Modifier, modified wollastonite modified by modifier, and preparation method and application of modified wollastonite

A technology of wollastonite and modifier, applied in the field of modified polypropylene, which can solve the problems of low heat distortion temperature, poor modification effect, and high modification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

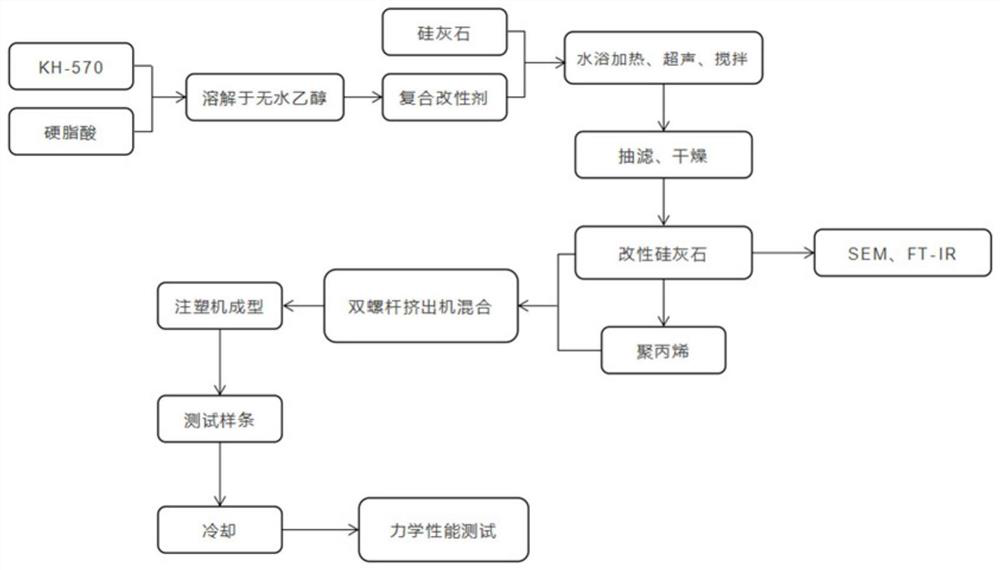

[0030] like figure 1 Shown, be the preparation process flowchart of modified wollastonite of the present invention, concrete preparation process steps are as follows:

[0031] Add 10g of wollastonite, 0.1g of stearic acid and 0.1g of silane coupling agent KH-570 to 300mL of absolute ethanol, and mix the modifier and wollastonite evenly under the action of ultrasonic dispersion and mechanical stirring. React at a temperature of 60°C for 1 hour, keep stirring during the entire heating reaction process, the stirring speed is 300rpm, after the reaction is completed, cool naturally, collect the precipitate in the mixed solution by suction filtration at room temperature, and dry the precipitate in an oven at 70°C for 12 hours , to obtain modified wollastonite.

