Low-smoke halogen-free flame-retardant automobile foot mat material and preparation method thereof

A technology of automobile floor mats and flame retardants, which is applied in the field of low-smoke halogen-free flame-retardant composite materials for automobile floor mats and its preparation field, which can solve the problems of limited improvement of flame retardancy, non-halogenation of unresolved materials, and the difficulty of floor mat materials Coloring and other problems, to achieve the effect of small smoke, maintain physical and mechanical properties, and reduce the smoke rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In order to better achieve the purpose of the above invention, the present invention also provides a method for preparing a low-smoke, halogen-free, flame-retardant automobile floor mat material, comprising the following steps:

[0031] In the first step, the polypropylene powder, simethicone oil and anti-wear agent in the stated parts by weight are sequentially added to the mixer, and mixed at a high speed for 3 to 5 minutes, so that the anti-abrasive agent alumina micropowder is evenly dispersed in the polypropylene powder middle;

[0032] In the second step, the polyolefin elastomer, polypropylene grafted maleic anhydride, flame retardant, flame retardant synergist I, flame retardant synergist II, light stabilizer, ultraviolet absorber and antioxidant The agent is added to the above-mentioned mixer in turn, and mixed at high speed for 5-10 minutes, so that all the raw materials are fully mixed evenly;

[0033] The third step is to set the temperature of the twin-scr...

