Infrared thermal wave destructive interference detecting device and method for fiber metal laminate defect using linear frequency modulation pulse coherent laser excitation

A technology of fiber metal laminates and chirps, which is applied in the field of devices for detecting defects in fiber metal laminates, can solve problems such as threats to the safety and reliability of aerospace vehicles, and achieve the effect of reducing performance requirements and increasing the depth range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

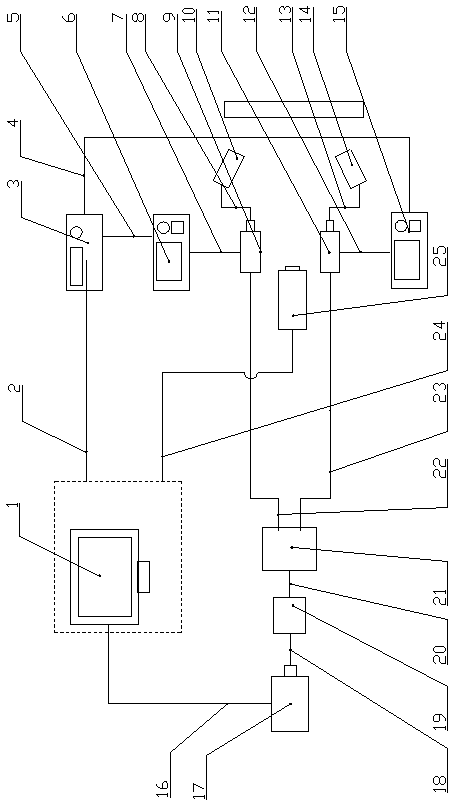

[0029] Specific implementation mode 1: This implementation mode provides a chirp coherent laser excitation infrared thermal wave destructive interference detection device for defects in fiber metal laminates, such as figure 1 As shown, the shown device consists of a computer 1, a first signal line 2, a dual-channel function generator 3, a second signal line 4, a third signal line 5, a first RF drive source 6, a fourth signal line 7, a tenth A signal line 8, a first acousto-optic modulator 9, a first beam expander shaping mirror 10, a second acousto-optic modulator 11, a fifth signal line 12, a twelfth signal line 13, a second beam expander shaping mirror 14, The second RF driving source 15, the sixth signal line 16, the laser 17, the seventh signal line 18, the amplifier 19, the eighth signal line 20, the fiber beam splitter 21, the ninth signal line 22, the tenth signal line 23, the tenth signal line Three signal lines 24 and an infrared thermal imager 25 are formed, wherein:...

specific Embodiment approach 2

[0043] Embodiment 2: This embodiment provides a method for detecting fiber metal laminate defect chirp coherent laser excitation infrared thermal wave destructive interference detection using the device described in Embodiment 1. The steps of the method are as follows:

[0044] Step 1: complete and check the communication connection of each component and element of the device as required;

[0045] The second step: adjust the thermal imaging camera 25 so that the lens of the thermal imaging camera is vertical and facing the part to be tested, and the distance is 30cm;

[0046] The third step: turn on the computer 1, the second beam expander shaping mirror 14, the dual-channel function generator 3, the first acousto-optic modulator 9, the second acousto-optic modulator 11, the infrared thermal imager 25, the amplifier 19, the first The RF drive source 6, the second RF drive source 15, the first beam expander shaping mirror 10, the fiber beam splitter 21, and the laser 17 is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com