A kind of attapulgite composite glass fiber core material and preparation method thereof

A technology of attapulgite and attapulgite, which is applied in the field of glass fiber and its preparation, can solve the problems of failure of vacuum insulation panels and increase of thermal conductivity, achieve high structural stability, rich mineral resources, and improve corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

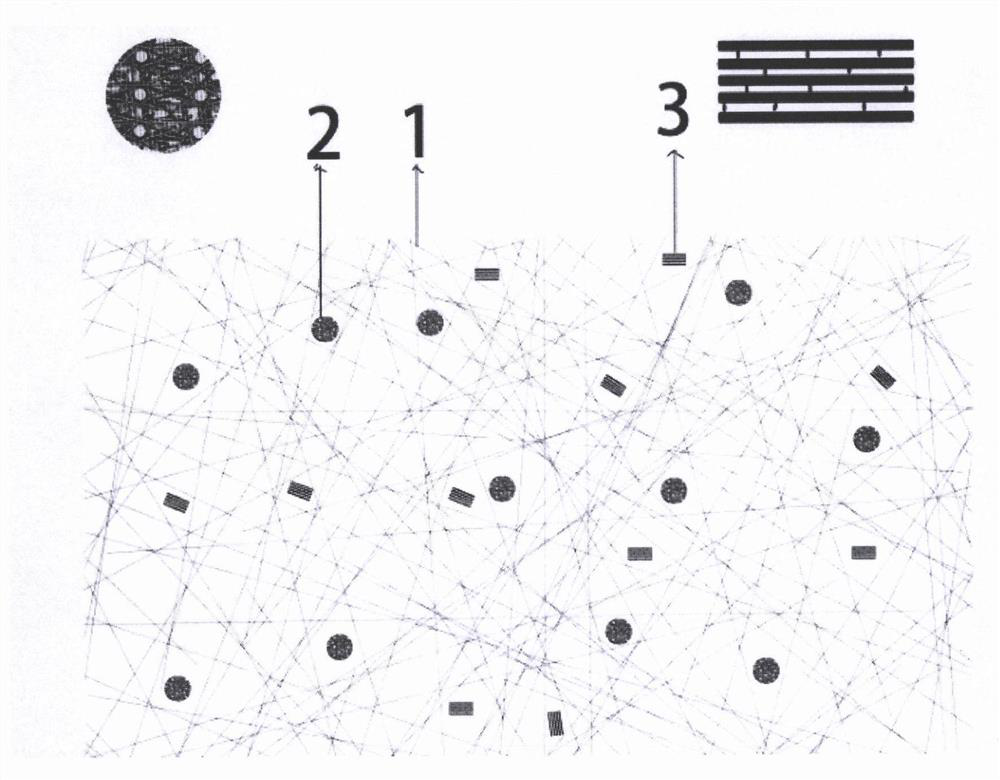

[0024] Refer figure 1 , Attapulgite a fiberglass composite core member, glass fibers 1, 2 is a nest-like crystal nanorods attapulgite, a layer 3 chain attapulgite aerogels, wherein: the fiber has a core material between binders, doped nanorods attapulgite and attapulgite crystal between glass airgel pores, percentage by mass comprising 70% glass fibers, 25 percent attapulgite crystal nanorods, attapulgite 3% soil airgel and 2% of sodium silicate. In preparing the specific process is as follows:

[0025] (1) attapulgite crystal nanorods take amide and polypropylene mixed with water, by ultrasound, arranged uniformly stirred suspension of attapulgite;

[0026] (2) a tetraethyl orthosilicate, aluminum chloride, and boric acid prepared in a molar ratio of uniform Al / Si / B in water 2:5:1 of Al-B-Si sol;

[0027] (3) The Al-B-Si attapulgite sol was added the suspension was stirred to give a uniform dispersion, the dispersion is degassed in a vacuum chamber after transferred into a mo...

Embodiment 2

[0033] Refer figure 1 , Attapulgite a fiberglass composite core member, glass fibers 1, 2 is a nest-like crystal nanorods attapulgite, a layer 3 chain attapulgite aerogels, wherein: the fiber has a core material between binders, doped nanorods attapulgite and attapulgite crystal between glass airgel pores, percentage by mass of glass fibers comprising 65%, 25% attapulgite crystal nanorods, 5% attapulgite soil airgel and 5% sodium silicate. In preparing the specific process is as follows:

[0034] (1) attapulgite crystal nanorods take amide and polypropylene mixed with water, by ultrasound, arranged uniformly stirred suspension of attapulgite;

[0035] (2) a tetraethyl orthosilicate, aluminum chloride, and boric acid prepared in a molar ratio of uniform Al / Si / B in water 2:5:1 of Al-B-Si sol;

[0036] (3) The Al-B-Si attapulgite sol was added the suspension was stirred to give a uniform dispersion, the dispersion is degassed in a vacuum chamber after transferred into a mold, by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com