Assessment and test method and device for I-type interlaminar fracture toughness GIC of fiber-metal laminates (FMLs)

A fiber metal laminate and interlaminar fracture toughness technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, which can solve the problems of significant anisotropy, large test error, and small extensibility of composite materials, and improve the The effect of interlayer interface performance, avoidance of out-of-plane displacement, and simple test operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

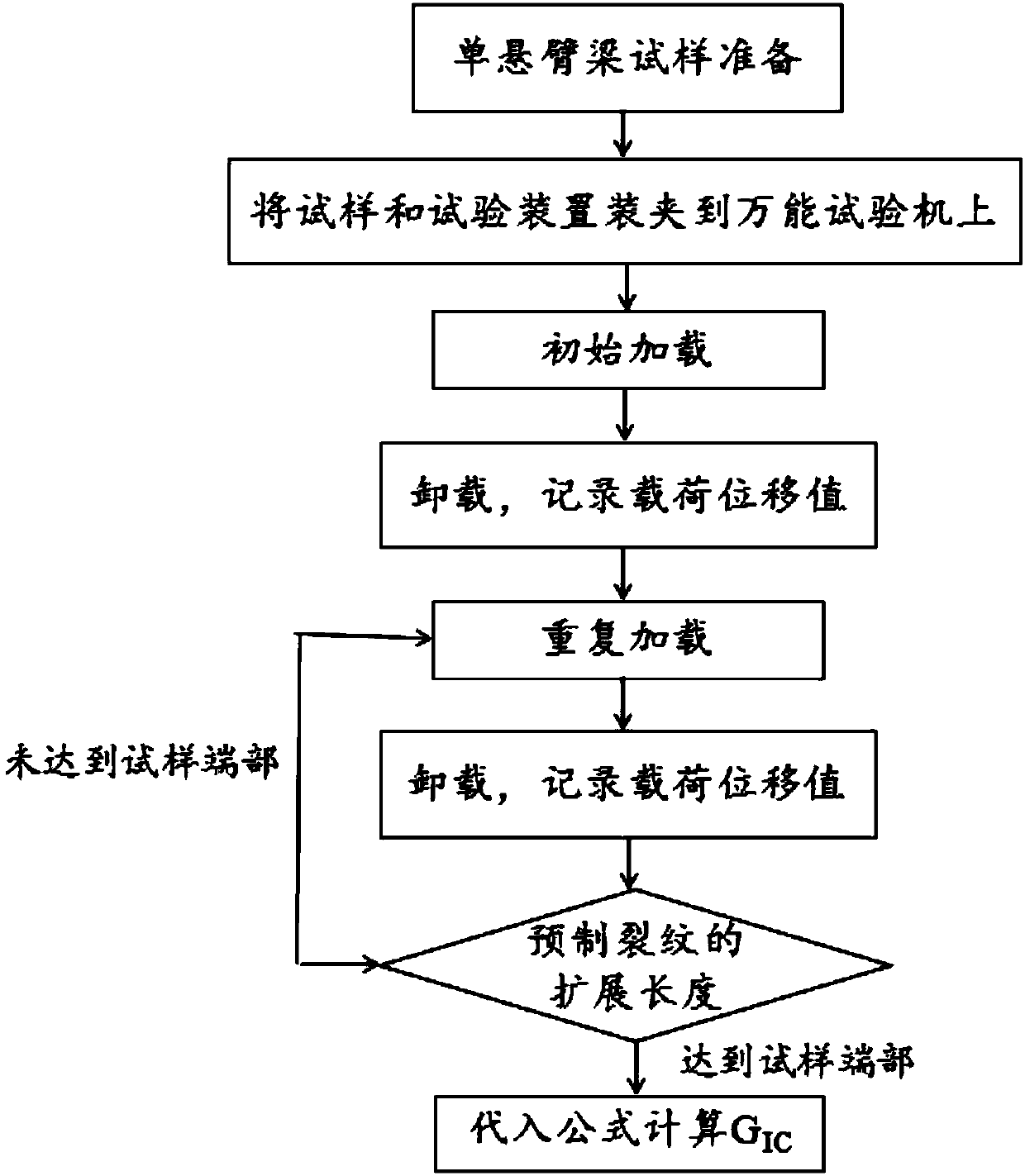

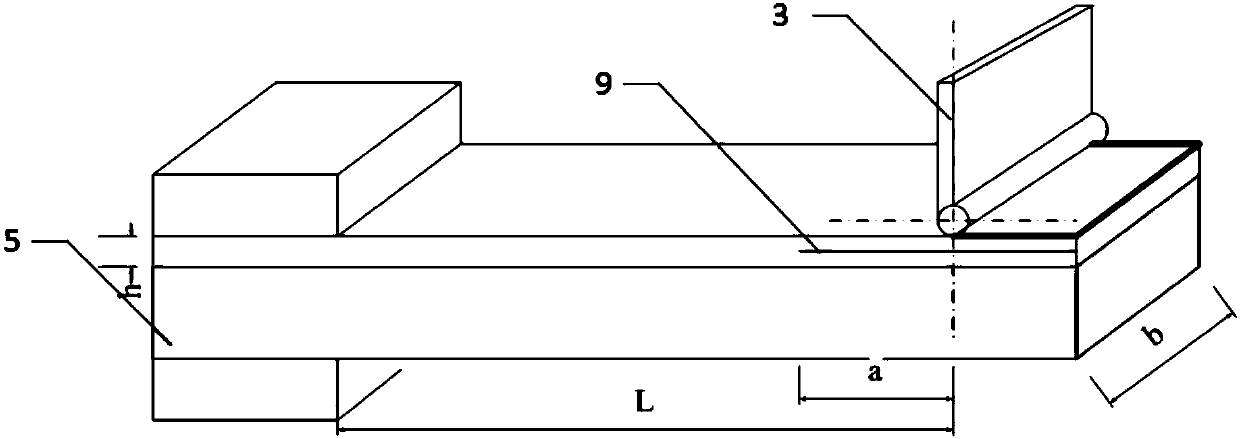

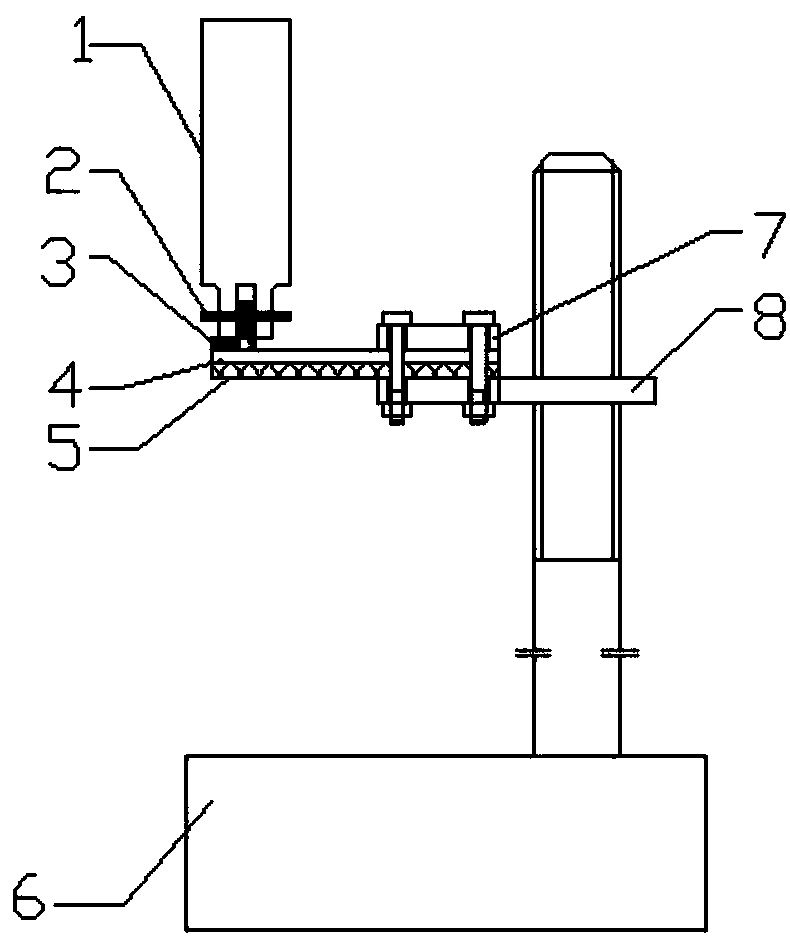

[0041] The first step is the single cantilever beam sample preparation, select Al alloy thin plate and polypropylene fiber reinforced polypropylene composite material 0° / 90° alternate lamination 4 / 3 structure laminate, the length of the laminate is 200mm, the width is 20mm; the first layer The interface between Al alloy and polypropylene fiber reinforced polypropylene composite material was put into a 55 mm long aluminum foil as a prefabricated crack, and a 3 mm thick glass fiber reinforced plastic laminate was bonded to the lower surface of the Al plate to enhance the rigidity of the sample. Connected to one end of the prefabricated crack in the laminate for applying load displacement;

[0042] The second step is to clamp the prepared single cantilever beam sample to the clamping device, start the universal testing machine, load the sample at a constant rate of 3mm / min (pull upward), and continuously record the load and displacement values. Record the location of the crack. ...

Embodiment 2

