Soluble flame-retardant wholly aromatic copolyester with low dielectric constant and low dielectric loss as well as preparation method and application of soluble flame-retardant wholly aromatic copolyester

A low dielectric constant, dielectric constant technology, applied in the direction of one-component copolyester rayon, additive processing, etc., can solve the problem of difficult to solve the vertical anisotropy of the film and interlayer peeling, limited application, product Single form and other problems, to achieve the effects of excellent anti-droplet resistance, expansion of processing methods, and reduction of bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

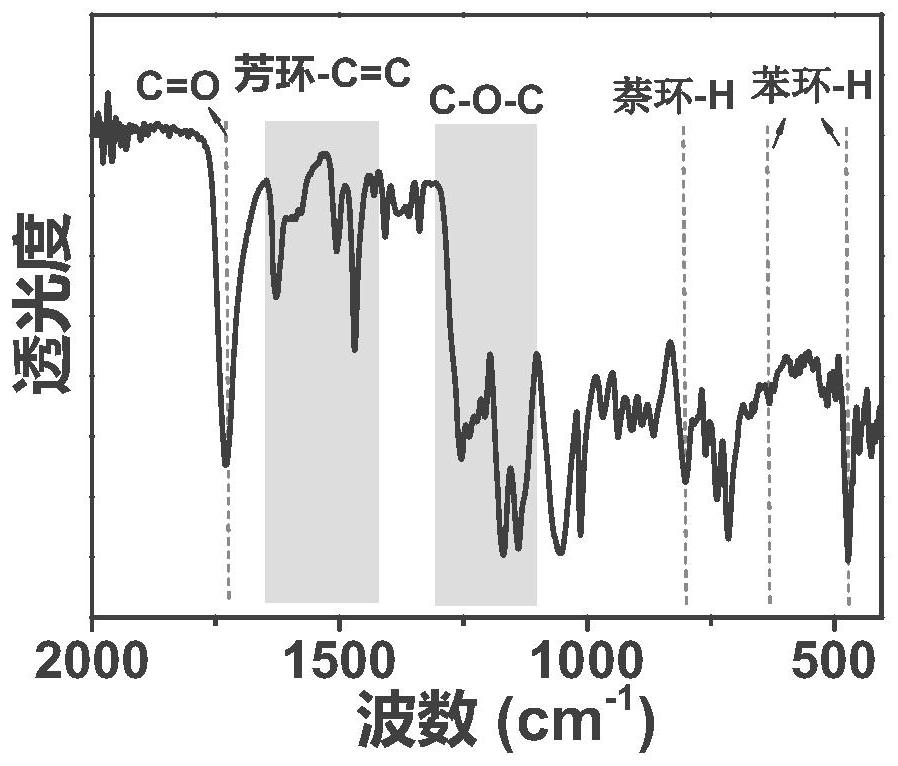

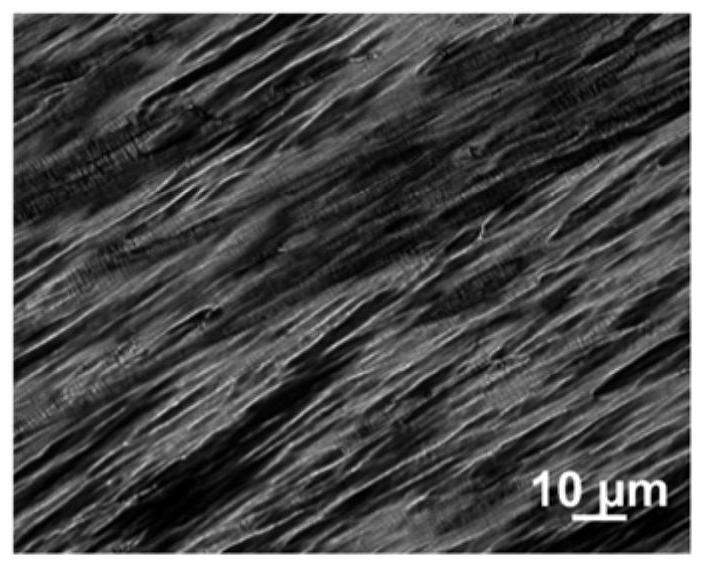

Method used

Image

Examples

Embodiment 1

[0089] 1560g of 4-hydroxybenzoic acid, 701g of [1,1'-biphenyl]-3,5-diol, 0.15g of N-methylimidazole and 1537g of acetic anhydride were added to the reaction kettle, and the temperature was raised to 130°C under nitrogen atmosphere. After acylation reaction for 2 h, the product was washed with pure water until the pH value was close to neutral, and dried to constant weight to obtain acylated compound; then, acylated compound, 739g 2-methoxyterephthalic acid and 0.15 g of 2-methoxyterephthalic acid were added to the reactor. g N-methylimidazole, and gradually heated to 360 °C at a heating rate of 0.5 °C / min under normal pressure, reacted for 0.5 h, and then melted and polycondensed under the condition of low vacuum of 10 Pa for 0.5 h, and filled the reaction kettle with Nitrogen, extruding the melt, and cooling with water, the target copolyester can be obtained.

[0090] The dielectric constant of the copolyester is 4.5; the dielectric loss is 0.05; the limiting oxygen index is ...

Embodiment 2

