Polyimide modified polyisocyanurate foam and preparation method thereof

A polyisocyanurate and polyimide technology, which is applied in the field of foam plastics, can solve the problems of not involving polyimide precursors and the like, and achieves the effects of easy popularization and application, low smoke density and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

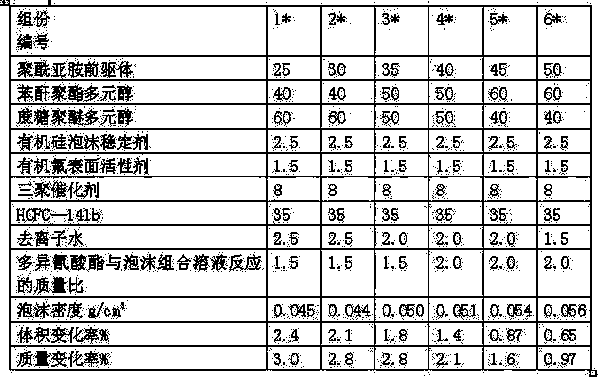

Image

Examples

Embodiment 1

[0030] In a 1000ml three-necked bottle equipped with a stirrer, a thermometer and a reflux condenser, drop 275 grams of 3,3 , ,4,4 , Benzophenone tetracarboxylic dianhydride (BTDA) and 500 grams of dimethylformamide, stir well and slowly raise the temperature to 100 ° C, wait for 3,3 , ,4,4 , When all the solid particles of benzophenone tetracarboxylic dianhydride (BTDA) are dissolved and the solution becomes clear, add 35 grams of 4,4 , Diaminodiphenyl ether is reacted at 100-110°C to a clear orange-red solution, cooled to 65°C and put into 65 grams of anhydrous methanol for esterification reaction. After the solution is clear and transparent, cool down and discharge to produce a light yellow polyimide precursor solution.

Embodiment 2

[0032] Put 80 grams of 1,2,4,5 pyromellitic dianhydride (PMDA) and 140 grams of dimethylformamide into a 500ml three-necked flask equipped with a stirrer, thermometer and reflux condenser, stir well and slowly raise the temperature At 90-100°C, when the solid particles of 1,2,4,5 pyromellitic dianhydride are completely dissolved, add 5 grams of 4,4 , Diaminodiphenyl ether (4,4 , -ODA) was heated to 120 °C to react to a clear solution. The temperature was lowered to 65° C. and 12 grams of anhydrous methanol was added to carry out esterification reaction to a reddish-brown transparent solution to obtain a polyimide precursor solution.

Embodiment 3

[0034] Put 80 grams of 3 , ,3,4 , , 4 biphenyltetracarboxylic dianhydride (BPDA) and 210 grams of dimethylformamide, stir well and slowly heat up to 100-110 ° C, add 12 grams of 4.4 , Diaminodiphenyl ether (4,4 , -ODA), continue to heat up to 130°C, so that 3,3 , ,4,4 , Biphenyltetracarboxylic dianhydride and 4,4 , All solid particles of diaminodiphenyl ether were dissolved, and when the solution became clear, the temperature was lowered to 65° C. and 24 grams of anhydrous methanol was added to carry out esterification reaction. When the solution was clear and transparent, a bordeaux polyimide precursor solution was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com