Method for significantly improving metal joint strength by using metal complex

A technology of metal complexes and metal glues, applied in metal material coating process, anodic oxidation, electrolytic coating, etc., can solve the problems of high temperature resistance, improve interface performance, simple preparation process, and controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

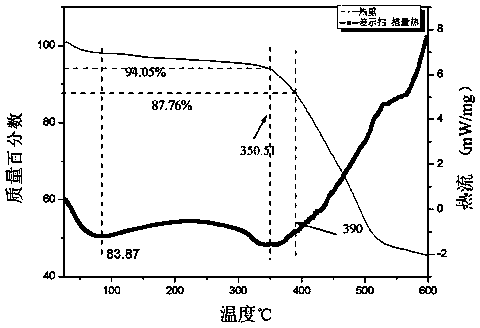

Examples

Embodiment 1

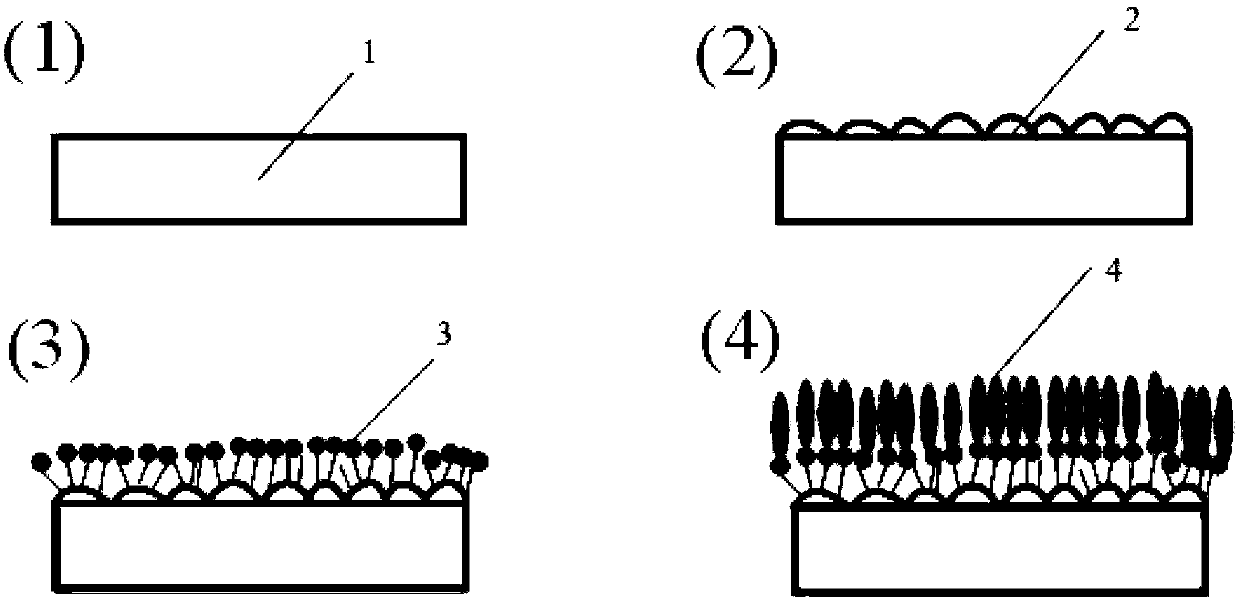

[0031] The first step is metal pretreatment. Cut a TC4 titanium plate of appropriate size, wash it with distilled water, and put the sample into acetone to clean it to remove oil; Rinse the sample with clean water and then transfer it to acid solution for cleaning for about 40 seconds to remove the oxide film on the surface of the TC4 titanium plate.

[0032] The second step is metal anodizing. Preparation of electrolyte: sodium hydroxide 300g / L, sodium tartrate 65g / L, ethylenediaminetetraacetic acid 30g / L, sodium silicate 6g / L. A TC4 titanium plate is used as the anode, and a stainless steel of the same size is used as the cathode, and the distance between the cathode and the anode is fixed at 3 cm. The voltage of the DC power supply during anodizing is 10V-15V, and the time is 10min-20min.

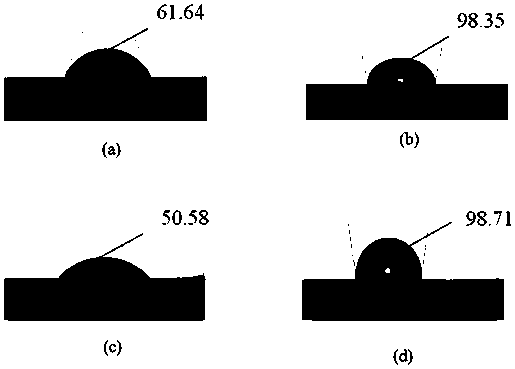

[0033] The third step is the hydroxylation of the metal surface. Configure Piranha solution, where H 2 SO 4 with H 2 o 2 The volume ratio of the solution is 7:3. Immerse the tre...

Embodiment 2

[0039] The first step is metal pretreatment. Cut a TC4 titanium plate of appropriate size, wash it with distilled water, and then put the sample into an acetone solution to clean it to remove oil stains; Rinse the sample with clean water and then transfer it to acid solution for cleaning for about 40s to remove the oxide film on the surface of the TC4 titanium plate.

[0040] In the second step, the metal surface is hydroxylated. Configure Piranha solution, where H 2 SO 4 with H 2 o 2 The volume ratio of the solution is 7:3. Immerse the treated TC4 in the above solution, treat it at a high temperature of 90°C for about 5 minutes, take out the metal plate, rinse it with distilled water several times, dry it, and set it aside.

[0041] The third step is to prepare Schiff base complexes and Schiff base titanium complexes. Weigh 9.4g (0.04mol) of 3,5-di-tert-butylsalicylaldehyde in 60mL of absolute ethanol, dissolve under magnetic stirring under reflux, and quickly drop 1.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com