Aerogel composite aramid non-woven fabric thermal protection material and preparation method thereof

A thermal protection material, non-woven technology, applied in textiles and papermaking, fiber type, fiber processing and other directions, can solve the problems of poor air permeability, affect work efficiency, affect comfort and other problems, achieve low density, excellent thermal insulation performance , good flame retardant and high temperature resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of the thermal protection material of airgel composite aramid fiber nonwoven fabric comprises the following steps:

[0029] 1) Mix methyl orthosilicate, anhydrous methanol and water at a volume ratio of 1:5:2 at room temperature, stir well, and add hydrochloric acid aqueous solution with a mass concentration of 5% to the pH value of the mixed solution dropwise. After reaching 4.5, heat to 60°C, stir evenly and continue to keep warm for 2.5h, that is, the silica sol is made;

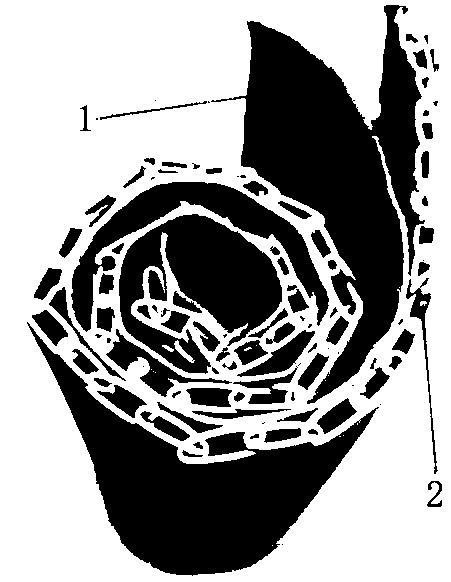

[0030] 2) Step 1) After adjusting the temperature of the obtained silica sol to 40°C, add an aqueous solution of sodium hydroxide with a mass concentration of 1% and mix until the pH value is 8.0, and spray the silica sol after adjusting the pH value on the aramid fiber nonwoven fabric On the cloth (aramid nonwoven fabric is aramid 1313, its thickness is 0.3mm, it is a meta-aramid nonwoven fabric made by spunlace process, and its thermal conductivity is 0.0313W / m.k), so that the sil...

Embodiment 2

[0036] The preparation of the thermal protection material of airgel composite aramid fiber nonwoven fabric comprises the following steps:

[0037] 1) Mix ethyl orthosilicate, absolute ethanol and water at a volume ratio of 1:3.5:1.2 at room temperature, stir well, and add hydrochloric acid aqueous solution with a mass concentration of 10% to the mixed solution dropwise until the pH value After reaching 4.0, heat to 55°C, stir evenly and continue to keep warm for 2.0h, the silica sol is made;

[0038] 2) After adjusting the temperature of the silica sol obtained in step 1 to 40°C, add an aqueous solution of sodium hydroxide with a mass concentration of 0.5% and mix until the pH value is 7.5, and spray the silica sol after adjusting the pH value on the aramid fiber nonwoven fabric On the cloth (the thickness of the aramid fiber nonwoven fabric is 1.0mm, it is a nonwoven fabric made of aramid fiber 1313 and aramid fiber 1414 by needle punching process, and the mass ratio of the a...

Embodiment 3

[0043] The preparation of the thermal protection material of airgel composite aramid fiber nonwoven fabric comprises the following steps:

[0044] 1) Mix ethyl orthosilicate, absolute ethanol and water at a volume ratio of 1:2:0.5 at room temperature, stir well, and add sulfuric acid aqueous solution with a mass concentration of 5% to the mixed solution dropwise until the pH value After reaching 3.5, heat to 50°C, stir evenly and continue to keep warm for 2.5h, the silica sol is made;

[0045] 2) Step 1) After adjusting the temperature of the obtained silica sol to 40°C, add ammonia solution with a mass concentration of 2% and mix until the pH value is 7.0, and spray the silica sol after adjusting the pH value on the aramid fiber nonwoven fabric (Aramid nonwoven fabric is aramid 1414, its thickness is 0.3mm, and it is made by spunlace process), so that the silica sol can penetrate into the inside of the aramid nonwoven fabric evenly, and keep it warm for 3 minutes (at this tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com