Composite material U-shaped long-girder wall plate integral formation method and tool of method

A technology of forming tooling and integral forming, applied in other household appliances, household appliances, household components, etc., can solve the problem of not mentioning the overall curing of reinforced siding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

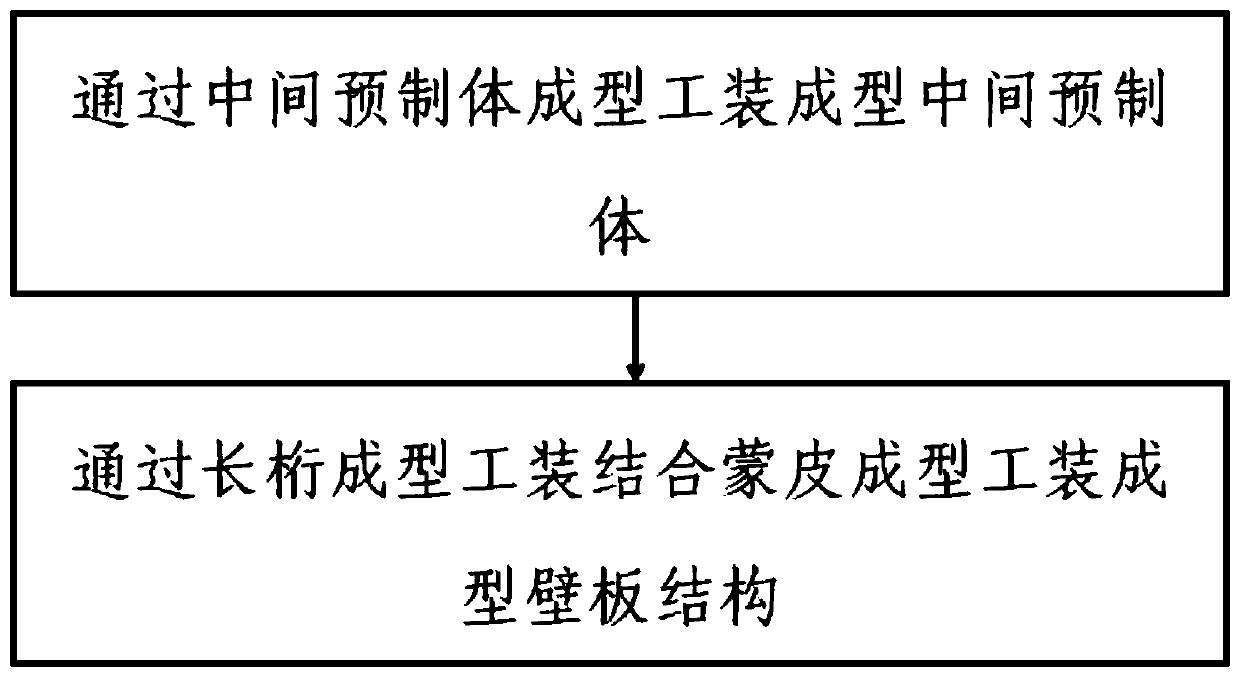

Method used

Image

Examples

Embodiment

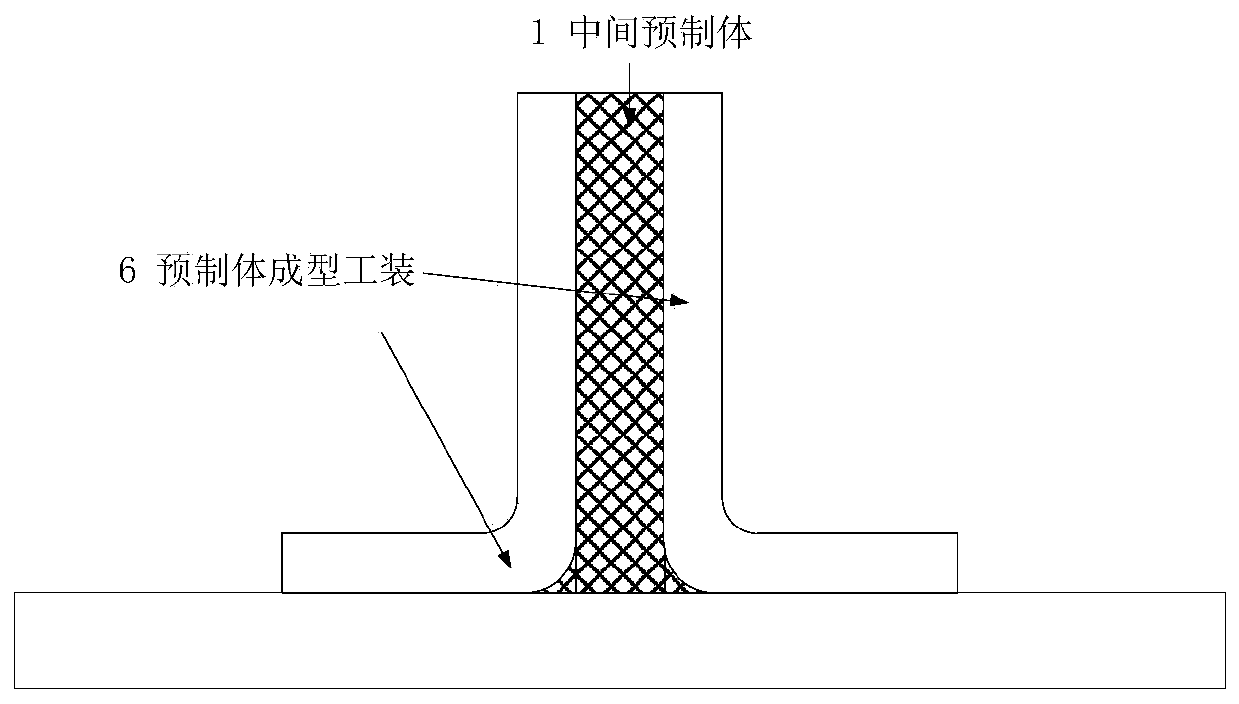

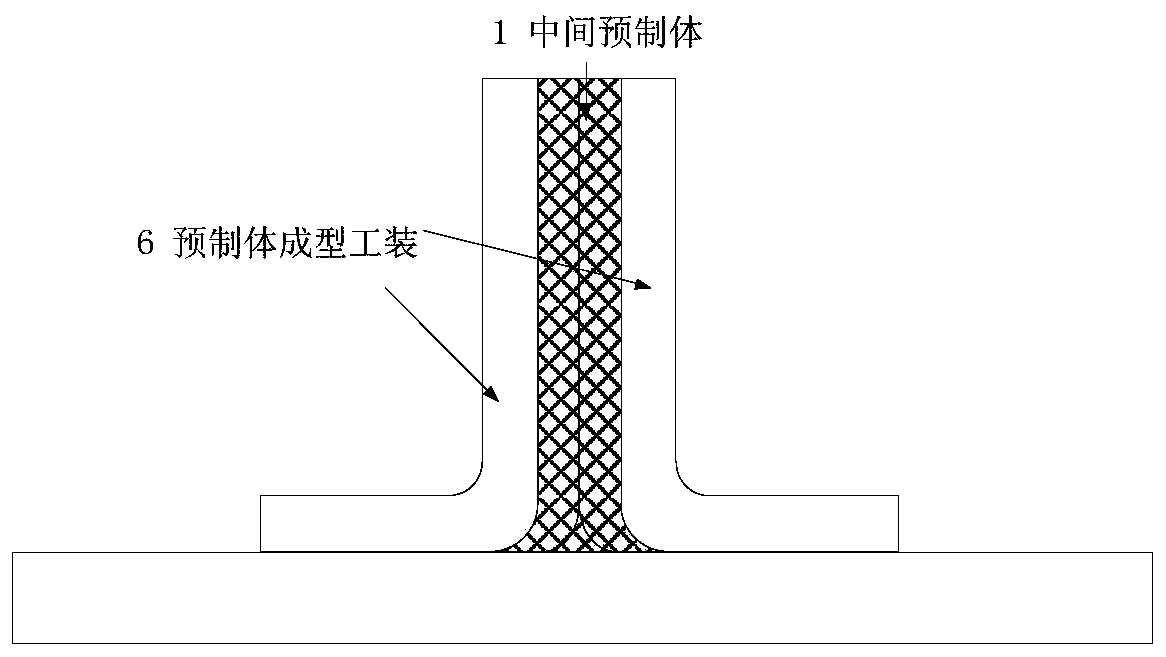

[0076] The present invention involves a total of 5 kinds of intermediate prefabrication structures, and intermediate prefabricated bodies and forming tooling of different configurations are shown in Figure 2- Image 6 shown. In the preform forming process, the preformed intermediate interlayer and the twister strip are combined as required, and then the solidification and forming process is completed under a given temperature and pressure after the overall assembly and packaging of a given forming tool.

[0077] like figure 2 As shown, the I-type intermediate prefab includes a set of intercalation along the web of the girder and two sets of small triangular twist sub-strips.

[0078] like image 3 As shown, the type II intermediate prefab includes two sets of intercalation along the web of the girder and a set of large triangular twist strips.

[0079] like Figure 4 As shown, the type III intermediate prefab includes two sets of intercalation along the web of the girder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com