Novel fiber metal laminate and preparation method thereof

A fiber metal, laminate technology, applied in the direction of metal layer products, chemical instruments and methods, lamination, etc., can solve the problems of weak interface bonding performance, laminate damage tolerance, interlaminar shear performance, etc. Improved fatigue performance, improved interlaminar shear performance, and uniform distribution of internal tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and technical solutions.

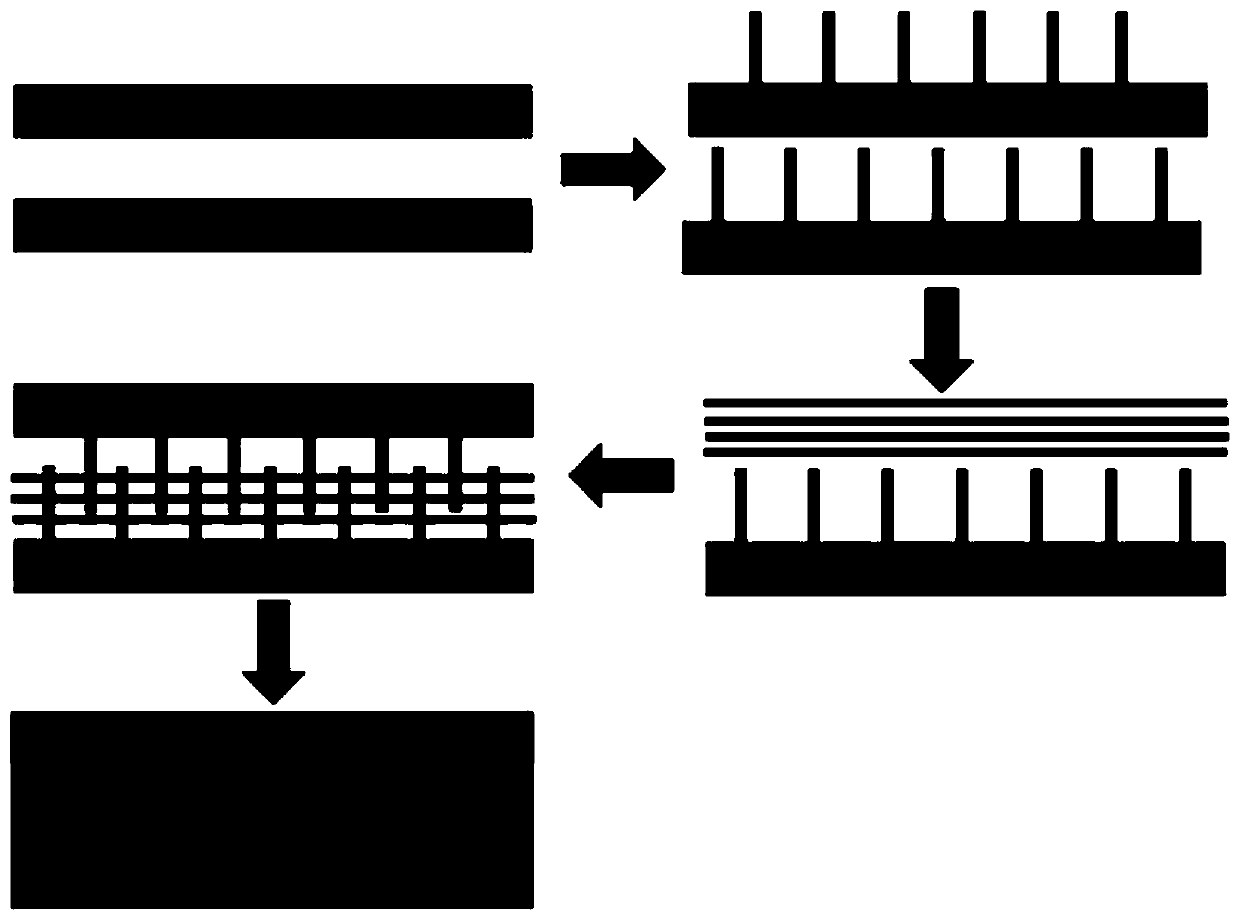

[0025] Such as figure 1 As shown, the fiber metal laminate is composed of upper and lower surfaces with "raised" structures and a middle prepreg layer. The preparation method of novel fiber metal laminated board shown in the present invention comprises the following steps:

