Polyvinyl chloride (PVC) two-layer composite board used for refrigeration equipment

A technology for refrigeration equipment and composite panels, which is applied in layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve problems such as poor products, foaming agent corrosion, and single appearance, and achieve good flame retardancy and Effects of self-extinguishing, improved tensile properties, reduced risk of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

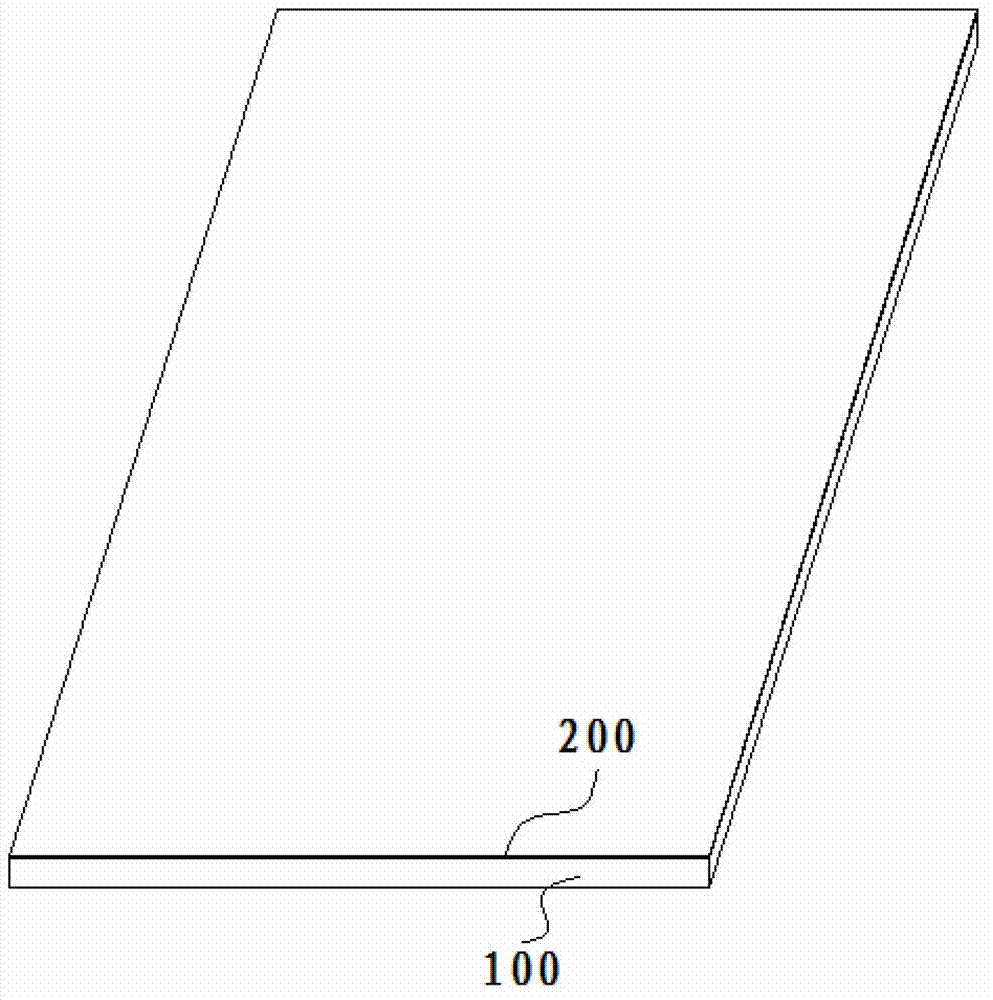

[0047] Embodiment 1: A PVC two-layer composite board for refrigeration equipment according to the embodiment of the present invention (total thickness: 1.0mm)

[0048] PVC panel 200 is made of PVC film imitating metal wire drawing effect.

[0049] The PVC substrate 100 is made of modified PVC.

[0050] Choose 100 parts by weight of low molecular weight PVC-SG5 (Formosa Plastics S-60), 4 parts by weight of calcium / zinc composite stabilizer, 2.5 parts by weight of CPE, 3 parts by weight of ACR, 1 part by weight of stearic acid, 1 The barium stearate of parts by weight, the activated calcium carbonate of 20 parts by weight, and an appropriate amount of toner are mixed. Extruded by a twin-screw extruder, and rolled to form a semi-finished sheet, the thickness of the PVC substrate 100 is 0.95mm by adjusting the gap between the rollers in the calendering equipment, and a PVC panel 200 with a thickness of 0.05mm and an imitation metal wire drawing effect is selected.

[0051] The a...

Embodiment 2

[0052] Example 2: Another PVC two-layer composite board for refrigeration equipment according to the embodiment of the present invention (total thickness: 1.2mm)

[0053] PVC panel 200 selects the PVC film of imitating stainless steel effect for use.

[0054] The PVC substrate 100 is made of modified PVC.

[0055] Choose 100 parts by weight of low molecular weight PVC-SG5 (Qilu S-700), 4 parts by weight of calcium / zinc composite stabilizer, 2.5 parts by weight of CPE, 2.5 parts by weight of ACR, 0.8 parts by weight of stearic acid, 1 weight part The barium stearate of 20 parts, the activated calcium carbonate of 20 parts by weight, and an appropriate amount of toner are mixed. Extruded by a twin-screw extruder, and rolled to form a semi-finished plate, the thickness of the PVC substrate 100 is 1.1 mm by adjusting the gap between the rollers in the calendering equipment, and a PVC panel 200 with a thickness of 0.1 mm and an effect of imitating stainless steel is selected.

[...

Embodiment 3

[0057] Embodiment 3: Another PVC two-layer composite board for refrigeration equipment according to the embodiment of the present invention (total thickness: 0.8mm)

[0058] The PVC panel 200 selects a piano-painted black PVC film for use.

[0059] The PVC substrate 100 is made of modified PVC.

[0060] Choose 100 parts by weight of low molecular weight PVC-SG5 (Shanghai Chlor-Alkali WS-700), 5 parts by weight of calcium / zinc composite stabilizer, 4 parts by weight of CPE, 1 part by weight of ACR, 1 part by weight of stearic acid, 1.5 parts by weight The barium stearate of parts by weight, the activated calcium carbonate of 30 parts by weight, and an appropriate amount of toner are mixed. It is extruded by a twin-screw extruder and calendered to form a semi-finished sheet. The thickness of the PVC substrate 100 is 0.76 mm by adjusting the gap between the rollers in the calendering equipment, and a PVC panel 200 with a thickness of 0.04 mm and a piano-painted black effect is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com