[0092] Add 2085g of 4'-hydroxyl-[1,1'-biphenyl]-4-carboxylic acid, 451g of 5-methoxy-[1,1'-biphenyl]-3,4'-diol into the reaction kettle , 464g of 2-(tert-butyl)terephthalic acid, 0.15g of p-toluenesulfonic acid and 1207g of acetic anhydride were heated to 130°C under nitrogen atmosphere for acylation reaction for 2h, then 0.15g of N-methylimidazole was added, and Under normal pressure, the temperature was gradually raised to 320°C at a heating rate of 0.5°C / min, reacted for 0.5h, then melted and polycondensed for 0.5h under a low vacuum of 10Pa, filled with nitrogen in the reaction kettle, extruded the melt, and cooled with water. , the target copolyester can be obtained.

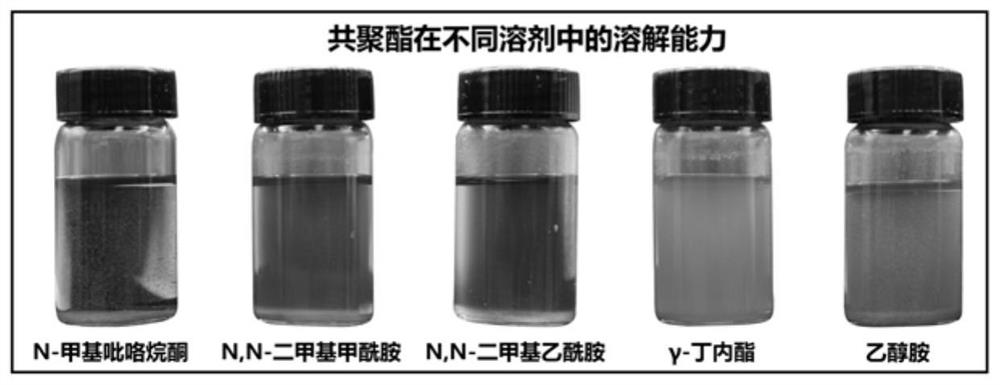

[0093] The dielectric constant of the copolyester is 4.2; the dielectric loss is 0.03; the limiting oxygen index is 30%; the vertical combustion grade is V-0; Amide, N,N-dimethylacetamide, tetrahydrofuran, γ-butyrolactone, ethylene glycol monobutyl ether, triethylene glycol, ethanolamine and other solvents...

Embodiment 3

[0095] 75g of 4-hydroxybenzoic acid, 1333g of 5-phenoxyisophthalic acid, 565g of phosgene and 6g of N,N-dimethylformamide were added to the reaction kettle, and the temperature was gradually raised to 60°C under stirring for 5h. pressure distillation, washing, drying to constant weight to obtain acid chloride; acid chloride is dissolved in toluene to prepare 0.1wt% organic phase solution A, 1592g 2-fluoro-3",5"-dimethyl-[1 ,1':3',1"-terphenyl]-4,5'-diol and 343 g of sodium hydroxide were dissolved in water to prepare 0.1 wt% aqueous solution B. The above organic solution A was quickly poured into water In the phase solution B, under the stirring condition of 2000rpm, the stirring reaction was continued for 100 minutes, and the whole aromatic copolyester prepolymer was obtained after suction filtration, washing and drying; The polyester prepolymer and 0.15g N-methylimidazole are then gradually heated up to 280°C at a heating rate of 0.5°C / min, and then reacted under a low vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com