Patents

Literature

31results about How to "Low flame retardant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

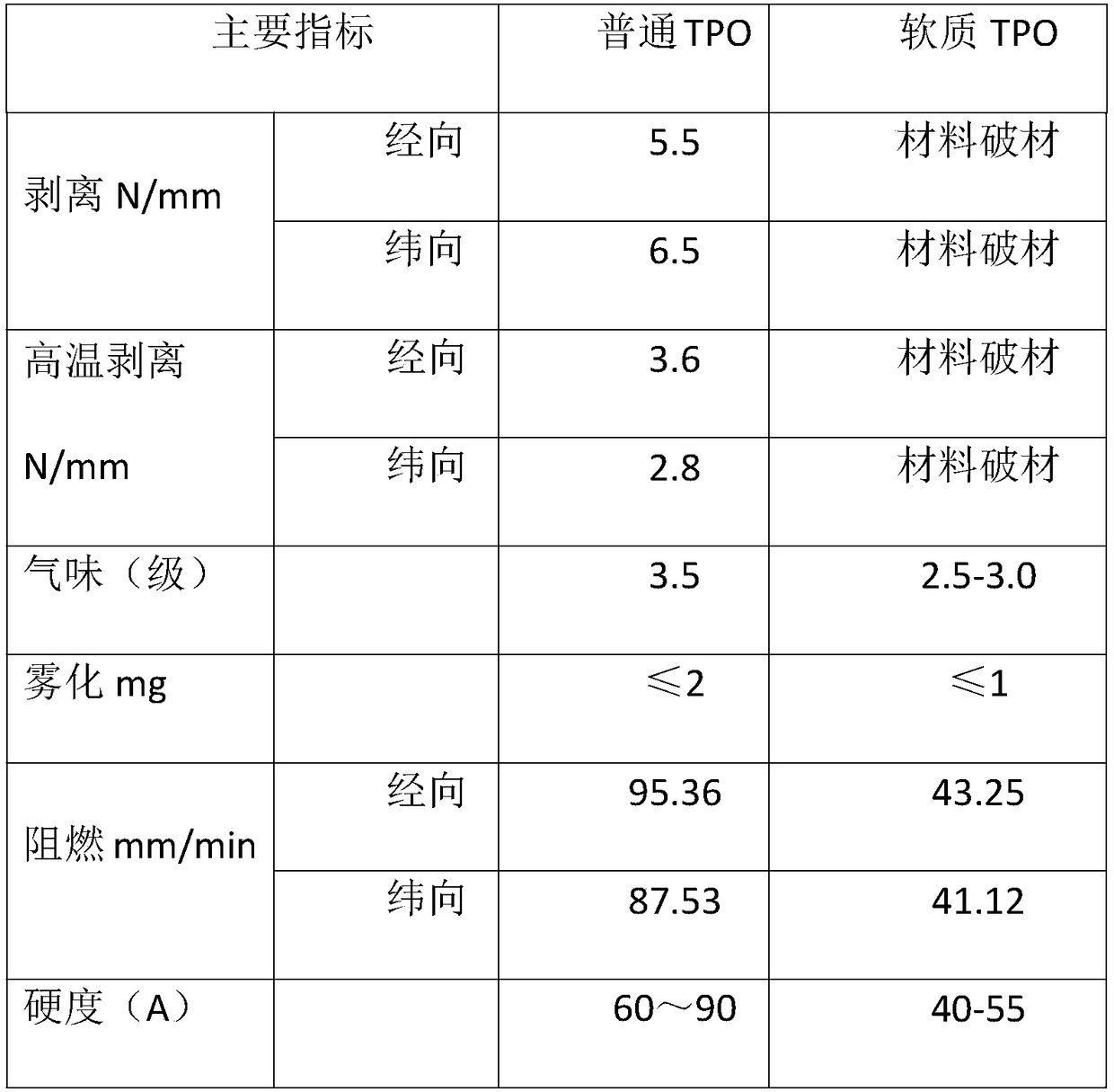

Soft TPO material for automobile interior decoration as well as preparation method thereof

InactiveCN109159513AHas a soft feelSoft feel lowSynthetic resin layered productsSuperstructure subunitsElastomerWater based

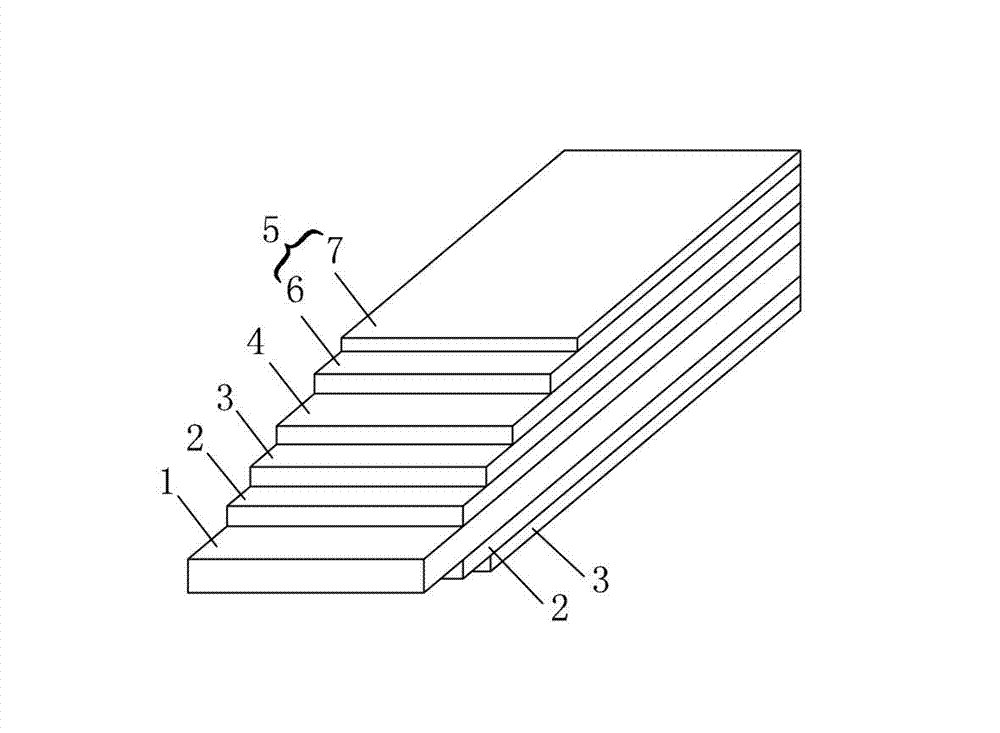

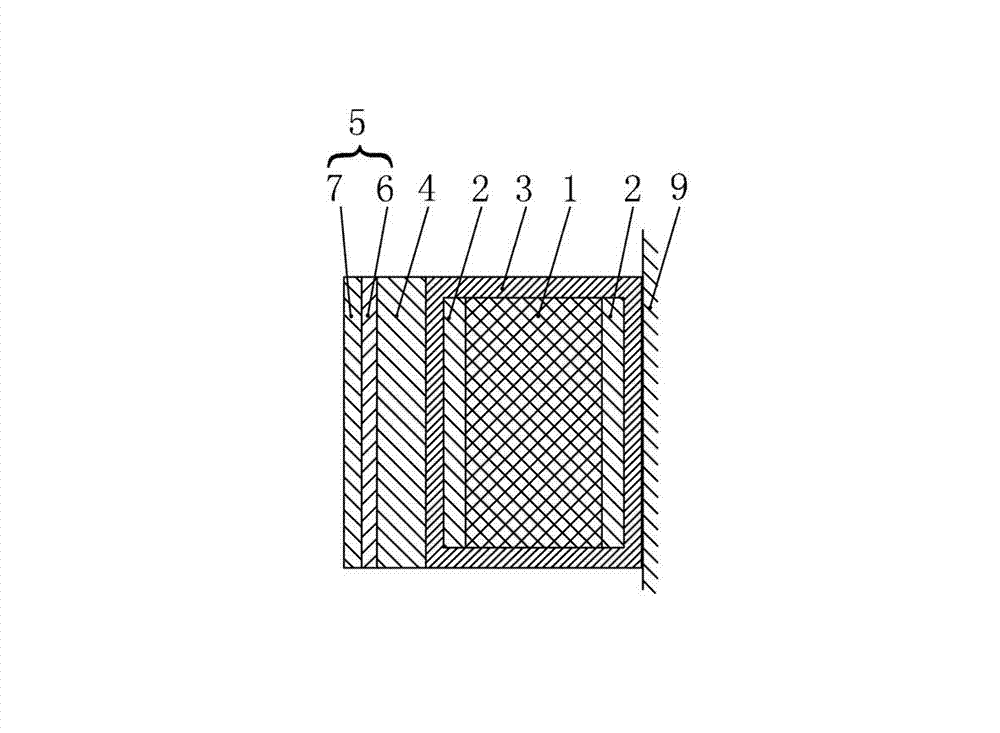

The invention provides a soft TPO material for automobile interior decoration as well as a preparation method thereof. The soft TPO material comprises a back coating, a foaming agent, a soft TPO layerand a water-based coating layer sequentially from bottom to top, wherein the back coating is a polyurethane type coating agent or a polyolefin coating agent; the foaming agent is a polypropylene foamlayer; the soft TPO layer comprises the following components in parts by weight: 20 to 60 parts of TPO, 10 to 40 parts of ethylene propylene diene monomer rubber, 5 to 20 parts of polyolefin elastomer, 5 to 15 parts of modified polypropylene, 0 to 5 parts of light stabilizer, 0 to 5 parts of heat stabilizer and 4 to 8 parts of pigment; and the water-based coating agent is a water-based polyurethane coating agent. The preparation method of the soft TPO material for automobile interior decoration comprises the following steps: extruding soft TPO skin by an extruding method, performing surface treatment, compounding the foaming agent and finally preparing the soft TPO material. The soft TPO material prepared by the method has soft hand feeling and soft touch feeling, is comfortable to use, has the advantages of low odor and low VOC, and is recoverable, green and environmentally-friendly.

Owner:SUZHOU RUIGAO NEW MATERIAL CO LTD

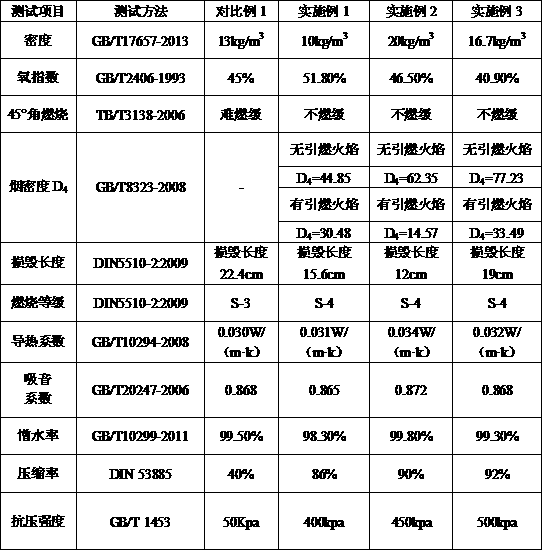

Novel high-strength low-volume-weight heat preservation fireproof decoration integration plate and preparation method thereof

ActiveCN102817453AControllable thicknessLight weightFireproof paintsCovering/liningsHeat conservationPolymer chemistry

The invention relates to a novel high-strength low-volume-weight heat preservation fireproof decoration integration plate. The technical scheme includes that the integration plate is composed of a heat preservation layer, a fireproof layer which is coated on the outer surface of the heat preservation layer, a strengthening layer and decorative surface layer. The heat preservation layer is composed of polyurethane foaming plate double-faced composite cement alkali-resistant glass fabric. According to the plate and the preparation method, the strength is high, the heat preservation performance is high, the volume weight of the integration plate is less than 8kg / m2, compared with the volume weight of a conventional integration plate, the volume weight of the integration plate is reduced by 4-6kgm2, fireproof interface agent processing is performed on six surfaces of a core material, compared with existing products, the plate improves the fireproof performance substantially, and fire is prevented from spreading along a wall body.

Owner:辽宁宝山生态涂料有限公司

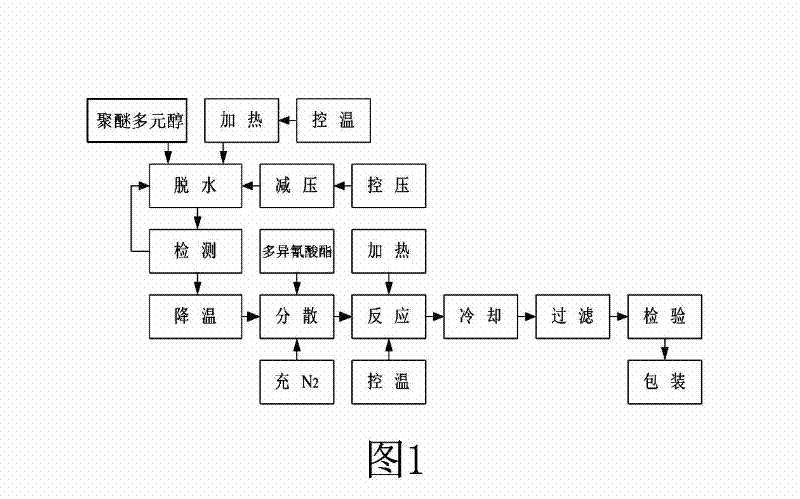

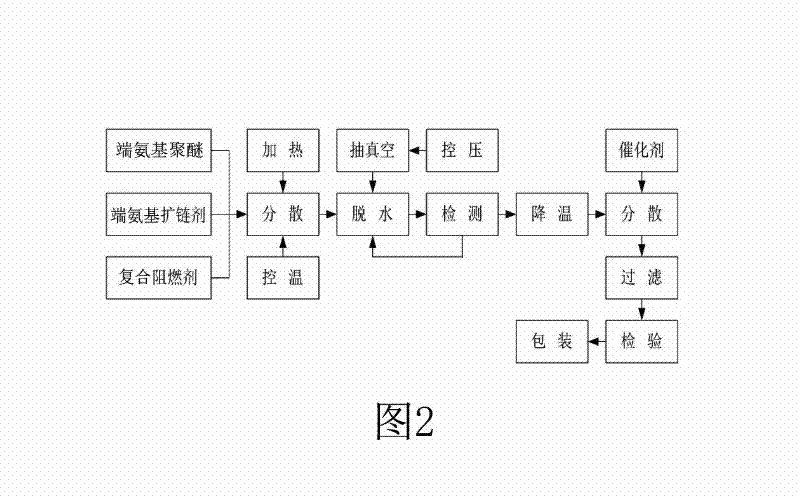

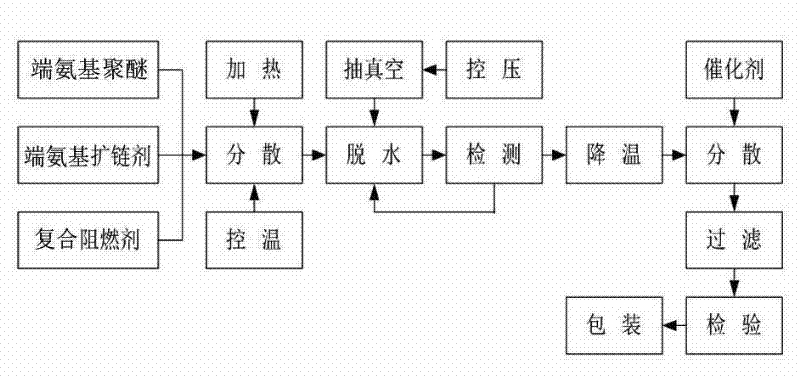

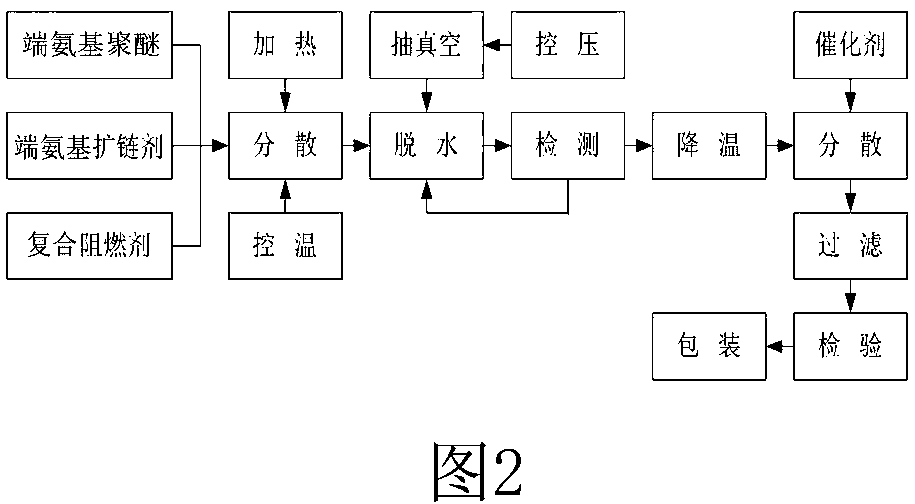

Flame-retardant spray polyurea elastomer coating and preparation method thereof

InactiveCN102391766AImprove flame retardant performanceGood flame retardant durability and migration resistanceFireproof paintsPolyurea/polyurethane coatingsChemistryPolyurea