[0048] The first step is to prepare the single cantilever beam sample, select the composite material composed of Ti alloy thin plate and polyimide resin, the length of the laminate is 180mm, and the width is 25mm; put the aluminum foil with a length of 50mm at the interface between the Ti plate and the resin as a prefabricated crack, use Araldite epoxy resin bonded glass fiber / epoxy resin honeycomb to the lower Ti board, and bonded the piano hinge to one end of the prefabricated crack in the laminate for applying load displacement;

[0049] In the second step, the prepared single cantilever beam sample is clamped on the clamping device, and the universal testing machine is loaded at a constant rate of 1 mm / min, and the load and displacement values are continuously recorded, and the crack position is recorded. Stop loading when the length of the crack outside the pre-crack reaches 3mm-5mm; unload at a constant rate lower than 25mm / min, after unloading, mark the tip of the pre-...

Embodiment 3

[0055] The first step is the preparation of the single cantilever beam sample. Select the 3 / 2 structural laminate of Al alloy thin plate and glass fiber reinforced epoxy resin composite material with 0° unidirectional lamination. The length of the laminate is 180mm and the width is 25mm; the length of the interface is 50mm polytetrafluoroethylene film is used as the prefabricated crack, Araldite epoxy resin is used to bond the glass fiber / epoxy resin honeycomb to the lower Al plate, and the piano hinge is bonded to one end of the prefabricated crack in the laminate for applying load displacement;

[0056] In the second step, the prepared single cantilever beam sample is clamped on the clamping device, loaded at a constant rate of 5mm / min, the load and displacement values are continuously recorded, and the crack position is recorded. Stop loading when the length of the crack outside the pre-crack reaches 3mm-5mm; unload at a constant rate lower than 25mm / min, after unloading, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com