Flame-retardant low-viscosity rubber asphalt and preparation method thereof

A technology of rubber asphalt and rubber powder, which is applied in the field of flame-retardant low-viscosity rubber asphalt and its preparation, can solve the problems of high energy consumption, reduction of flame-retardant oxygen index of rubber asphalt, mixing, paving, rolling temperature, and environmental pollution. Achieve the effects of reducing the flame retardant oxygen index, increasing the softening point, and overcoming environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

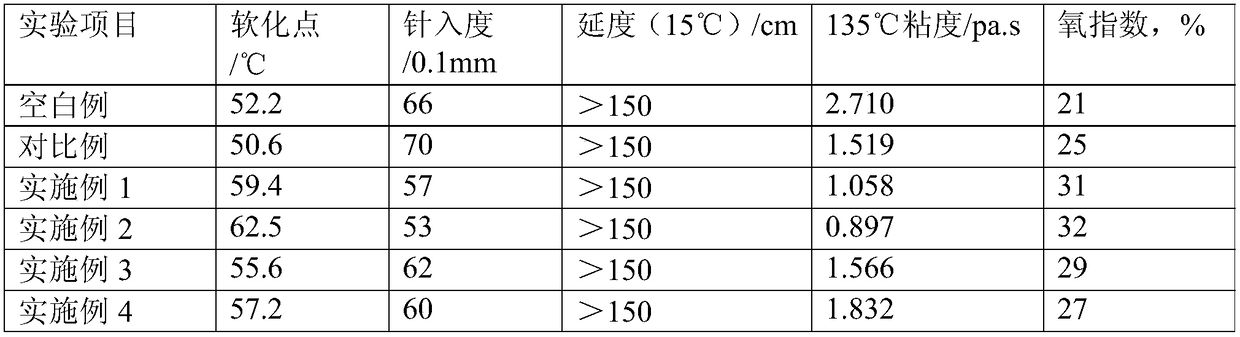

Examples

Embodiment 1

[0025] Heat 100 parts of base asphalt to a molten state, add 2 parts of rubber powder, 8 parts of chlorinated paraffin, 5 parts of stearic acid, 2 parts of low-density polyethylene, 6 parts of aromatic oil, and cut at 165 ° C for 30 minutes.

Embodiment 2

[0027] Heat 100 parts of base asphalt to a molten state, add 3 parts of rubber powder, 6 parts of chlorinated paraffin, 3 parts of stearic acid, 1 part of barium stearate, 3 parts of low-density polyethylene, 8 parts of aromatic oil, at 160 ℃ shear 25min.

Embodiment 3

[0029] Heat 100 parts of base asphalt to a molten state, add 1.5 parts of rubber powder, 4 parts of chlorinated paraffin, 1 part of barium stearate, 0.5 parts of low-density polyethylene, 4 parts of catalytic cracking oil slurry, and shear at 170 ° C for 15 minutes That's it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com