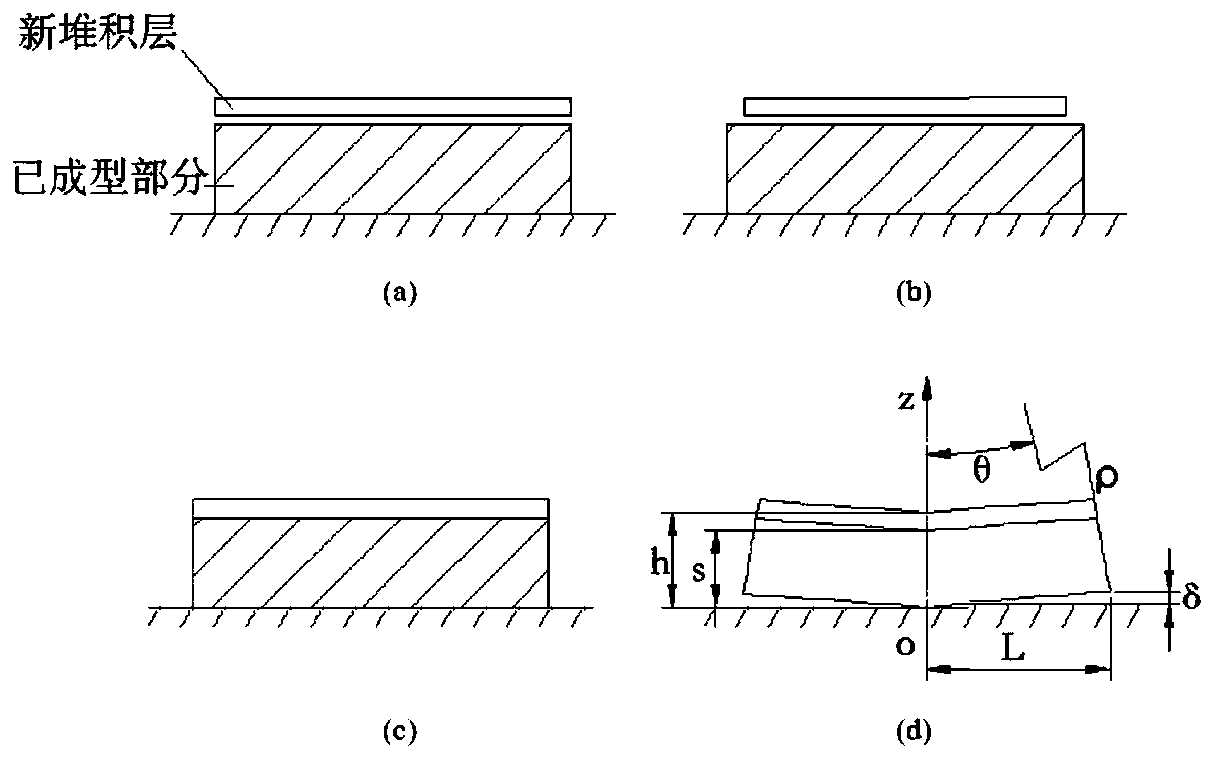

[0022] In the FDM process, the filament in the molten state will pass through the viscous state, the high elastic state, and the glass state during the cooling process. The schematic diagram of the warping deformation of the printed part is shown in figure 1 As shown, picture (a) shows that the new accumulation layer has just been deposited on the printed part (hot bed platform); figure (b) shows the theoretical deformation of the new accumulation layer during cooling from the melting temperature to the glass transition temperature. In fact, this process is due to the In the thermoplastic stage, the new accumulation layer will be stretched by the external force of the lower part of the print, and will be elongated and deformed as shown in figure (c); figure (d) is the deformation of the accumulation layer from the glass transition temperature to the ambient temperature of the molding room. The generation of stress causes the workpiece to warp and deform upward.

[0023] Accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com