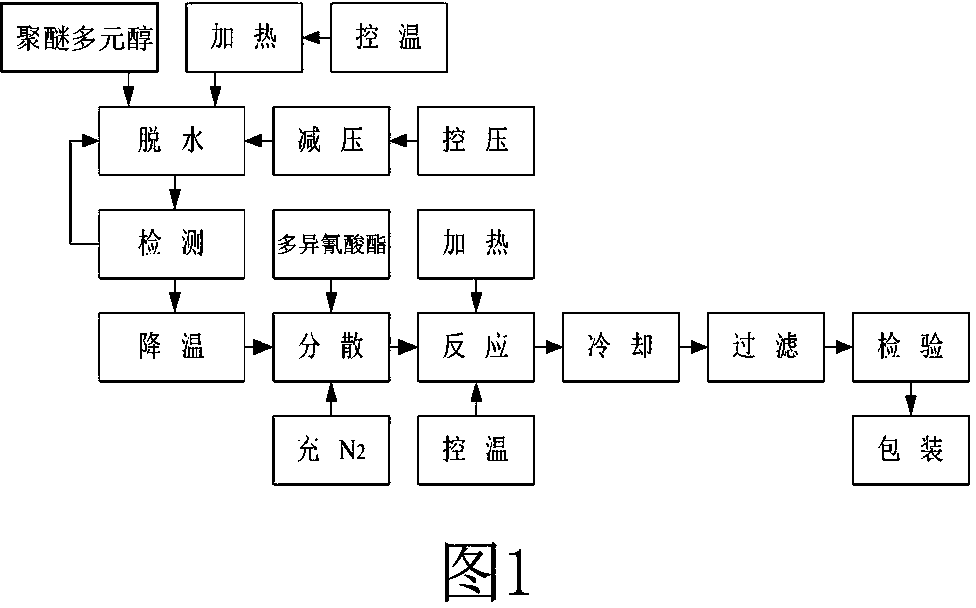

The invention relates to a flame-retardant spray polyurea elastomer coating and a preparation method thereof. The coating consists of a component A and a component B. The component A comprises the following raw materials in percentage by weight: 40 percent to 60 percent of polyether polyol and 40 percent to 60 percent of polyisocyanates. The component B comprises the following raw materials in percentage by weight: 35 percent to 55 percent of amino terminated polyether, 20 percent to 35 percent of amino terminated chain extender, 20 percent to 40 percent of composite flame retardant and 0.05 percent to 0.1 percent of catalyst. The composite flame retardant comprises the following components in percentage by weight: 29 percent to 58 percent of tetrabromophthlate diol PHT4-DIOL, 6 percent to 12 percent of Tris (2-clorisopropyl) phosphate TCPP, 20 percent to 40 percent of chlorinated paraffin and 10 percent to 25 percent of antimony trioxide. On the basis of keeping good physical properties of materials, the flame retardant property of the coating is further improved. The flame-retardant spray polyurea elastomer coating can be applied to the concrete or steel surfaces of various buildings.

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD +1

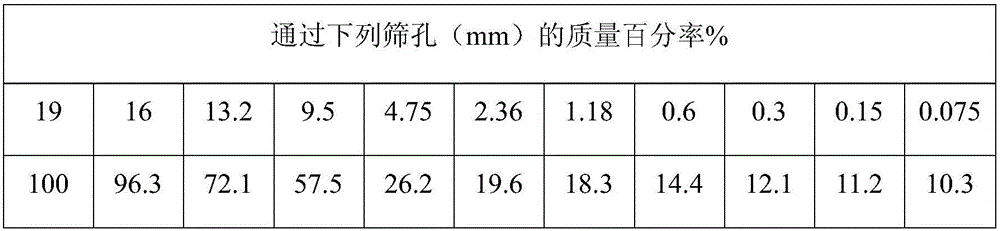

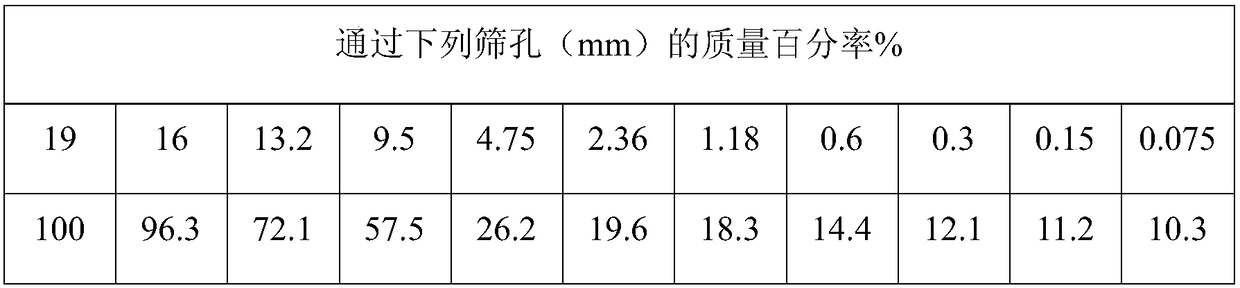

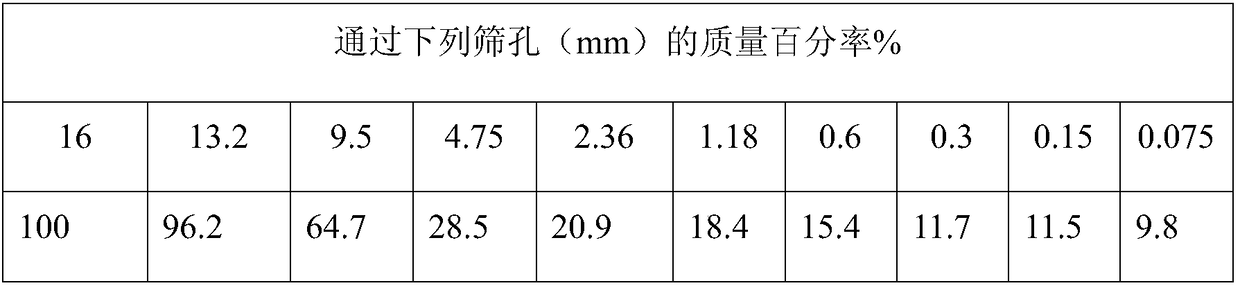

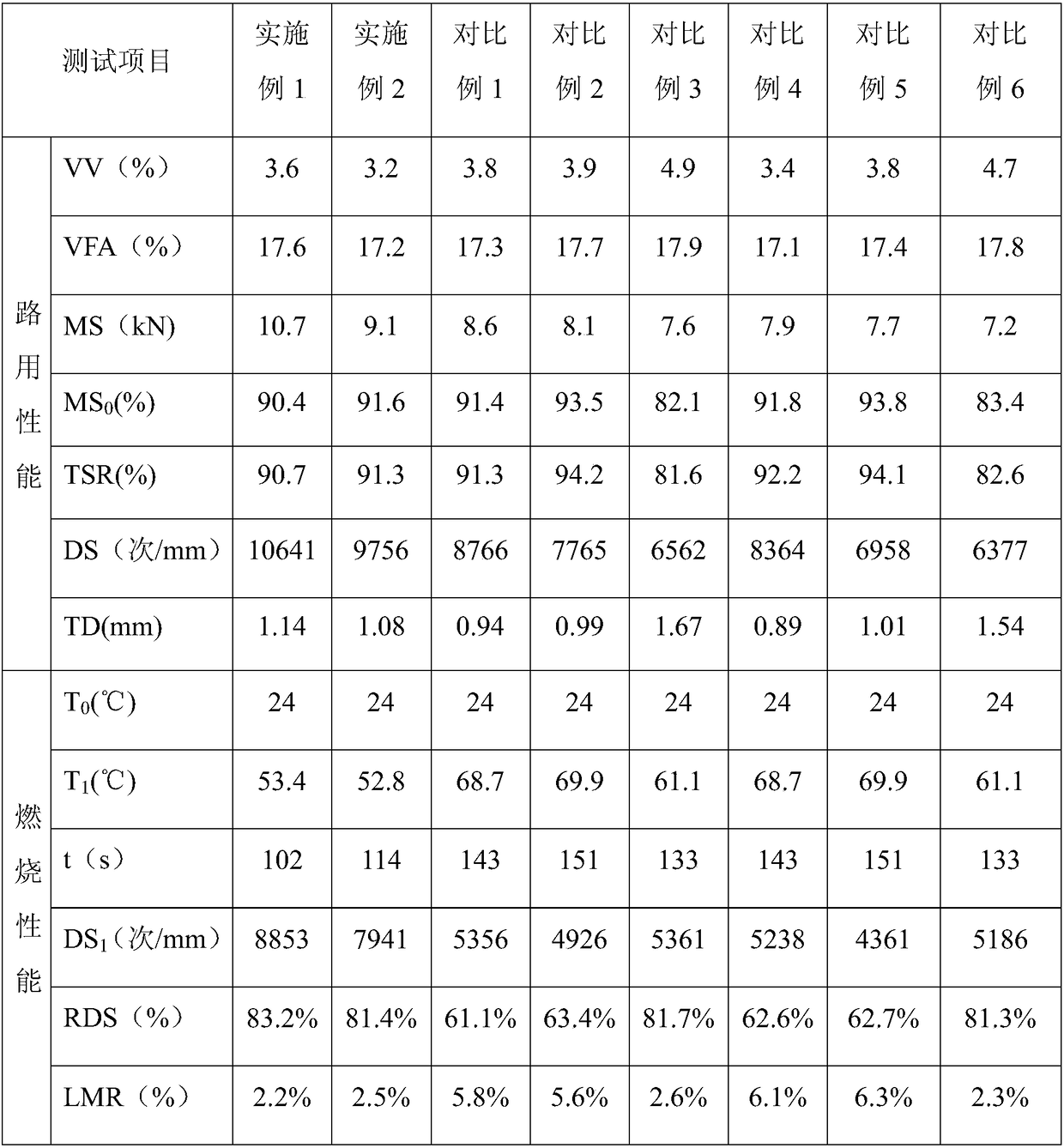

Composite warm-mixed flame-retarding antiskid asphalt tunnel pavement material and preparation method thereof

ActiveCN105837091AReasonable construction depthImproves rutting resistanceSolid waste managementClimate change adaptationFiberRoad surface

The invention discloses a composite warm-mixed flame-retarding antiskid asphalt tunnel pavement material which includes, by weight, 80-90 parts of aggregate, 5-15 parts of a functional filling material, 4-7 parts of high-viscosity high-elasticity modified asphalt, 0.4-0.7 parts of a warm mixing agent, and 0.2-0.5 parts of mineral fibers. The composite warm-mixed flame-retarding antiskid asphalt tunnel pavement material has a compact framework structure and has reasonable construction depth and high anti-track capability, thereby ensuring antiskid and durable performances of the mixture. The emulsifying-type warm mixing agent is compounded with the functional filling material for comprehensively controlling the mixing temperature of the asphalt mixture. With the composite flame-retarding component, a gradient-temperature flame-retarding effect is achieved. The asphalt tunnel pavement material is antiskid when being spread, is flame-retarding and is low in mixing temperature, and satisfies a special semi-sealed environment.

Owner:广州市市维新材料科技有限公司

Thermal insulation building paint containing nanoparticles and preparation method of paint

InactiveCN107189596ANon-combustibleEasy to useFireproof paintsCellulose coatingsAdhesiveThermal insulation

The invention discloses thermal insulation building paint containing nanoparticles. The thermal insulation building paint containing the nanoparticles comprises, by weight, 60-90 parts of nanoparticles, 30-50 parts of sepiolite, 20-30 parts of diatomite, 10-30 parts of talcum powder, 40-50 parts of filler, 20-30 parts of glass hollow microspheres, 8-24 parts of desulfurization rubber powder, 10-20 parts of acrylic emulsion, 6-18 parts of high-temperature resin, 5-15 parts of polyethylene glycol, 12-18 parts of defoaming agent, 5-8 parts of adhesive, 5-10 parts of thickening agent, 8-16 parts of mildew preventive, 9-12 parts of bactericide, 2-8 parts of flame retardant and water. The thermal insulation building paint containing the nanoparticles and prepared through the method is convenient to use, has low heat conductivity, heat preservation and flame retardancy, and is environmentally friendly and good in chemical stability.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

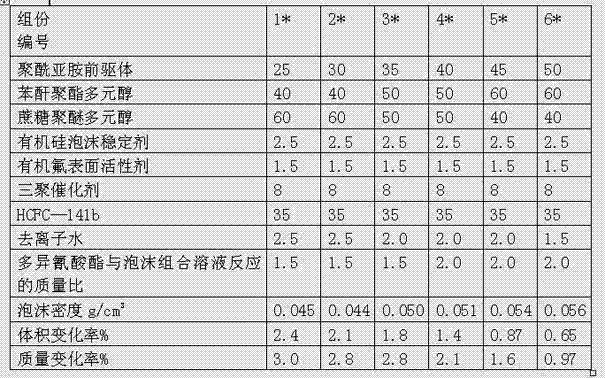

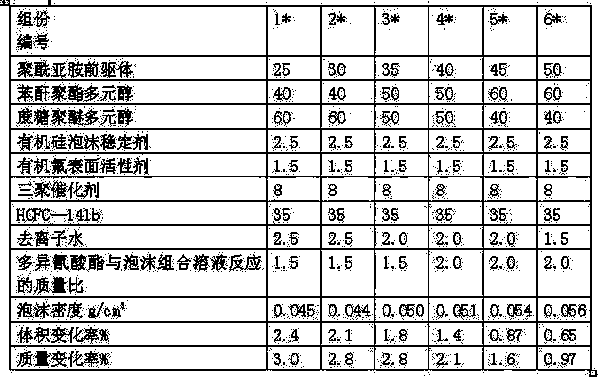

Polyimide modified polyisocyanurate foam and preparation method thereof

The invention discloses a polyimide modified polyisocyanurate foam material and a preparation method thereof. A polyimide precursor prepared by esterification reaction of aromatic dianhydride and aromatic diamine with fatty alcohol is compounded with polyester polyol, polyether polyol, a surfactant, a foaming agent, a catalyst, and the like to form a foam combination solution, the solution chemically reacts with polyisocyanate to foam, and then the polyimide modified polyisocyanurate foam is endued with properties such as high-temperature resistance and flame retardance. The modified polyisocyanurate foam material comprises (1) the foamable polyimide precursor, (2) benzoic anhydride polyester and sucrose polyether polyol, (3) a polyisocyanate curing agent, and (4) an organosilicon foam stabilizer, the organic fluorinated surfactant, the trimerization catalyst and the foaming agent. According to the foam material and the preparation method, a one-step foaming technology is adopted, and the technology is simple and convenient and low in cost; and the foam is temperature-resistant, flame-retardant and low in smoke density, so that the popularization and application are facilitated.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

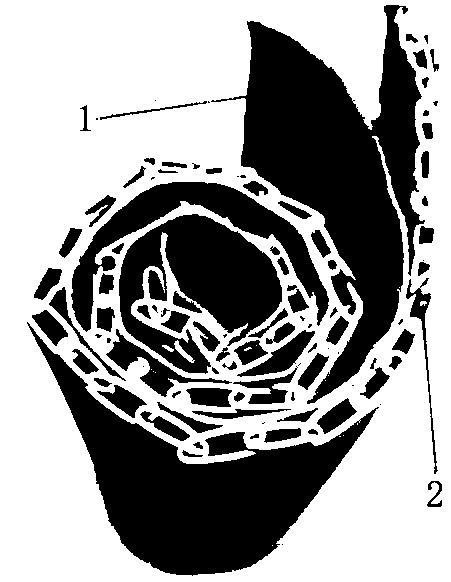

Aerogel composite aramid non-woven fabric thermal protection material and preparation method thereof

The invention discloses an aerogel composite aramid non-woven fabric thermal protection material and a preparation method thereof. The preparation method of the aerogel composite aramid non-woven fabric thermal protection material comprises the following steps of uniformly mixing a silicon source, organic solvent and water, dropwise adding in acid catalysts to regulate the pH, and then heating, mixing and temperature-keeping the mixture to obtain a silicon sol; regulating the temperature of the silicon sol, adding in alkali catalysts to regulate the pH, spraying the pH-regulated silicon sol onto an aramid non-woven fabric, standing the sprayed aramid non-woven fabric to obtain a wet gel-aramid non-woven fabric complex; lining macrocyclic polyester spiral drying screens into the wet gel-aramid non-woven fabric complex, rolling the lined wet gel-aramid non-woven fabric complex, immersing the fabric roll into ageing solution for ageing, performing supercritical drying on the aged fabric roll inside a supercritical drying device to obtain the aerogel composite aramid non-woven fabric thermal protection material. The prepared aerogel composite aramid non-woven fabric thermal protectionmaterial is excellent in properties such as thermal insulation, fire resistance, light weight and breathability.

