Novel high-strength low-volume-weight heat preservation fireproof decoration integration plate and preparation method thereof

A high-strength, bulk density technology, applied in fire-resistant coatings, coatings, buildings, etc., can solve problems such as difficult application, no fire protection layer, and fatal hazard of upper void construction workers breathing in the lungs, to reduce bulk density, improve fire performance, Eliminate the effect of wall spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Novel high-strength, low-volume-weight thermal insulation, fireproof and decorative integrated board and its preparation method

[0034] (1) The structure is as follows:

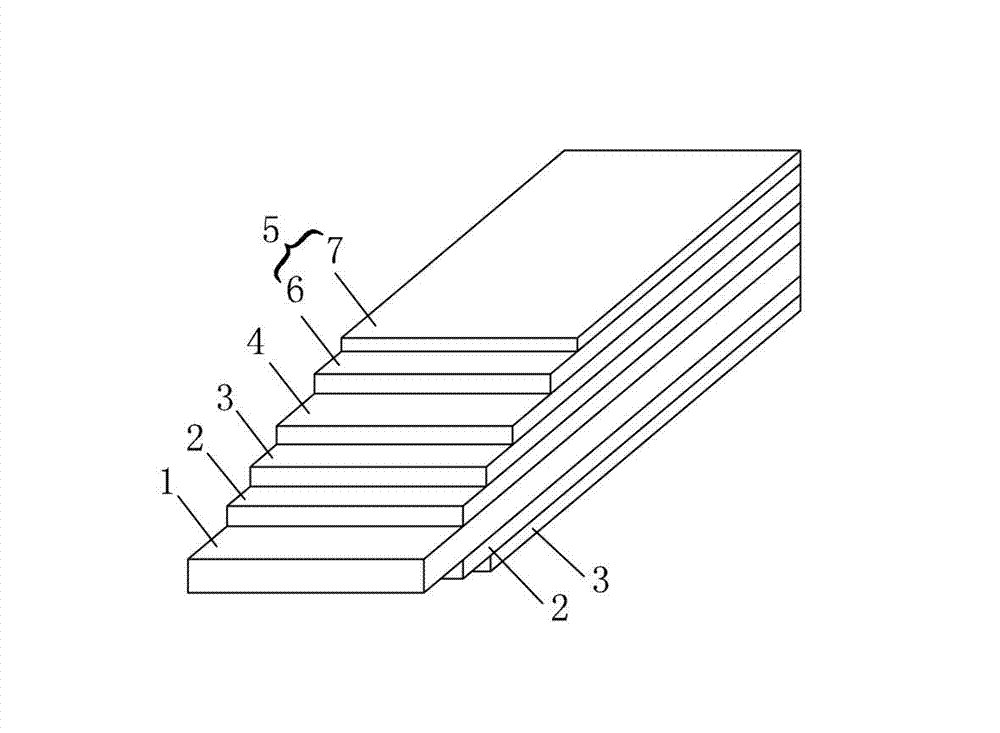

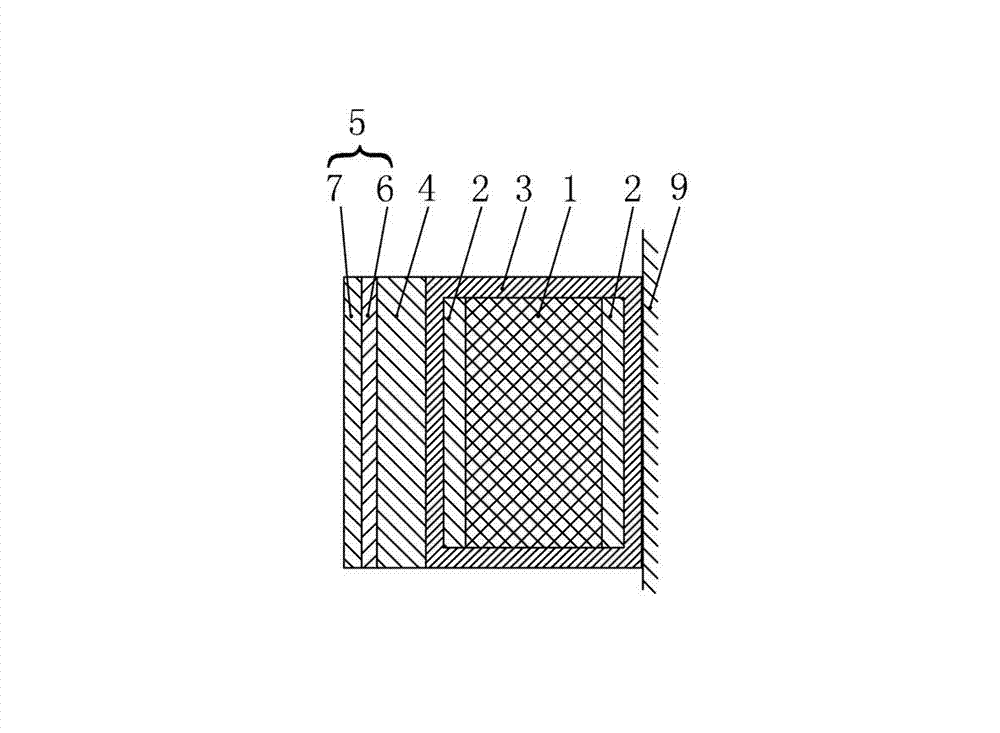

