Anti-adhesion conveying belt and preparation process thereof

A preparation process and technology of conveyor belts, applied in conveyors, belts, transportation and packaging, etc., can solve the problems of wearing belts, reducing the service life of conveyor belts, reducing conveying efficiency, etc., to enhance strength and elongation, reduce surface Friction, effect of optimizing plasticizing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

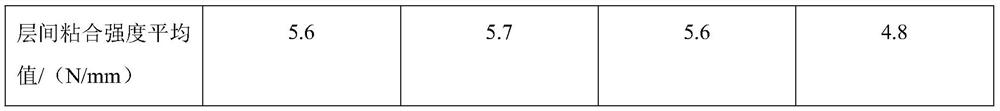

Embodiment 1

[0028] Step 1: Add 100g of methanol and 10g of sodium hydrosulfide into the reactor, heat up to 55°C, slowly add 10ml of 5-chloroisophthalic acid dropwise, react for 11h under nitrogen protection, vacuum dry, pour into ethanol, and vacuum dry to obtain 5-mercaptoisophthalic acid; add 100ml of acetone and 10g of chlorinated paraffin into the reactor, stir, add 12g of 5-mercaptoisophthalic acid and 20g of potassium tert-butoxide, and react under nitrogen protection at 70°C for 11h; After the reaction, extract with ethanol, adjust the pH to 4 with hydrochloric acid, and dry in vacuum to obtain a plasticizer.

[0029] Step 2: Weigh 60g of tetramethylcyclotetrasiloxane and 30g of allyl glycidyl ether, 20g of resorcinol under nitrogen protection, add catalyst; heat up to 55°C at a rate of 3°C / min and react for 2.5h; Then raise the temperature to 90°C at a rate of 3°C / min and react for 2.5 hours; distill under reduced pressure until no low boilers are distilled out to obtain a thicke...

Embodiment 2

[0034] Step 1: Add 100g of methanol and 10g of sodium hydrosulfide into the reactor, heat up to 50°C, slowly add 10ml of 5-chloroisophthalic acid dropwise, react for 10h under nitrogen protection, vacuum dry, pour into ethanol, and vacuum dry to obtain 5-mercaptoisophthalic acid; add 100ml of acetone and 10g of chlorinated paraffin into the reactor, stir, add 12g of 5-mercaptoisophthalic acid and 20g of potassium tert-butoxide, and react under nitrogen protection at 60°C for 10h; After the reaction, extract with ethanol, adjust the pH to 4 with hydrochloric acid, and dry in vacuum to obtain a plasticizer.

[0035] Step 2: Weigh 60g of tetramethylcyclotetrasiloxane and 30g of allyl glycidyl ether, 20g of resorcinol under nitrogen protection, add catalyst; heat up to 50°C at a rate of 2°C / min and react for 2h; then Raise the temperature to 80°C at a rate of 2°C / min and react for 2 hours; distill under reduced pressure until no low boilers are evaporated to obtain a thickener.

...

Embodiment 3

[0040] Step 1: Add 100g of methanol and 10g of sodium hydrosulfide into the reactor, heat up to 60°C, slowly add 10ml of 5-chloroisophthalic acid dropwise, react for 12h under nitrogen protection, vacuum dry, pour into ethanol, and vacuum dry to obtain 5-mercaptoisophthalic acid; add 100ml of acetone and 10g of chlorinated paraffin into the reactor, stir, add 12g of 5-mercaptoisophthalic acid and 20g of potassium tert-butoxide, and react under nitrogen protection at 80°C for 12h; After the reaction, extract with ethanol, adjust the pH to 4 with hydrochloric acid, and dry in vacuum to obtain a plasticizer.

[0041] Step 2: Weigh 60g of tetramethylcyclotetrasiloxane and 30g of allyl glycidyl ether, 20g of resorcinol under nitrogen protection, add catalyst; heat up to 60°C at a rate of 4°C / min and react for 3h; then Raise the temperature to 100°C at a rate of 4°C / min and react for 3 hours; distill under reduced pressure until no low boilers are evaporated to obtain a thickener. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com