Method for preparing continuous carbon fiber enhanced polyether-ether-ketone matrix fiber metal laminates

A technology of polyether ether ketone and metal laminates, which is applied in the preparation of fiber metal laminates and the preparation of continuous carbon fiber reinforced polyetheretherketone matrix fiber metal laminates, which can solve the problems of limited applications and achieve easy operation and high density. The effect of low and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

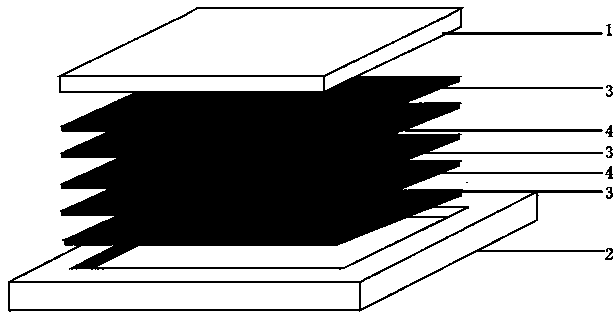

[0027] like figure 1 As shown, Example 1 is a five-layer continuous carbon fiber reinforced polyether ether ketone fiber metal laminate, which consists of three layers of 0.3mm thick TA2 titanium plate 3, two layers of continuous carbon fiber reinforced polyether ether ketone prepreg 4 composition.

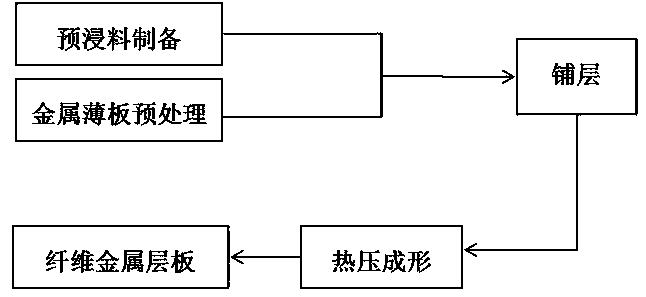

[0028] The specific preparation method is as follows:

[0029] In the first step, the continuous carbon fiber is impregnated through the modified polyether ether ketone chloroform solution at a speed of 15m / min at room temperature, and then evenly arranged on the roller to form a unidirectional prepreg with a carbon fiber volume content of 50%.

[0030] The second step is to rinse the surface of the TA2 titanium plate 3 with distilled water to remove surface pollutants; then wipe the surface of the TA2 thin plate 3 with acetone to remove surface grease; then put the TA2 titanium plate 3 into nitric acid and 60g / L of 350g / L In a mixed acid solution composed of hydrofluoric acid,...

Embodiment 2

[0034] This embodiment is a three-layer continuous carbon fiber reinforced PEEK fiber metal laminate, which is composed of two layers of 0.1 mm thick TA1 titanium plate 3 and one layer of continuous carbon fiber reinforced PEEK prepreg 4 .

[0035] The specific preparation method is as follows:

[0036] In the first step, the continuous carbon fiber is impregnated through the modified polyether ether ketone powder chloroform solution at a speed of 18m / min at room temperature, and then evenly arranged on the roller to form a unidirectional prepreg with a carbon fiber volume content of 60%.

[0037] In the second step, rinse the surface of the TA1 titanium plate 3 with distilled water to remove surface pollutants; then wipe the surface of the TA1 titanium plate 3 with isopropanol to remove surface grease; then put the TA1 titanium plate 3 into nitric acid and In a mixed acid solution composed of 60g / L hydrofluoric acid, at 40 o Pickling under C for 40s to remove the surface ox...

Embodiment 3

[0041]This embodiment is a five-layer continuous carbon fiber reinforced polyetheretherketone fiber metal laminate, which is composed of three layers of 0.5mm thick TC4 titanium plate 3 and two layers of continuous carbon fiber reinforced polyetheretherketone prepreg.

[0042] The first step, the preparation of prepreg: at room temperature, the continuous carbon fiber is impregnated through the modified polyether ether ketone chloroform solution at a speed of 20m / min, and then evenly arranged on the roller to make a single carbon fiber with a volume content of 60%. to prepreg.

[0043] The second step, metal sheet pretreatment: rinse the surface of TC4 titanium plate 3 with distilled water to remove surface pollutants; then wipe the surface of titanium plate with acetone to remove surface grease; then put TC4 titanium plate 3 into nitric acid of 350g / L and 60g / L hydrofluoric acid mixed acid solution, at 40 o Pickling under C for 40s to remove the surface oxide layer; finally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com