[0035] like Figure 1-Figure 4 As shown in the figure, the new high-strength and low-volume-weight thermal insulation and fireproof decoration integrated board is composed of a thermal insulation layer, a fireproof layer (3), a reinforcement layer (4) and a decorative layer (5).

[0036] The thermal insulation layer is composed of a polyurethane foam board (1) and a double-sided composite cement alkali-resistant glass fiber cloth (2).

[0037] Six sides of the thermal insulation layer are coated with a fireproof layer (3), and the side of the fireproof layer facing away from the wall surface (9) is followed by a reinforcement layer (4), a decorative layer (6) and a finish layer composed of a cover protective layer (7). (5).

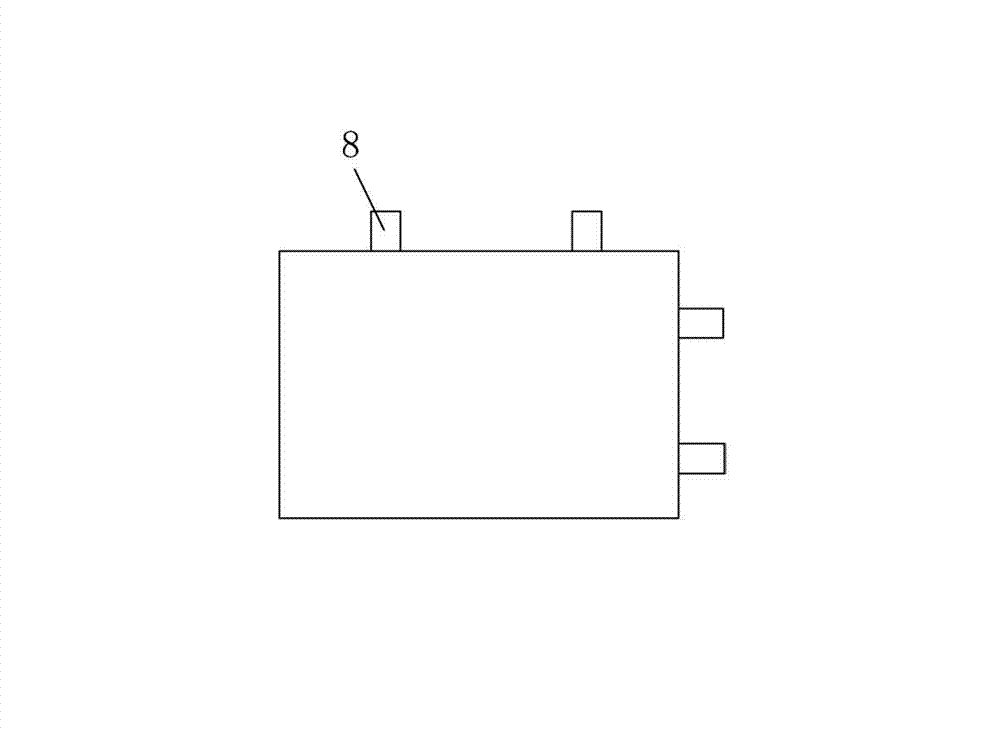

[0038] The above-mentioned integrated board is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com