Low-friction, low-shrinkage, high-temperature-resistant, low-smoke and halogen-free sheath material for 5G optical cable and preparation method thereof

A low-smoke, halogen-free sheath and low-friction technology, applied to plastic/resin/wax insulators, organic insulators, etc., can solve the problems that the deformation rate cannot meet the requirements of 5G sheath materials and 5G cables, and achieve Improve the mixing effect of dispersion and distribution, reduce the dynamic friction coefficient, and have favorable effects on stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

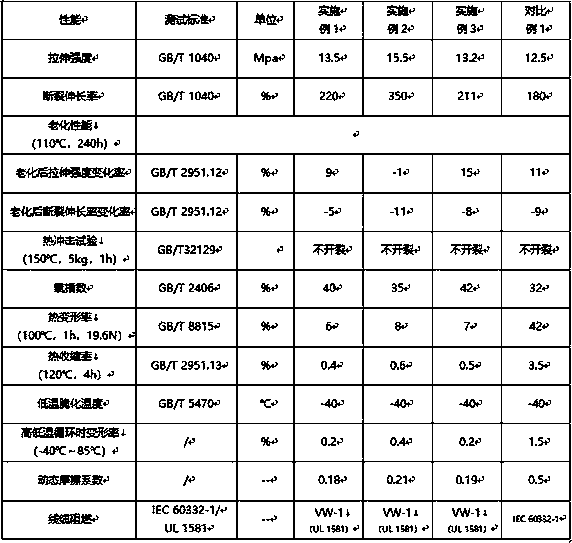

Examples

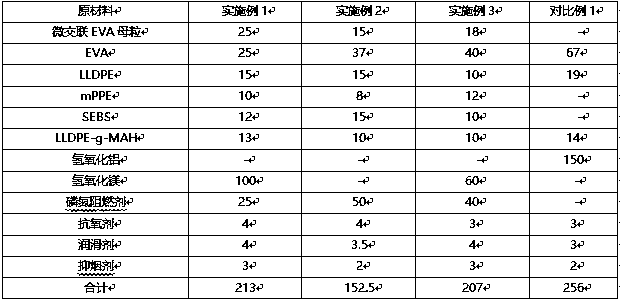

Embodiment 1-3

[0052] The preparation method of embodiment 1-3 cable sheath material is as follows:

[0053] The first step, the production of micro-crosslinked EVA masterbatch

[0054]Ethylene-vinyl acetate copolymer (EVA) with a vinyl acetate (Va) content of 28-33%, cross-linking agent, coupling agent, anti-aging agent, ultra-high molecular weight silicone masterbatch and magnesium hydroxide according to specific After the proportion is weighed, put it into the internal mixer and knead for 10-15min, so that the material melt temperature reaches 130±30°C; then transfer the kneaded material to a twin-screw-single-screw two-stage blending unit to continue mixing. Make the melt temperature of the material reach 170-180° C., cut into pellets by cooling wind, and obtain the micro-crosslinked EVA master batch for future use.

[0055] The second step, pretreatment of raw materials

[0056] The micro-crosslinked EVA masterbatch, ethylene-vinyl acetate copolymer (EVA), linear low-density polyethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com