Owner:浙江鹏辰造纸研究所有限公司

Low-friction, low-shrinkage, high-temperature-resistant, low-smoke and halogen-free sheath material for 5G optical cable and preparation method thereof

ActiveCN111040286AImprove mechanical propertiesReduce coefficient of frictionPlastic/resin/waxes insulatorsClimate change adaptationStyreneLow smoke zero halogen

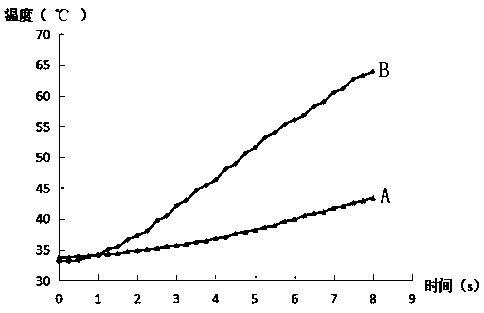

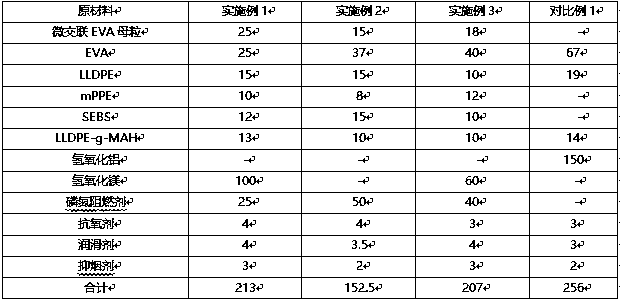

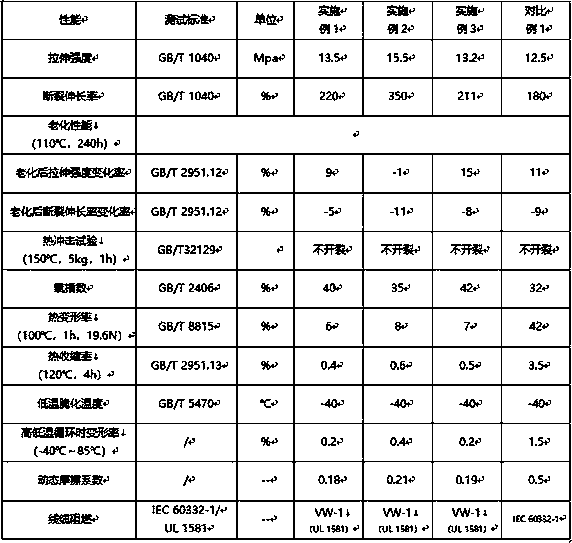

The invention discloses a low-friction, low-shrinkage, high-temperature-resistant, low-smoke and halogen-free sheath material for 5G optical cables and a preparation method thereof. The sheath material comprises the following raw materials in parts by mass: 15-30 parts of micro-crosslinked EVA master batch, 20-45 parts of an ethylene-vinyl acetate copolymer, 5-15 parts of linear low density polyethylene, 5-15 parts of modified polyphenyl ether, 10-20 parts of a hydrogenated styrene-butadiene block copolymer, 5-15 parts of a maleic acid glycoside graft, 0-100 parts of magnesium hydroxide, 25-50parts of a phosphorus-hydrogen flame retardant, 2-4 parts of an antioxidant, 3-6 parts of a lubricant and 1-3 parts of a smoke suppressant. According to the invention, the raw material formula is improved, particularly, the excellent characteristics of high and low temperature resistance, low shrinkage, high mechanical property, low dielectric property, self flame retardance, low friction coefficient, wear resistance and the like of the modified polyphenyl ether are fully utilized, by combining with the micro-crosslinked EVA master batch, the defects of large shrinkage and no temperature resistance of common low-smoke halogen-free materials are overcome, so that the sheath material disclosed by the invention is low in friction coefficient, low in shrinkage, resistant to high and low temperature and simple in preparation method.

Owner:CGN DELTA (ZHONGSHAN) POLYMER CO LTD

Low-density, high-flame retardation and high-weatherability bulk molding compound and application thereof

The invention discloses a low-density, high-flame retardation and high-weatherability bulk molding compound and an application thereof. Preparation raw materials of the bulk molding compound comprise high pressure-resistant hollow ceramic beads used as a filling material, unsaturated resin, a low shrinkage agent, a curing agent, a mold lubricant, an antioxidant, a color paste, an inorganic flame retardation filler and glass fibers according to an appropriate ratio, so the density of the above product is reduced, the insulating property, the fireproof property, the rigidity and the hardness of the compound are improved, and the compound has high strength, low density, high weatherability, can be widely applied to the field of integrated ceiling gusset plates and other fields, solves very large technical problems, and has economic and social values.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

Flame-retardant spray polyurea elastomer coating and preparation method thereof

InactiveCN102391766BThe flame retardant effect reachesPlay a synergistic roleFireproof paintsPolyurea/polyurethane coatingsElastomerPolyol

The invention relates to a flame-retardant spray polyurea elastomer coating and a preparation method thereof. The coating consists of a component A and a component B. The component A comprises the following raw materials in percentage by weight: 40 percent to 60 percent of polyether polyol and 40 percent to 60 percent of polyisocyanates. The component B comprises the following raw materials in percentage by weight: 35 percent to 55 percent of amino terminated polyether, 20 percent to 35 percent of amino terminated chain extender, 20 percent to 40 percent of composite flame retardant and 0.05 percent to 0.1 percent of catalyst. The composite flame retardant comprises the following components in percentage by weight: 29 percent to 58 percent of tetrabromophthlate diol PHT4-DIOL, 6 percent to 12 percent of Tris (2-clorisopropyl) phosphate TCPP, 20 percent to 40 percent of chlorinated paraffin and 10 percent to 25 percent of antimony trioxide. On the basis of keeping good physical properties of materials, the flame retardant property of the coating is further improved. The flame-retardant spray polyurea elastomer coating can be applied to the concrete or steel surfaces of various buildings.