Embodiment 1~3

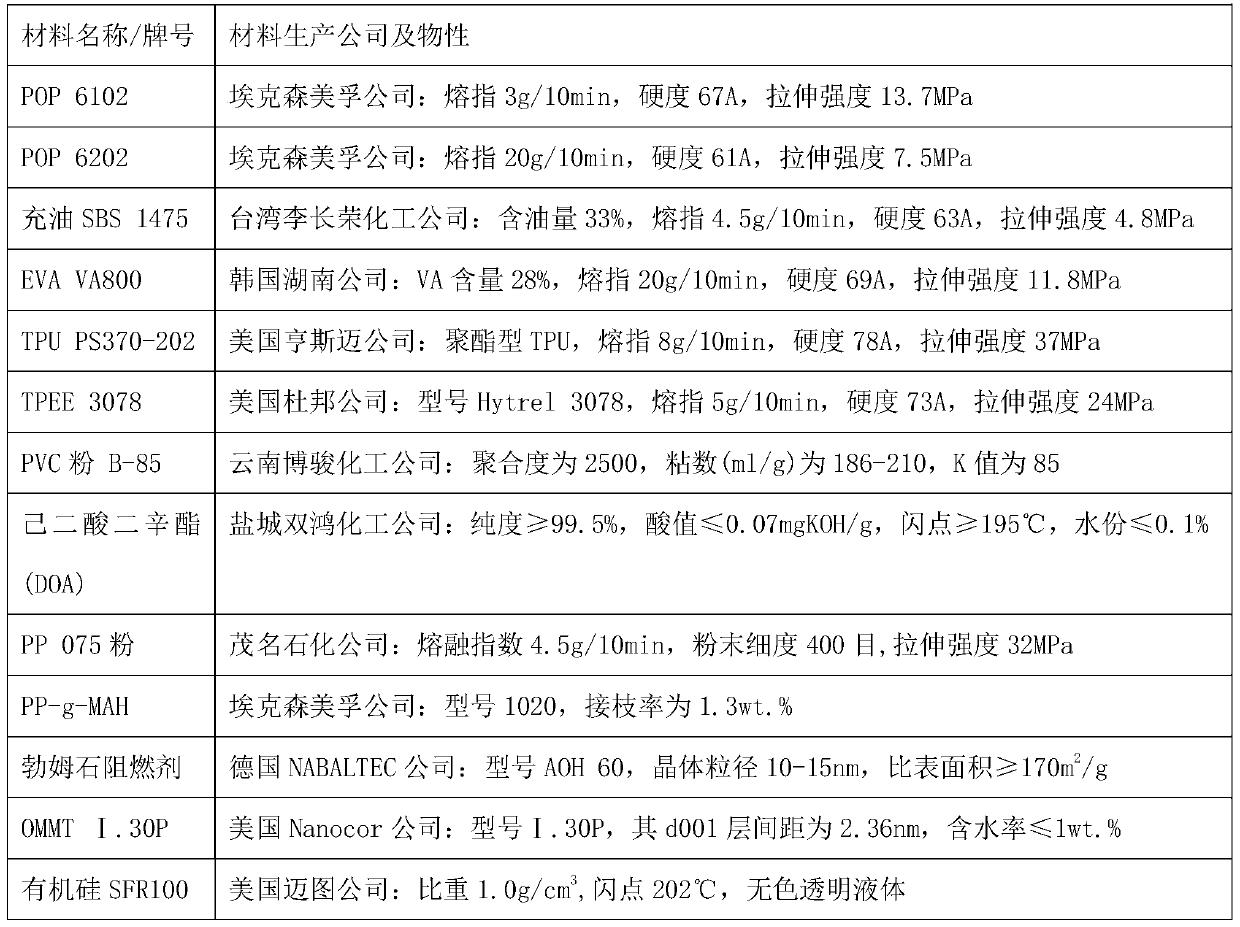

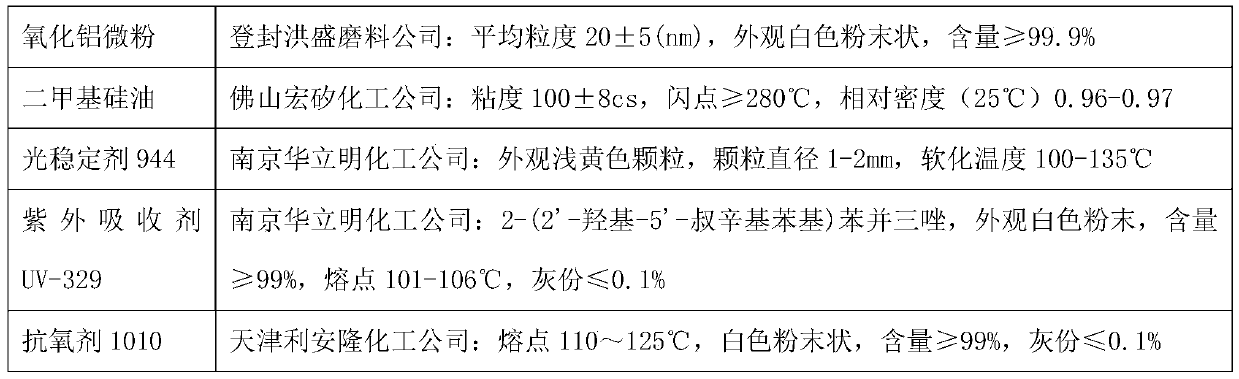

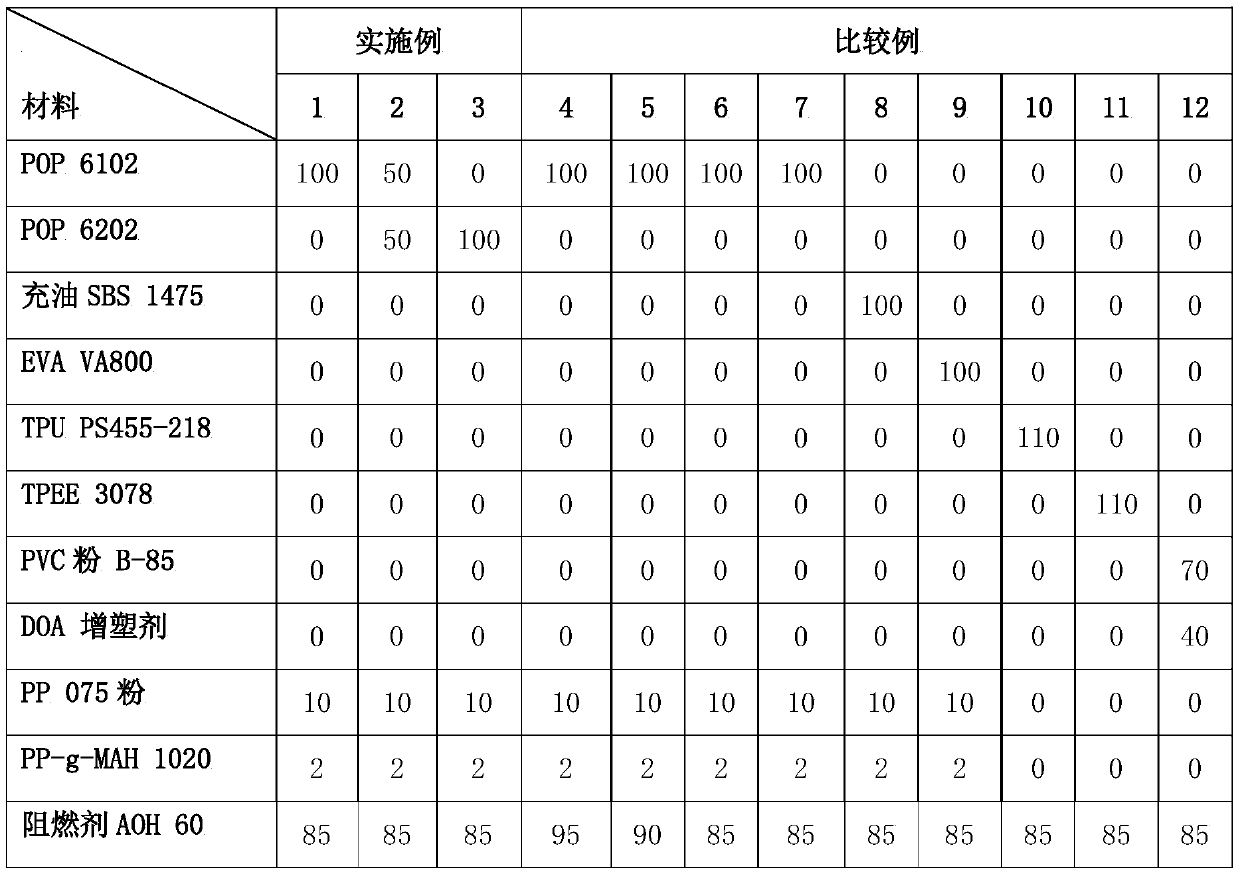

[0048] Examples 1-3: Using POP elastomer and PP powder as basic materials, adding boehmite AOH as inorganic flame retardant, adding OMMT and SFR-100 as flame retardant synergist, adding alumina micropowder as wear-resistant agent, and others See the example data in Table 2 for each component in detail; From the test results of Examples 1 to 3 in Table 3, it can be seen that the prepared low-smoke, halogen-free, and flame-retardant automobile floor mat material has halogen-free, low-smoke, and flame-retardant properties. , soft, high strength, anti-aging, wear-resistant and odorless.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com