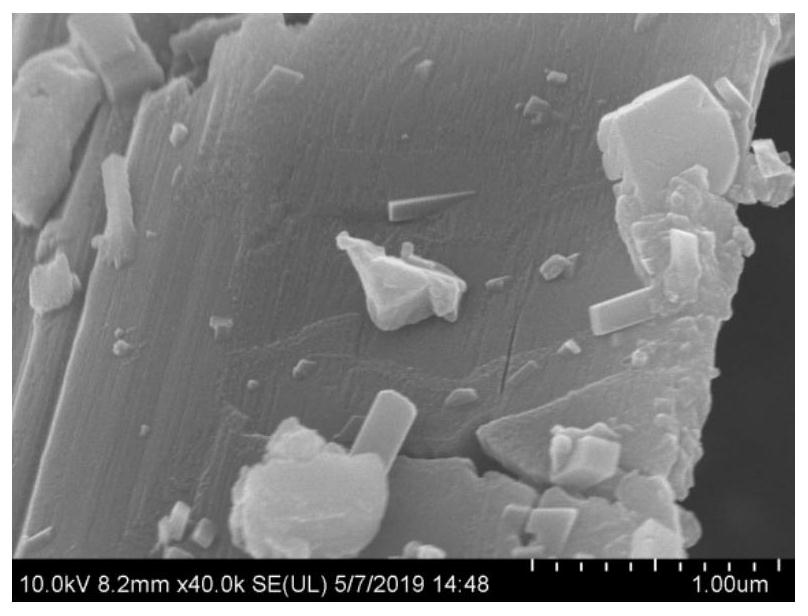

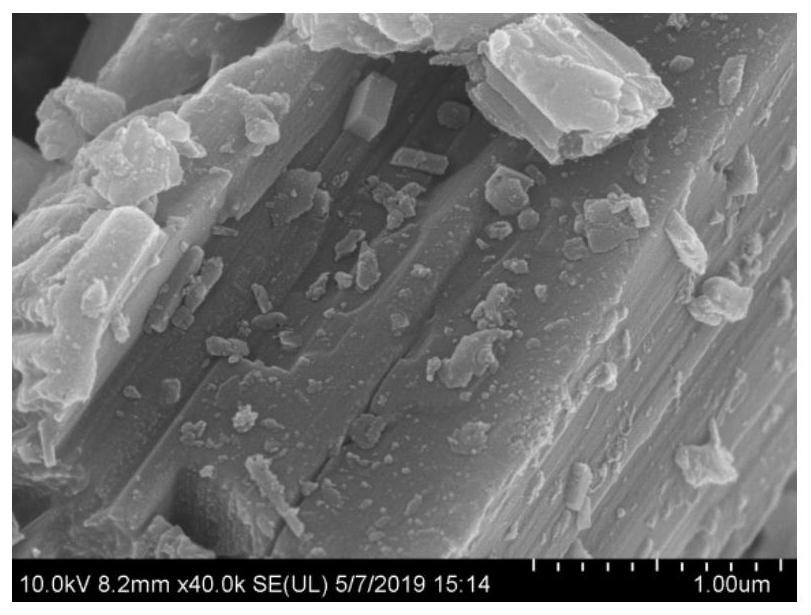

[0032] like figure 2 and 3 As shown, the SU8010 field emission electron microscope was used to observe the surface morphology of wollastonite before and after modification. By comparing the electron microscope photos of ...

Embodiment 2

[0040] The preparation process of embodiment 2 is basically the same as that of embodiment 1, and the difference is that the volume of dehydrated alcohol is 333mL, and the total mass of modifier is respectively 0.1g, 0.2g, 0.3g, 0.4g, wherein stearic acid The ratio of the mass to the mass of the silane coupling agent KH-570 is 1:1, such as Figure 5 Shown is the relationship diagram between the change of modifier content and the oil absorption value of modified wollastonite, which is represented by Figure 5 It can be seen that when the total mass of the modifier is 2% of the wollastonite mass, the oil absorption value of the modified wollastonite is the lowest, and the optimum modifier ratio is 2%.

Embodiment 3

[0042] The preparation process of embodiment 3 is basically the same as that of embodiment 1, the difference is that the volume of dehydrated alcohol is 333mL, the total mass of modifier is 0.2g, and the amount of stearic acid and silane coupling agent KH-570 is adjusted. Mass ratio, the silane coupling agent KH-57 in the present embodiment accounts for 30%, 40%, 50%, 60%, 70% of the modifier gross mass respectively, as Image 6 Shown is the relationship diagram between the mass proportion of silane coupling agent KH-57 and the oil absorption value of modified wollastonite, which is represented by Image 6 It can be seen that when the silane coupling agent KH-57 accounts for 50% of the total mass of the modifier, the oil absorption value of the modified wollastonite is the lowest, and the optimal mass proportion of the silane coupling agent KH-57 is 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com