Ultrahigh molecular weight polyethylene fiber reinforced fiber metal laminate and preparation method thereof

A fiber metal laminate and polyethylene fiber technology, applied in the field of composite material manufacturing, can solve the problems of low elongation, long hot pressing time, brittle fiber, etc., and achieve high fiber shear strength, high work efficiency, and fiber toughness. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

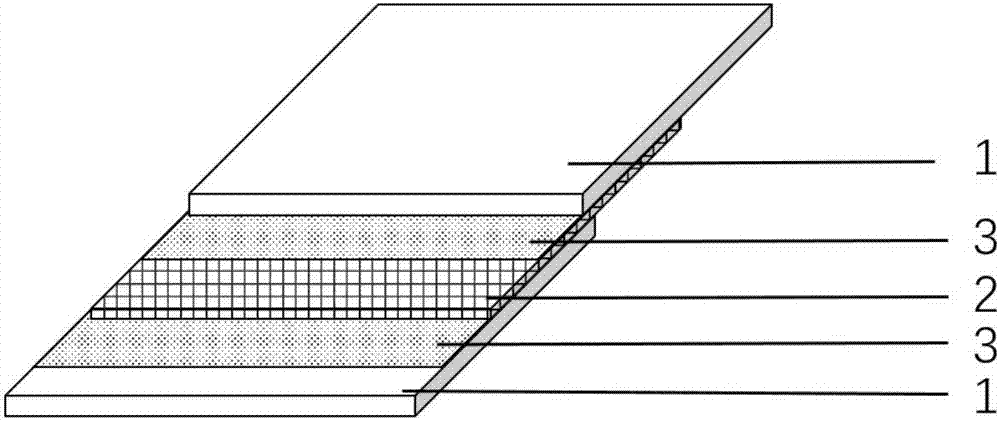

[0037] see Figure 1-2 , figure 1 A 2 / 1 structure UHMWPE fiber-reinforced fiber-metal laminate is shown, consisting of two layers of 0.8mm thick aluminum alloy 5083-O sheet 1 and a layer of 0.4mm thick UHMWPE fiber reinforced polystyrene matrix Prepreg 2, in which aluminum alloy 5083-O sheet 1 and UHMWPE fiber reinforced polystyrene-based prepreg 2 are alternately laminated, and there is a layer of polystyrene with a thickness of 0.03mm between the aluminum alloy and the prepreg Adhesive layer 3.

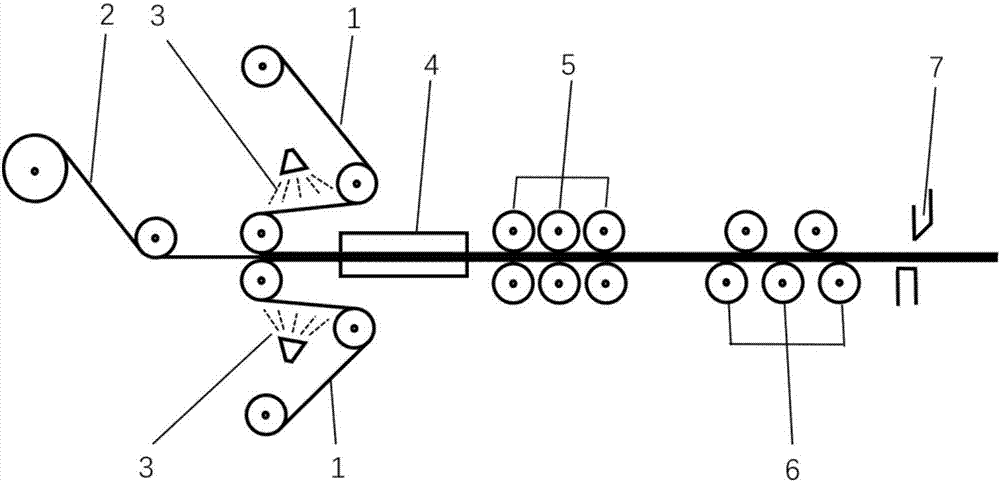

[0038] Such as figure 1 with figure 2 Shown, the preparation process of the fiber metal laminate reinforced by this UHMWPE fiber is:

[0039] (1) Preparation of prepreg: impregnate UHMWPE fiber woven cloth through molten modified polystyrene at 120°C at a speed of 10m / min, and then evenly arrange it on the roller, and cut it after the resin is cooled to make UHMWPE The fiber volume content is 70%, and the UHMWPE fiber woven fabric reinforced prepreg 2 with a thickness of 0.4mm...