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD +1

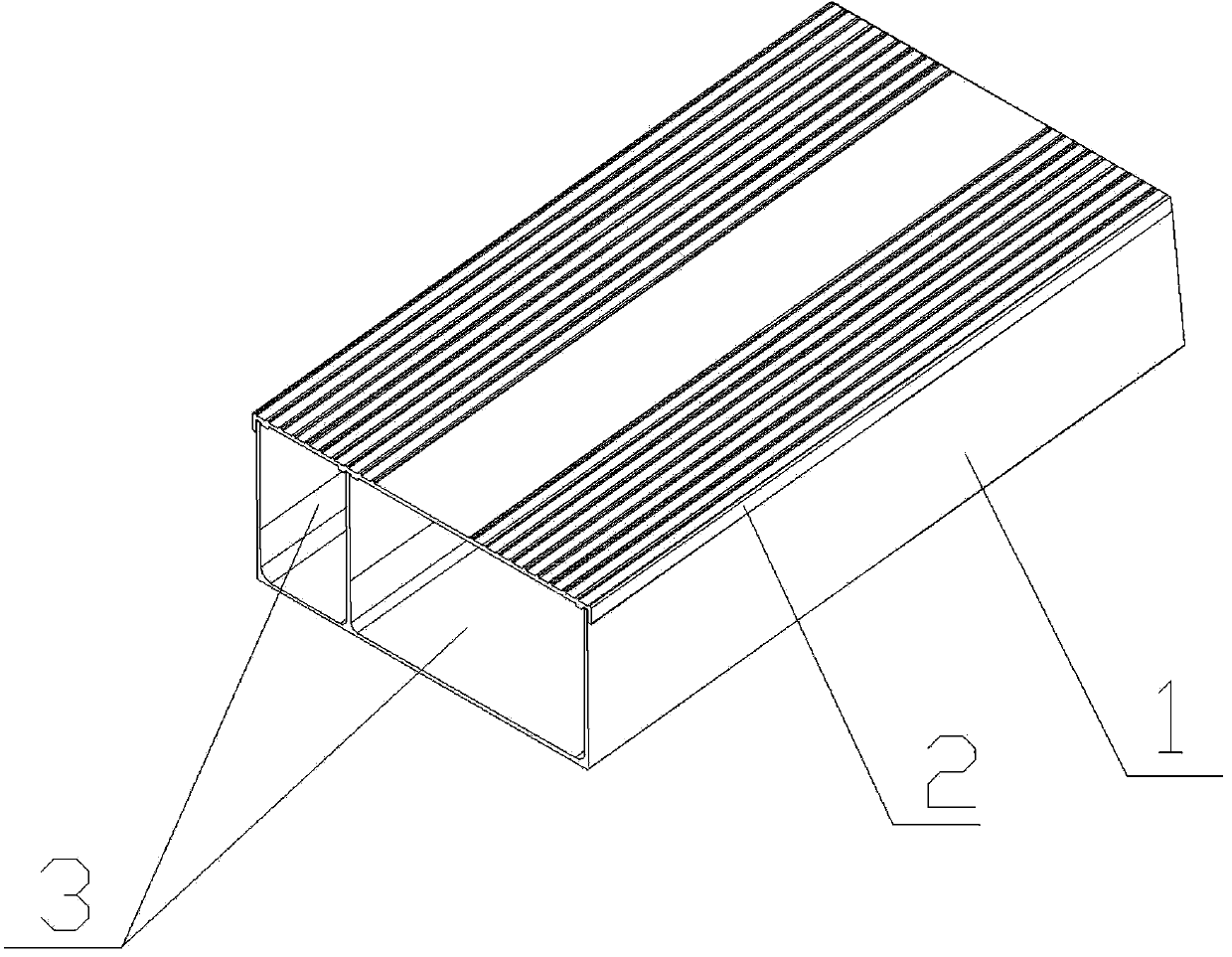

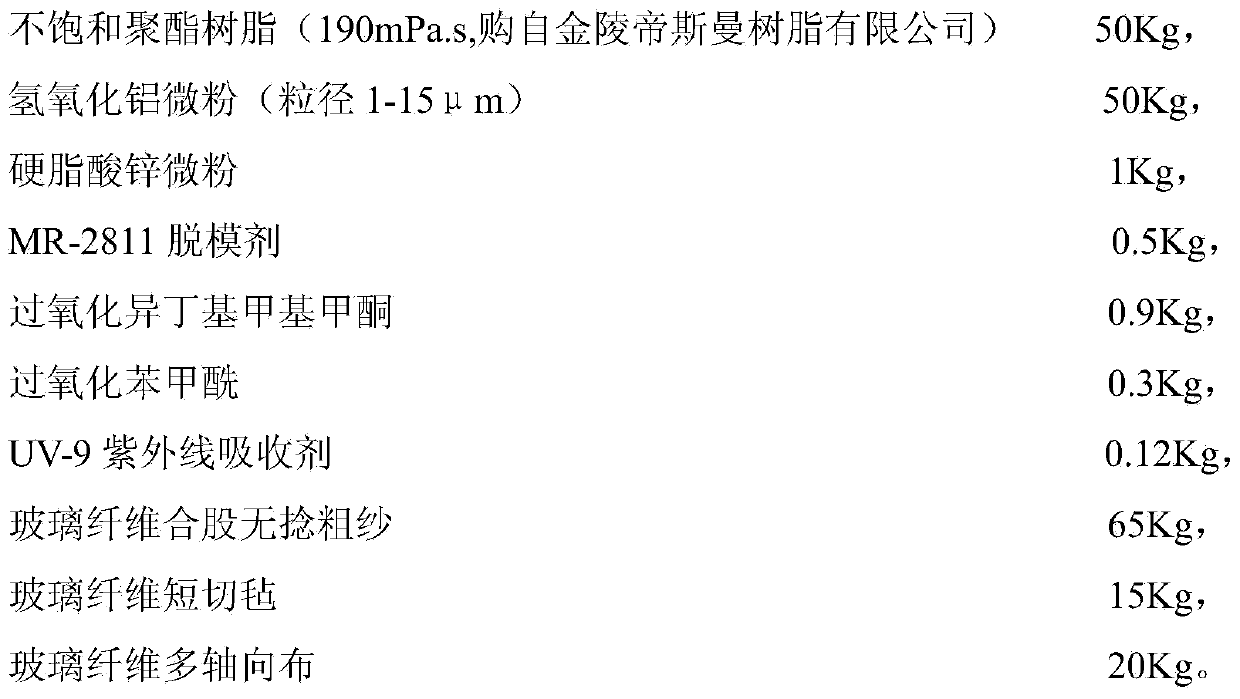

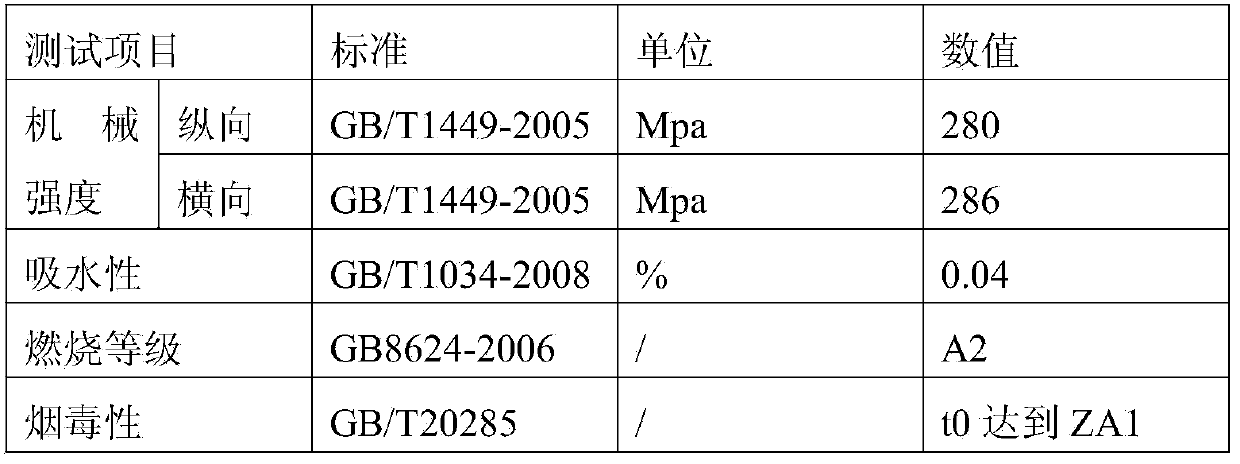

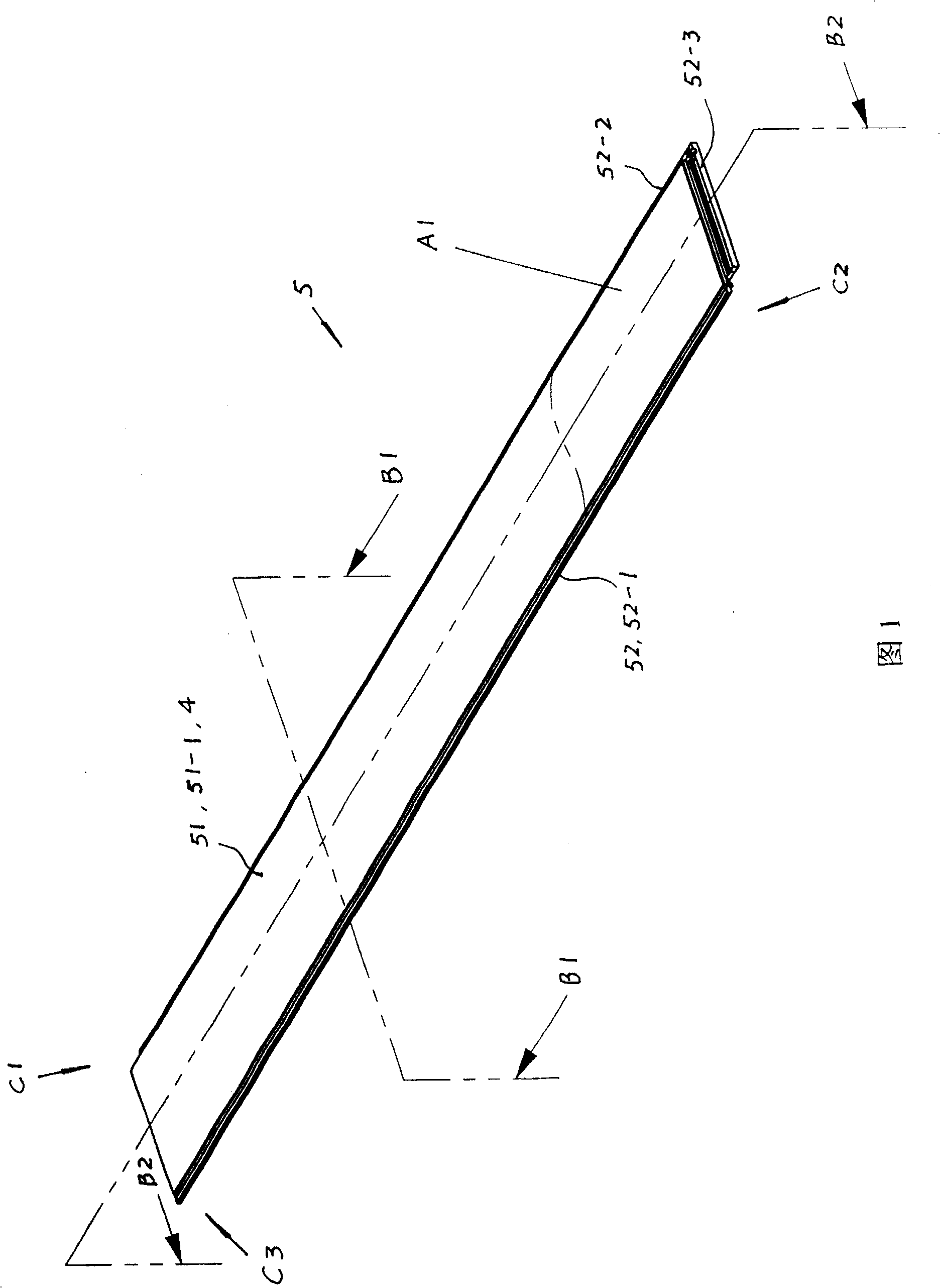

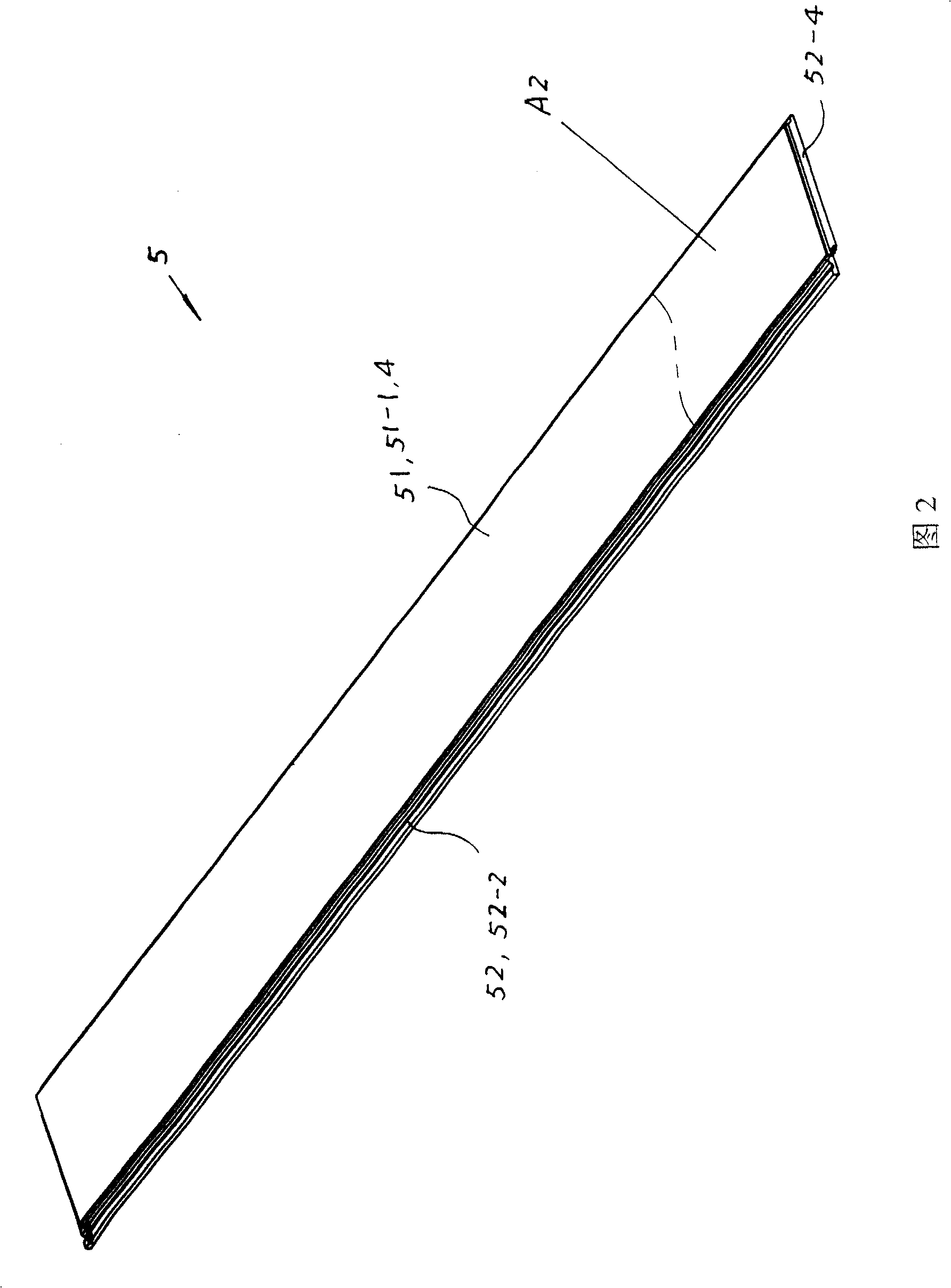

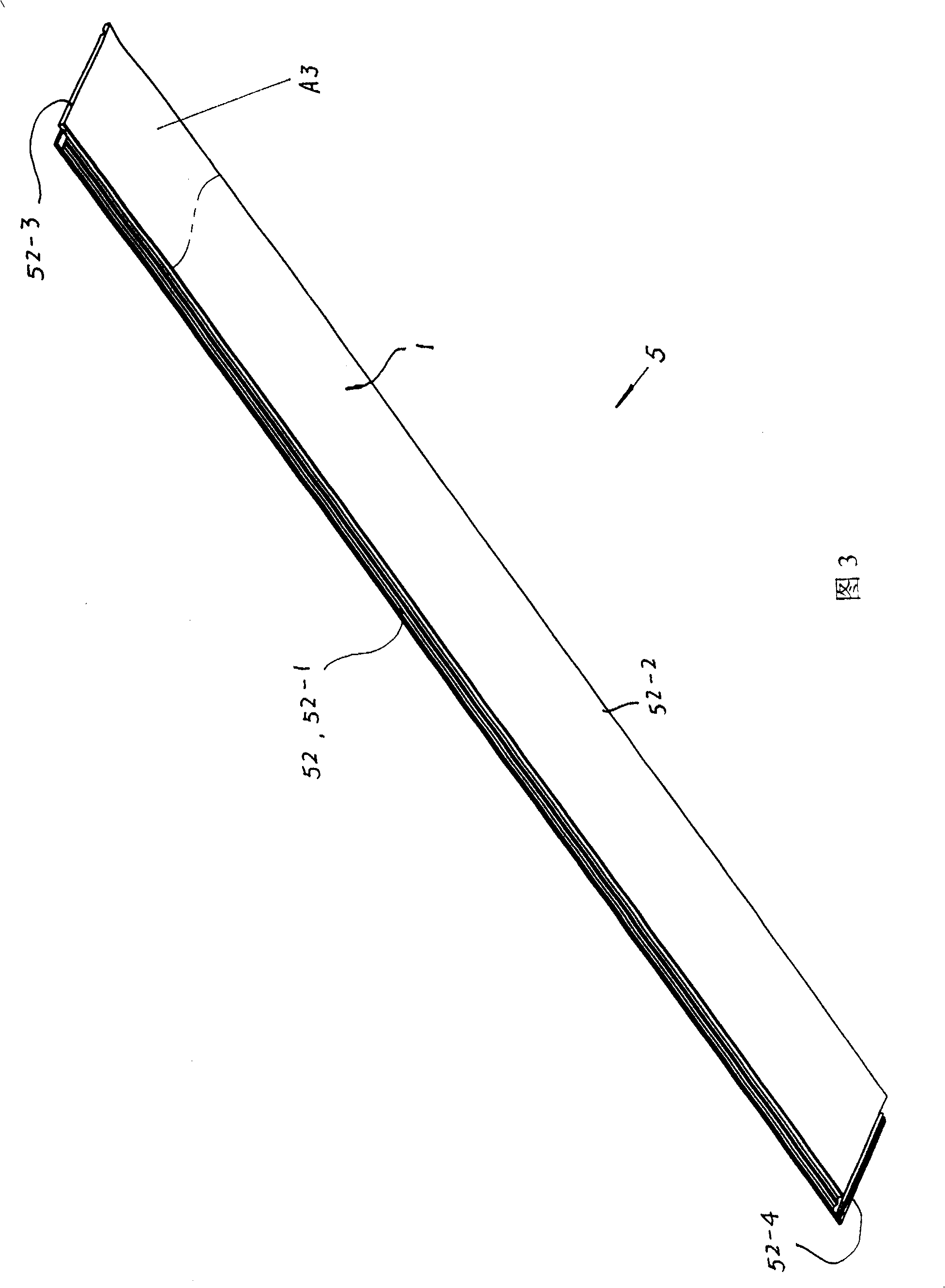

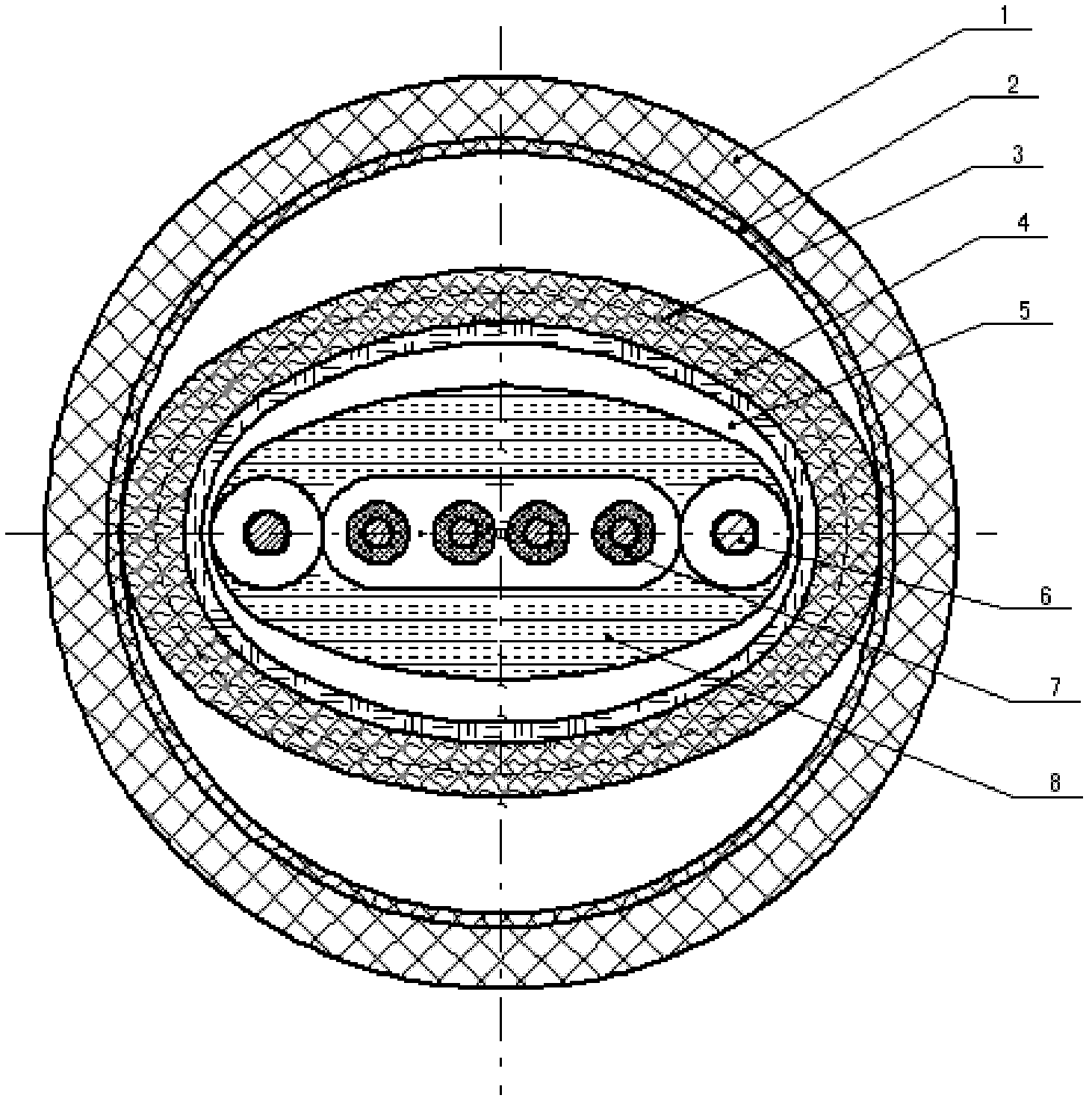

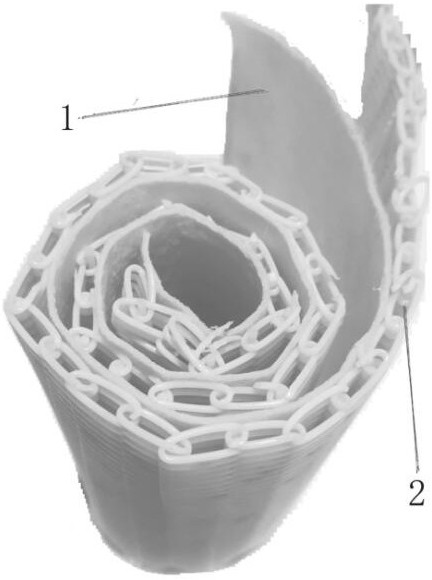

Novel composite material cable trough box for rail transit

The invention provides a novel composite material cable trough box for rail transit. The novel composite material cable trough box comprises a cable trough body (1) and a cable trough cover (2) which covers the upper surface of the cable trough body (1), wherein the cable trough box is prepared from the following components in parts by weight by virtue of a pultrusion process: 15-35 parts of unsaturated polyester resin, 15-35 parts of aluminum hydroxide micro powder, 40-70 parts of glass fiber, 0.5-1.5 parts of mold releasing agent, 0.1-0.2 part of ultraviolet absorbent and 3-10 parts of additives. The cable trough box provided by the invention has the advantages of high flame-retardant performance, low smoke toxicity, high strength, low density, good aging resistance, convenience in assembly, low cost, short production cycle and the like.

