Deep microporous ultrasound-assisted electrosparking system based on inner impact liquid of main shaft

A technology of electric spark and liquid flushing, which is applied in the aerospace manufacturing and aviation fields, can solve the problems of decreased processing speed, difficulty in effectively discharging electric corrosion products from the processing area, and poor stability of electric discharge processing, etc., and achieves the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

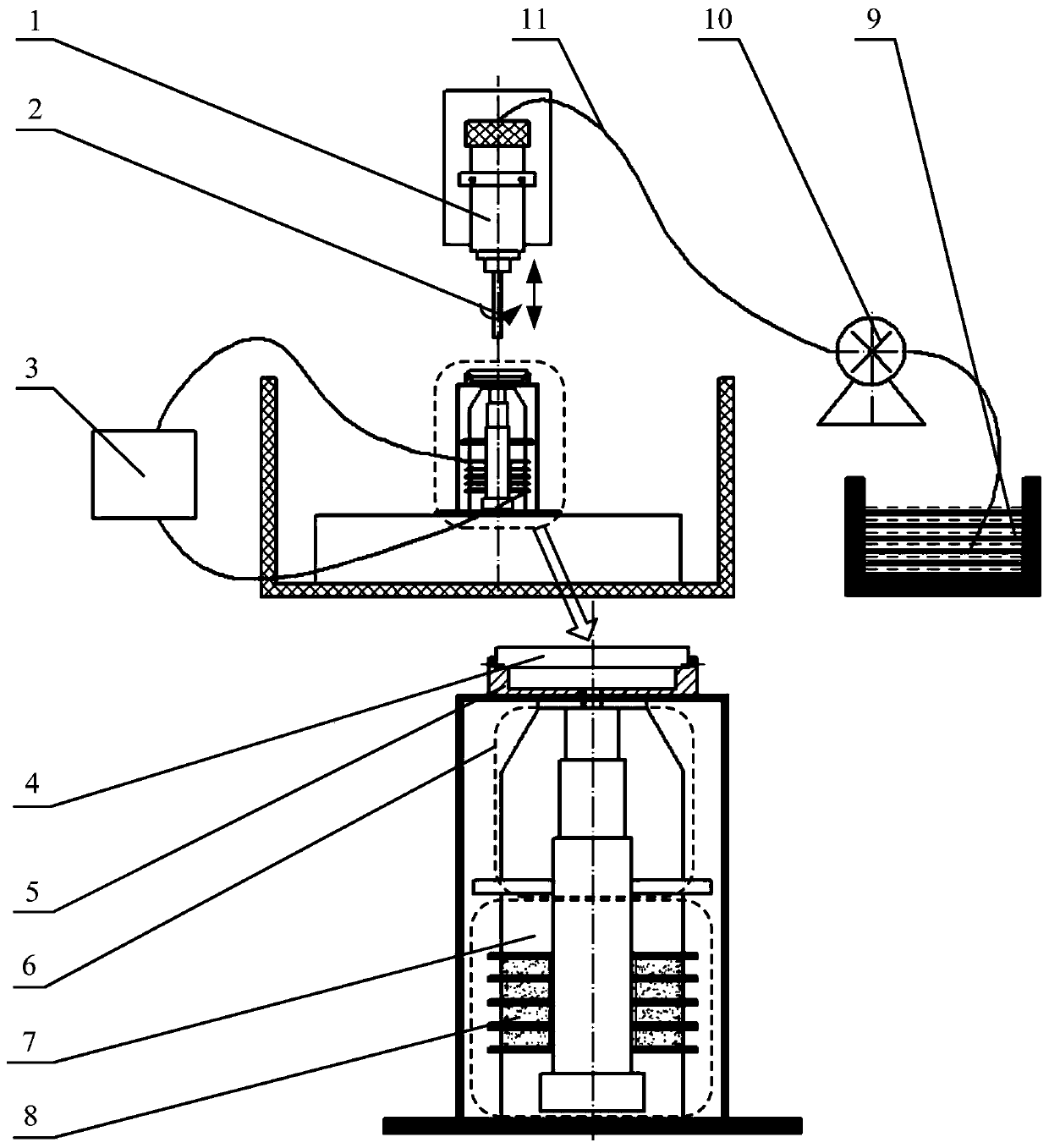

[0029] The present invention is a processing system for improving the stability of deep microhole electric discharge machining and the ratio of small hole depth to diameter by adding an ultrasonic vibration device based on workpiece vibration and a flushing device in the main shaft to the electric discharge machining system. The system is suitable for Micro-hole processing of metal materials with a hole diameter less than 1mm and a depth-to-diameter ratio greater than 10:1.

[0030] The workpiece to be processed is connected to the ultrasonic frequency output end of the ultrasonic vibration device through the tooling, and the ultrasonic frequency vibration of the workpiece is used during EDM to improve the stability of the machining process. The ultrasonic vibration device is composed of an ultrasonic generator, a transducer and a horn. Under the action of the excitation signal of the ultrasonic generator, the transducer converts the electrical energy provided by the ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com