Preparation method of fiber metal laminate and fiber metal laminate

A technology of fiber metal laminates, applied in the field of fiber metal laminates and fiber metal laminates, can solve the problems of long manufacturing process time, possibility limitation, stability problems, etc., and achieve weight reduction and uniform distribution of tensile stress , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

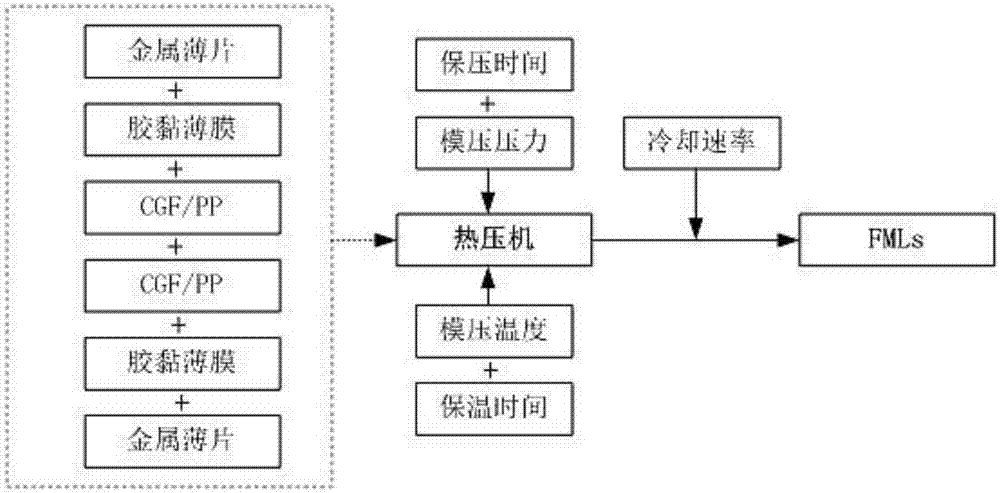

[0027] Such as figure 1 As shown, the fiber metal laminate preparation method of the present embodiment includes the following steps:

[0028] S1, smear release wax / release agent on the mold in hot press;

[0029] S2. Place one layer of metal sheet, at least one layer of interface film, at least two layers of fiber prepreg fabric, at least one layer of interface film, and one layer of metal sheet in sequence in the mold;

[0030] S3. Set the process parameters of the hot press and start the hot press. After the mold in the hot press reaches the preset temperature, heat preservation is carried out, and the pressure is maintained at the preset temperature, and finally cooled at the preset cooling rate The fiber metal laminate was obtained.

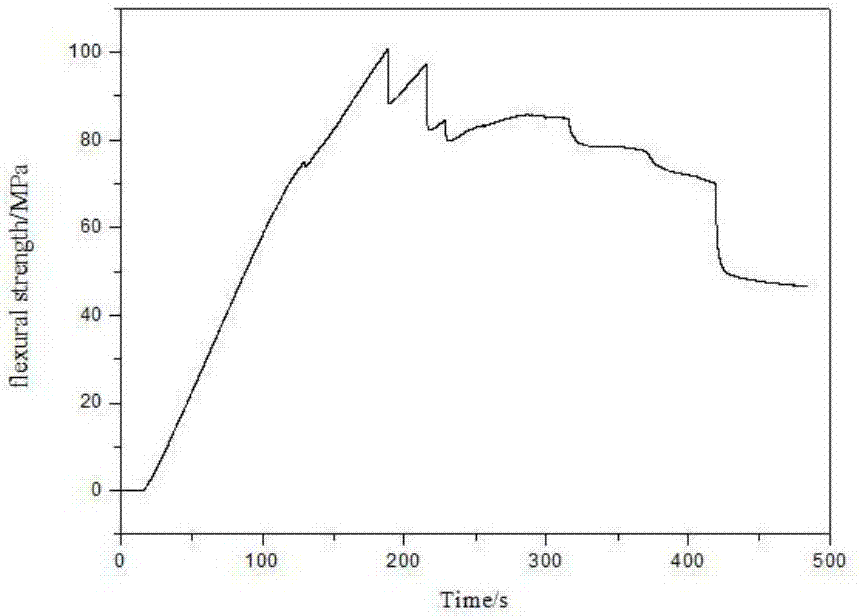

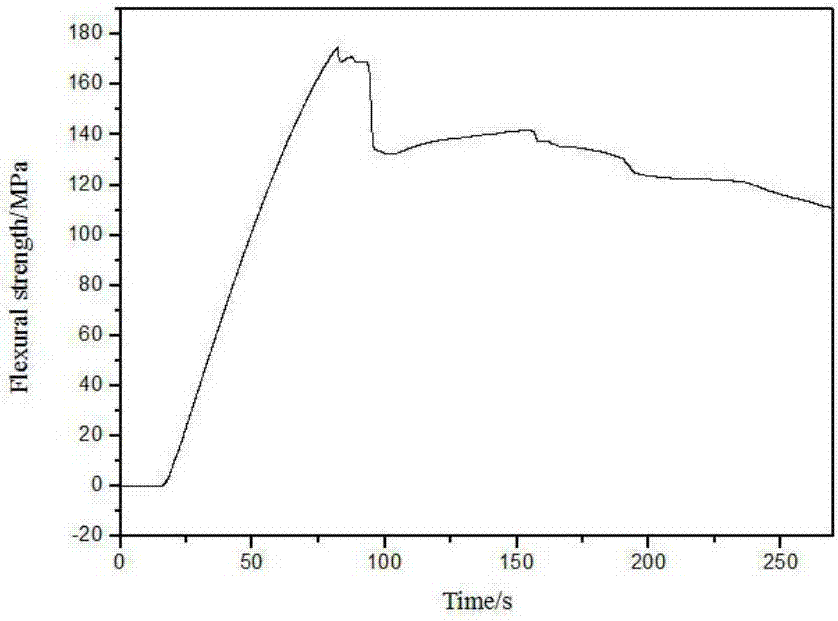

[0031] In this embodiment, the composite molding of the fiber prepreg tape and the metal sheet is realized by means of a hot press using hot molding, so that the surface of the product is smooth and flat without warping and has high bendin...

Embodiment 2

[0039] As a convertible implementation, the difference between this example and Example 1 is that in this example, the preset temperature is set to 220°C, the holding time is set to 7min, and the holding pressure is set to 0.7MPa, the holding time is set to 7min, and the preset cooling rate is set to 10°C / min.

[0040] In this embodiment, preferably, the shape of the glass fiber reinforced polypropylene prepreg fabric is twill 2 / 2.

Embodiment 3

[0042] As a convertible implementation, the difference between this example and Example 1 is that in this example, the preset temperature is set to 160°C, the holding time is set to 10min, and the holding pressure is set to 1MPa, the holding time is set to 0.5min, and the preset cooling rate is set to 40°C / min.

[0043] In this embodiment, preferably, the shape of the glass fiber reinforced polypropylene prepreg fabric is twill 2 / 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com