Pavement cooling material

A technology of epoxy resin and dispersant, applied in epoxy resin coatings, coatings and other directions, can solve the problems of low reuse rate, slow down the service life of asphalt pavement, reduce pavement and other problems, so as to reduce traffic load damage and improve structural stability. the effect of reducing the temperature of the road surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

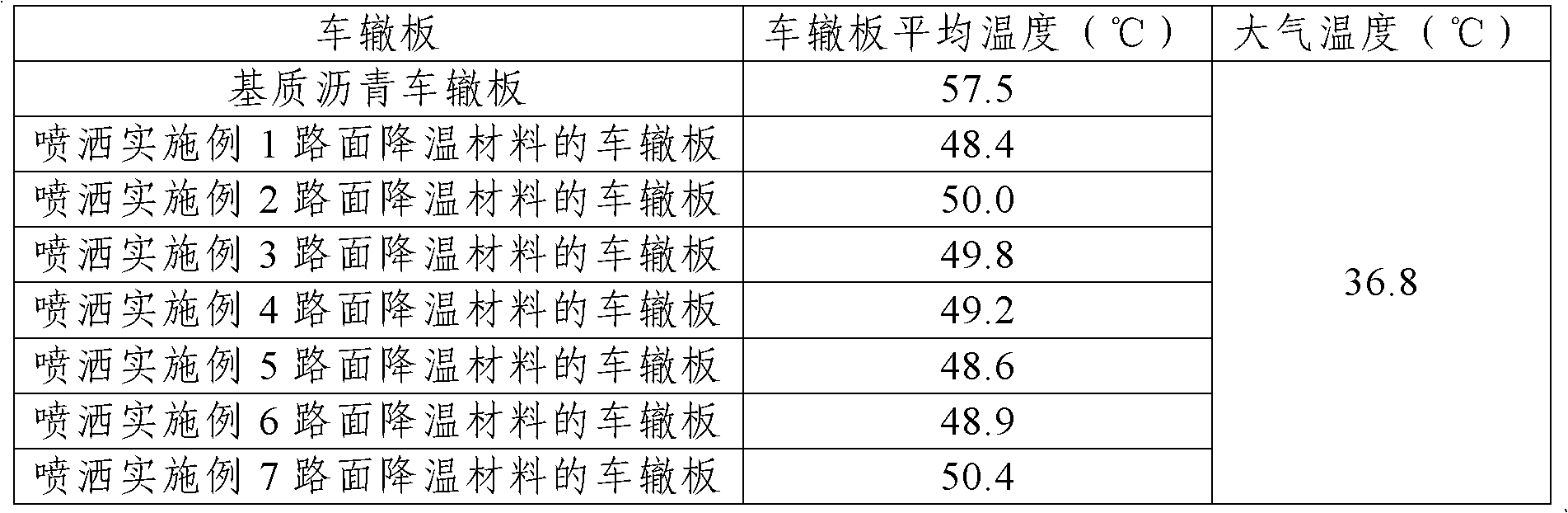

Embodiment 1

[0023] The pavement cooling material of this embodiment is made by mixing 52kg film-forming material, 42kg tourmaline and 6kg auxiliary agent; said film-forming material is made of epoxy resin, polyamide curing agent and methanol diluent according to the quality of 1:0.4:0.1 It is made by mixing, wherein the epoxy resin is bisphenol A type E44 epoxy resin, and the polyamide curing agent is polyamide curing agent 650; the tourmaline is the tourmaline anion powder with anion release of 1000ions; the auxiliary agent It is made by mixing dispersant, defoamer and leveling agent at a mass ratio of 1:1:1, wherein the dispersant is BYK-163 dispersant, the defoamer is BYK-141 defoamer, and the leveling agent is BYK -333 leveling agent.

[0024] The preparation method of the pavement cooling material in this embodiment is as follows: Weigh the components of the film-forming material and the auxiliary agent, and weigh the tourmaline, then mix the weighed film-forming material and the com...

Embodiment 2

[0027] The pavement cooling material of the present embodiment is made by mixing 45kg film-forming material, 35kg tourmaline and 4kg auxiliary agent; the film-forming material is made of epoxy resin, polyamide curing agent and methanol diluent according to the quality of 1:0.3:0.05 It is prepared by mixing, wherein the epoxy resin is epoxy resin E52D, and the polyamide curing agent is polyamide curing agent 651; the tourmaline is that the fineness is 325 purpose tourmaline powder; the auxiliary agent is composed of dispersant, defoamer It is mixed with leveling agent at a mass ratio of 0.5:0.5:1, wherein the dispersant is BOK-F-501 dispersant, the defoamer is BYK-052 defoamer, and the leveling agent is BOK-L-302 leveling agent.

[0028] The preparation method of the pavement cooling material of this embodiment is the same as that of Embodiment 1.

[0029] The construction method of the pavement cooling material of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0031]The pavement cooling material of this embodiment is made by mixing 48kg film-forming material, 38kg tourmaline and 6kg auxiliary agent; said film-forming material is made of epoxy resin, polyamide curing agent and methanol diluent according to the quality of 1:0.5:0.2 It is made by mixing, wherein the epoxy resin is bisphenol A type E44 epoxy resin, and the polyamide curing agent is polyamide curing agent 651; the tourmaline is tourmaline powder with a fineness of 325 meshes and a tourmaline powder with anion release of 5000ions A mixture of stone anion powder mixed in a mass ratio of 1:1; the additive is made by mixing a dispersant, an antifoaming agent and a leveling agent in a mass ratio of 1.5:1.5:1, wherein the dispersant is BYK- 161 dispersant, the defoamer is BOK-X-401 defoamer, and the leveling agent is BYK-306 leveling agent.

[0032] The preparation method of the pavement cooling material of this embodiment is the same as that of Embodiment 1.

[0033] The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com