Flexible combined clamping device and clamping method of weak-rigidity composite material parts

A composite material and weak rigidity technology, applied in the direction of workpiece clamping device, positioning device, metal processing machinery parts, etc., can solve the problems of low efficiency and high cost of clamping methods, achieve easy operation, improve flexibility, and facilitate expansion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

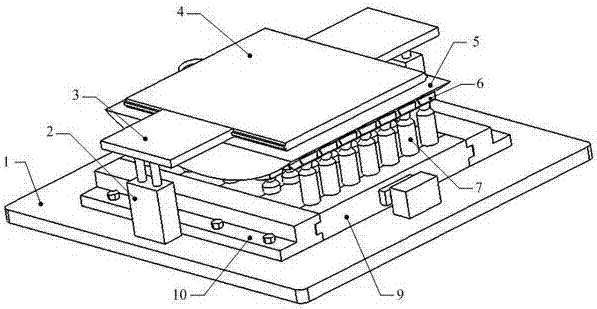

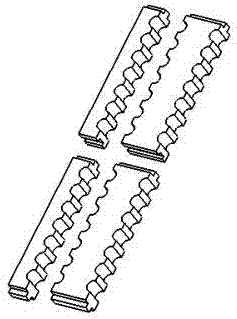

[0032] A flexible combined clamping device for weakly rigid composite material parts, characterized in that it includes a combined base, a flexible support system and a positioning and pressing device, the flexible supporting system is installed on the combined base, and the positioning and pressing device Located above the flexible support system; the flexible support system includes a plurality of support units, each support unit includes a support rod 7, a vacuum chuck 6 and a spring 8, and the two ends of the support rod 7 are respectively connected to the vacuum chuck 6 and the spring 8, and the vacuum chuck 6 is connected to the support rod 7 through a spherical joint. The spherical joint enables the vacuum chuck 6 to adjust its posture with multiple degrees of freedom, so that it fits the surface of the clampable part. The invention can realize fast clamping of weakly rigid composite material parts with different profile features, adapt to different external dimensions ...

Embodiment 2

[0034] A flexible combined clamping device for weakly rigid composite parts includes a combined base, a flexible support system and a positioning and pressing device. The flexible supporting system is installed on the combined base, and the positioning and pressing device is located on the flexible supporting system. Above; the flexible support system includes a plurality of support units, each support unit includes a support rod 7, a vacuum chuck 6 and a spring 8, and the two ends of the support rod 7 are respectively connected with the vacuum chuck 6 and the spring 8, and the The vacuum chuck 6 is connected with the support rod 7 through a spherical joint. The spherical joint enables the vacuum chuck 6 to adjust its posture with multiple degrees of freedom, so that it fits the surface of the clampable part.

[0035] The vacuum chuck 6 is made of rubber material.

[0036] The positioning and pressing device comprises a pressing plate 3, an auxiliary positioning plate 4 and a...

Embodiment 3

[0042] A flexible combined clamping method for weakly rigid composite material parts, comprising the following steps:

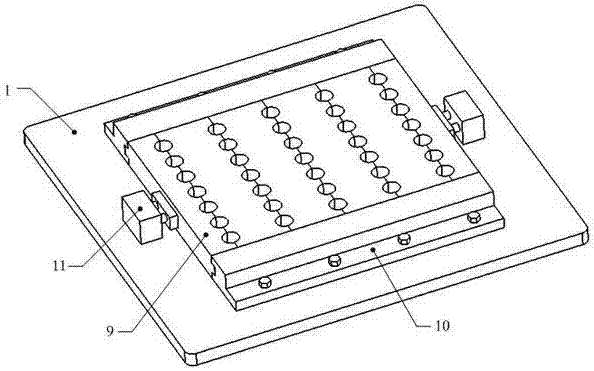

[0043] The first step is to set the perforated base 9 and the flexible support unit according to the size of the part 5 to be processed: select the perforated base 9 and install it on the workbench 1 in combination with the guide block 10, and install hydraulic cylinders on both sides of the perforated base 9 11. Place springs 8, support rods 7 and vacuum suction cups 6 in the holes of the combined perforated base 9 to form a flexible support system;

[0044] The second step is to use the first cylinder 2 to drive the pressing plate 3 and the auxiliary positioning plate 4 to realize the positioning and pressing of the parts: install at least two first air cylinders 2 and the pressing plate 3, place the parts to be processed 5 on the flexible support system, and place the auxiliary positioning The plate 4 is installed on the pressing plate 3, the positioning a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com