Carbon fiber metal laminate

A carbon fiber and metal plate technology, applied in the direction of metal layered products, layered products, synthetic resin layered products, etc., can solve the problems of fatigue, high fracture toughness and machinability, and achieve high fracture toughness and high fracture toughness And machinability, high specific strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

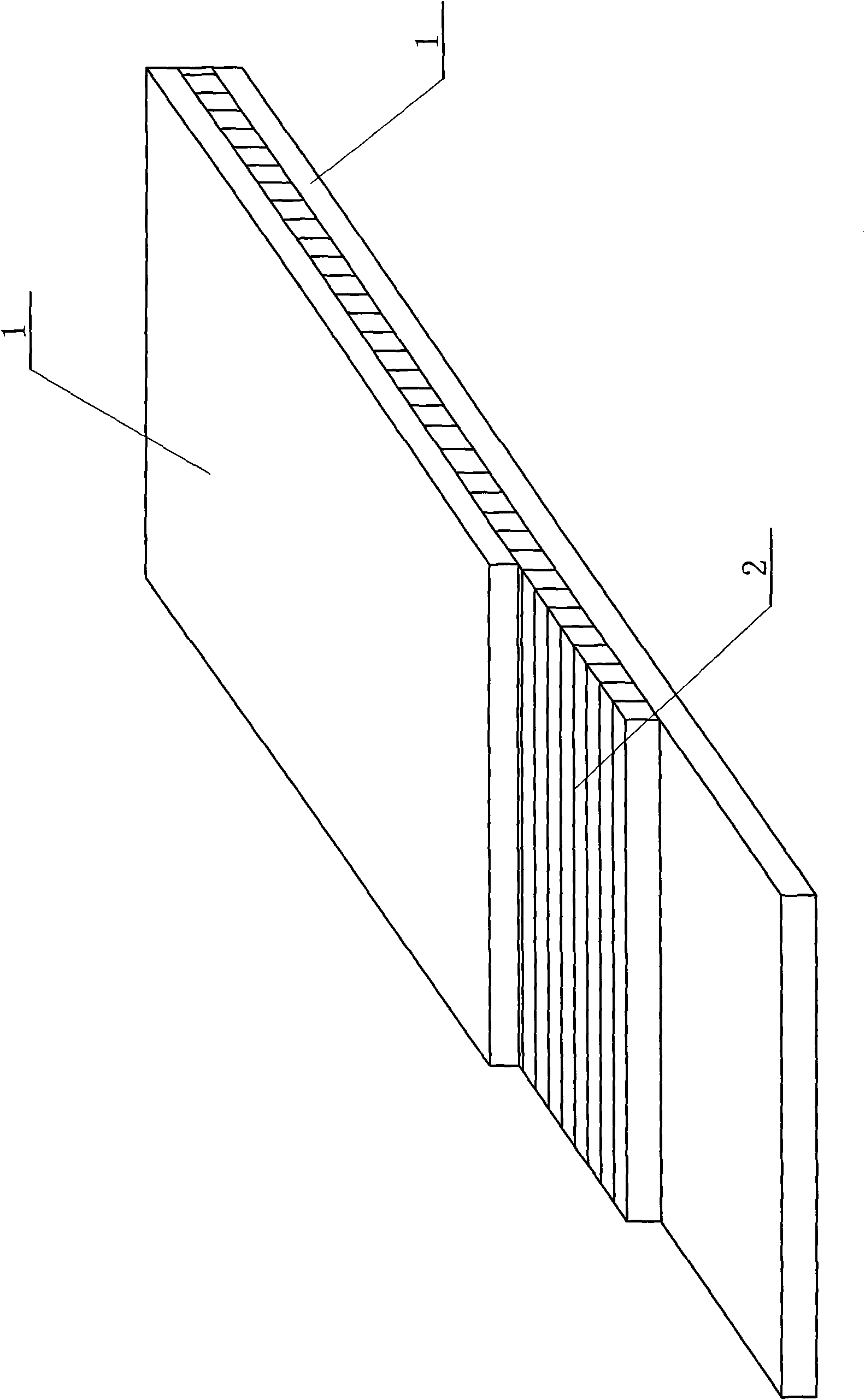

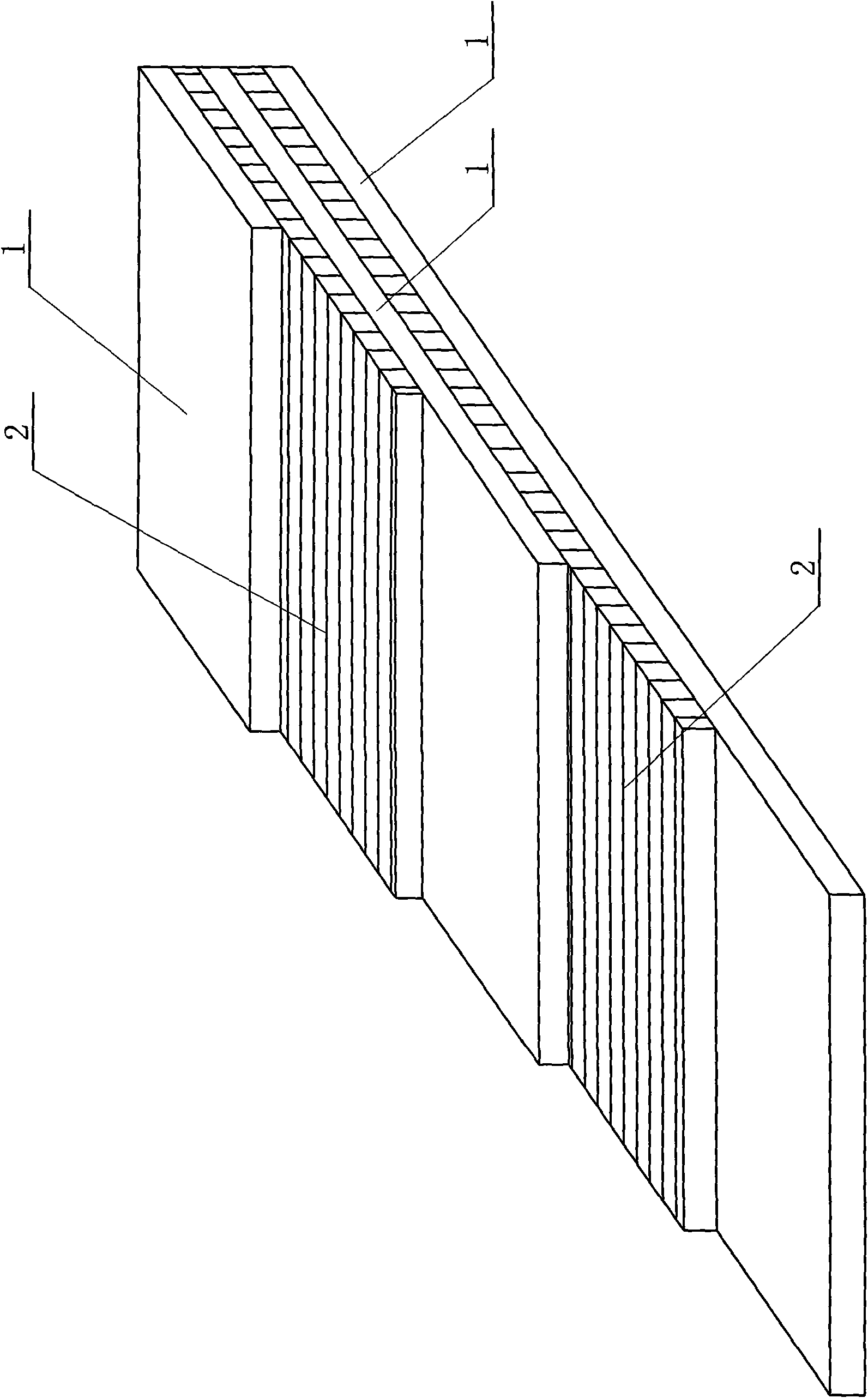

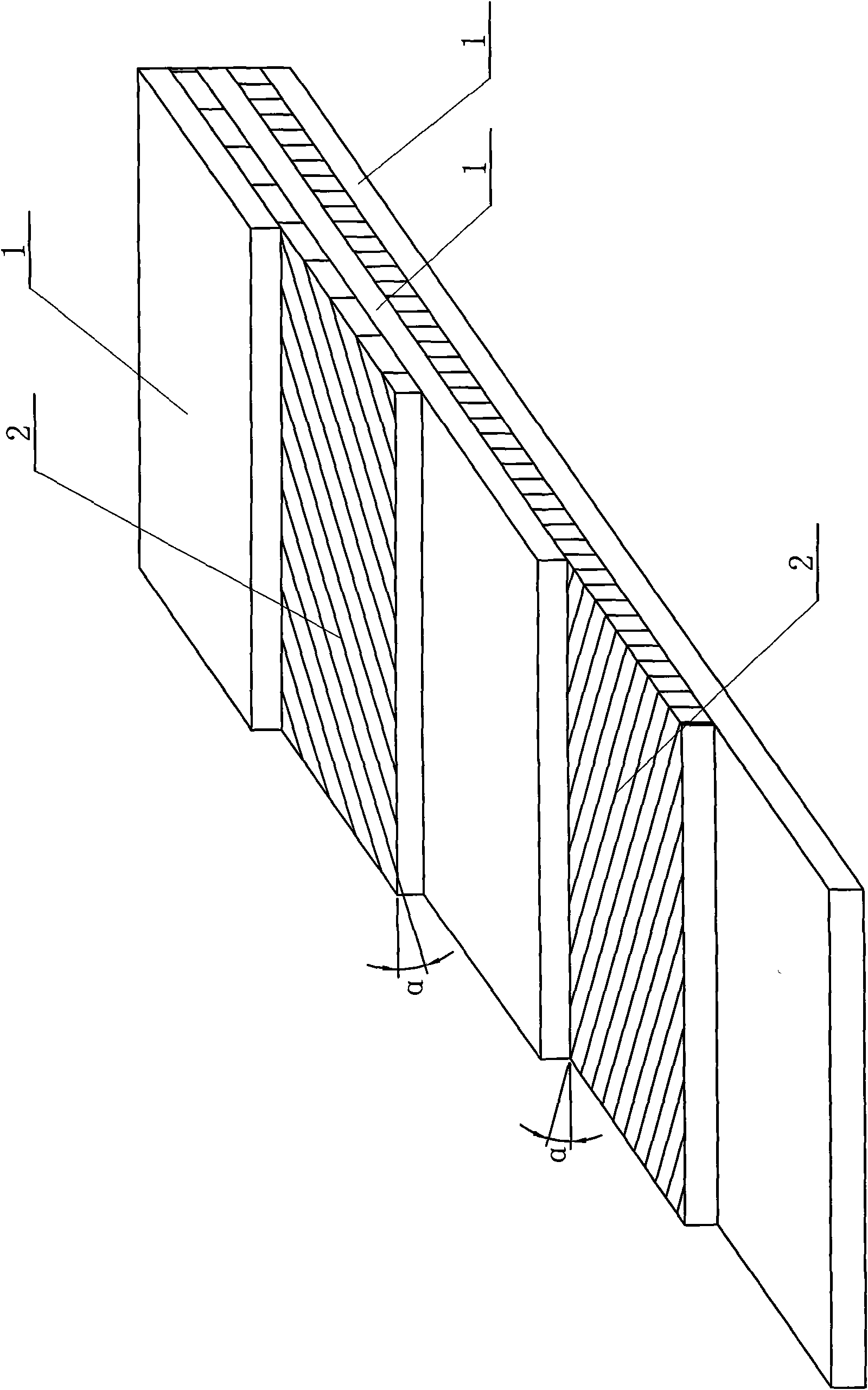

[0008] Specific implementation mode one: combine Figure 1 to Figure 5 To illustrate this embodiment, the laminated plate of this embodiment is composed of at least two metal plates 1 and at least one layer of carbon fiber composite material 2; the at least two metal plates 1 are stacked together, A layer of carbon fiber composite material layer 2 glued to the two adjacent metal plates 1 is laid between them, the thickness of the metal plate 1 is 0.2 mm to 0.4 mm, and the thickness of the carbon fiber composite material layer 2 is 0.15 mm. The carbon fiber model in this embodiment is T300, T700, T800 or T1000.

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 This embodiment will be described. In this embodiment, there are two metal plates 1 and one carbon fiber composite material layer 2 . Such arrangement has higher specific strength and higher specific rigidity, and at the same time has higher fracture toughness and workability. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 2 to Figure 5 This embodiment will be described. In this embodiment, there are three metal plates 1 and two carbon fiber composite material layers 2 . Such setting not only has high specific strength and high specific stiffness, but also has high fracture toughness and workability. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com