Embodiment 2

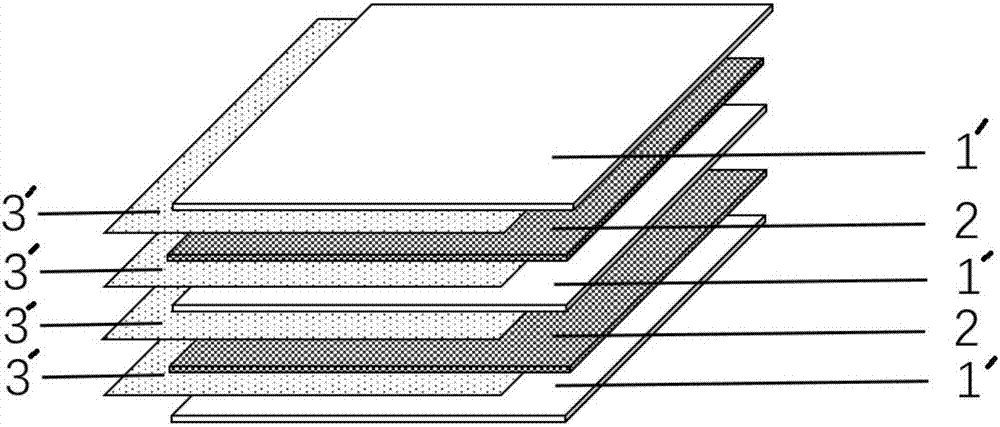

[0047] The invention is a 3 / 2 structure UHMWPE fiber-reinforced fiber metal laminate consisting of three layers of 0.3mm thick titanium alloy TC4 sheet 1' and two layers of 0.3mm thick UHMWPE fiber reinforced epoxy resin base Prepreg 2 is composed of titanium alloy TC4 sheet 1' and UHMWPE fiber reinforced epoxy resin-based prepreg 2 alternately laminated, and there is a layer of 0.05mm thick between titanium alloy TC4 sheet 1' and prepreg 2 The epoxy resin adhesive layer 3'.

[0048] Such as image 3 with Figure 4 Shown, the preparation process of the fiber metal laminate reinforced by this UHMWPE fiber is:

[0049] (1) Prepreg preparation: impregnate the continuous unidirectional UHMWPE fiber through the epoxy resin solution at room temperature at a speed of 10m / min, and then take it out of the room and let it stand to make a UHMWPE fiber with a volume content of 60% and a thickness of 0.3mm unidirectional UHMWPE fiber cloth reinforced epoxy resin prepreg 2. After the re...

Embodiment 3

[0057] The invention is a 4 / 3 structure UHMWPE fiber-reinforced fiber metal laminate, consisting of four layers of 0.3mm thick aluminum alloy 2024-T8 sheet 1" and three layers of 0.3mm thick UHMWPE fiber non-woven fabric Reinforced polyurethane-based prepreg 2 is composed of aluminum alloy 2024-T8 sheet 1" and UHMWPE fiber non-woven reinforced polyurethane-based prepreg 2 alternately laminated, and there is a layer between the aluminum alloy and the prepreg with a thickness of 0.05mm thick polyurethane adhesive layer 3".

[0058] Such as Figure 5 with Image 6 Shown, the preparation process of the fiber metal laminate reinforced by this UHMWPE fiber is:

[0059] (1) Preparation of prepreg: impregnate the unidirectional UHMWPE fiber fabric with the modified polyurethane solution at room temperature at a speed of 10mm / min, and then alternately laminate and heat-press in two directions of 0° and 90°. Cutting after cooling, making UHMWPE fiber volume content is 60%, the polyur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com