Owner:NINGBO HUAYUAN FRP ELECTRICAL APPLIANCE MFR

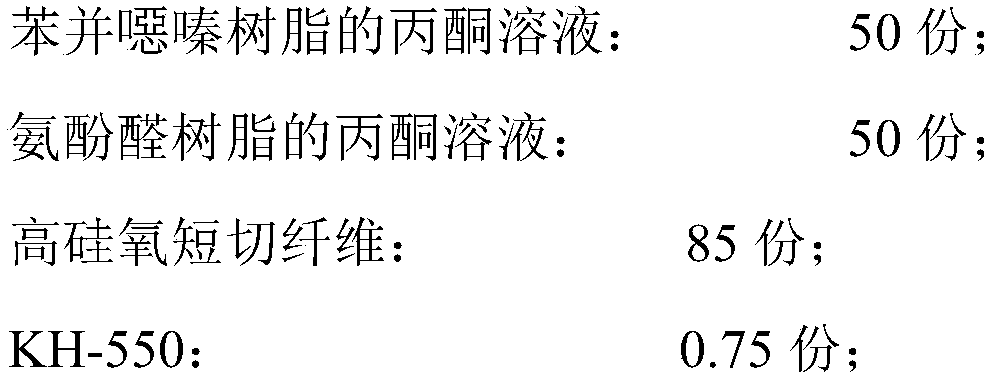

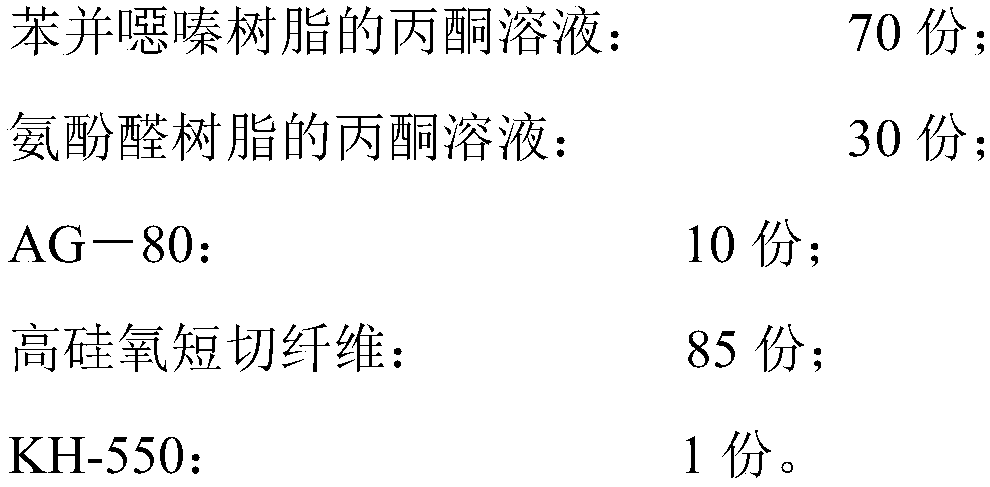

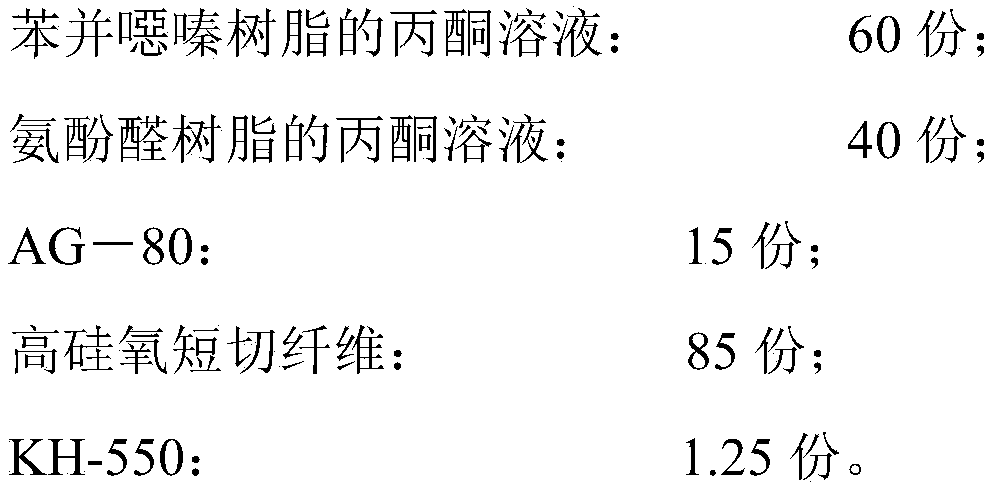

Benzoxazine resin-based reinforcing fiber composite material and forming method thereof

InactiveCN109486104AImprove mechanical propertiesImproves ablation resistanceCompression moldingKetone solvents

The invention provides a benzoxazine resin-based reinforcing fiber composite material and a forming method thereof. The method includes steps: dissolving, by weight, 50-70 parts of benzoxazine resin and 30-50 parts of ammonia phenolic resin into a ketone solvent in equal weight; well mixing with, by weight, 0.5-2.5 parts of gamma-aminopropyl triethoxysilane and 170 parts of high-silica chopped fibers; airing in the sun, drying and performing compression molding. A prepared lining is smooth and glossy in surface and free of bumps and cracks, the tested average tensile strength is 145MPa, the bending strength is 150MPa, the linear ablative rate is 0.13mm / s, and the lining is dense and flawless internally. The benzoxazine resin-based reinforcing fiber composite material can be applied to preparation of solid rocket engine jet pipe linings and other heatproof structures and has advantages of great product manufacturability, no pores, no cracks, ablation resistance and flame retardation.

Owner:西安长峰机电研究所

Hot pressed reinforced wooden floor board and upper mold steel plate of hot press

The present invention belongs to hot pressed reinforced wooden floor board and molding steel plate of hot press for making the wooden floor board. The working surface of the molding steel plate has criss-cross ribs including longitudinal ribs in the length direction of the steel plate and transverse ribs in the width direction of the steel plate. The hot press with the steel plate is used to make reinforced wooden floor board with criss-cross grooves in the upper surface, and the reinforced wooden floor board may be further processed into reinforced wooden floor board with ramps in the edges. Using the reinforced wooden floor board in laying floor can form V-shaped seams and this results in lowered requirement of floor board in flatness and laying effect similar to that of solid timber floor boards.

Owner:江苏力驰新能源科技有限公司

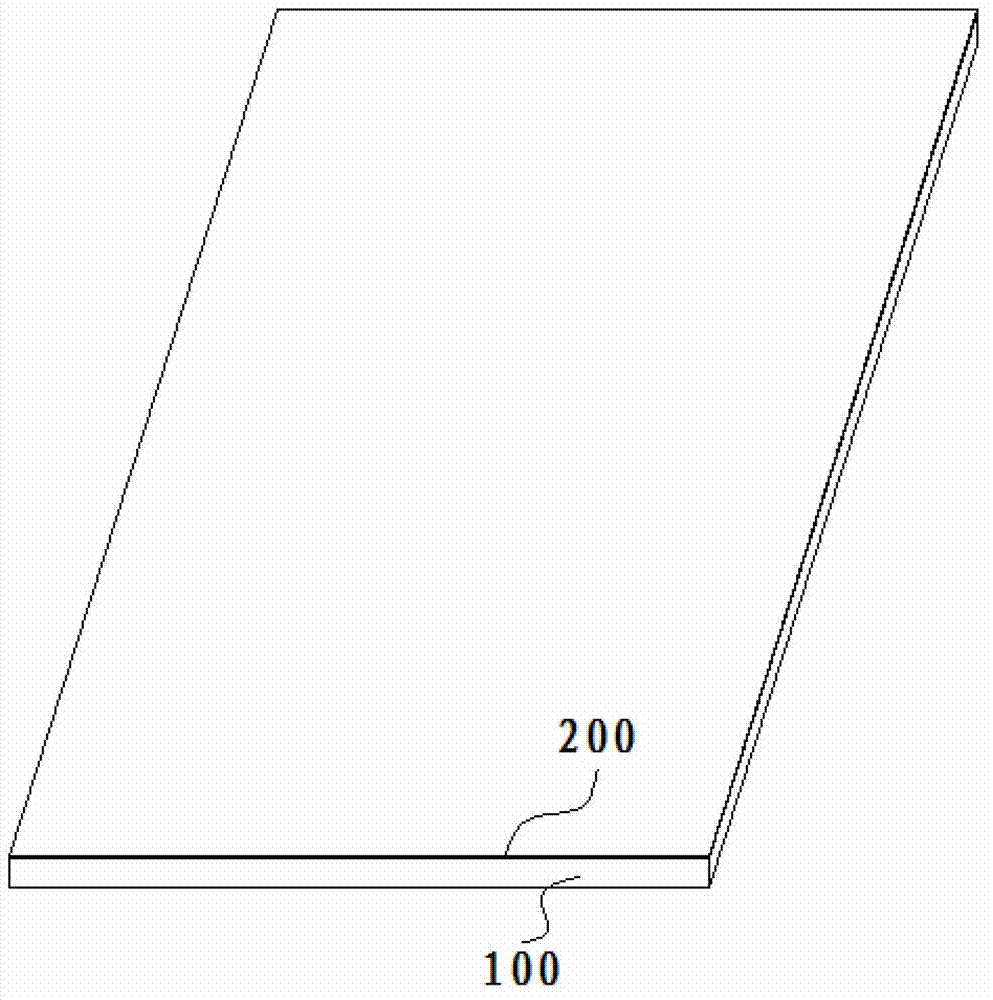

Polyvinyl chloride (PVC) two-layer composite board used for refrigeration equipment

InactiveCN103158315AGood compatibilityImprove tensile propertiesSynthetic resin layered productsEngineeringSurface plate

The invention discloses a polyvinyl chloride (PVC) two-layer composite board used for refrigeration equipment. The PVC two-layer composite board used for the refrigeration equipment comprises a modified PVC base plate and a PVC panel. The PVC panel is arranged on the upper surface of the modified PVC base plate. Due to the fact that the base plate and the panel are both made of PVC materials, the PVC two-layer composite board used for the refrigeration equipment possesses good compatibility, can improve tensile property of plates and reduces crazing risks, and the PVC materials possess good fire resistance and self-extinguishment and are low in cost.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

Fire-proof composite board core material and preparation method

InactiveCN108395200ALow solid state heat transferReduce fireCeramic shaping apparatusFiberFire protection

The invention discloses a fire-proof composite board core material. Powder of the fire-proof composite board core material comprises a base material and mixing liquid. The base material is prepared from aluminium silicate fibers, magnesium hydrate, mineral cotton, silicon dioxide, expanded vermiculite, silicon carbide and nano-reinforced fibers. The mixing liquid is ZRY fiber flame-retardant liquid. The nano-reinforced fibers comprise nano aluminium oxide powder and flame-retardant fibers or fire-proof fibers covered by the nano aluminium oxide powder. A core board is rational in formula design, the synergistic effect is achieved between components, the core board prepared by the formula of the preparation method has low solid heat conduction, and fire protection and flame retarding effects, and the effect is apparently superior to the prior art.

Owner:JIANGSU ALUMEIGE NEW MATERIALS

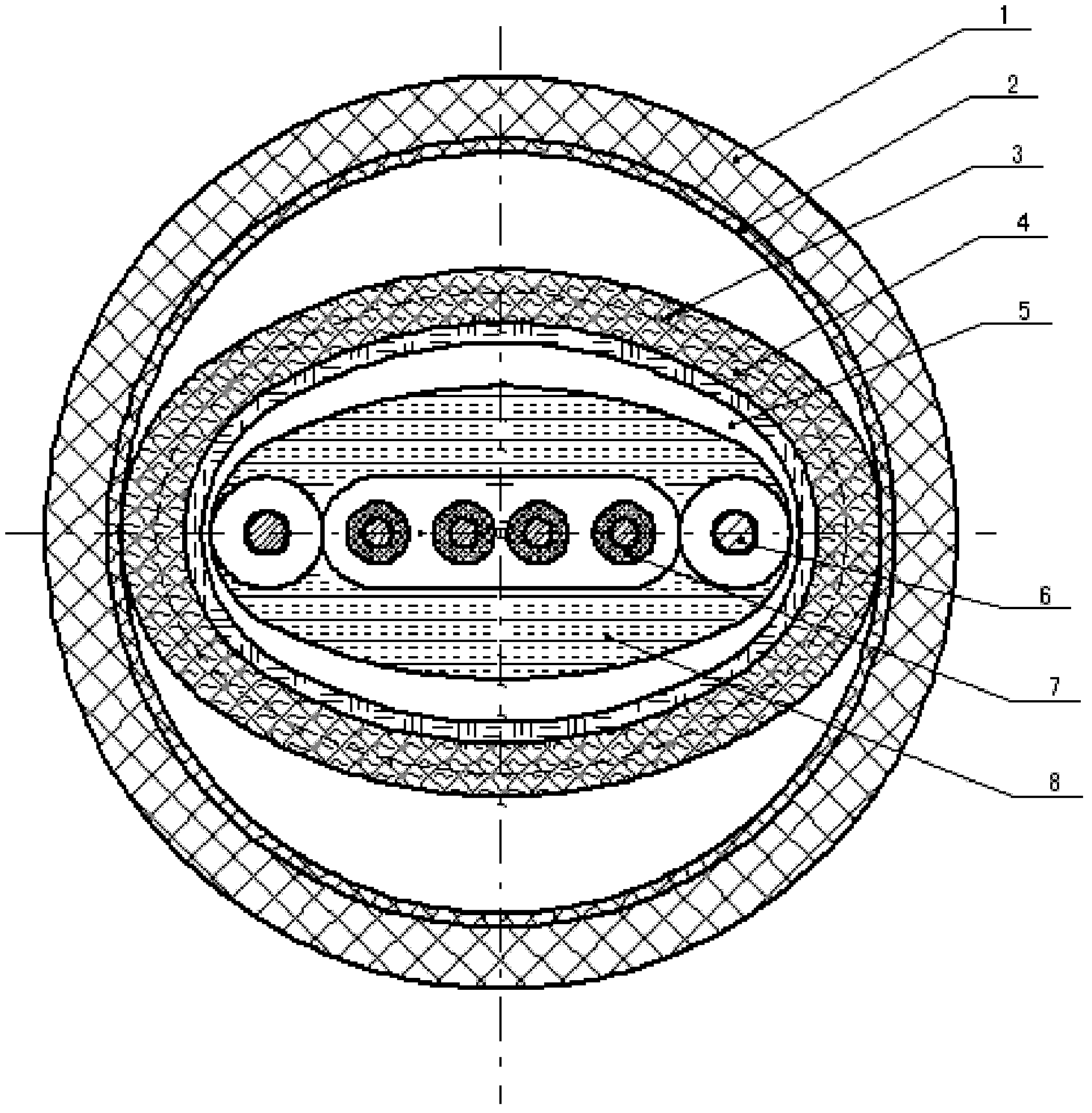

Wear-resistant vibration cable with multiple parallel cores

InactiveCN102426882AImprove reliabilityStrong reliabilityInsulated cablesBurglar alarm mechanical actuationPolyesterWear resistant

The invention relates to a wear-resistant vibration cable with multiple parallel cores. An inner sheath layer is coaxially sleeved in an outer sheath layer; an outer sheath adopts a wear-resistant flame-retardant polyurethane material, and the inner sheath layer adopts a polyethylene material; an elliptic polyester aluminum-plastic composite layer is coaxially sleeved in the inner sheath layer, a metal woven mesh is coaxially embedded in the polyester aluminum-plastic composite layer, a polyester film layer is coaxially sleeved in the polyester aluminum-plastic composite layer, and two directionally-slotted rubber magnetic stripes which are parallelly arranged on an upper part and a lower part along a cable direction and have different magnetic properties are coaxially sleeved in the polyester film layer; and parallel integrated signal wires are arranged on the center part in the two directionally-slotted rubber magnetic stripes, and a vibration line in mirror symmetry is movably arranged in each directionally-slotted rubber magnetic stripe between the parallel integrated signal wires and the polyester film layer. The vibration cable opens up a new path in the field of warning cables, has an intelligent warning function with a very low rate of false alarm and has strong blocking effect and deterrent effect, so that the perimeter security precaution technology of China goes up to a new stage.

