Semi-curing forming process for thermosetting fiber metal laminate

A technology of fiber metal laminates, forming process, applied in the direction of lamination, lamination device, anodizing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

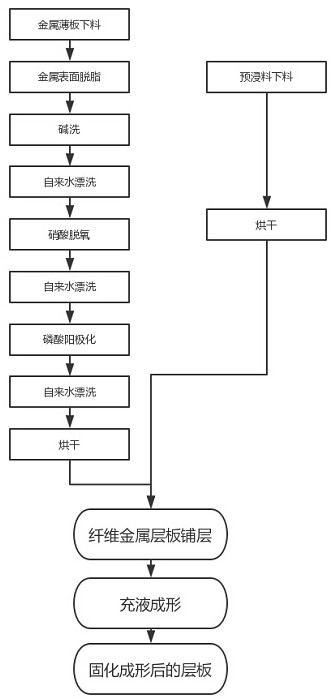

[0026] A kind of semi-solidified fiber metal laminate forming process of the present invention, the steps are:

[0027] 1) Pretreatment of sheet metal: including surface decontamination and chemical oxidation. ① Degrease the metal surface with acetone; ② Alkaline wash with 60° sodium hydroxide and sodium carbonate aqueous solution; ③ Rinse with tap water; ④ Deoxidize with nitric acid; ⑤ Rinse with tap water; ⑥ Phosphoric acid anodization;

[0028] 2) The aluminum alloy plate after phosphoric acid anodization can be laminated with glass fiber prepreg. Layers should be laid at the angle of laying. Care should be taken to prevent the generation of air bubbles during the laying process. Use rollers or heavy objects to compact the laminates and discharge the air bubbles between layers.

[0029] 3) To seal around the sheet, use a plastic film with low strength. The purpose is to prevent the hydraulic oil from entering the fiber layer to contaminate the sheet and affect the performa...

Embodiment 2

[0034] A kind of semi-solidified fiber metal laminate forming process provided by the invention comprises the following steps carried out in order:

[0035] 1) Pretreatment of aluminum alloy 2024-T3 sheet: including surface decontamination and chemical oxidation. ① Degrease the surface of the aluminum alloy plate with acetone; ② Alkaline wash with 60° sodium hydroxide and sodium carbonate aqueous solution; ③ Rinse with tap water; ④ Deoxidize with nitric acid; ⑤ Rinse with tap water; ⑥ Phosphoric acid anodization; .

[0036] 2) The aluminum alloy plate after phosphoric acid anodization treatment can be laminated with glass fiber prepreg. First, a layer of J133 adhesive is applied on the aluminum alloy surface, and then the glass fiber prepreg is cut and dried. , Lay the layers according to the specified angle of laying. Care should be taken to prevent the generation of air bubbles during the laying of the layers. Use rollers or heavy objects to compact the laminates so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com