Repairing material for cement concrete structure

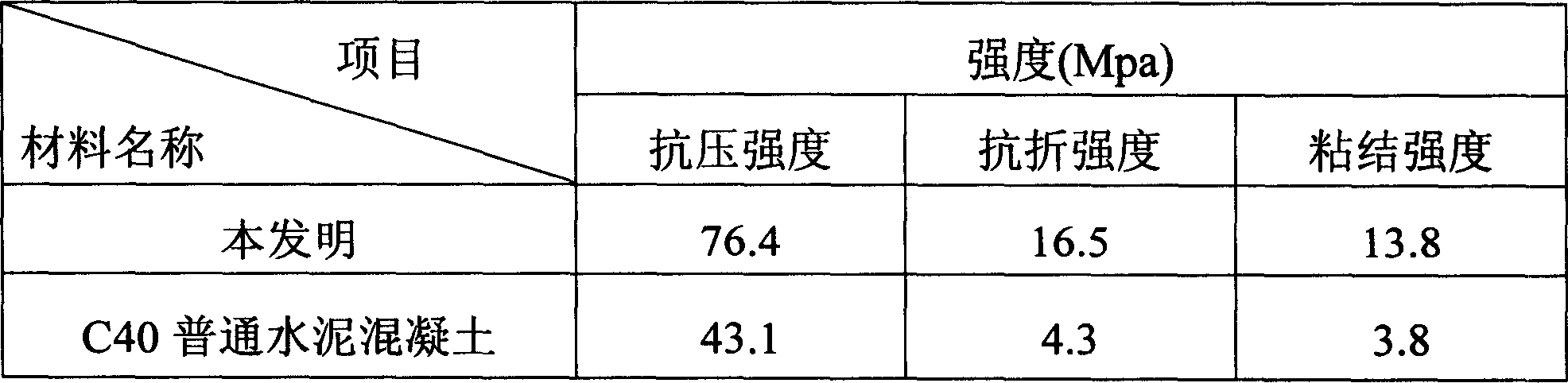

A technology of cement concrete and repair materials, applied in the field of building materials, can solve the problems of low bond strength and early strength, long maintenance time, and large waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 1500g of Portland cement, 20g of superplasticizer, 75g of SH external admixture, 3500g of yellow sand, 3000g of crushed stone, 2.5g of polyvinyl alcohol solution (mixed with yellow sand), 50g of steel fiber, and place them in the mixer , stirred and mixed for 5 minutes at a speed of 57 rpm to prepare a uniform (powder-like) mixture for later use; during actual construction, put the mixture in a mixer, add 407.375g of water, mix and stir, and pour construction . The ratio of water and mixture in the present embodiment is 5:100.

Embodiment 2

[0030] Weigh 2000g of Portland cement, 5g of superplasticizer, 600g of SH external admixture, 1500g of yellow sand, 7000g of gravel, 1g of polyvinyl alcohol solution (mixed with yellow sand), 400g of steel fiber, and place them in the mixer. Stir and mix at a speed of 57 rpm for 5 minutes to prepare a uniform (powder-like) mixture for subsequent use; during actual construction, place the mixture in a mixer, add 1610.84g of water, mix and stir, and pour construction. The ratio of water and mixture in the present embodiment is 14:100.

Embodiment 3

[0032] Weigh 1750g of Portland cement, 12.5g of superplasticizer, 337.5g of SH external admixture, 2500g of yellow sand, 5000g of gravel, 1.8g of polyvinyl alcohol solution (mixed with yellow sand), 225g of steel fiber, and place in the mixing In the machine, stir and mix at a speed of 57 rpm for 5 minutes to prepare a uniform (powder) mixture for subsequent use; during actual construction, place the mixture in a mixer, add 982.68g of water, and mix and stir while Pouring construction. The ratio of water and mixture in the present embodiment is 10:100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com