Owner:天津亨特尔线缆有限公司

Neutral phenolic foam plastic and preparation method thereof

The invention provides a neutral phenolic foam plastic which is prepared from the following raw materials in parts by weight: 100 parts of thermosetting phenolic resin, 2-5 parts of a surfactant, 3-13parts of a foamer, 0.5-3 parts of melamine and 1.5-5 parts of an acid curing agent. The invention also provides a preparation method of the neutral phenolic foam plastic. The preparation method comprises the following steps: mixing the thermosetting phenolic resin, the surfactant and the foamer; then adding the acid curing agent to be uniformly mixed to prepare a mixture; and foaming the mixturein a microwave environment. The neutral phenolic foam plastic prepared by the invention is reasonable in formula, simple in preparation process and low in cost, and the dosage of the acidifying agentis reduced greatly; the prepared phenolic foam plastic does not corrode the building surface or metal contacting the phenolic foam plastic.

Owner:LONGYAN ZIJIN INNOVATION RES INST

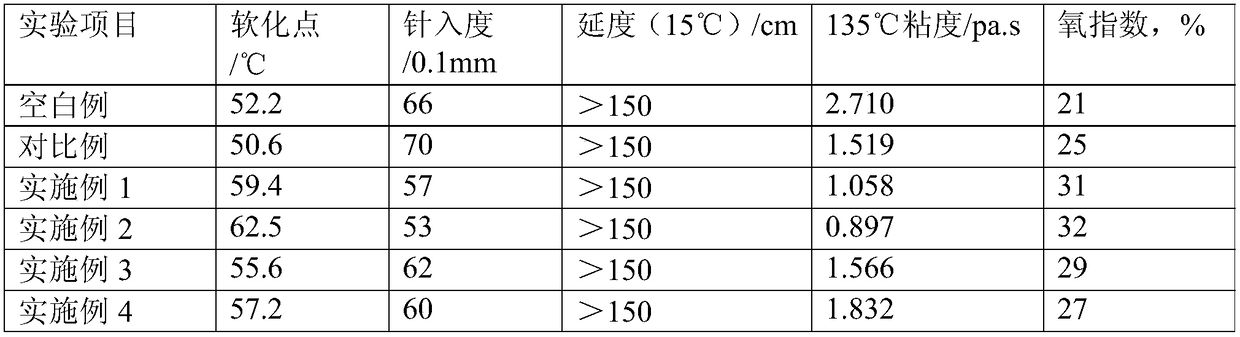

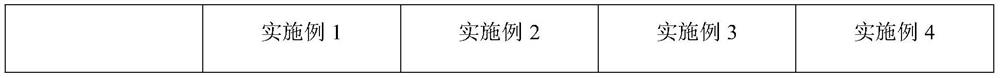

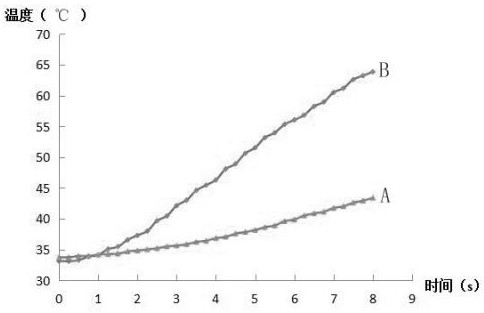

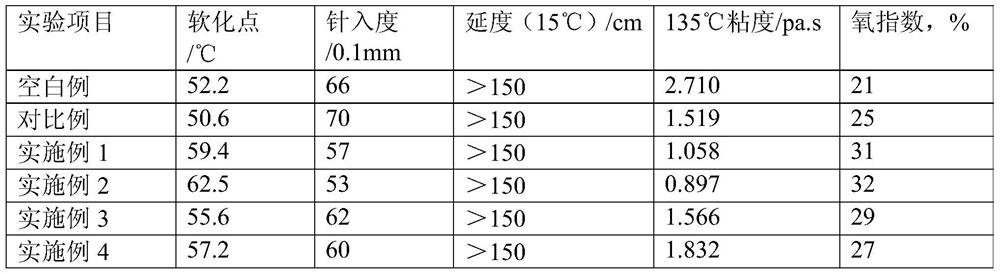

Flame-retardant low-viscosity rubber asphalt and preparation method thereof

ActiveCN108659554AHigh softening pointGood swelling effectBuilding insulationsRubberized asphaltPetroleum

The invention belongs to the technical field of petroleum asphalt, and particularly relates to flame-retardant low-viscosity rubber asphalt and a preparation method thereof. The flame-retardant low-viscosity rubber asphalt is prepared from the following raw materials in parts by mass: 100 parts of matrix asphalt, 0.5-3 parts of rubber powder, 0.5-10 parts of chlorinated paraffin, 1-10 parts of a swelling agent, 0.5-3 parts of polyethylene, and 1-5 parts of stearic acid substances. The flame-retardant low-viscosity rubber asphalt and preparation method provided by the invention effectively reduce a flame-retardant oxygen index of rubber asphalt and mixing, paving and rolling temperature of a mixture, and overcome the problems of environmental pollution, large energy consumption and asphaltaging; and the preparation method provided by the invention is simple and easy to implement and realize.

Owner:CHINA PETROLEUM & CHEM CORP

Anti-adhesion conveying belt and preparation process thereof

PendingCN114103318ALow priceReduced compatibilityConveyorsLamination ancillary operationsMicro nanoPolymer science

The invention discloses an anti-adhesion conveying belt and a preparation process thereof. Comprising upper covering glue, upper sticking glue, a belt core, lower sticking glue and lower covering glue. The 5-chloroisophthalic acid modified chlorinated paraffin and the superfine active pottery clay are added into the adhesive tape, so that the adhesive strength of the conveying belt under repeated flexing in the using process is guaranteed. Oleamide and a perfluorinated copolymer are added into the covering rubber to play lubricating and anti-adhesion roles, and meanwhile, an anti-adhesion film of which the surface is of a micro-nano double-layer coarse structure is coated on the surface of the covering rubber, and a micro-nano second-order composite surface structure formed by the anti-adhesion film is adopted, so that the form and stability of water drops on the surface of the covering rubber are kept. The original hydrophobic structure can be kept for a long time without being damaged, the hydrophobic stability is relatively good, the anti-adhesion effect is good, and industrial transportation and use are facilitated.

Owner:QINGDAO HUIYANG MINING BELT

Flame-retardant epoxy resin

The invention discloses flame retardant epoxy resin. The epoxy resin comprises the following raw material components in parts by weight: 10-20 parts of a cyclic hydrocarbon compound, 10-15 parts of aflame retardant and curing compound, 60-65 parts of an epoxy resin monomer, 10-15 parts of a flame retardant microcapsule, 8-10 parts of modified phenolic resin, 0.5-1 part of expanded graphite, 3-5 parts of a curing agent, 1.5-4.5 parts of talcum powder, 2-5 parts of quartz sand, 0.5-1 part of a defoaming agent and 0.2-1.5 parts of a leveling agent. The flame retardant microcapsule contains a halogen-free flame retardant, the halogen-free flame retardant is an inorganic flame retardant, and the halogen-free flame retardant contains more than 40% of aluminum hydroxide Al (OH) 3, has flame retardant, smoke abatement and filling three functions, and can generate synergistic flame retardant effect with various substances. The flame retardant microcapsule is a pollution-free inorganic flame retardant, the epoxy resin contains flame retardant and curing compounds, the flame retardant and curing compounds contain the phenolic resin, and an important application of the phenolic resin is as abinder. The phenolic resin can be used as abrasive tools and refractory materials, can provide required mechanical strength, heat resistance and electrical properties for the epoxy resin after crosslinking.

Owner:ANHUI MEIJIA NEW MATERIAL

Production of polycyclic aromatic acetyl compounds

InactiveCN1321957CImprove heat resistanceHigh refractive indexHydrocarbonsAdsorption purification/separationAcenaphthyleneHydrogen halide

Owner:NIPPON STEEL CHEMICAL CO LTD

Carbon fiber composite material and preparation method thereof

InactiveCN111098561AImprove recoverabilityHigh densityLaminationLamination apparatusCarbon fiber compositeFibrous composites

The invention provides a carbon fiber composite material which is formed by mixing chopped carbon fibers and an organic material and then hot-pressing, wherein the hot-pressing temperature of hot-pressing molding is equal to or higher than the melting point of the organic material, and the weight ratio of the chopped carbon fibers to the organic material is (70-90): (10-30). The carbon fiber composite material has the properties of low density, flame retardance, fire prevention, high heat insulation and sound insulation of the carbon fiber composite material, and also has good pressure resistance and high resilience. The invention also provides a preparation method of the carbon fiber composite material. The composite material prepared by the method is stable and uniform in structure.

Owner:广东航科新材料有限公司

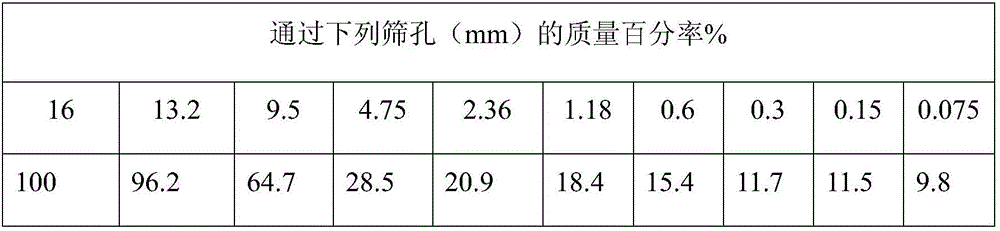

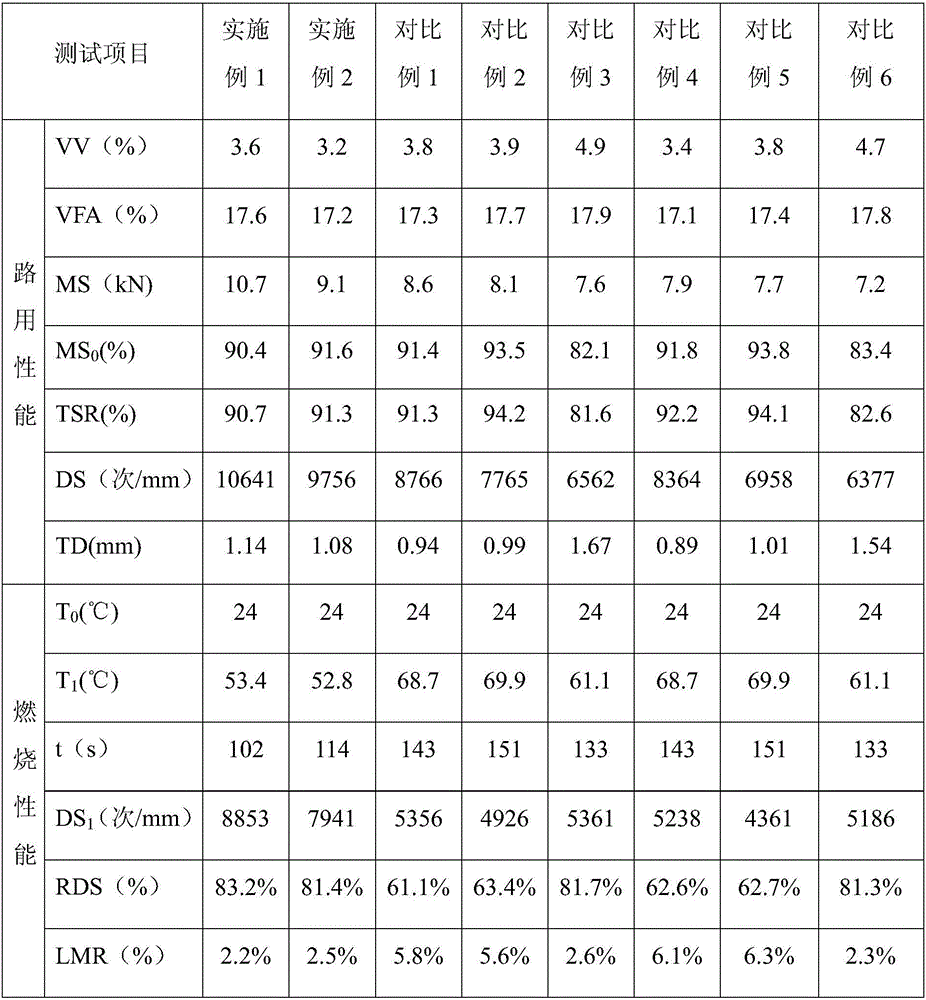

A composite warm-mix flame-retardant anti-skid asphalt tunnel pavement material and its preparation method

ActiveCN105837091BReasonable construction depthImproves rutting resistanceSolid waste managementClimate change adaptationFiberRoad surface

The invention discloses a composite warm-mixed flame-retarding antiskid asphalt tunnel pavement material which includes, by weight, 80-90 parts of aggregate, 5-15 parts of a functional filling material, 4-7 parts of high-viscosity high-elasticity modified asphalt, 0.4-0.7 parts of a warm mixing agent, and 0.2-0.5 parts of mineral fibers. The composite warm-mixed flame-retarding antiskid asphalt tunnel pavement material has a compact framework structure and has reasonable construction depth and high anti-track capability, thereby ensuring antiskid and durable performances of the mixture. The emulsifying-type warm mixing agent is compounded with the functional filling material for comprehensively controlling the mixing temperature of the asphalt mixture. With the composite flame-retarding component, a gradient-temperature flame-retarding effect is achieved. The asphalt tunnel pavement material is antiskid when being spread, is flame-retarding and is low in mixing temperature, and satisfies a special semi-sealed environment.

