Carbon fiber composite material and preparation method thereof

A composite material and carbon fiber technology, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve the problems of product size and thickness changes, permanent deformation, heat insulation, and negative effects of sound insulation, etc., to achieve improved recovery sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

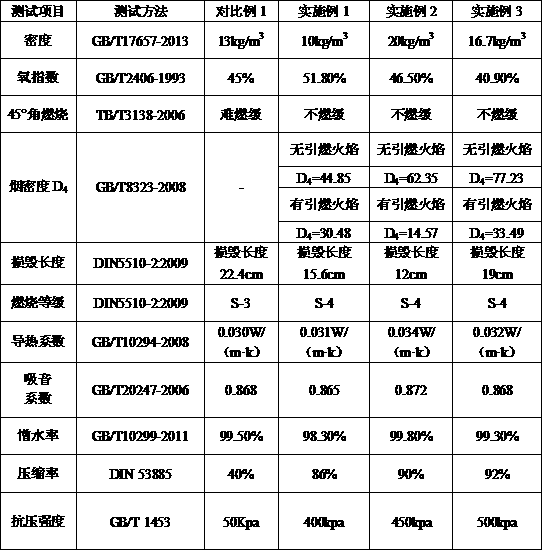

Examples

Embodiment 1

[0037] A carbon fiber composite material, prepared by mixing 261.25g of carbon fiber and 46.1g of organic fiber, and then hot pressing. The diameter of the carbon fiber is 8μm and the density is 1.8g / cm. 3 ;

[0038] The organic fiber is made of LMPA polyamide with a melting point of 100°C.

[0039] Low melting point nylon (LMPA) is a kind of modified product with a lower melting point than conventional nylon. It has the characteristics of controllable melting point, narrow melting range and excellent bonding performance. It uses low melting point polyamide and ordinary fiber-forming polymer through composite Spinning technology.

[0040] The preparation method of the above carbon fiber composite material specifically includes the following steps:

[0041] S1: Mix carbon fiber and organic fiber to obtain a mixture;

[0042] At the same time, S1 includes the following sub-steps:

[0043] S11: Cut the filamentous carbon fiber and the filamentous organic fiber according to the weight throu...

Embodiment 2

[0049] A carbon fiber composite material, prepared by mixing 1500g of carbon fiber and 500g of organic fiber (the mass percentage of carbon fiber and organic fiber is 75%: 25%) and then hot pressing. The diameter of the carbon fiber is 5μm and the density is 1.76 g / cm 3 ;

[0050] The organic fiber is made of LMPA polyamide with a melting point of 100°C.

[0051] Low melting point nylon (LMPA) is a kind of modified product with a lower melting point than conventional nylon. It has the characteristics of controllable melting point, narrow melting range and excellent bonding performance. It uses low melting point polyamide and ordinary fiber-forming polymer through composite Spinning technology.

[0052] The preparation method of the above carbon fiber composite material specifically includes the following steps:

[0053] S1: Mix carbon fiber and organic fiber to obtain a mixture;

[0054] At the same time, S1 includes the following sub-steps:

[0055] S11: Cut the filamentous carbon fib...

Embodiment 3

[0061] A carbon fiber composite material, which is prepared by mixing 700g of carbon fiber and 300g of organic fiber (the mass percentage of carbon fiber and organic fiber is 70%: 30%) and then hot pressing. Among them, the diameter of the carbon fiber is 7μm and the density is 1.78 g / cm 3 ;

[0062] The organic fiber is made of LMPA polyamide with a melting point of 100°C.

[0063] Low melting point nylon (LMPA) is a kind of modified product with a lower melting point than conventional nylon. It has the characteristics of controllable melting point, narrow melting range and excellent bonding performance. It uses low melting point polyamide and ordinary fiber-forming polymer through composite Spinning technology.

[0064] The preparation method of the above carbon fiber composite material specifically includes the following steps:

[0065] S1: Mix carbon fiber and organic fiber to obtain a mixture;

[0066] At the same time, S1 includes the following sub-steps:

[0067] S11: Cut the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com