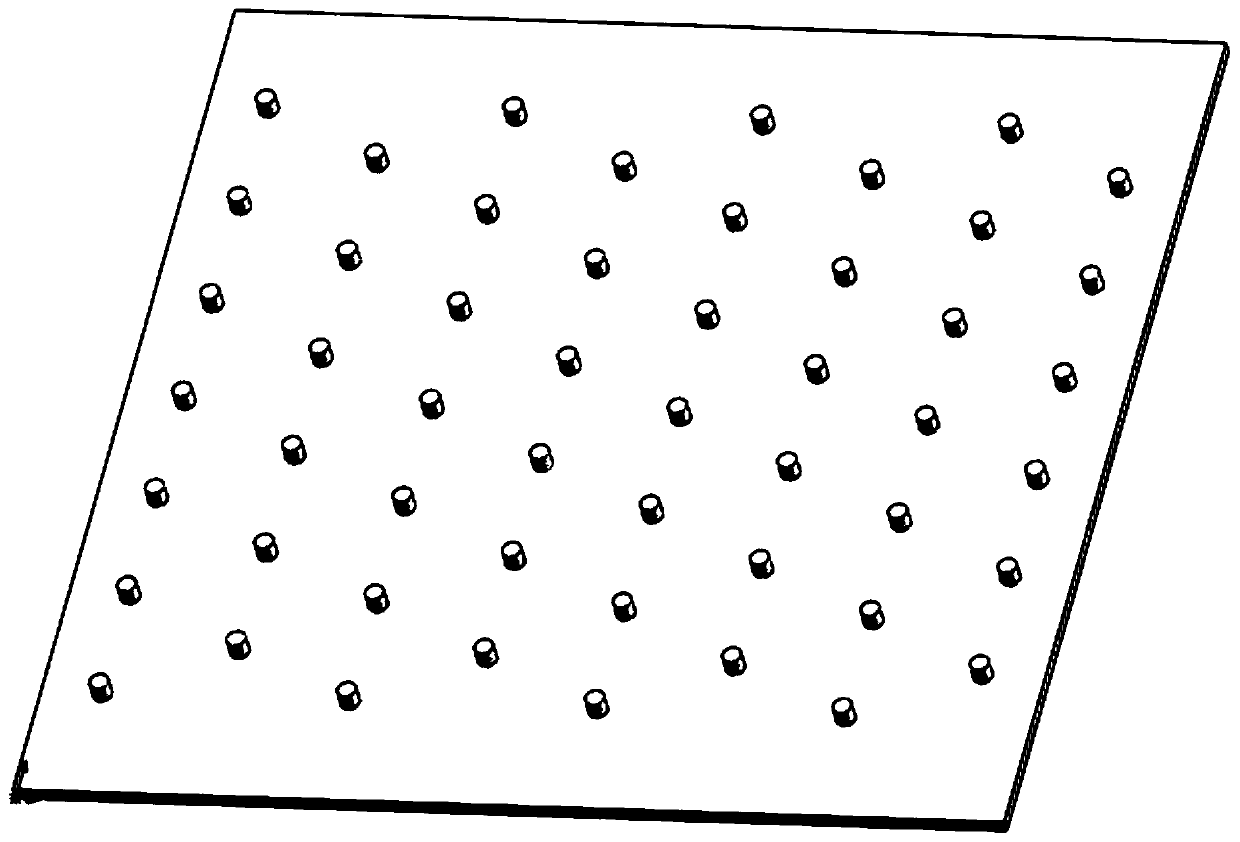

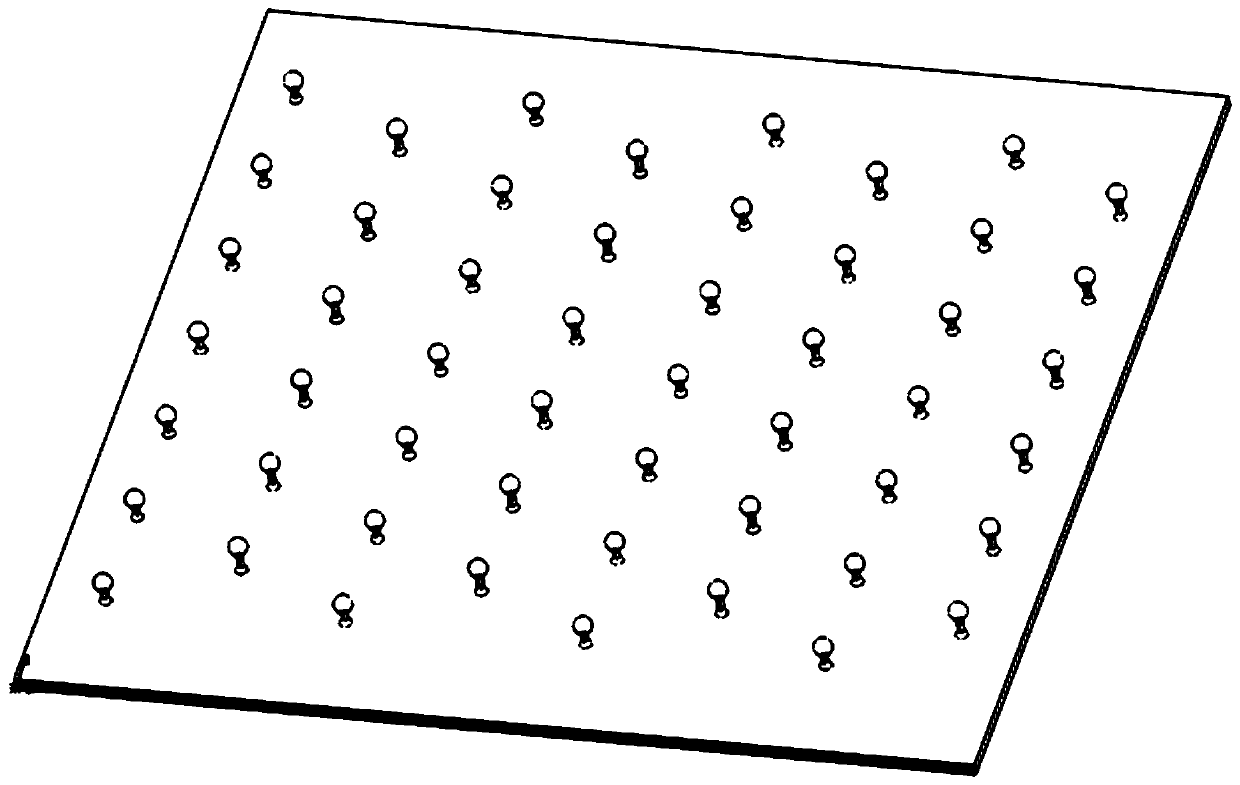

[0026] Step (1): Use 3D printing technology to print a thin metal plate with a "protrusion" structure, as shown in Figure 2, the size of the metal plate is 80×80×1mm, the "protrusion" structure is a cylinder, and the "protrusion" structure is a cylinder. The diameter of the "structure is 1.5mm, the height is 2mm, and the spacing of the "protrusion" structures is 10mm. The metal plate is cut into samples with a size of 80×10×1mm by wire cutting.

[0027] Step (2): The prepreg is made of T300 plain weave prepreg, and the prepreg is cut on the workbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com