Owner:广州市市维新材料科技有限公司

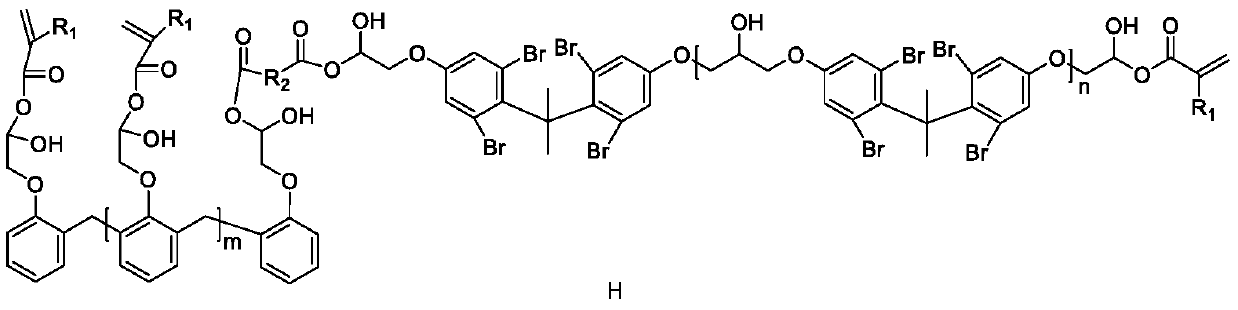

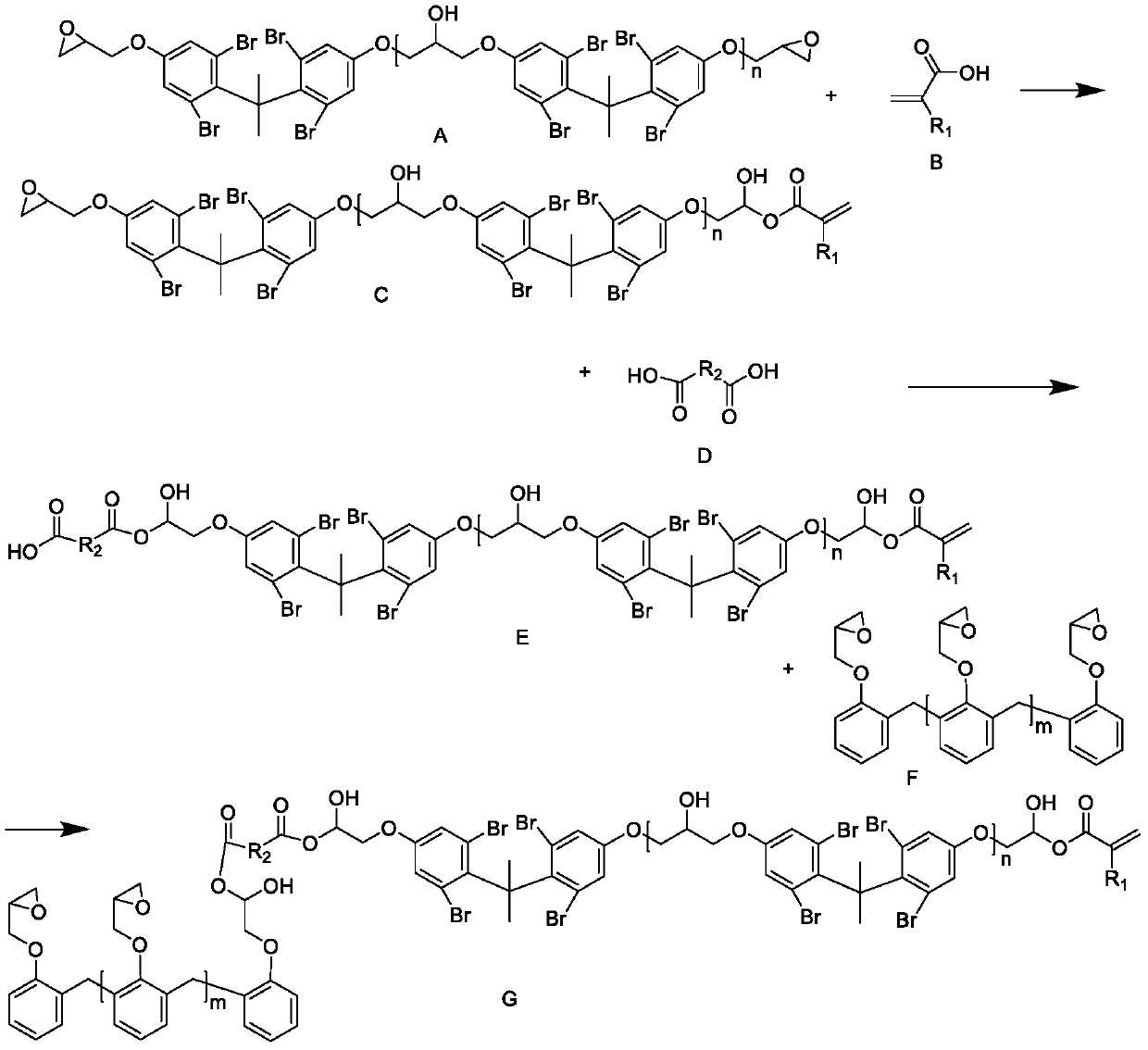

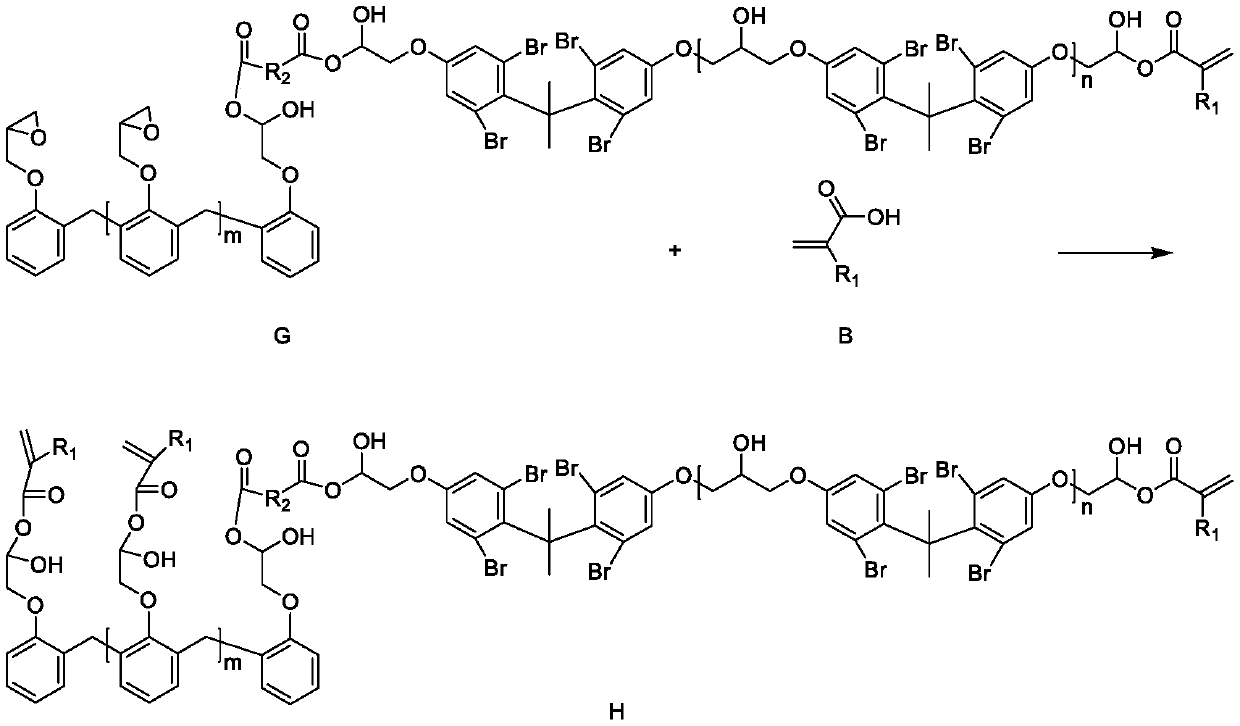

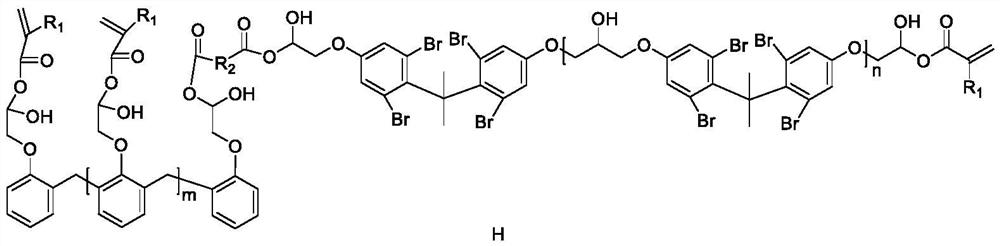

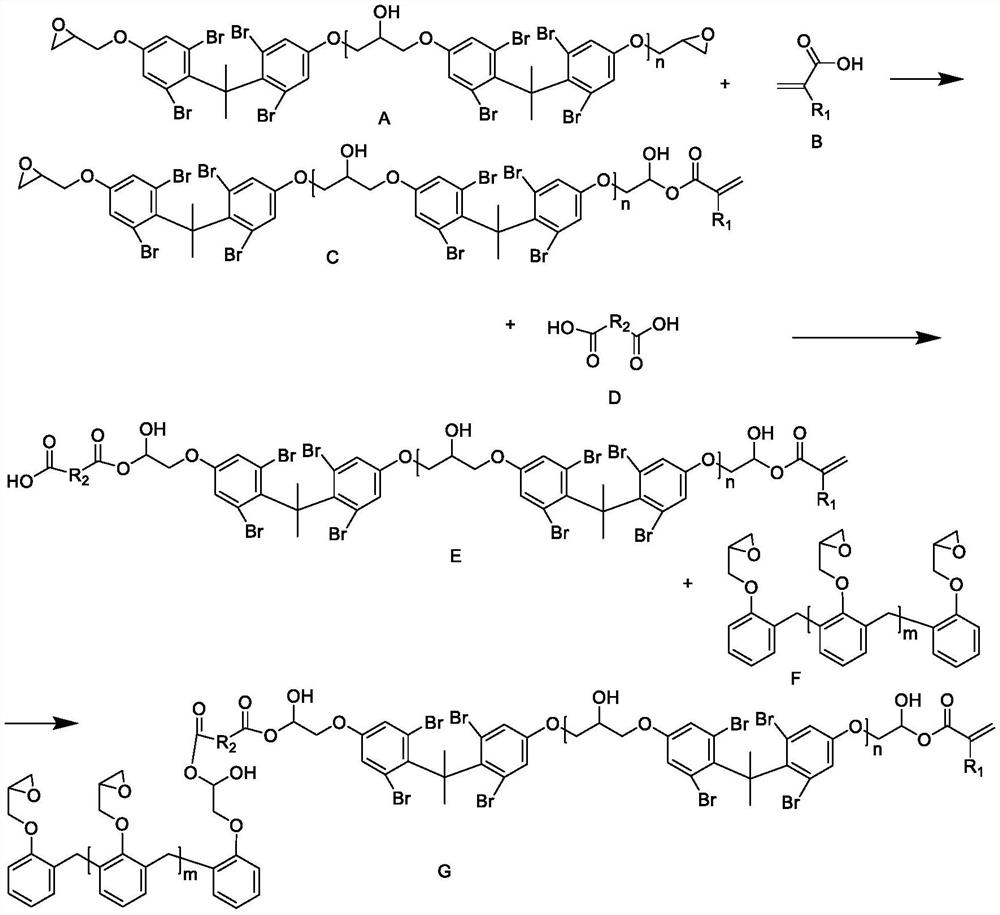

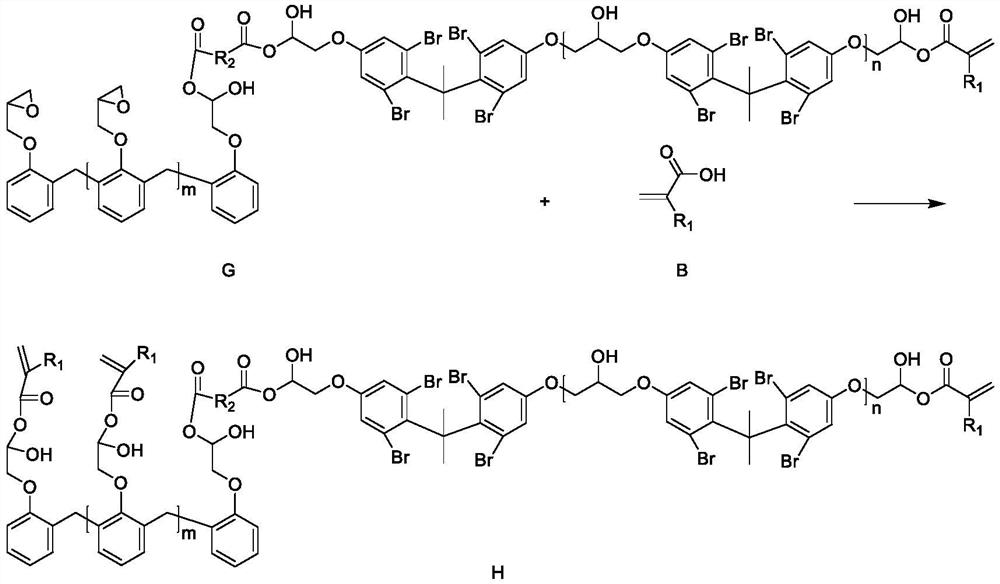

Vinyl ester resin as well as preparation method and application thereof

The invention relates to the technical field of high polymer materials, and particularly discloses a vinyl ester resin as well as a preparation method and application thereof. The vinyl ester resin ofthe present invention contains one or more resin H units having a structure disclosed in the invention, where n is 1-3; m is 1 to 3; R1 is -H or-CH3, R2 is-(CH2)2-, and -(CH2)4-. The preparation method comprises the following steps: (1) reacting brominated bisphenol A epoxy resin A with a monocarboxylic acid to prepare resin C; (2) reacting the resin C with a dicarboxylic acid to obtain resin E;(3) reacting the resin E with phenolic epoxy resin F to obtain resin G. The preparation method is simple in preparation, and the prepared modified vinyl ester resin is colorless and transparent in appearance, high in strength, possesses corrosion resistance, flame resistance, heat resistance and the like, can be cured in a photocuring mode, and is suitable for being applied to environmental protection engineering.

Owner:力森诺科高分子材料(上海)有限公司

Polyimide modified polyisocyanurate foam and preparation method thereof

The invention discloses a polyimide modified polyisocyanurate foam material and a preparation method thereof. A polyimide precursor prepared by esterification reaction of aromatic dianhydride and aromatic diamine with fatty alcohol is compounded with polyester polyol, polyether polyol, a surfactant, a foaming agent, a catalyst, and the like to form a foam combination solution, the solution chemically reacts with polyisocyanate to foam, and then the polyimide modified polyisocyanurate foam is endued with properties such as high-temperature resistance and flame retardance. The modified polyisocyanurate foam material comprises (1) the foamable polyimide precursor, (2) benzoic anhydride polyester and sucrose polyether polyol, (3) a polyisocyanate curing agent, and (4) an organosilicon foam stabilizer, the organic fluorinated surfactant, the trimerization catalyst and the foaming agent. According to the foam material and the preparation method, a one-step foaming technology is adopted, and the technology is simple and convenient and low in cost; and the foam is temperature-resistant, flame-retardant and low in smoke density, so that the popularization and application are facilitated.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

