Benzoxazine resin-based reinforcing fiber composite material and forming method thereof

A benzoxazine resin, benzoxazine technology, applied in high-strength glass fiber reinforced plastic products, high temperature resistance field, can solve the problems of incomplete release of small molecules, stress concentration, bulging and cracks, etc., to achieve mechanical properties and ablation resistance. Excellent performance, dense internal shape, and the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

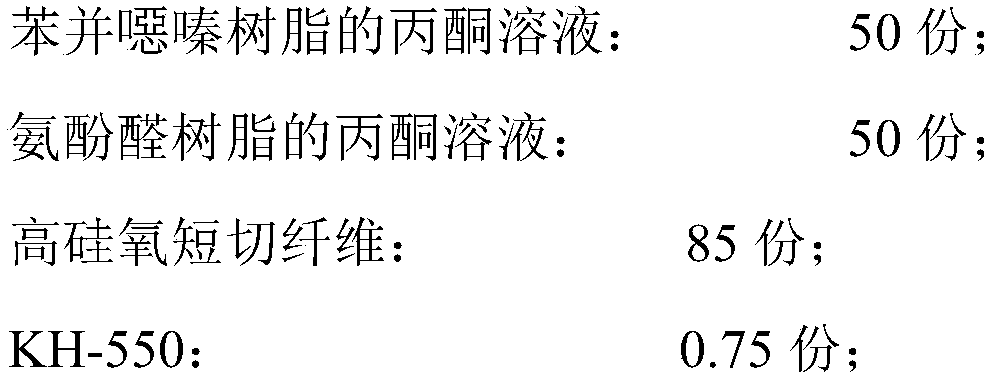

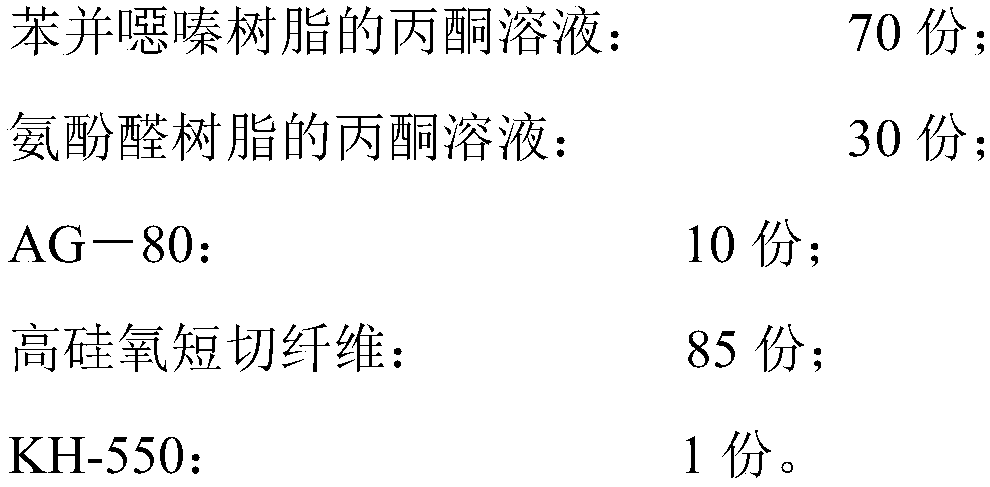

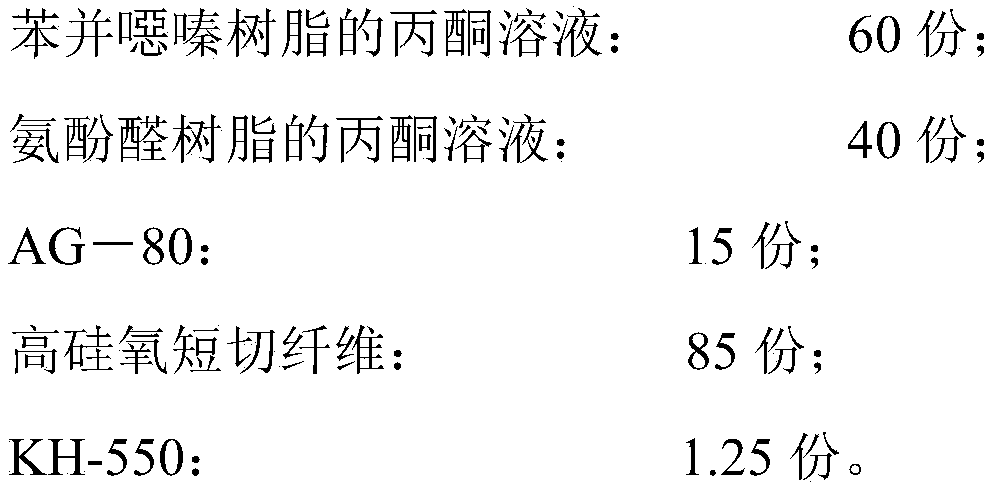

[0016] The present invention will be further described below in conjunction with the examples, and the present invention includes but not limited to the following examples.

[0017] Under the premise of ensuring the tensile performance of the solid rocket motor heat-resistant lining ≥ 39Mpa, the bending strength ≥ 59MPa, and the oxyacetylene line ablation rate < 0.18mm / s, the aminophenol-formaldehyde resin used in the molding production of the nozzle lining is cured During the process, polycondensation reaction will occur, and small molecules will be released. After the product is cooled and demoulded, the release of small molecules will often be incomplete, stress concentration will occur on the surface of the product, and bulges and cracks will appear. The invention provides a benzoxazine resin base-reinforced fiber composites. .

[0018] The commonly used aminophenol-formaldehyde resin used in the molding of the nozzle lining of solid rocket motors is diluted with ethanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile properties | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com