Integrated formation device and method for wind power blade

A wind power blade and molding device technology, applied in the field of wind power blade integrated molding device, can solve the problems of slow filling speed, high manufacturing cost, poor molding quality, etc., and achieve the effects of low cost, improved blade quality, and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the following, the present invention will be described in detail with reference to the accompanying drawings and specific implementation examples. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. After reading the present invention, those skilled in the art all fall into the appended claims of the present application to the amendments of various equivalent forms of the present invention limited range.

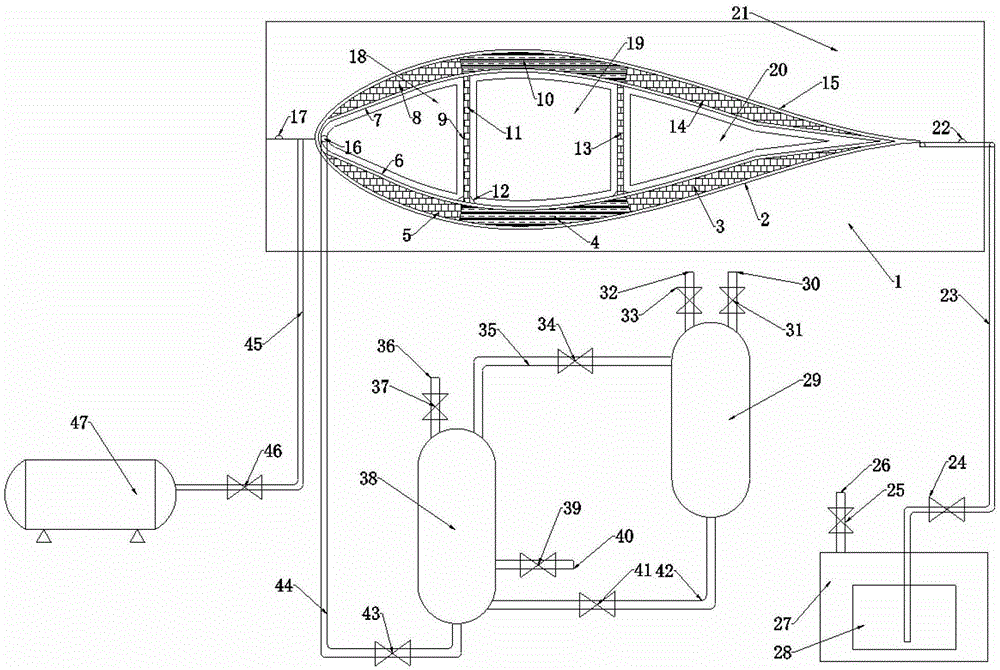

[0040] figure 1 It is an integrated drawing of positive pressure assisted vacuum perfusion integrated molding adopted in the present invention. The female molds 1 and 21 provide the molds for producing the upper and lower shells of the blades. During the blade manufacturing process, the mold trusses and the positioning and locking devices on the sides of the molds are fastened together to form a whole. The molds contain water heating or electric heating. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com