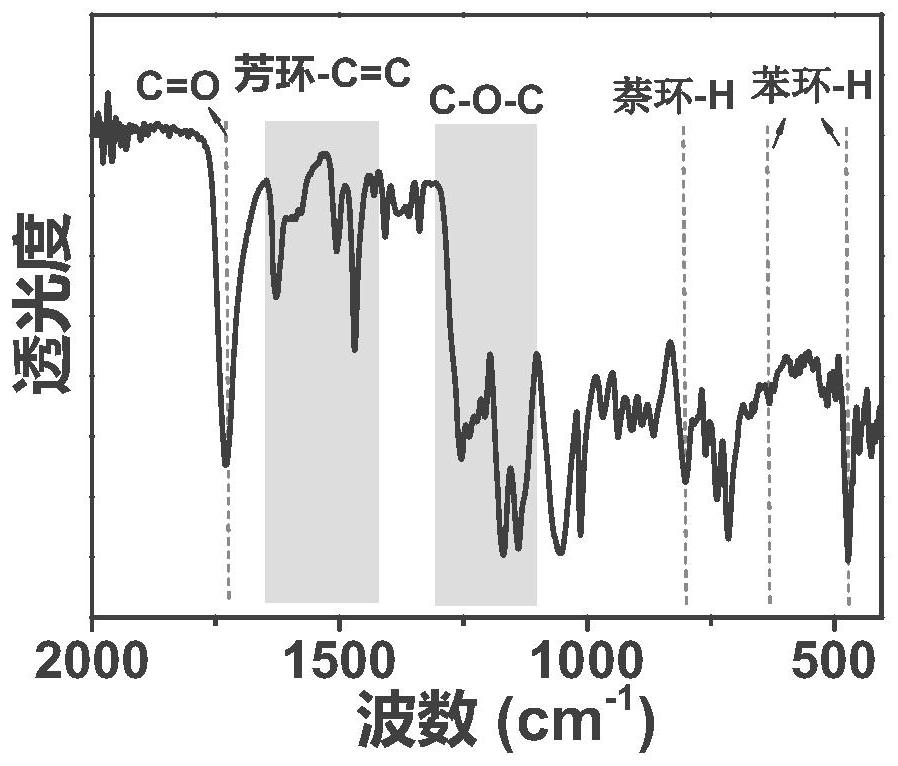

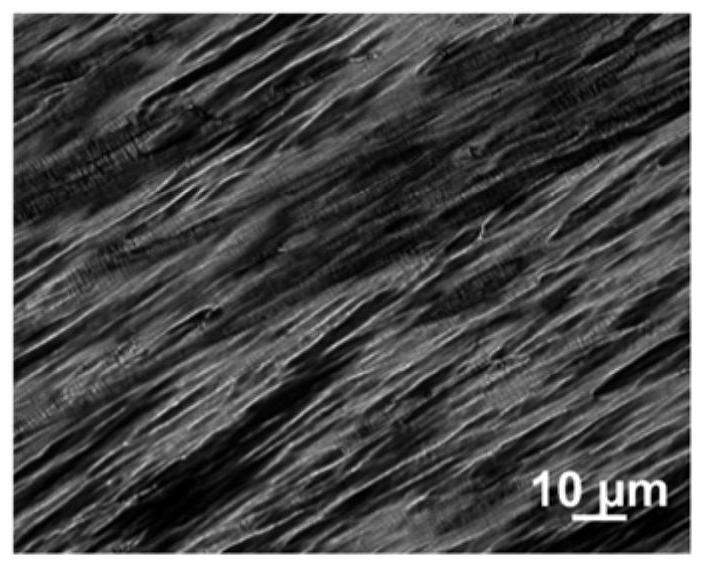

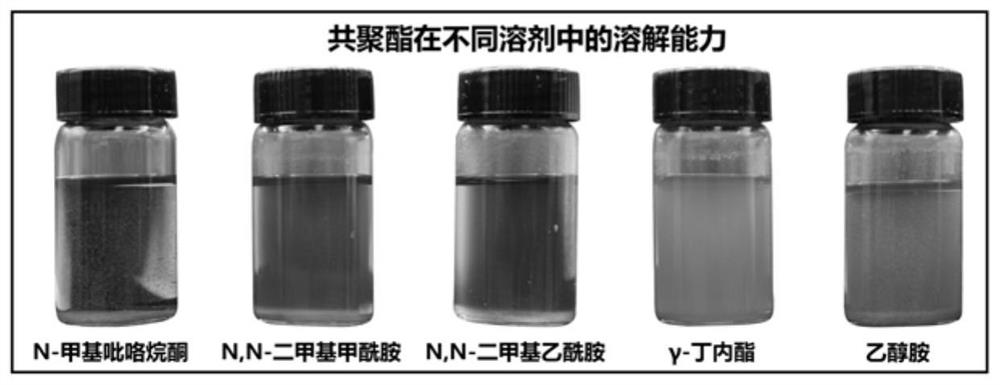

Soluble flame-retardant wholly aromatic copolyester with low dielectric constant and low dielectric loss as well as preparation method and application of soluble flame-retardant wholly aromatic copolyester

PendingCN114853992AImprove solubilityImprove processing methodsAdditive manufacturing apparatusMonocomponent copolyesters artificial filamentPolymer scienceMeth-

The soluble low-dielectric-constant low-dielectric-loss flame-retardant wholly-aromatic copolyester is composed of structural units represented by I, II and III, the mole percent of II and the mole percent of III are the same, I + II + III is equal to 100 mole percent, I is larger than or equal to 0 mole percent and smaller than or equal to 90 mole percent, II is larger than or equal to 5 mole percent and smaller than or equal to 50 mole percent, III is larger than or equal to 5 mole percent and smaller than or equal to 50 mole percent, the dielectric constant of the soluble low-dielectric-constant low-dielectric-loss flame-retardant wholly-aromatic copolyester is 1.5-4.5, and the dielectric loss of the soluble low-dielectric-constant low-dielectric-loss flame-retardant wholly-aromatic copolyester is 0.0008-0.050. The limit oxygen index is 28-50%; the vertical combustion grade of UL-94 is V-0 grade; the compound can be completely or partially dissolved in conventional solvents such as N-methyl pyrrolidone, N, N-dimethylformamide, N, N-dimethylacetamide and the like. The invention also discloses a preparation method and application of the compound. The copolyester disclosed by the invention not only can obviously enhance the dissolving capacity of the copolyester in a conventional organic solvent, but also can effectively reduce the dielectric constant and the dielectric loss, can obtain excellent flame retardance and molten drop resistance, can be directly used as a high polymer material, and can also be used as a flame-retardant molten drop-resistant additive.

Owner:SICHUAN UNIV

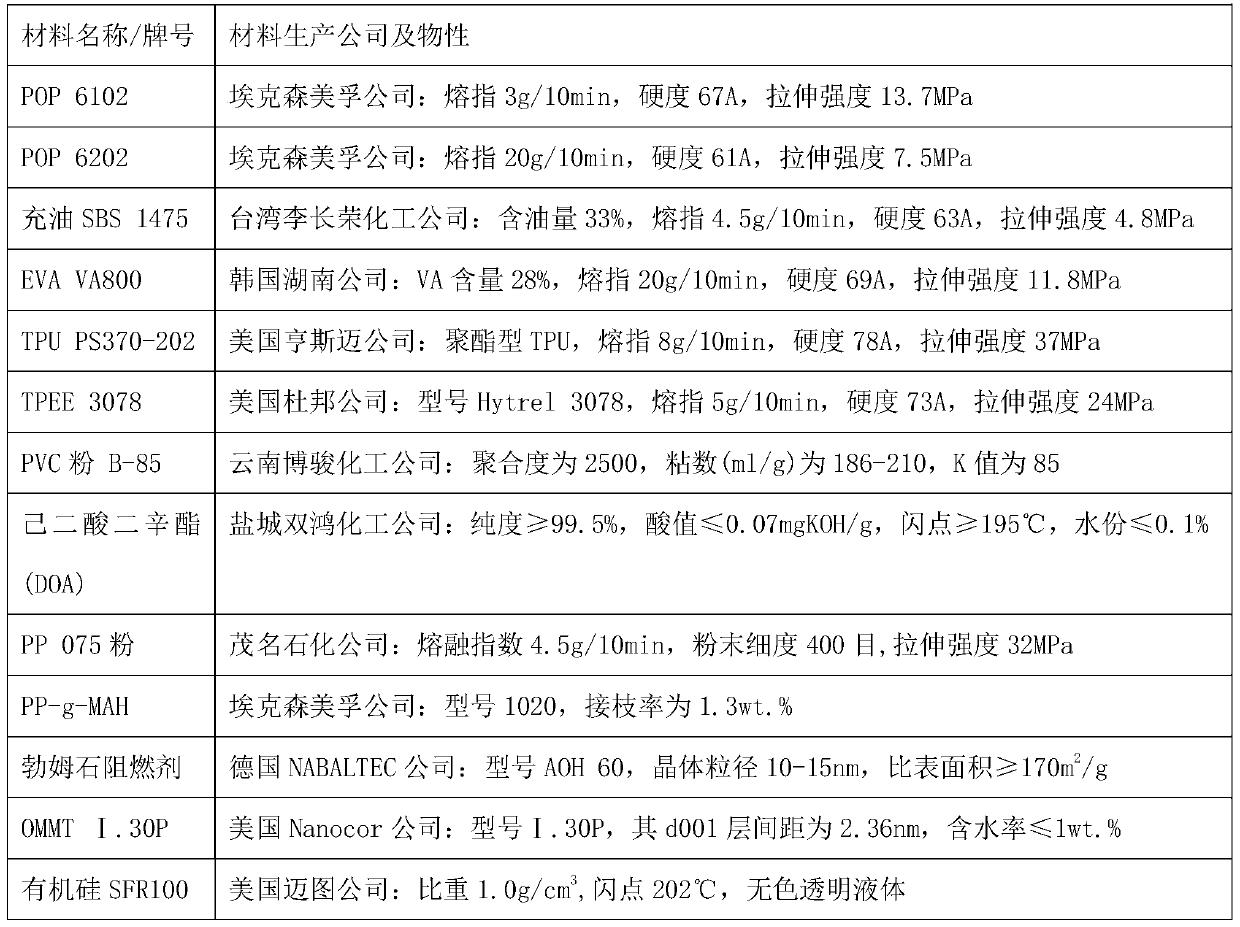

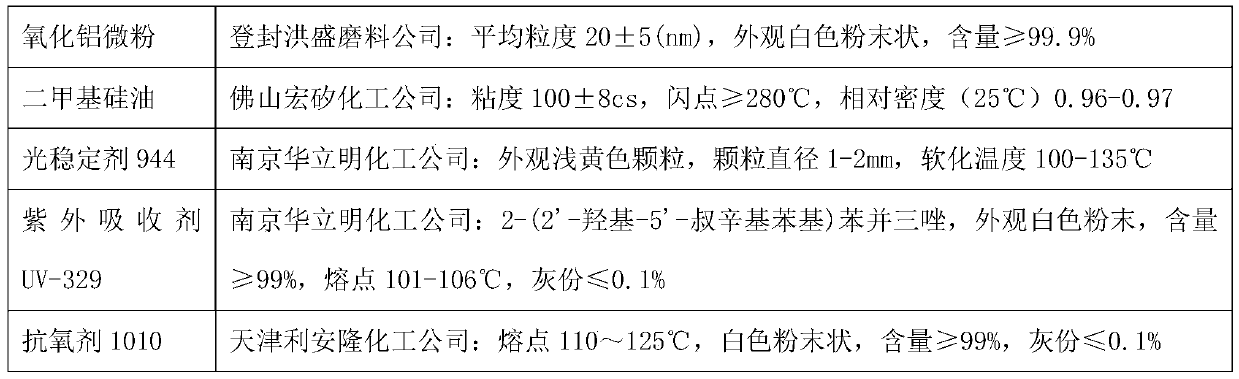

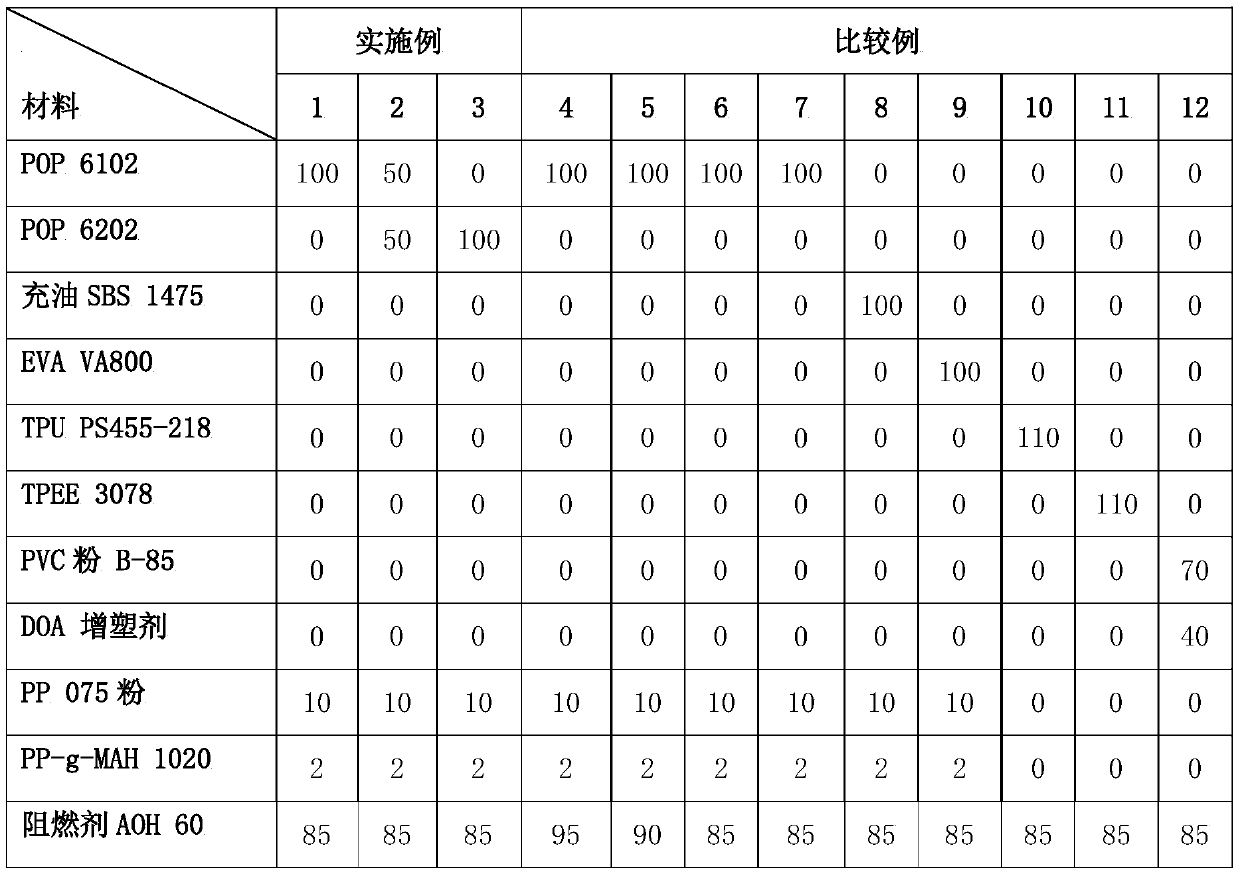

Low-smoke halogen-free flame-retardant automobile foot mat material and preparation method thereof

The invention discloses a low-smoke halogen-free flame-retardant automobile foot mat material and a preparation method thereof. The composition is prepared from the following raw materials in parts byweight: 20-40 parts of starch and 20-40 parts of water. 100 parts by weight of a polyolefin elastomer; 5 to 25 parts by weight of polypropylene powder; 1 to 3 parts by weight of polypropylene graftedmaleic anhydride; 50 to 150 parts by weight of a flame retardant; the composition comprises the following components in parts by weight: 3-15 parts of a flame-retardant synergist I, 5-30 parts of a flame-retardant synergist II, 2-20 parts of a wear-resistant agent, 1.5-3 parts of simethicone, 0.5-2 parts of a light stabilizer, 0.5-2 parts of an ultraviolet absorbent and 0.1-1 part of an antioxidant. The automobile foot mat material prepared by the invention has the characteristics of low smoke, no halogen, flame retardance, softness, wear resistance, aging resistance, easiness in coloring andthe like.

Owner:NANTONG UNIVERSITY +1

A kind of vinyl ester resin and its preparation method and application

The invention relates to the technical field of polymer materials, and specifically discloses a vinyl ester resin, a preparation method and application thereof. The vinyl ester resin of the present invention contains one or more resins H of the following structure, wherein, n is 1-3; m is 1-3; R 1 is ‑H or ‑CH 3 , R 2 for—(CH 2 ) 2 —,—(CH 2 ) 4 -or the preparation method of the present invention comprises the following steps: (1) reacting brominated bisphenol A type epoxy resin A with monocarboxylic acid to obtain resin C; (2) reacting resin C with dibasic carboxylic acid to obtain resin E; (3) Resin G is obtained by reacting resin E with novolac epoxy resin F. The method is simple to prepare, and the prepared modified vinyl ester resin has colorless and transparent appearance, high strength, corrosion resistance, flame retardancy, heat resistance and other properties, can be cured by light curing, and is suitable for application in environmental protection projects.

Owner:SHANGHAI SHOWA HIGHPOLYMER CO LTD

A kind of thermal protection material of airgel composite aramid fiber nonwoven fabric and preparation method thereof

Owner:浙江鹏辰造纸研究所有限公司

Flame-retardant low-viscosity rubber asphalt and preparation method thereof

ActiveCN108659554BHigh softening pointHigh elongationBuilding insulationsStearic acidChlorinated paraffins

The invention belongs to the technical field of petroleum asphalt, and in particular relates to a flame-retardant low-viscosity rubber asphalt and a preparation method thereof. The flame-retardant low-viscosity rubber asphalt is made of the following raw materials in parts by mass: 100 parts of base asphalt, 0.5-3 parts of rubber powder, 0.5-10 parts of chlorinated paraffin, 1-10 parts of swelling agent, 0.5-3 parts of polystyrene Ethylene, 1 to 5 parts of stearic acid substances. The invention effectively reduces the flame retardant oxygen index of the rubber asphalt and the mixing, paving and rolling temperature of the mixture, and overcomes the problems of environmental pollution, high energy consumption and asphalt aging and decay. The preparation method of the invention is simple and easy to implement.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com